door lock LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 674 of 873

CHASSIS AND BODY

7

REPAIR REAR SIDE DOORS

Service repair no - 76.28.02

Remove

1.Disconnect battery negative lead.

2.Detach the convoluted grommet from the 'B'

post.

3.Withdraw the door harness multiplugs from the

'B' post and disconnect them.

4.Remove the bolts and washers securing the

check strap to the 'B' post.

WARNING: Instruction 5 MUST BE carried

out with assistance.

5.Remove the door hinge 'C' clips from the hinge

posts and with assistance carefully lift the door

from the vehicle.

Refit

6.Reverse removal procedure. Fitting new 'C' clips

if the existing ones are worn or distorted.

7.Check the operation of the door and lock. If

necessary, adjust the door and striker.

Adjust

8.Adjust the door by adding or removing shims

between the hinge and the door to move the

door forward or rearward in the opening.

9.To adjust the door up, down or in and out of the

opening, loosen the screws securing the hinges

to the door, adjust as necessary and retighten

the screws to the correct torque value.

10.Adjustment of the door striker is identical to the

procedure for front doors.

NOTE: If it is necessary to remove the

hinges from the 'B' post they must be

refitted in exactly the same position, using

an equal thickness of shims to those removed.

Page 676 of 873

CHASSIS AND BODY

9

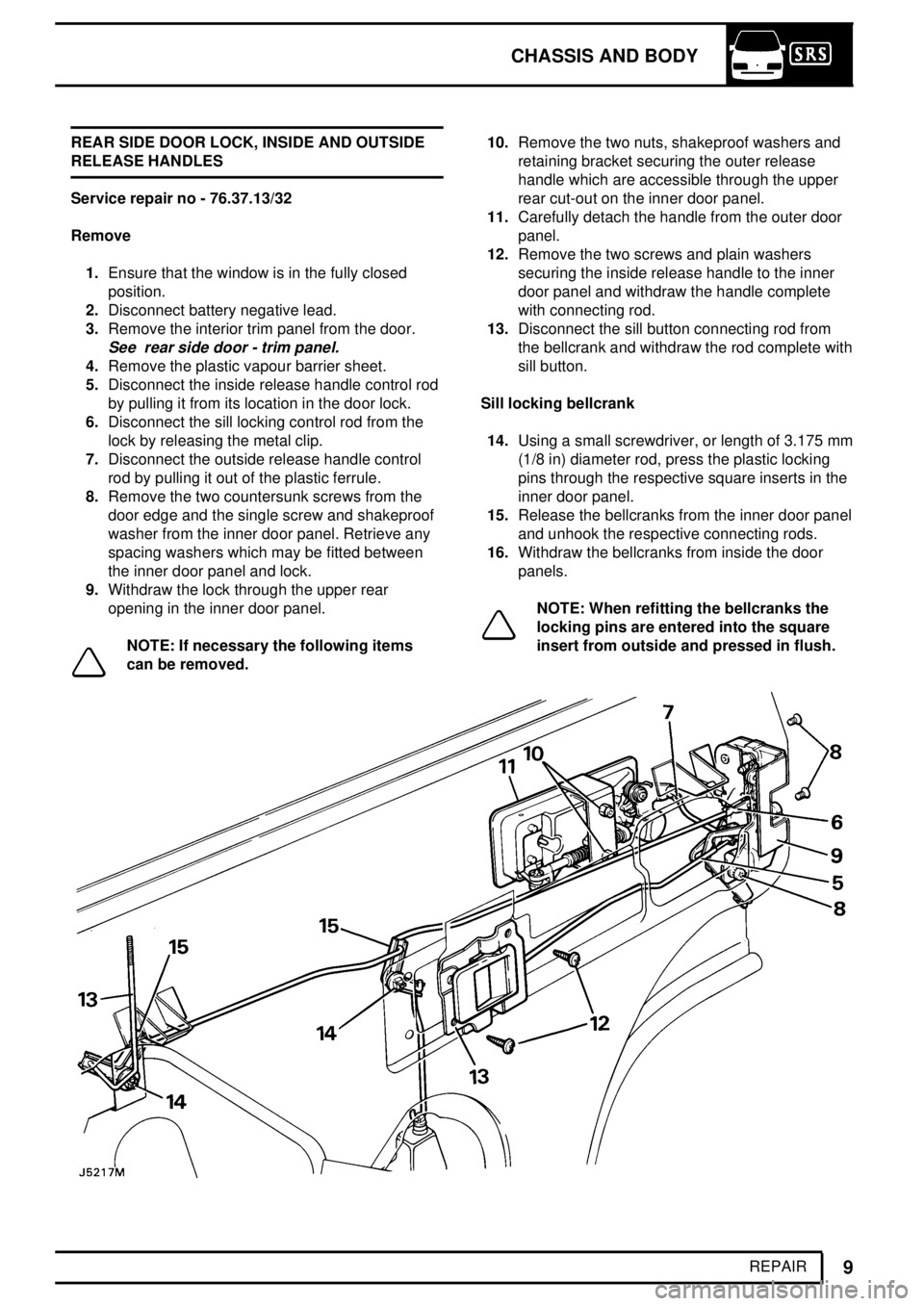

REPAIR REAR SIDE DOOR LOCK, INSIDE AND OUTSIDE

RELEASE HANDLES

Service repair no - 76.37.13/32

Remove

1.Ensure that the window is in the fully closed

position.

