electrical LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 863 of 873

ELECTRICAL

43

REPAIR ANTI-THEFT ALARM ECU (96 MODELS)

Service repair no - 86.55.85

Remove

1.Remove 4 studs securing fascia left hand

closing panel.

2.Remove closing panel.

3.Disconnect 2 multiplugs from ECU.

4.Remove nut securing ECU/relay bracket.

5.Lower bracket.

6.Remove 2 nuts securing ECU to bracket.

7.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

8.Reverse removal procedure.HANDSET (96 MODELS)

If vehicle does not respond to handset immediately, it

may have lost synchronisation. To re-synchronise,

press either button, 4 times in quick succession. If

handset still fails to respond, check batteries, refer to

Owner's handbook. If batteries are okay, it may be

necessary to use emergency key access, refer to

Owner's handbook.

NOTE: New handsets must be initialised

using TestBook.

PASSIVE COIL (96 MODELS)

Service repair no - 86.77.35

Remove

1.Remove steering column shroud.

See

STEERING, Repair, Steering column shroud

2.Release multiplug from harness clip and

disconnect.

3.Release passive coil from starter switch.

4.Remove bulb holder/starter switch shroud.

5.Remove coil.

Refit

6.Fit coil, ensuring switch illumination bulb harness

passes through large cut-out.

7.Secure coil with cable tie.

8.Position bulb holder/starter switch shroud and

locate bulb.

9.Locate bulb holder/starter switch shroud,

ensuring cut-out in shroud aligns with lug on

starter switch.

10.Connect multiplug and secure to clip.

11.Fit column shroud.

Page 864 of 873

86ELECTRICAL

44

REPAIR BONNET SWITCH

Service repair no - 86.55.89

Remove

1.Remove 2 bolts securing sounder, move

sounder aside.

2.Locate and disconnect bonnet switch multiplug.

3.Release and remove switch.

Refit

4.Reverse removal procedure.ULTRASONIC SENSOR

Service repair no - 86.77.32

Remove1.Release sensor from switch panel.

2.Disconnect multiplug and remove sensor.

Refit

3.Reverse removal procedure.

ANTI-THEFT ALARM INDICATOR LIGHT (96

MODELS)

Service repair no - 86.45.61

See Instrument illumination and warning light

bulbs

ENGINE IMMOBILISATION WARNING LIGHT (96

MODELS)

