warning LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 764 of 873

AIR CONDITIONING

5

ADJUSTMENT AIR CONDITIONING SYSTEM - PERFORMANCE

TEST

WARNING: R134a is hazardous, refer to

the GENERAL PRECAUTIONS given at the

beginning of this section.

Carry out this test with bonnet and doors or windows

open, air conditioning switched on, temperature

control set to cold and blower at maximum speed. Set

the air supply control to supply fresh air.

1.Close low pressure valve on refrigerant station.

2.Close high pressure valve on refrigerant station.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.4.Insert dry bulb thermometer into cold air outlet

and position dry and wet bulb thermometer close

to outside air inlet.

Do not spill water from the wet thermometer

(psychrometer).

5.Start engine and run it at 1500 rev/min for 10

minutes with air conditioning switched on.

6.Check that sight glass is free of bubbles.

7.Read both pressure gauges and thermometers.

Check readings against table below with

humidity between 60% and 80%. If readings are

incorrect.

See Fault diagnosis, Refrigeration

System Faults.

8.Switch off air conditioning, stop engine,

disconnect test equipment.

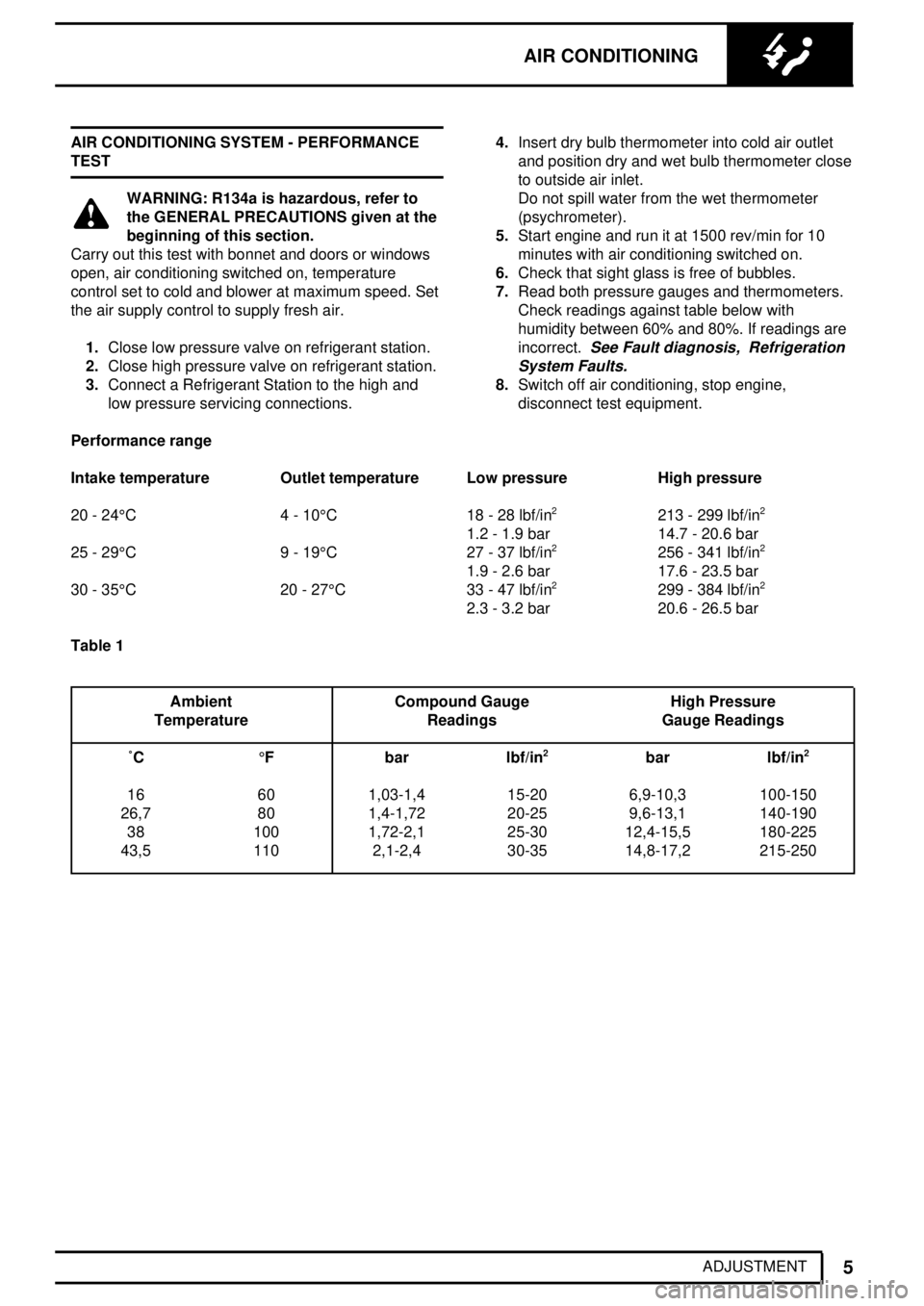

Performance range

Intake temperature Outlet temperature Low pressure High pressure

20 - 24°C4-10°C 18 - 28 lbf/in

2213 - 299 lbf/in2

1.2 - 1.9 bar 14.7 - 20.6 bar

25 - 29°C9-19°C 27 - 37 lbf/in2256 - 341 lbf/in2

1.9 - 2.6 bar 17.6 - 23.5 bar

30 - 35°C20-27°C 33 - 47 lbf/in2299 - 384 lbf/in2

2.3 - 3.2 bar 20.6 - 26.5 bar

Table 1

Ambient Compound Gauge High Pressure

Temperature Readings Gauge Readings

ÊC°F bar lbf/in

2bar lbf/in2

16 60 1,03-1,4 15-20 6,9-10,3 100-150

26,7 80 1,4-1,72 20-25 9,6-13,1 140-190

38 100 1,72-2,1 25-30 12,4-15,5 180-225

43,5 110 2,1-2,4 30-35 14,8-17,2 215-250

Page 766 of 873

AIR CONDITIONING

1

REPAIR PRECAUTIONS IN HANDLING REFRIGERANT

LINES

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

1.When disconnecting any hose or pipe

connection the system must be discharged of all

pressure. Proceed cautiously, regardless of

gauge readings. Open connections slowly,

keeping hands and face well clear, so that no

injury occurs if there is liquid in the line. If

pressure is noticed, allow it to bleed off slowly.

2.Lines, flexible end connections and components

must be capped immediately they are opened to

prevent the entrance of moisture and dirt.

3.Any dirt or grease on fittings must be wiped off