2.Disconnect battery negative lead.

3.Remove the interior trim panel from the door.

See rear side door - trim panel.

4.Remove the plastic vapour barrier sheet.

5.Disconnect the inside release handle control rod

by pulling it from its location in the door lock.

6.Disconnect the sill locking control rod from the

lock by releasing the metal clip.

7.Disconnect the outside release handle control

rod by pulling it out of the plastic ferrule.

8.Remove the two countersunk screws from the

door edge and the single screw and shakeproof

washer from the inner door panel. Retrieve any

spacing washers which may be fitted between

the inner door panel and lock.

9.Withdraw the lock through the upper rear

opening in the inner door panel.

NOTE: If necessary the following items

can be removed.10.Remove the two nuts, shakeproof washers and

retaining bracket securing the outer release

handle which are accessible through the upper

rear cut-out on the inner door panel.

11.Carefully detach the handle from the outer door

panel.

12.Remove the two screws and plain washers

securing the inside release handle to the inner

door panel and withdraw the handle complete

with connecting rod.

13.Disconnect the sill button connecting rod from

the bellcrank and withdraw the rod complete with

sill button.

Sill locking bellcrank

14.Using a small screwdriver, or length of 3.175 mm

(1/8 in) diameter rod, press the plastic locking

pins through the respective square inserts in the

inner door panel.

15.Release the bellcranks from the inner door panel

and unhook the respective connecting rods.

16.Withdraw the bellcranks from inside the door

panels.

NOTE: When refitting the bellcranks the

locking pins are entered into the square

insert from outside and pressed in flush.

