oil LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 823 of 873

ELECTRICAL

3

REPAIR BATTERY

Service repair no - 86.15.01

NOTE: Some vehicles are fitted with a

battery backed-up sounder. Disconnecting

the vehicle battery will cause the alarm to

sound unless the following procedure is followed:

1.Turn starter switch 'ON' then 'OFF'.

2.Disconnect battery WITHIN 15 SECONDS (see

WARNING).

If alarm is accidentally activated, ensure sounder is

connected and silence by turning the starter switch to

position II.

Remove

WARNING: During battery removal or

before carrying out any repairs or

maintenance to electrical components

always disconnect battery negative lead first. If

positive lead is disconnected with negative lead in

place, accidental contact of wrench to any

grounded metal part could cause a severe spark,

possibly resulting in personal injury. Upon

installation of battery connect positive lead first.

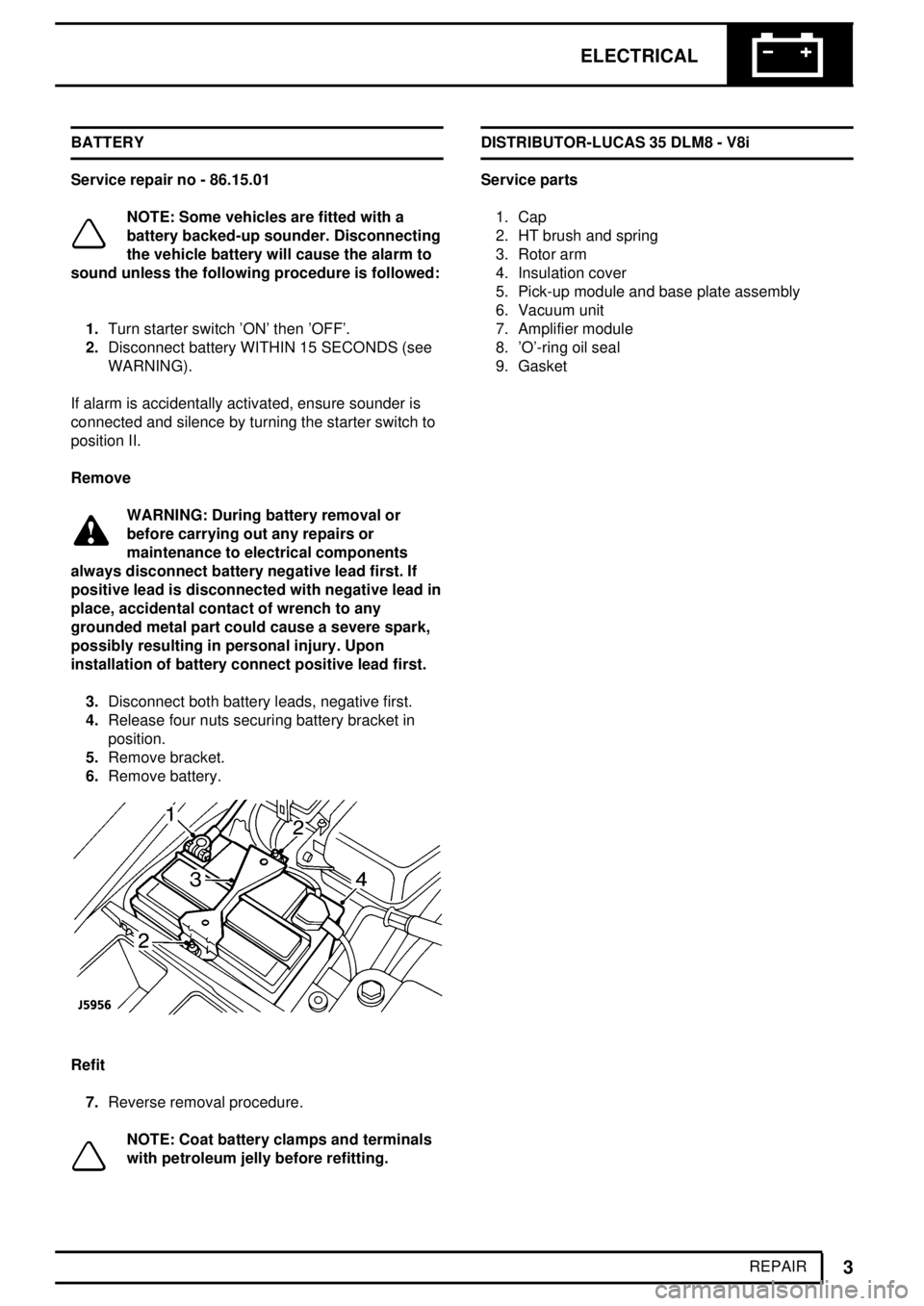

3.Disconnect both battery leads, negative first.