with a clean alcohol dampened cloth. Do not use

chlorinated solvents such as trichloroethylene. If

dirt, grease or moisture cannot be removed from

inside the hoses, they must be replaced with

new hoses.

4.All replacement components and flexible end

connections must be sealed, and only opened

immediately prior to making the connection.

5.Ensure the components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters.

6.Components must not remain uncapped for

longer than fifteen minutes. In the event of delay,

the caps must be fitted.

7.Receiver/driers must never be left uncapped as

they contain Silica Gel crystals which will absorb

moisture from the atmosphere. A receiver/ drier

left uncapped must not be used, fit a new unit.

8.The compressor shaft must not be rotated until

the system is entirely assembled and contains a

charge of refrigerant.

9.A new compressor contains an initial charge of

of refrigerant oil. The compressor also contains a

holding charge of gas when received which

should be retained by leaving the seals in place

until the pipes are re-connected.10.The receiver/drier should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection of

the system.

11.All precautions must be taken to prevent

damage to fittings and connections. Slight

damage could cause a leak with the high

pressures used in the system.

12.Always use two wrenches of the correct size,

one on each fitting when releasing and

tightening refrigeration unions.

13.Joints and 'O' rings should be coated with

refrigeration oil to aid correct seating. Fittings

which are not lubricated with refrigerant oil are

almost certain to leak.

14.All lines must be free of kinks. The efficiency of

the system is reduced by a single kink or

restriction.

15.Flexible hoses should not be bent to a radius

less than 90mm.

16.Flexible hoses should not be within 100mm of

the exhaust manifold.

17.Completed assemblies must be checked for

refrigeration lines touching metal panels. Any

direct contact of lines and panels transmits noise

and must be eliminated.

Page 767 of 873

82AIR CONDITIONING

2

REPAIR PERIODIC MAINTENANCE

Routine servicing, apart from visual checks, is not

necessary. The visual inspections are as follows:

Condenser

With a water hose or air line, clean the fins of the

condenser to remove flies, leaves, etc. Check the pipe

connections for signs of oil leakage.

Compressor

Check pipe connections for signs of oil leakage.