Page 677 of 873

76CHASSIS AND BODY

10

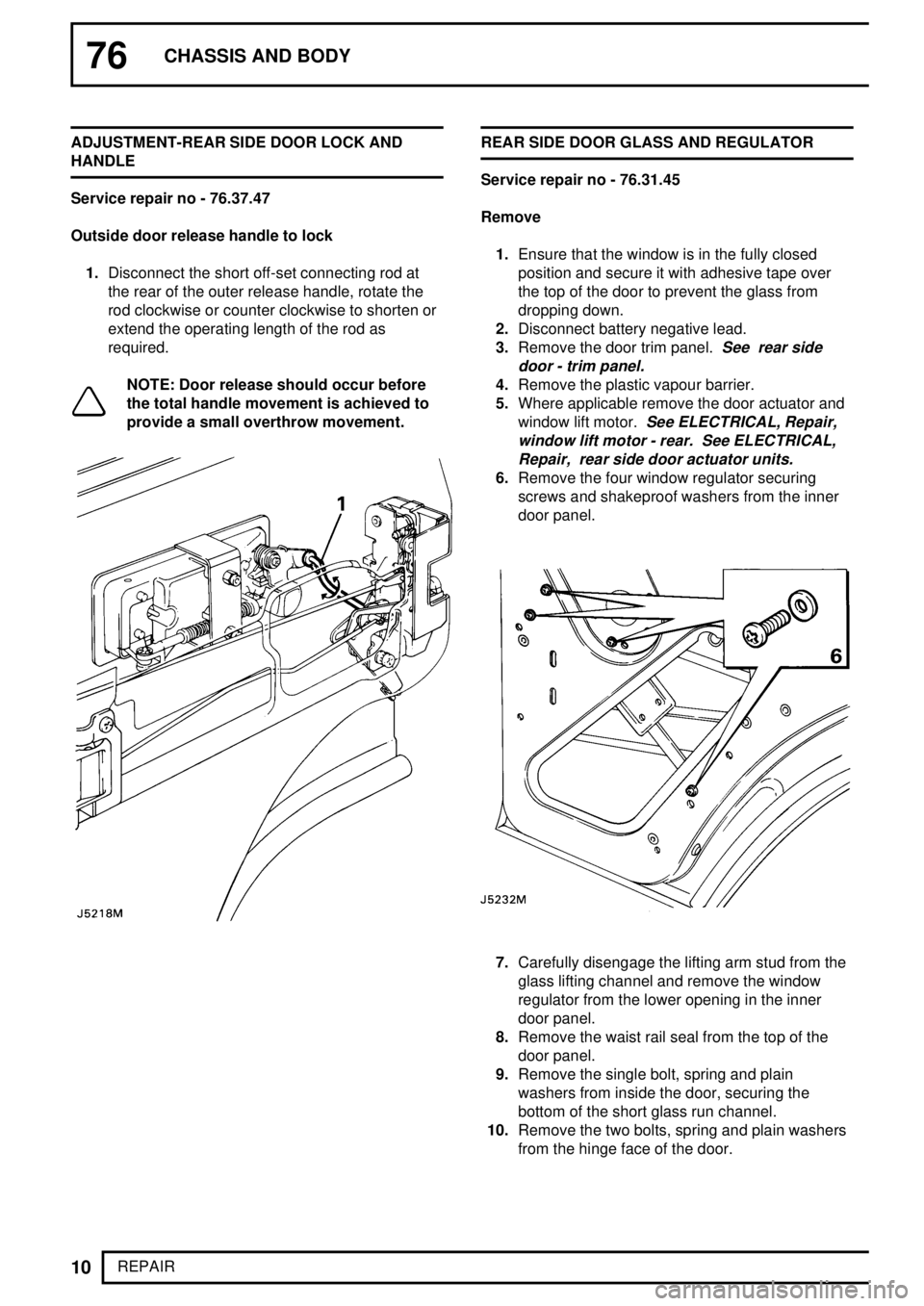

REPAIR ADJUSTMENT-REAR SIDE DOOR LOCK AND

HANDLE

Service repair no - 76.37.47

Outside door release handle to lock

1.Disconnect the short off-set connecting rod at

the rear of the outer release handle, rotate the

rod clockwise or counter clockwise to shorten or

extend the operating length of the rod as

required.

NOTE: Door release should occur before

the total handle movement is achieved to

provide a small overthrow movement.

REAR SIDE DOOR GLASS AND REGULATOR

Service repair no - 76.31.45

Remove

1.Ensure that the window is in the fully closed

position and secure it with adhesive tape over

the top of the door to prevent the glass from

dropping down.

2.Disconnect battery negative lead.

3.Remove the door trim panel.

See rear side

door - trim panel.

4.Remove the plastic vapour barrier.

5.Where applicable remove the door actuator and

window lift motor.

See ELECTRICAL, Repair,

window lift motor - rear. See ELECTRICAL,

Repair, rear side door actuator units.

6.Remove the four window regulator securing

screws and shakeproof washers from the inner

door panel.

7.Carefully disengage the lifting arm stud from the

glass lifting channel and remove the window

regulator from the lower opening in the inner

door panel.

8.Remove the waist rail seal from the top of the

door panel.

9.Remove the single bolt, spring and plain

washers from inside the door, securing the

bottom of the short glass run channel.

10.Remove the two bolts, spring and plain washers

from the hinge face of the door.

Page 679 of 873

76CHASSIS AND BODY

12

REPAIR REAR DOOR TRIM PANEL

Service repair no - 76.34.09

Remove

1.Remove the two screws securing the door pull

and remove it from the door.

2.Remove the finisher from the inner door handle.

3.Using a trim panel removing tool release the

seventeen trim panel fasteners and withdraw the

panel from the door.

4.If necessary remove the sixteen screws securing

the stowage bins to the trim panel and detach

the bins.