4.Release four nuts securing battery bracket in

position.

5.Remove bracket.

6.Remove battery.

Refit

7.Reverse removal procedure.

NOTE: Coat battery clamps and terminals

with petroleum jelly before refitting.DISTRIBUTOR-LUCAS 35 DLM8 - V8i

Service parts

1. Cap

2. HT brush and spring

3. Rotor arm

4. Insulation cover

5. Pick-up module and base plate assembly

6. Vacuum unit

7. Amplifier module

8. 'O'-ring oil seal

9. Gasket

Page 825 of 873

ELECTRICAL

5

REPAIR ELECTRONIC IGNITION - V8i

A Lucas 35DLM8 distributor is employed. This has a

conventional vacuum advance unit and centrifugal

automatic advance mechanism.

A pick-up module, in conjunction with a rotating timing

reluctor inside distributor body, generates timing

signals. These are applied to an electronic ignition

amplifier module mounted on side of distributor body.

NOTE: Pick-up air gap is factory set. Do

not adjust gap unless pick-up is being

changed or base plate has been moved.

Use a non-ferrous feeler gauge to set air gap.

IGNITION COIL

Service repair no - 86.35.32

Remove

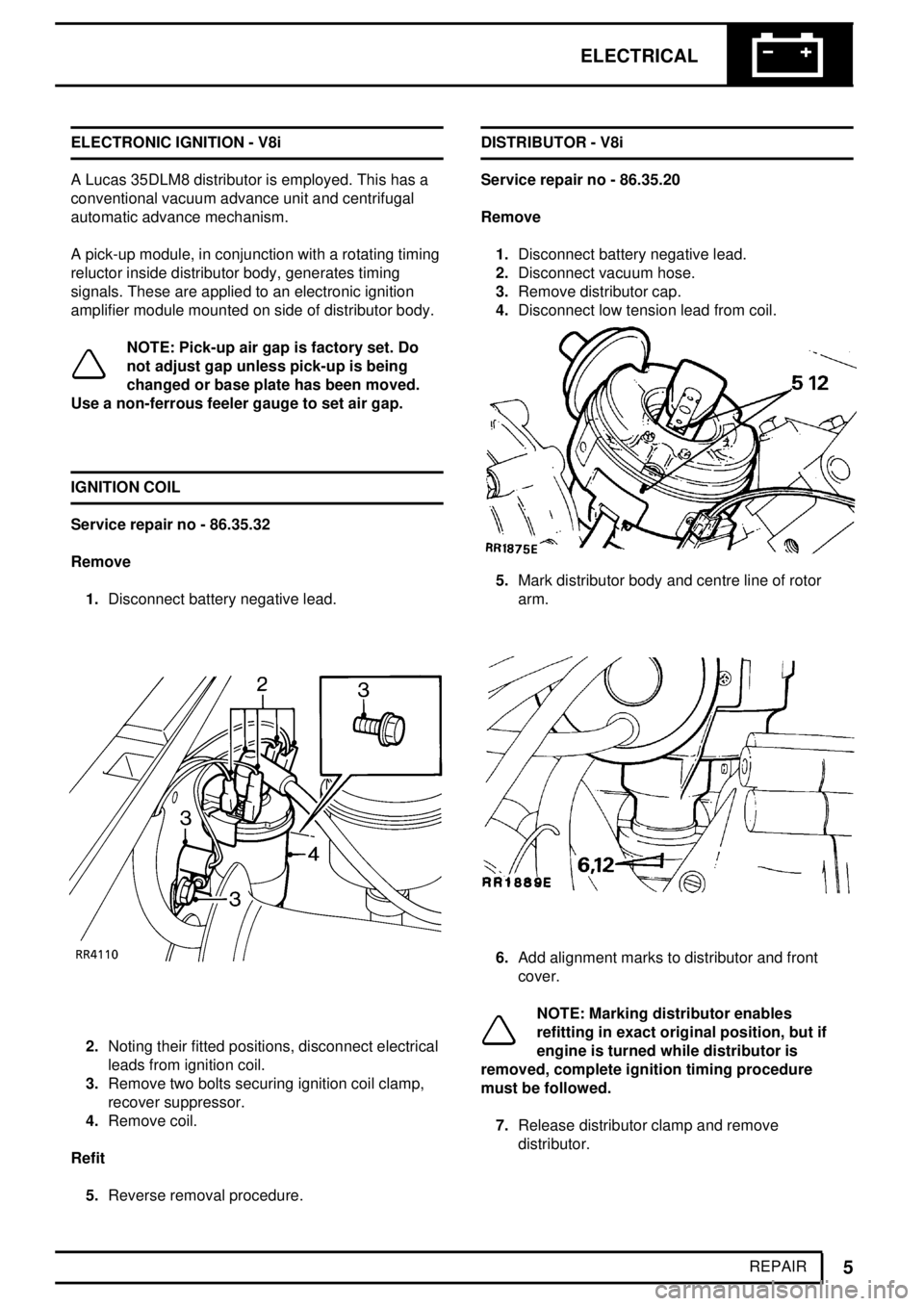

1.Disconnect battery negative lead.

2.Noting their fitted positions, disconnect electrical

leads from ignition coil.

3.Remove two bolts securing ignition coil clamp,

recover suppressor.

4.Remove coil.

Refit

5.Reverse removal procedure.DISTRIBUTOR - V8i

Service repair no - 86.35.20

Remove

1.Disconnect battery negative lead.

2.Disconnect vacuum hose.

3.Remove distributor cap.

4.Disconnect low tension lead from coil.

5.Mark distributor body and centre line of rotor

arm.

6.Add alignment marks to distributor and front

cover.

NOTE: Marking distributor enables

refitting in exact original position, but if

engine is turned while distributor is

removed, complete ignition timing procedure

must be followed.

7.Release distributor clamp and remove

distributor.

Page 826 of 873

86ELECTRICAL

6

REPAIR Refit

NOTE: If a new distributor is being fitted,