Check flexible hoses for swelling. Examine the

compressor belt for tightness and condition.

Sight glass and Receiver/Drier

Examine the sight glass for bubbles with the system

operating. Check connections for leakage.

Evaporator

Examine the refrigeration connections at the unit. If

the system should develop a fault, or if erratic

operation is noticed,

See Fault diagnosis,

Refrigeration System Faults

RECEIVER DRIER

Service repair no - 82.17.01

Remove

CAUTION: If receiver/drier is to be refitted,

the ports must be blanked off immediately

on disconnection. Exposed life of unit is

only 15 minutes.

1.Disconnect battery negative lead.

2.Recover refrigerant from system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

3.Remove 3 screws from bonnet locking platform

and remove radiator grille.

Automatic gearbox

4.Remove 4 bolts securing transmission oil cooler

to body.

Page 768 of 873

AIR CONDITIONING

3

REPAIR 5.Disconnect 2 pipe unions from oil cooler. Use a

second wrench to support hose adapter.

6.Remove transmission oil cooler. Seal

connections.

All models

7.Remove bolt securing receiver/drier clamp.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

8.Move receiver/drier just sufficiently to gain

access to pipe flange bolts without distorting the

pipes.

9.Remove bolt securing each pipe flange to

receiver/drier.

10.Disengage pipe flanges and withdraw

receiver/drier from mounting bracket.

11.Remove 'O' ring from each pipe flange.Refit

12.Fit new 'O' ring to each pipe flange, lubricate

with refrigerant oil.

13.Position receiver/drier in mounting bracket with

inlet and outlet connections correctly aligned.

14.Engage pipe flanges, fit bolts in turn and tighten.

15.Fit clamp bolt.

Automatic gearbox

16.Refit transmission oil cooler. Use a second

wrench to support pipe unions.

17.Check gearbox fluid level, top-up if necessary.

All models

18.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

19.Perform a leak test on disturbed joints.

20.Carry out a functional check.

Page 769 of 873

82AIR CONDITIONING

4

REPAIR AIR CONDITIONING SWITCH

Service repair no - 82.20.29

Remove

1.Remove fascia centre louvre vent panel.

See

CHASSIS AND BODY, Repair, Dash Panel

Central Louvre Panel

2.Disconnect multiplug from switch

3.From the rear, push switch out of panel.

Refit

4.Reverse removal procedure.DUAL PRESSURE SWITCH

Service repair no - 82.20.20

Remove

1.Disconnect battery negative lead.

2.Recover refrigerant from system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

3.Disconnect multiplug from switch.

4.Unscrew switch from adapter. Use a second

wrench to support adapter.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

5.Remove 'O' ring from switch.

Refit

6.Reverse removal procedure. Lubricate new 'O'

ring with refrigerant oil and fit to switch.

7.Screw switch into adapter and tighten to

11 Nm.

8.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

Page 770 of 873

AIR CONDITIONING

5

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Disconnect battery negative lead.

2.Recover refrigerant from air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

3.Remove screws retaining centre panel to fan

cowl

4.Remove centre panel.

V8i engine illustrated

5.Remove 2 bolts securing hose flanges to

compressor.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.6.Disconnect high pressure hose from

compressor.

7.Disconnect low pressure hose from compressor.

8.Remove 'O' ring from each flange.

9.Disconnect electrical lead from compressor

clutch.

10.Release drive belt from compressor pulley.

See

ENGINE, Repair, Drive Belt

11.Remove 4 bolts securing compressor to

mounting bracket.

12.Remove compressor from mounting bracket.

Refit

13.New compressor to be fitted: Drain oil from new

compressor outlet port. Drain and measure oil

from old compressor. Measure new oil equal to

amount drained from old compressor, add 30 ml

extra to this amount and refill new compressor

through outlet port.

14.Locate compressor in mounting bracket, fit bolts.

Tighten to

25 Nm.

15.Connect electrical lead to compressor clutch.

16.Fit new 'O' rings to high and low pressure hose

flanges, lubricate with refrigerant oil.

17.Engage hose flanges, fit bolts. Tighten to

10

Nm.

18.Fit compressor drive belt.See ENGINE, Repair,

Drive Belt

19.Fit centre panel to fan cowl.

20.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

21.Perform a leak test on disturbed joints.

22.Carry out a functional check.