Refit

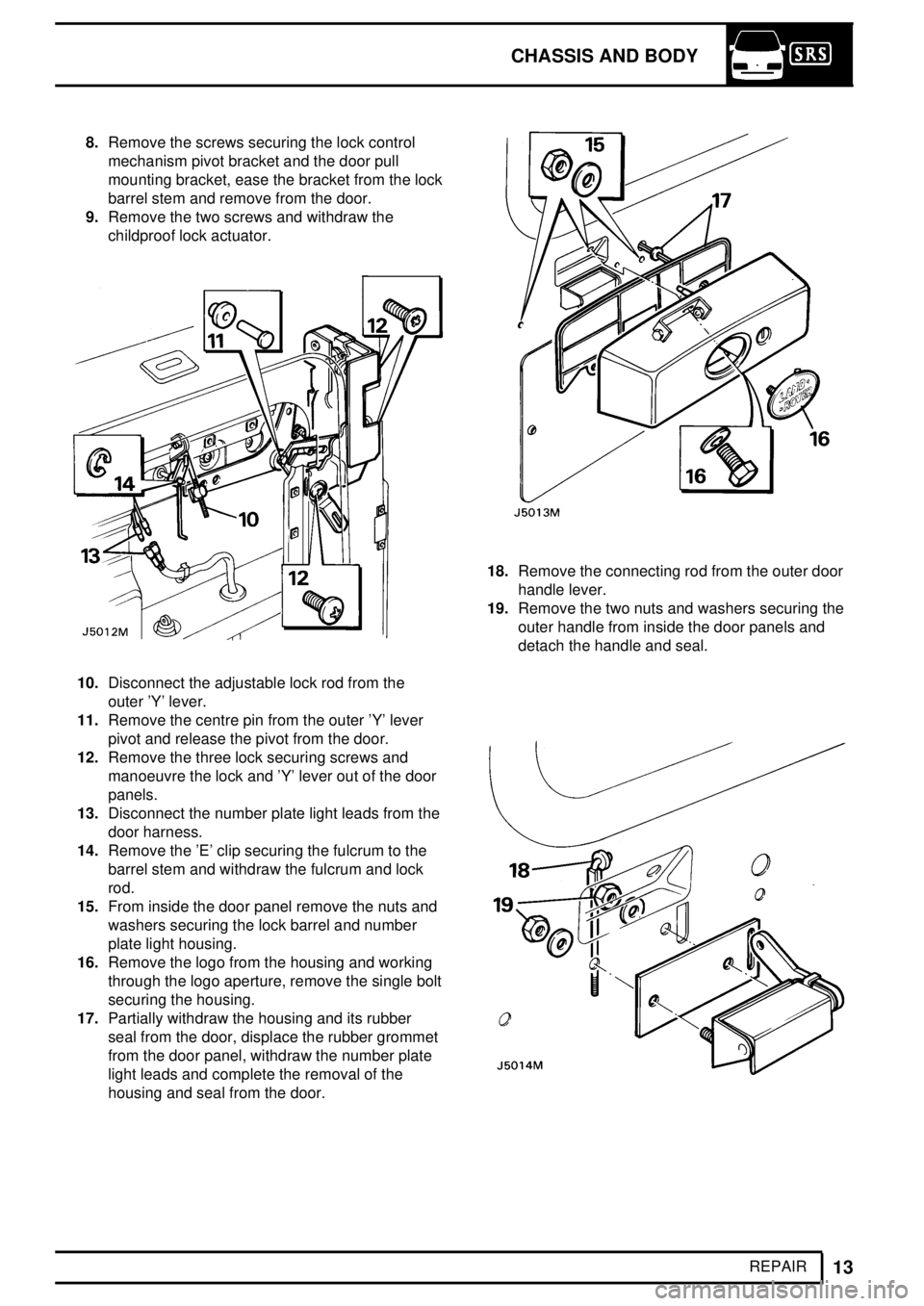

5.Reverse removal procedure.REAR DOOR LOCK AND INNER AND OUTER

RELEASE HANDLES

Service repair no - 76.37.16/74/77/78

Remove

1.Disconnect battery negative lead.

2.Remove the door pull, the trim panel and the

vapour protective sheet, to allow access to the

door handles and lock mechanisms.

3.Disconnect the inner release handle connecting

rod at the lock.

4.Remove the two screws securing the inner

handle and withdraw the handle complete with

connecting rod.

NOTE: Two identical 'Y' shaped levers

(bellcranks) are fitted to the rear door lock

mechanism and are referred to as inner

and outer 'Y' levers; the inner one being the

nearest to the inner door panel.

5.If fitted, remove the central locking actuator

control rod link from the actuator and from the

inner 'Y' lever.

6.Detach the remote button connecting rod at the

inner 'Y' lever and withdraw from inside the door.

7.Detach the lock and barrel connecting rods from

the upper leg of the inner 'Y' lever.

Page 680 of 873

CHASSIS AND BODY

13

REPAIR 8.Remove the screws securing the lock control

mechanism pivot bracket and the door pull

mounting bracket, ease the bracket from the lock

barrel stem and remove from the door.

9.Remove the two screws and withdraw the

childproof lock actuator.

10.Disconnect the adjustable lock rod from the

outer 'Y' lever.

11.Remove the centre pin from the outer 'Y' lever

pivot and release the pivot from the door.

12.Remove the three lock securing screws and

manoeuvre the lock and 'Y' lever out of the door

panels.

13.Disconnect the number plate light leads from the

door harness.

14.Remove the 'E' clip securing the fulcrum to the

barrel stem and withdraw the fulcrum and lock

rod.

15.From inside the door panel remove the nuts and

washers securing the lock barrel and number

plate light housing.

16.Remove the logo from the housing and working

through the logo aperture, remove the single bolt

securing the housing.

17.Partially withdraw the housing and its rubber

seal from the door, displace the rubber grommet

from the door panel, withdraw the number plate

light leads and complete the removal of the

housing and seal from the door.

18.Remove the connecting rod from the outer door

handle lever.

19.Remove the two nuts and washers securing the

outer handle from inside the door panels and

detach the handle and seal.