Service repair no - 86.45.61

See Instrument illumination and warning light

bulbs

Page 865 of 873

ELECTRICAL

45

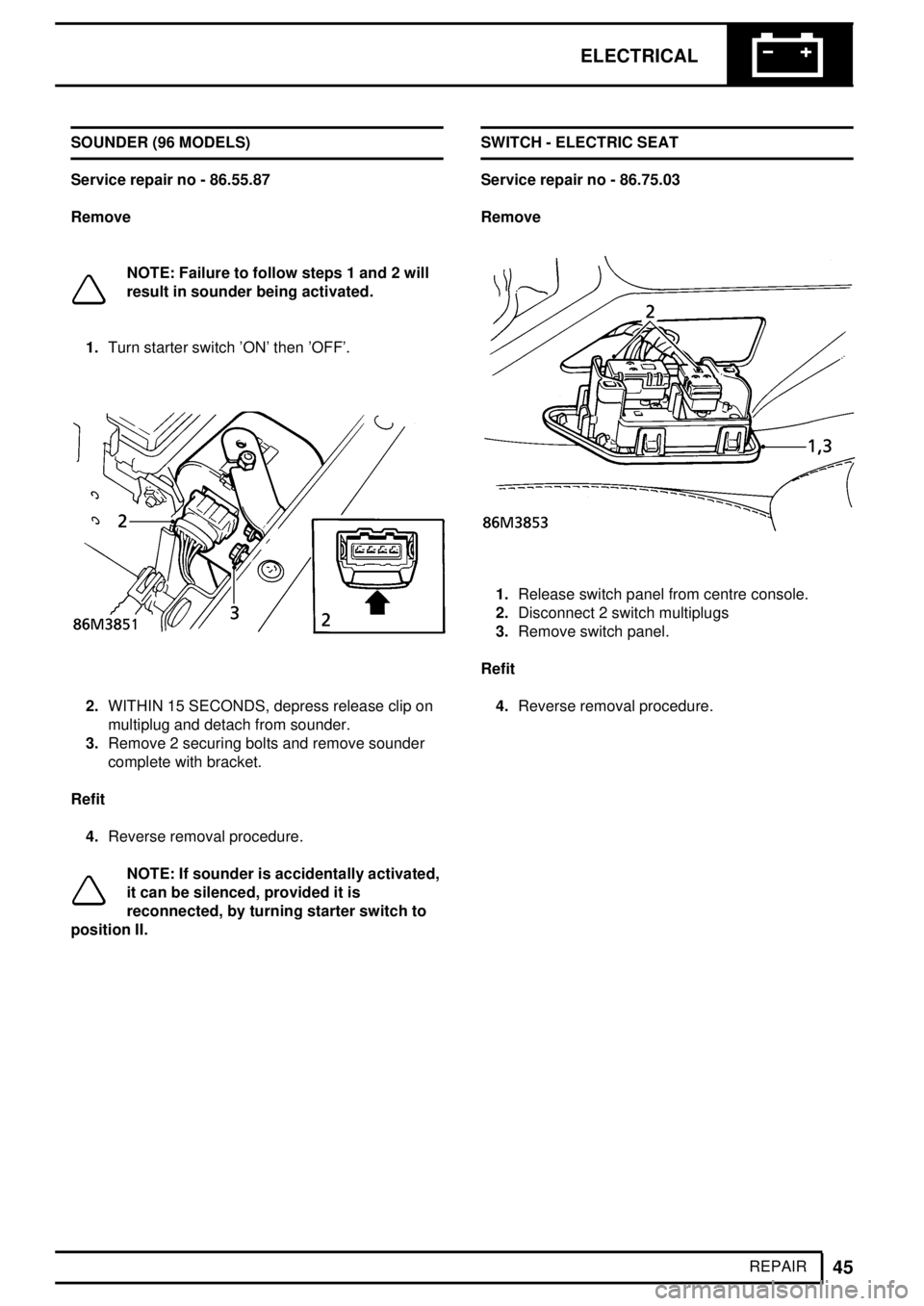

REPAIR SOUNDER (96 MODELS)

Service repair no - 86.55.87

Remove

NOTE: Failure to follow steps 1 and 2 will

result in sounder being activated.

1.Turn starter switch 'ON' then 'OFF'.

2.WITHIN 15 SECONDS, depress release clip on

multiplug and detach from sounder.

3.Remove 2 securing bolts and remove sounder

complete with bracket.

Refit

4.Reverse removal procedure.

NOTE: If sounder is accidentally activated,

it can be silenced, provided it is

reconnected, by turning starter switch to

position II.SWITCH - ELECTRIC SEAT

Service repair no - 86.75.03

Remove

1.Release switch panel from centre console.

2.Disconnect 2 switch multiplugs

3.Remove switch panel.

Refit

4.Reverse removal procedure.

Page 866 of 873

86ELECTRICAL

46

REPAIR STARTER MOTOR - 4.0 V8

Service repair no - 86.60.01

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove heated oxygen sensor from RH front

exhaust pipe.

See EMISSION CONTROL,

Repair, Heated Oxygen Sensor (HO2S) - 4.0

V8

4.Mark front propeller shaft and drive flanges for

assembly reference.

5.Remove 4 nuts and bolts securing propeller

shaft flange.

NOTE: Raise 1 front road wheel and rotate

propeller shaft to gain access to all

fixings.

6.Tie propeller shaft aside.

7.Position starter motor heat shield above motor.

See Starter Motor Heat Shield - 4.0 V8

8.Disconnect Lucar from solenoid.

9.Remove nut securing feed wires to starter

solenoid and disconnect from terminal.