mark body in same relative position as

distributor removed.

8.Leads for distributor cap should be connected as

illustrated.

Figures 1 to 8 inclusive indicate plug lead

numbers.

RH-Right hand side of engine, when viewed

from rear.

LH-Left hand side of engine, when viewed from

rear.

9.If engine has not been turned while distributor

has been removed, carry out instructions 10. to

17. Alternatively proceed to instruction 18.

10.Fit new 'O' ring seal to distributor housing.

11.Turn distributor drive until centre line of rotor arm

is 30Ê anti-clockwise from mark made on top

edge of distributor body.

12.Fit distributor in accordance with alignment

markings.

NOTE: It may be necessary to align oil

pump drive shaft to enable distributor

drive shaft to engage in slot.

13.Fit clamp and bolt. Secure distributor in exact

original position.

14.Connect vacuum hose to distributor and low

tension lead to coil.

15.Fit distributor cap.

16.Reconnect battery.

17.Using suitable electronic equipment, set ignition

timing.

See Adjustment, Ignition timing

18.If engine has been turned with distributor

removed, carry out instructions 19 to 30.

19.Set engine-No. 1 piston to static ignition timing

figure

See ENGINE TUNING DATA,

Information, Engine 3.9 V8i

20.Turn distributor drive until rotor arm is

approximately 30Ê anti-clockwise from number

one sparking plug lead position on cap.

21.Fit distributor to engine.

22.Check that centre line of rotor arm is now in line

with number one sparking plug lead on cap.

Reposition distributor if necessary.

23.If distributor does not seat correctly in front

cover, oil pump drive is not engaged. Engage by

lightly pressing down distributor while turning

engine.

24.Fit clamp and bolt, do not tighten.

25.Set ignition timing statically to 6Ê B.T.D.C.

26.Connect vacuum hose to distributor.

27.Fit low tension lead to coil.

28.Fit distributor cap.

29.Reconnect battery.

30.Using suitable electronic equipment set the

ignition timing.