Page 681 of 873

76CHASSIS AND BODY

14

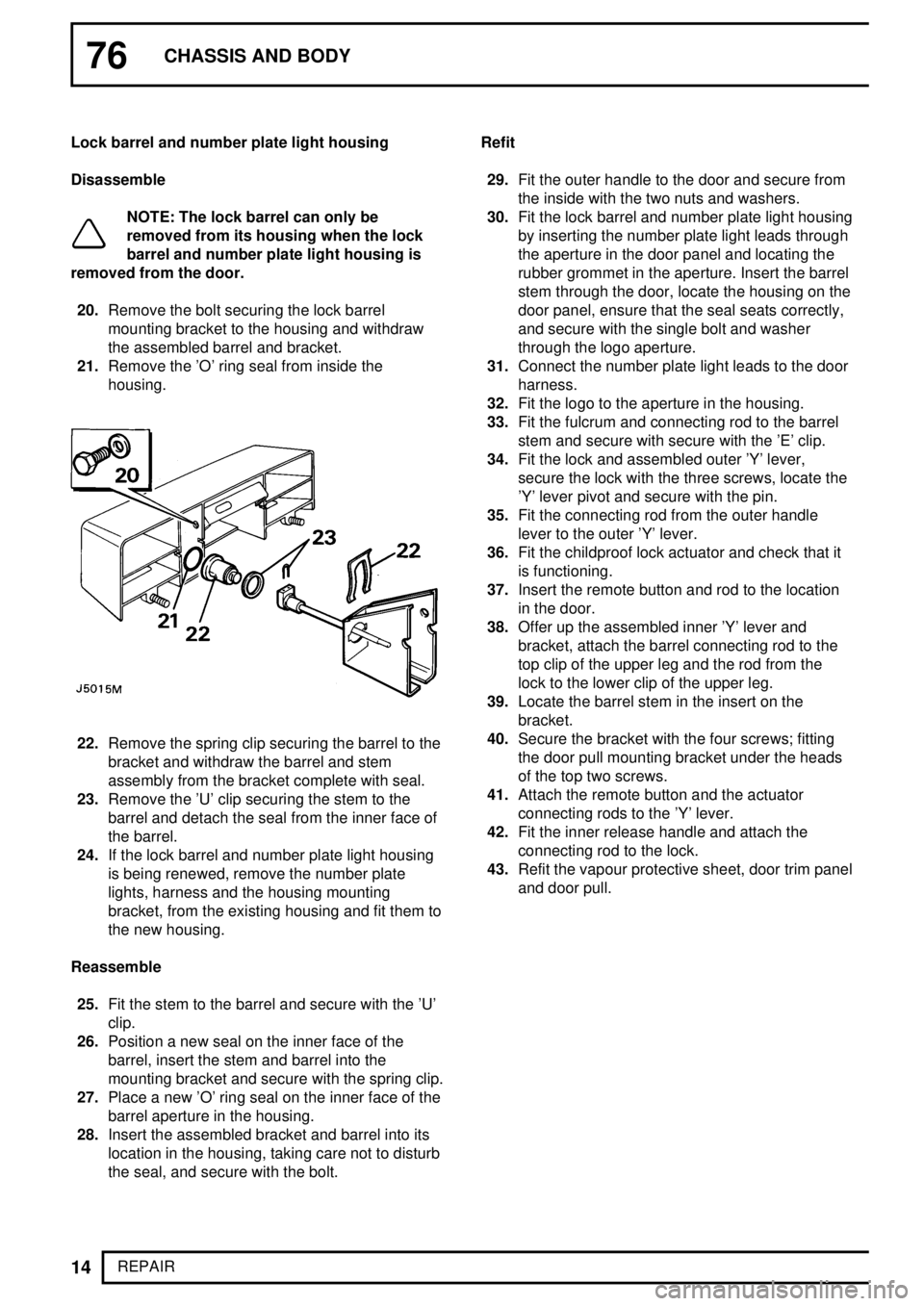

REPAIR Lock barrel and number plate light housing

Disassemble

NOTE: The lock barrel can only be

removed from its housing when the lock

barrel and number plate light housing is

removed from the door.

20.Remove the bolt securing the lock barrel

mounting bracket to the housing and withdraw

the assembled barrel and bracket.

21.Remove the 'O' ring seal from inside the

housing.

22.Remove the spring clip securing the barrel to the

bracket and withdraw the barrel and stem

assembly from the bracket complete with seal.

23.Remove the 'U' clip securing the stem to the

barrel and detach the seal from the inner face of

the barrel.

24.If the lock barrel and number plate light housing

is being renewed, remove the number plate

lights, harness and the housing mounting

bracket, from the existing housing and fit them to

the new housing.

Reassemble

25.Fit the stem to the barrel and secure with the 'U'

clip.

26.Position a new seal on the inner face of the

barrel, insert the stem and barrel into the

mounting bracket and secure with the spring clip.

27.Place a new 'O' ring seal on the inner face of the

barrel aperture in the housing.