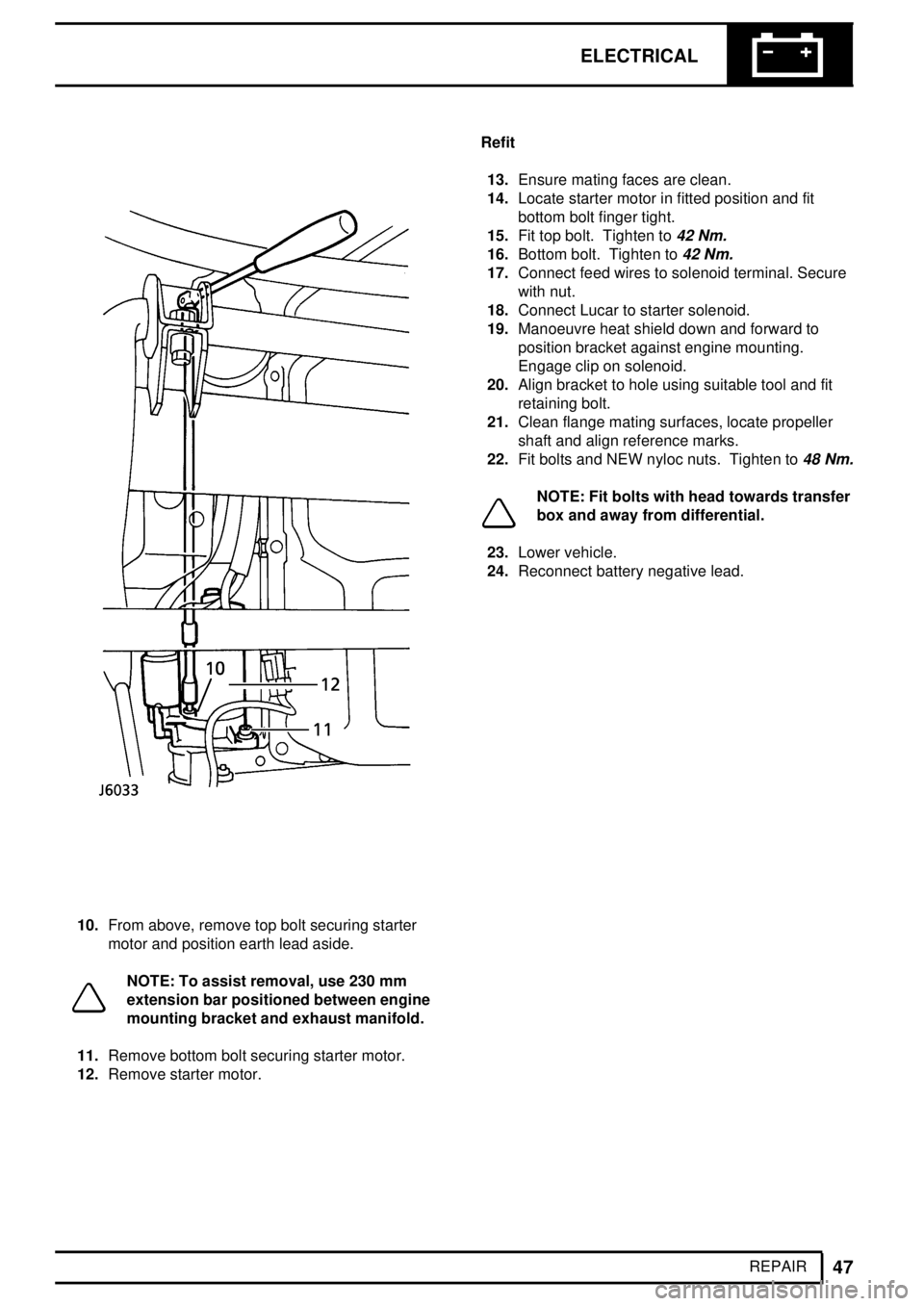

Page 867 of 873

ELECTRICAL

47

REPAIR

10.From above, remove top bolt securing starter

motor and position earth lead aside.

NOTE: To assist removal, use 230 mm

extension bar positioned between engine

mounting bracket and exhaust manifold.

11.Remove bottom bolt securing starter motor.

12.Remove starter motor.Refit

13.Ensure mating faces are clean.