Page 771 of 873

82AIR CONDITIONING

6

REPAIR CONDENSER

Service repair no - 82.15.07

Remove

1.Disconnect battery negative lead.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

2.Recover refrigerant from system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

3.Remove front grille panel.

4.Remove battery.

See ELECTRICAL, Repair,

Battery

5.Remove radiator and oil coolers assembly.See

COOLING SYSTEM, Repair, Radiator

6.Disconnect high and low pressure pipes at

condenser unions.

7.Discard 'O' ring seal from each union.

8.Remove 2 bolts securing condenser to body.

9.Pull condenser into radiator area.

10.Disconnect multiplug from each fan lead.

11.Remove condenser assembly.

Do not carry out

further dismantling if component is removed

for access only.

Blank off inlet and outlet ports.

Page 773 of 873

82AIR CONDITIONING

8

REPAIR HEATER AND COOLER UNIT

Service repair no - 86.25.21

WARNING: All work involving the service

and maintenance of air conditioning

requires special equipment, knowledge,

experience and a full awareness and adherence to

safety precautions.

Remove

1.Disconnect battery negative lead.

2.Drain engine coolant.

See COOLING SYSTEM,

Adjustment, Coolant

3.Recover refrigerant from air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

4.Remove fascia panel assembly.See CHASSIS

AND BODY, Repair, Dash Panel Assembly

5.Release clips and disconnect coolant hoses

from heater pipes.

6.Remove securing bolt and disconnect low

pressure pipe from evaporator.

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

7.Release 'P' clip retaining high and low pressure

pipes.

8.Remove securing bolt and disconnect high

pressure pipe from evaporator.

9.Discard 'O' ring seals.

Page 774 of 873

AIR CONDITIONING

9

REPAIR

10.Disconnect multiplug connecting heater to

blower unit, remove 3 screws and remove

blower unit.

11.Remove 5 screws securing casing to bulkhead

and tunnel.

12.Remove 2 securing bolts and remove centre

console front mounting bracket.

13.Disconnect 2 drain tubes..

14.Ease heater and cooler unit from its location and

remove from vehicle.

Refit

15.Ease heater and cooler unit into position.

16.Fit retaining bolts finger tight. Tighten in

sequence, centre and top bolts and then the

bottom bolt.

17.Reverse removal procedure.

18.Use new 'O' rings and lubricate with refrigerant

oil.

19.Evacuate and recharge system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

20.Leak test any disturbed joints.See Adjustment,

Leak Test System

21.Perform a functional check.EVAPORATOR AND EXPANSION VALVE

Service repair no - 86.25.20 - Evaporator

Service repair no - 86.25.01 - Expansion valve

Remove

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

1.Remove heater and cooler unit.

See Heater

and Cooler Unit

Page 776 of 873

AIR CONDITIONING

11

REPAIR THERMOSTAT

Service repair no - 86.25.50

Remove

1.Remove heater and cooler unit.

See Heater

and Cooler Unit

2.Remove lower cover and evaporator.See

Evaporator and Expansion Valve

3.Remove 5 clips and screw securing evaporator

top cover.

4.Remove evaporator top cover.

5.Remove thermostat sensor from evaporator

matrix.

6.Remove 2 screws securing sensor unit.

7.Remove thermostat and insulation.

Refit

8.Reverse removal procedure.

CAUTION: The thermostat insulation must

be installed in the ORIGINAL POSITION in

the evaporator.EVAPORATOR/BLOWER MOTOR ASSEMBLY -

REAR

Service repair no - 82.26.01

Remove

1.Recover refrigerant from system.

See

Adjustment, refrigerant recovery recycling

recharging

WARNING: Wear eye and hand protection

when disconnecting components

containing refrigerant. Plug all exposed

connections immediately.

2.Remove evaporator to alpine light duct.

See

evaporator to alpine light duct

3.Remove LH rear mud flap.See CHASSIS AND

BODY, Repair, mud flap - rear - lh

4.Clean area around low and high pressure air

conditioning pipe unions, beneath rear wheel

arch, to prevent any risk of dirt entering the

system.

5.Loosen and disconnect high and low pressure

air conditioning pipe unions beneath rear wheel

arch.

6.Remove and discard 'O' rings from pipe unions.

CAUTION: Use 2 spanners when loosening

or tightening air conditioning pipe unions.

CAUTION: Plug exposed connections

immediately.