28.Insert the assembled bracket and barrel into its

location in the housing, taking care not to disturb

the seal, and secure with the bolt.Refit

29.Fit the outer handle to the door and secure from

the inside with the two nuts and washers.

30.Fit the lock barrel and number plate light housing

by inserting the number plate light leads through

the aperture in the door panel and locating the

rubber grommet in the aperture. Insert the barrel

stem through the door, locate the housing on the

door panel, ensure that the seal seats correctly,

and secure with the single bolt and washer

through the logo aperture.

31.Connect the number plate light leads to the door

harness.

32.Fit the logo to the aperture in the housing.

33.Fit the fulcrum and connecting rod to the barrel

stem and secure with secure with the 'E' clip.

34.Fit the lock and assembled outer 'Y' lever,

secure the lock with the three screws, locate the

'Y' lever pivot and secure with the pin.

35.Fit the connecting rod from the outer handle

lever to the outer 'Y' lever.

36.Fit the childproof lock actuator and check that it

is functioning.

37.Insert the remote button and rod to the location

in the door.

38.Offer up the assembled inner 'Y' lever and

bracket, attach the barrel connecting rod to the

top clip of the upper leg and the rod from the

lock to the lower clip of the upper leg.

39.Locate the barrel stem in the insert on the

bracket.

40.Secure the bracket with the four screws; fitting

the door pull mounting bracket under the heads

of the top two screws.

41.Attach the remote button and the actuator

connecting rods to the 'Y' lever.

42.Fit the inner release handle and attach the

connecting rod to the lock.

43.Refit the vapour protective sheet, door trim panel

and door pull.

Page 765 of 873

82AIR CONDITIONING

6

ADJUSTMENT SYSTEM TEST

1.Place the vehicle in a ventilated, shaded area

free from excessive draught, with the doors and

windows open.

2.Check that the surface of the condenser is not

restricted with dirt, leaves, flies, etc. Do not

neglect to check the surface between the

condenser and the radiator. Clean as necessary.

3.Switch on the ignition and the air conditioner air

flow control. Check that the blower is operating

efficiently at low, medium and high speeds.

Switch off the blower and the ignition.

4.Check that the evaporator condensate drain

tubes are open and clear.

5.Check the tension of the compressor driving belt,

and adjust if necessary.

6.Inspect all connections for the presence of

refrigerant oil. If oil is evident, check for leaks,

and repair as necessary.

NOTE: The compressor oil is soluble in

Refrigerant R134a and is deposited when

the refrigerant evaporates from a leak.

7.Start the engine.

8.Set the temperature controls to cold and switch

the air conditioner blower control on and off

several times, checking that the magnetic clutch

on the compressor engages and releases each

time.9.With the temperature control at maximum

cooling and the blower control at high speed,

warm up the engine and fast idle at 1000

rev/min. Check the sight glass for bubbles or

foam. The sight glass should be generally clear

after five minutes running, occasional bubbles

being acceptable. Continuous bubbles may

appear in a serviceable system on a cool day, or

if there is insufficient air flow over the condenser

at a high ambient temperature.

10.Repeat at 1800 rev/min.

11.Gradually increase the engine speed to the high

range, and check the sight glass at intervals.

12.Check for frosting on the service valves.

13.Check the high pressure hoses and connections

by hand for varying temperature. Low

temperature indicates a restriction or blockage at

that point.

14.Switch off the air conditioning blower and stop

the engine.

15.If the air conditioning equipment is still not

satisfactory, carry out a pressure test as

previously described in this section.

COMPRESSOR DRIVE BELT

Service repair no - 82.10.01.

Tdi -

See ENGINE, Repair, Compressor drive belt

V8i and MpiSee ENGINE, Repair, Drive belt

Page 800 of 873

84WIPERS AND WASHERS

4

REPAIR WIPER BLADES

Service repair no - 84.15.05

Remove

1.Pull wiper blade away from screen.

2.Depress spring clip and withdraw blade from

hooked end of wiper arm.

Refit

3.Reverse removal procedure. 1 and 2.REAR WINDOW WASHER JET

Service repair no - 84.30.09

Remove

1.Turn washer jet in a clockwise direction to

release it from the rear quarter panel.

2.Remove rear quarter/speaker trim panel.

3.Feed washer tubing through rear quarter panel

to allow removal of washer jet.

4.Remove washer jet from tubing.

Refit

5.Reverse removal procedure. 1 to 4.

NOTE: The tubing run from the reservoir to

rear door washer jet differs between left

and right hand drive vehicles. On right

hand vehicles the tubing run is on the left hand

side of the roof. On left hand drive vehicles, the

right side.