14.Locate starter motor in fitted position and fit

bottom bolt finger tight.

15.Fit top bolt. Tighten to

42 Nm.

16.Bottom bolt. Tighten to42 Nm.

17.Connect feed wires to solenoid terminal. Secure

with nut.

18.Connect Lucar to starter solenoid.

19.Manoeuvre heat shield down and forward to

position bracket against engine mounting.

Engage clip on solenoid.

20.Align bracket to hole using suitable tool and fit

retaining bolt.

21.Clean flange mating surfaces, locate propeller

shaft and align reference marks.

22.Fit bolts and NEW nyloc nuts. Tighten to

48 Nm.

NOTE: Fit bolts with head towards transfer

box and away from differential.

23.Lower vehicle.

24.Reconnect battery negative lead.

Page 868 of 873

86ELECTRICAL

48

REPAIR STARTER MOTOR HEAT SHIELD - 4.0 V8

Service repair no - 86.60.12

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove heated oxygen sensor from RH exhaust

front pipe.

See EMISSION CONTROL, Repair,

Heated Oxygen Sensor (HO2S) - 4.0 V8

4.Remove bolt securing heat shield to RH engine

mounting bracket.

5.Release heat shield clip from starter solenoid.

6.Manoeuvre heat shield rearwards and around

starter motor.

Refit

7.Reverse removal procedure.BULB - FRONT FOG LAMP

Service repair no - 86.40.94

Remove

1.Remove front fog lamp.

See fog lamp - front

2.Remove 2 Torx screws securing fog lamp to

bracket and collect 2 spacers.

3.Release fog lamp adjustment ball joint from

bracket and remove lamp.

4.Release lamp lens from shroud.

5.Disconnect 2 Lucars from bulb.

6.Release bulb retaining clip.

7.Remove bulb from lens.