See Adjustment, Ignition

timing

Page 854 of 873

86ELECTRICAL

34

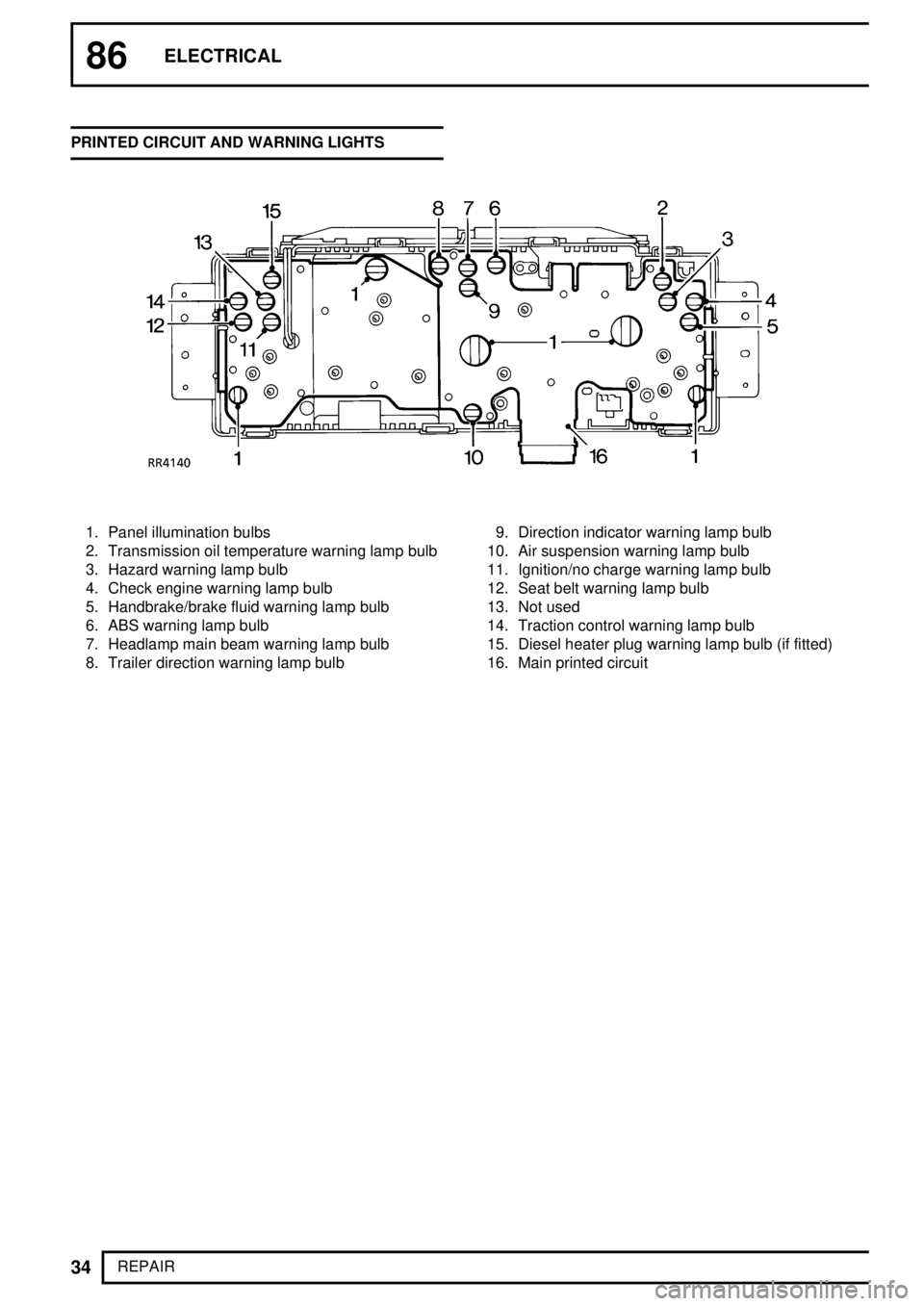

REPAIR PRINTED CIRCUIT AND WARNING LIGHTS

1. Panel illumination bulbs

2. Transmission oil temperature warning lamp bulb

3. Hazard warning lamp bulb

4. Check engine warning lamp bulb

5. Handbrake/brake fluid warning lamp bulb

6. ABS warning lamp bulb

7. Headlamp main beam warning lamp bulb

8. Trailer direction warning lamp bulb9. Direction indicator warning lamp bulb

10. Air suspension warning lamp bulb

11. Ignition/no charge warning lamp bulb

12. Seat belt warning lamp bulb

13. Not used

14. Traction control warning lamp bulb

15. Diesel heater plug warning lamp bulb (if fitted)

16. Main printed circuit

Page 859 of 873

ELECTRICAL

39

REPAIR CIGAR LIGHTER AND BULB

Service repair no - 86.65.60

Service repair no - 86.45.55

Cigar Lighter

Remove

1.Remove centre console.

See CHASSIS AND

BODY, Repair, Centre Console

2.Depress lugs securing cigar lighter, withdraw

lighter from centre console.