See Description and operation,

Windscreen Wiper and Washer Operation

Page 805 of 873

86ELECTRICAL

2

DESCRIPTION AND OPERATION ANTI-THEFT SYSTEM FUNCTION

Perimetric protection

Using the key in the correct sequence will turn on and

off perimetric protection only. When fully perimetrically

armed, all doors, and bonnet [hood] are protected

against unauthorised access. If the door key is used in

the normal manner the driver will be unaware of the

door key sequence. The time taken to lock or unlock

with the key must be less than 5 seconds. To prevent

unauthorised tampering, the alarm will sound if the

key is held in the unlocked position for longer than 5

seconds when armed. Cranking is disabled when

perimetric protection is armed.

NOTE: When key is turned left or right the

keyswitch input will be activated, in

conjunction with the sill button switch

when links are operated.

Volumetric protection

Using the handset transmitter will turn on and off

volumetric protection. In volumetric mode the vehicle

interior is protected using the ultrasonic sensor. Using

the handset also arms and disarms the vehicle

perimetrically. Cranking is disabled when volumetric

and perimetric protection is armed.

NOTE: If armed volumetrically the vehicle

CANNOT be disarmed using the key.

Alarm horn

When an intrusion is detected the alarm horn will

sound intermittently (Switzerland and Denmark

continuous horn sound) and the hazard lights flash

(where territorial regulations allow) for 30 seconds.

The alarm must be retriggered before alarm horn will

sound again.Vehicle status indication

Vehicle status is indicated by up to three devices: (a)

alarm horn, (b) hazard lights, (c) dash board LED.

When the vehicle arms in either mode the hazard

lights will flash three times and the LED will flash

rapidly for 10 seconds. LED will then flash at a slower

rate while vehicle is armed. When the vehicle disarms,

hazard lights will flash once and LED will extinguish. If

LED remains lit, it indicates that the alarm has been

triggered. Turning on ignition or arming the alarm will

extinguish LED. The LED will give a long pulse flash

to indicate the ultrasonic unit being activated.

Central locking

Central locking is controlled by the alarm ECU and

may be operated by the key, sill button(s) or handset.

The system works on both front doors on four door

vehicles or driver's door on two door vehicles.

NOTE: The central door locking system

will shut down for a short period after

more than 15 consecutive operations.

Inertia switch

An inertia switch is incorporated in the alarm system

ECU. If ignition is on and the vehicle receives an

impact sufficient to activate the inertia switch, the ECU

will signal to unlock central locking actuators and flash

hazard lights. Central locking will remain disabled for

30 seconds. To reset turn ignition off and then on after

the 30 second period has elapsed.

Ultrasonic unit

The unit operates by emitting an air pressure carrier

wave and receiving the wave back. Any disturbance

within the vehicle which disturbs the wave will be

detected, triggering the alarm.

When the volumetric sensor is activated it monitors

movement within the vehicle for 15 seconds before

detecting and responding to intrusions. If the sensor

detects movement within the vehicle it delays arming

until a 15 seconds quiet period has elapsed. If

continuous movement is detected the alarm will not

arm volumetrically.