Page 869 of 873

ELECTRICAL

49

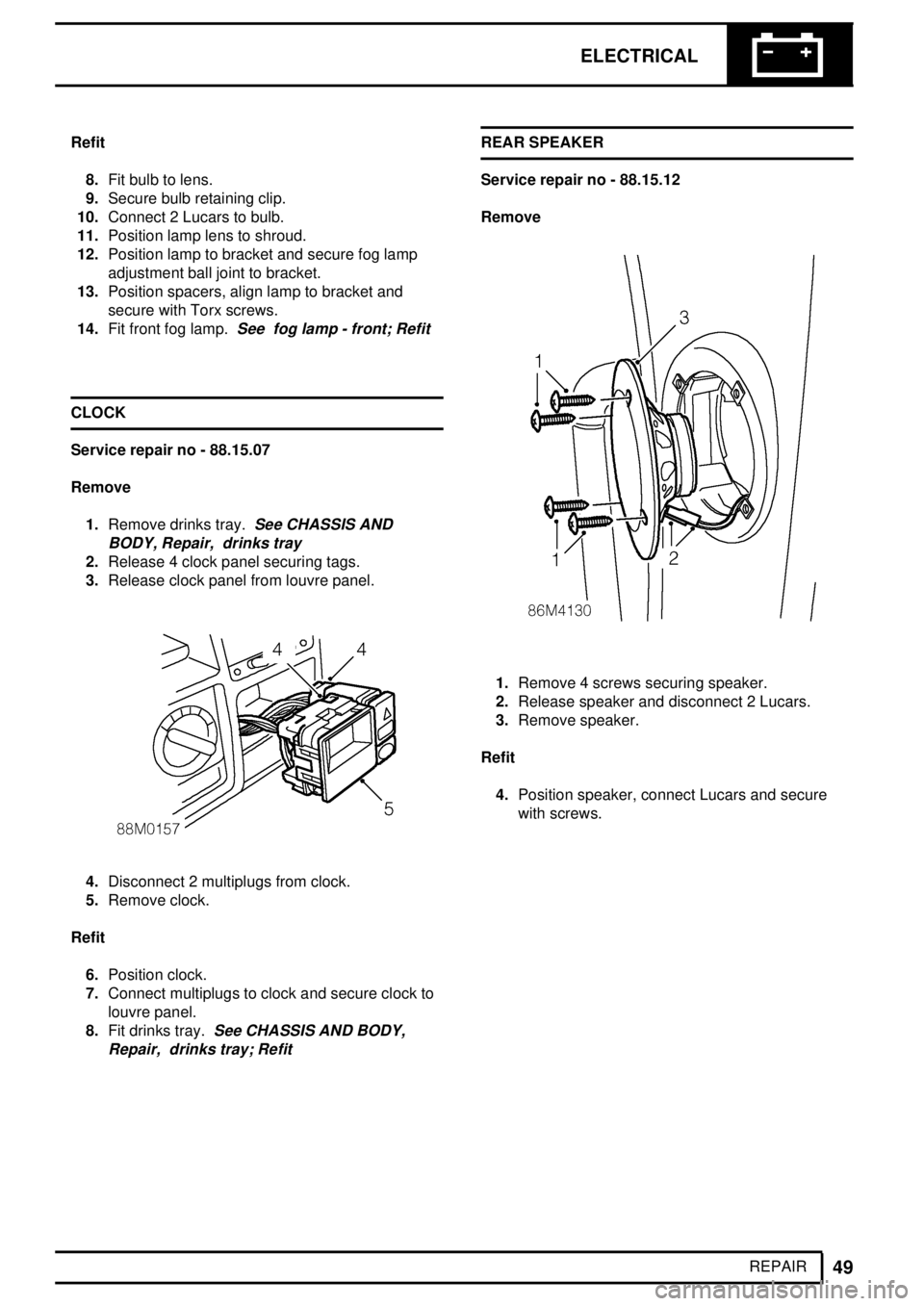

REPAIR Refit

8.Fit bulb to lens.

9.Secure bulb retaining clip.

10.Connect 2 Lucars to bulb.

11.Position lamp lens to shroud.

12.Position lamp to bracket and secure fog lamp

adjustment ball joint to bracket.

13.Position spacers, align lamp to bracket and

secure with Torx screws.

14.Fit front fog lamp.

See fog lamp - front; Refit

CLOCK

Service repair no - 88.15.07

Remove

1.Remove drinks tray.

See CHASSIS AND

BODY, Repair, drinks tray

2.Release 4 clock panel securing tags.

3.Release clock panel from louvre panel.

4.Disconnect 2 multiplugs from clock.

5.Remove clock.

Refit

6.Position clock.

7.Connect multiplugs to clock and secure clock to

louvre panel.

8.Fit drinks tray.

See CHASSIS AND BODY,

Repair, drinks tray; Refit

REAR SPEAKER

Service repair no - 88.15.12

Remove

1.Remove 4 screws securing speaker.

2.Release speaker and disconnect 2 Lucars.

3.Remove speaker.

Refit

4.Position speaker, connect Lucars and secure

with screws.