Bulb replacement

3.Remove bulb from holder.

Refit

4.Reverse removal procedure.OIL PRESSURE WARNING SWITCH - V8i

Service repair no - 86.65.30

Remove

1.Disconnect the battery negative lead.

2.Disconnect electrical lead.

3.Unscrew switch unit.

4.Remove switch and sealing washer.

Refit

5.Reverse removal procedure. Using a NEW

sealing washer.

Page 862 of 873

86ELECTRICAL

42

REPAIR FOG LAMP - FRONT

Service repair no - 86.40.96

Remove

1.Locate and release lamp harness multiplug from

clip behind headlamp.

2.Disconnect multiplug.

3.Attach a draw string to harness.

4.Remove 2 nuts securing lamp bracket to bumper

studs.

5.Remove 2 screws securing lamp bracket to

spoiler.

6.Release lamp assembly and pull lamp harness

through front panel.

7.Detach draw string from harness.

8.Remove lamp/bracket assembly.

9.Remove 2 spire nuts from lamp bracket.

Refit

10.Reverse removal procedure.

Page 863 of 873

ELECTRICAL

43

REPAIR ANTI-THEFT ALARM ECU (96 MODELS)

Service repair no - 86.55.85

Remove

1.Remove 4 studs securing fascia left hand

closing panel.

2.Remove closing panel.

3.Disconnect 2 multiplugs from ECU.

4.Remove nut securing ECU/relay bracket.

5.Lower bracket.

6.Remove 2 nuts securing ECU to bracket.

7.Remove ECU.

NOTE: A new ECU must be initialised

using TestBook.

Refit

8.Reverse removal procedure.HANDSET (96 MODELS)

If vehicle does not respond to handset immediately, it

may have lost synchronisation. To re-synchronise,

press either button, 4 times in quick succession. If

handset still fails to respond, check batteries, refer to

Owner's handbook. If batteries are okay, it may be

necessary to use emergency key access, refer to

Owner's handbook.

NOTE: New handsets must be initialised

using TestBook.

PASSIVE COIL (96 MODELS)

Service repair no - 86.77.35

Remove

1.Remove steering column shroud.

See

STEERING, Repair, Steering column shroud

2.Release multiplug from harness clip and

disconnect.

3.Release passive coil from starter switch.

4.Remove bulb holder/starter switch shroud.

5.Remove coil.

Refit

6.Fit coil, ensuring switch illumination bulb harness

passes through large cut-out.

7.Secure coil with cable tie.

8.Position bulb holder/starter switch shroud and

locate bulb.

9.Locate bulb holder/starter switch shroud,

ensuring cut-out in shroud aligns with lug on

starter switch.

10.Connect multiplug and secure to clip.

11.Fit column shroud.

Page 872 of 873

86ELECTRICAL

2

OVERHAUL

LUBRICATION

Apply clean engine oil:

a. A spot into rotor spindle before fitting rotor

arm.

Apply Omnilube 2 (or equivalent) grease.

b. Auto advance mechanism.

c. Pick-up plate centre bearing.

d. Pre tilt spring and its rubbing area (pick-up

and base plate assembly).

e. Vacuum unit connecting peg (pick-up and

base plate assembly).

f. Connecting peg hole in vacuum unit

connecting rod.

Fitting pick-up and base plate assembly

1.Pick-up leads must be prevented from fouling

rotating reluctor. Both leads should be located in

plastic guide as illustrated. Check during

re-assembly.

Fitting reluctor

2.Slide reluctor as far as it will go on rotor shaft,

rotate reluctor until it engages with coupling ring

beneath pick-up base plate. Distributor shaft,

coupling ring and reluctor are 'keyed' and rotate

together. Fit 'O' ring, flat washer and retaining

circlip.Pick-up air gap adjustment

1.Air gap between pick-up limb and reluctor teeth

must be set within specified limits, using a

non-ferrous feeler gauge.

2.If adjustment is necessary, loosen two barrel

nuts to set the air gap.

See ENGINE TUNING

DATA, Information, Engine 3.9 V8i

NOTE: When original pick-up and base

plate assembly has been refitted, air gap

should be checked, and adjusted if

necessary.

When fitting a new assembly air gap will require

adjusting to within specified limits.

Amplifier module

1.Before fitting module, apply MS4 Silicone grease

or equivalent heat-conducting compound to

amplifier module backplate, seating face on

distributor body and both faces of heatsink

casting.