Page 806 of 873

ELECTRICAL

3

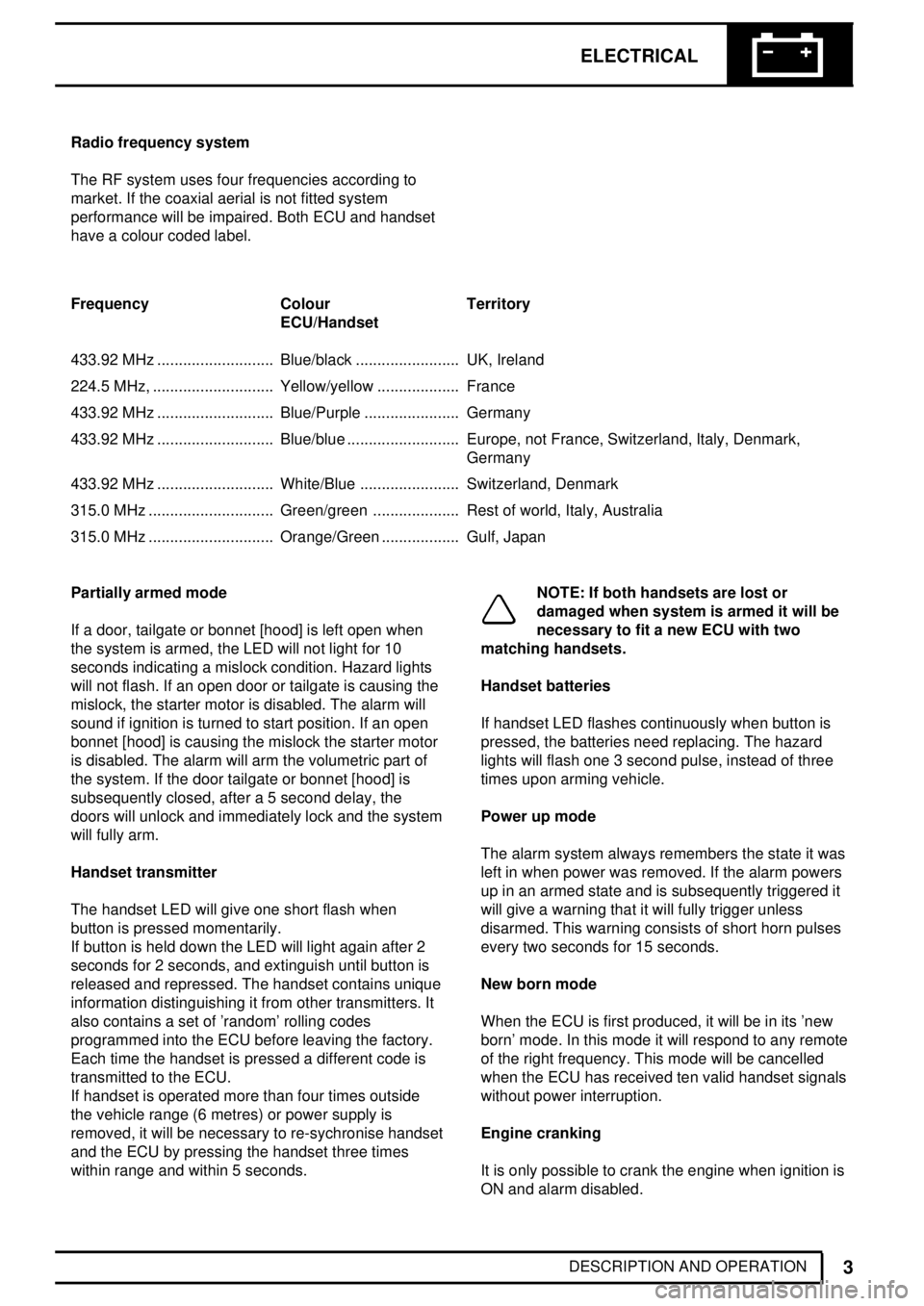

DESCRIPTION AND OPERATION Radio frequency system

The RF system uses four frequencies according to

market. If the coaxial aerial is not fitted system

performance will be impaired. Both ECU and handset

have a colour coded label.

Frequency Colour Territory

ECU/Handset

433.92 MHz Blue/black........................... UK, Ireland........................

224.5 MHz, Yellow/yellow............................ France...................

433.92 MHz Blue/Purple........................... Germany......................

433.92 MHz Blue/blue........................... Europe, not France, Switzerland, Italy, Denmark,..........................

Germany

433.92 MHz White/Blue........................... Switzerland, Denmark.......................

315.0 MHz Green/green............................. Rest of world, Italy, Australia....................

315.0 MHz Orange/Green............................. Gulf, Japan..................

Partially armed mode

If a door, tailgate or bonnet [hood] is left open when

the system is armed, the LED will not light for 10

seconds indicating a mislock condition. Hazard lights

will not flash. If an open door or tailgate is causing the

mislock, the starter motor is disabled. The alarm will

sound if ignition is turned to start position. If an open

bonnet [hood] is causing the mislock the starter motor

is disabled. The alarm will arm the volumetric part of

the system. If the door tailgate or bonnet [hood] is

subsequently closed, after a 5 second delay, the

doors will unlock and immediately lock and the system

will fully arm.

Handset transmitter

The handset LED will give one short flash when

button is pressed momentarily.

If button is held down the LED will light again after 2

seconds for 2 seconds, and extinguish until button is

released and repressed. The handset contains unique

information distinguishing it from other transmitters. It

also contains a set of 'random' rolling codes

programmed into the ECU before leaving the factory.

Each time the handset is pressed a different code is

transmitted to the ECU.

If handset is operated more than four times outside

the vehicle range (6 metres) or power supply is

removed, it will be necessary to re-sychronise handset

and the ECU by pressing the handset three times

within range and within 5 seconds.

NOTE: If both handsets are lost or

damaged when system is armed it will be

necessary to fit a new ECU with two

matching handsets.

Handset batteries

If handset LED flashes continuously when button is

pressed, the batteries need replacing. The hazard

lights will flash one 3 second pulse, instead of three

times upon arming vehicle.

Power up mode

The alarm system always remembers the state it was

left in when power was removed. If the alarm powers

up in an armed state and is subsequently triggered it

will give a warning that it will fully trigger unless

disarmed. This warning consists of short horn pulses

every two seconds for 15 seconds.

New born mode

When the ECU is first produced, it will be in its 'new

born' mode. In this mode it will respond to any remote

of the right frequency. This mode will be cancelled

when the ECU has received ten valid handset signals

without power interruption.

Engine cranking

It is only possible to crank the engine when ignition is

ON and alarm disabled.