Page 870 of 873

86ELECTRICAL

50

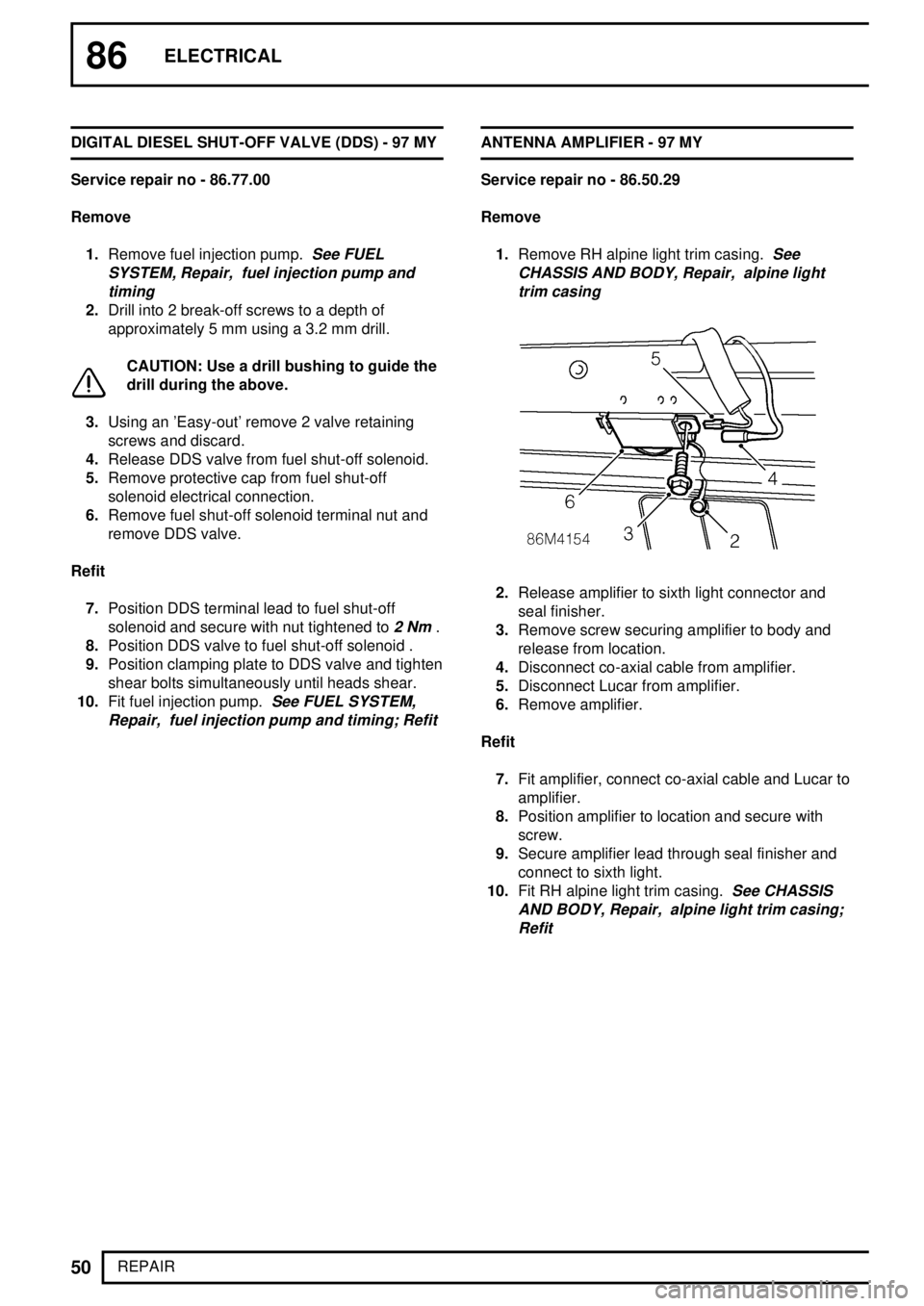

REPAIR DIGITAL DIESEL SHUT-OFF VALVE (DDS) - 97 MY

Service repair no - 86.77.00

Remove

1.Remove fuel injection pump.

See FUEL

SYSTEM, Repair, fuel injection pump and

timing

2.Drill into 2 break-off screws to a depth of

approximately 5 mm using a 3.2 mm drill.

CAUTION: Use a drill bushing to guide the

drill during the above.

3.Using an 'Easy-out' remove 2 valve retaining

screws and discard.

4.Release DDS valve from fuel shut-off solenoid.

5.Remove protective cap from fuel shut-off

solenoid electrical connection.

6.Remove fuel shut-off solenoid terminal nut and

remove DDS valve.

Refit

7.Position DDS terminal lead to fuel shut-off

solenoid and secure with nut tightened to

2Nm.

8.Position DDS valve to fuel shut-off solenoid .

9.Position clamping plate to DDS valve and tighten

shear bolts simultaneously until heads shear.

10.Fit fuel injection pump.

See FUEL SYSTEM,

Repair, fuel injection pump and timing; Refit

ANTENNA AMPLIFIER - 97 MY

Service repair no - 86.50.29

Remove

1.Remove RH alpine light trim casing.

See

CHASSIS AND BODY, Repair, alpine light

trim casing

2.Release amplifier to sixth light connector and

seal finisher.

3.Remove screw securing amplifier to body and

release from location.

4.Disconnect co-axial cable from amplifier.

5.Disconnect Lucar from amplifier.

6.Remove amplifier.

Refit

7.Fit amplifier, connect co-axial cable and Lucar to

amplifier.

8.Position amplifier to location and secure with

screw.

9.Secure amplifier lead through seal finisher and

connect to sixth light.

10.Fit RH alpine light trim casing.

See CHASSIS

AND BODY, Repair, alpine light trim casing;

Refit

Page 871 of 873

ELECTRICAL

1

OVERHAUL DISTRIBUTOR-LUCAS 35DLM8

Overhaul

DISTRIBUTOR CAP

Service repair no - 86.35.10

1.Unclip and remove cap

2.Fit a new cap if faulty.

3.Clean cap and HT brush with a lint free cloth.

ROTOR ARM

Service repair no - 86.35.16

1.Pull rotor arm from shaft.

2.Fit a new rotor arm if faulty.

INSULATION COVER (FLASH SHIELD)

Service repair no - 86.35.40

1.Remove cover secured by three screws.

2.Fit a new cover if faulty.

VACUUM UNIT

Service repair no - 86.35.21

1.Remove two screws from vacuum unit securing

bracket. Disengage vacuum unit connecting rod

from pick-up base plate connecting peg.

Withdraw vacuum unit from distributor body.AMPLIFIER MODULE

Service repair no - 86.35.30

1.Remove two screws and withdraw module.

2.Remove gasket.

3.Remove two screws and cast heatsink.

WARNING: Amplifier module is a sealed

unit containing Beryllia. This substance is

extremely dangerous if handled. DO NOT

attempt to open or crush module.

PICK-UP AND BASE PLATE ASSEMBLY

Service repair no - 86.35.42

1.Use circlip pliers to remove circlip retaining

reluctor on rotor shaft.

2.Remove flat washer, and 'O' ring recessed in top

of reluctor.

3.Gently withdraw reluctor from shaft, taking care

not to damage teeth.

NOTE: Coupling ring fitted beneath

reluctor.

4.Remove three support pillars and cable

grommet. Lift out pick-up and base plate

assembly.

NOTE: Do not disturb two barrel nuts

securing pick-up module, otherwise air

gap will need re-adjustment.

5.Fit a new pick-up and base plate assembly if

module is known to be faulty, otherwise check

pick-up winding resistance (2k-5k ohm).

Reassemble

6.This is mainly a reversal of dismantling

procedure, noting following points:

Page 872 of 873

86ELECTRICAL

2

OVERHAUL

LUBRICATION

Apply clean engine oil:

a. A spot into rotor spindle before fitting rotor

arm.

Apply Omnilube 2 (or equivalent) grease.

b. Auto advance mechanism.

c. Pick-up plate centre bearing.

d. Pre tilt spring and its rubbing area (pick-up

and base plate assembly).

e. Vacuum unit connecting peg (pick-up and

base plate assembly).

f. Connecting peg hole in vacuum unit

connecting rod.

Fitting pick-up and base plate assembly

1.Pick-up leads must be prevented from fouling

rotating reluctor. Both leads should be located in

plastic guide as illustrated. Check during

re-assembly.

Fitting reluctor

2.Slide reluctor as far as it will go on rotor shaft,

rotate reluctor until it engages with coupling ring

beneath pick-up base plate. Distributor shaft,

coupling ring and reluctor are 'keyed' and rotate

together. Fit 'O' ring, flat washer and retaining

circlip.Pick-up air gap adjustment

1.Air gap between pick-up limb and reluctor teeth

must be set within specified limits, using a

non-ferrous feeler gauge.

2.If adjustment is necessary, loosen two barrel

nuts to set the air gap.

See ENGINE TUNING

DATA, Information, Engine 3.9 V8i

NOTE: When original pick-up and base

plate assembly has been refitted, air gap

should be checked, and adjusted if

necessary.

When fitting a new assembly air gap will require

adjusting to within specified limits.

Amplifier module

1.Before fitting module, apply MS4 Silicone grease

or equivalent heat-conducting compound to

amplifier module backplate, seating face on

distributor body and both faces of heatsink

casting.