gearbox LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 85 of 873

12ENGINE

4

REPAIR 22.Disconnect feed pipe and spill return pipe from

injector pump.

23.Disconnect both pipes from fuel lift pump.

24.Disconnect servo hose from vacuum pump.

25.Remove three retaining nuts and disconnect

exhaust down pipe.

26.Remove oil cooler pipes from oil filter adaptor.

27.If automatic transmission is fitted, disconnect

feed and return pipes at gearbox oil cooler.

Remove retaining bracket from LH side of

cylinder block and release both oil cooler pipes.

28.Support gearbox.

29.Disconnect ground strap from starter motor.

30.On vehicles with automatic transmission, remove

fixings and detach drive plate housing access

panel and gasket.31.Working through drive plate housing aperture

mark the torque convertor and drive plate to

facilitate reassembly.

32.Remove the four convertor to flexible drive

securing bolts, rotating crankshaft to gain access

to each individual bolt.

33.Fit engine lifting bracket to the two RH rear

cylinder head fixing bolts.

34.Using suitable hoist, fit lifting chains to engine.

35.Remove four bolts, from both sides, securing

front engine mounting brackets to cylinder block.

36.Remove two bolts, from both sides, securing

front engine mounting bracket to bell housing.

Page 86 of 873

Tdi

5

REPAIR

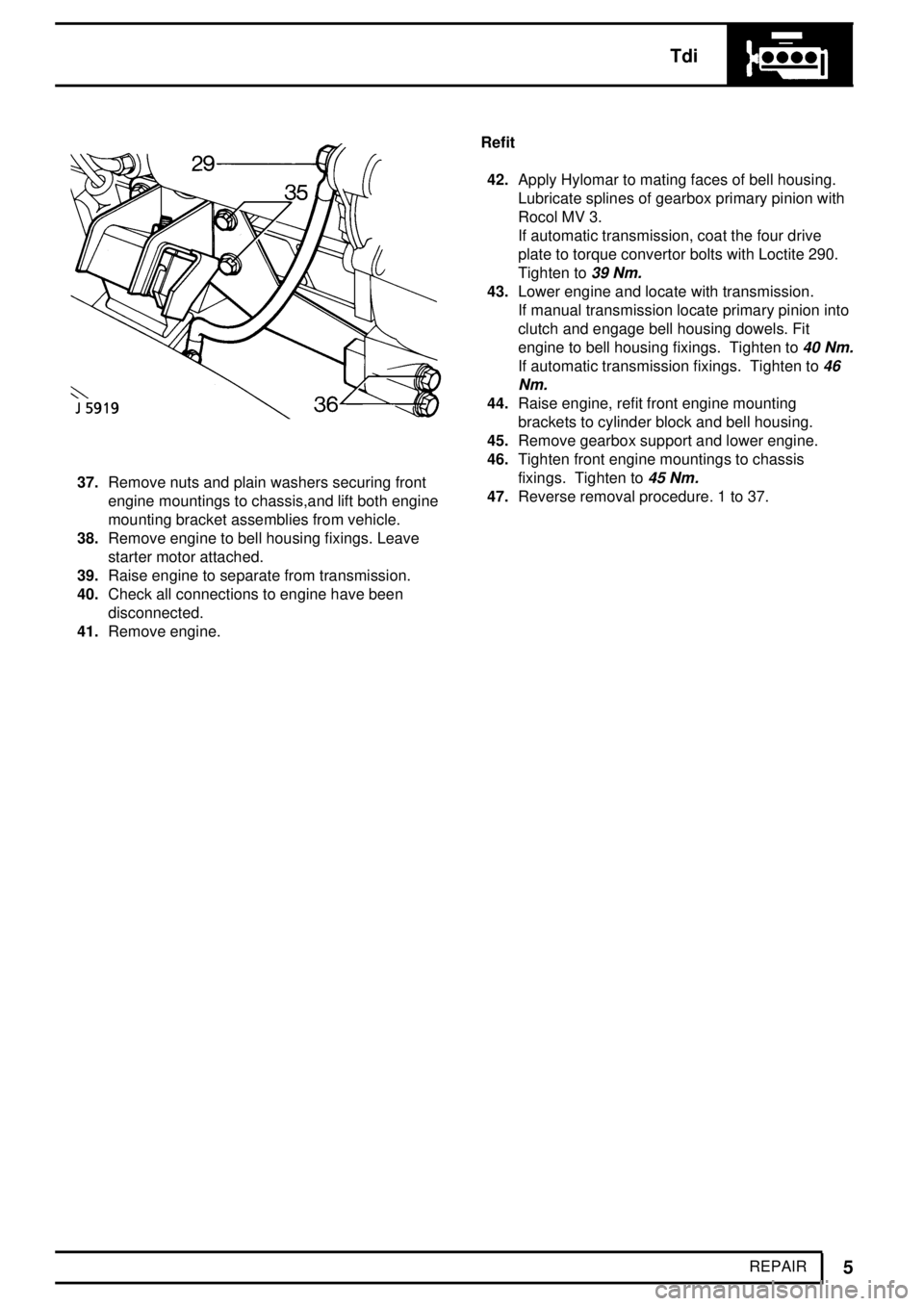

37.Remove nuts and plain washers securing front

engine mountings to chassis,and lift both engine

mounting bracket assemblies from vehicle.

38.Remove engine to bell housing fixings. Leave

starter motor attached.

39.Raise engine to separate from transmission.

40.Check all connections to engine have been

disconnected.

41.Remove engine.Refit

42.Apply Hylomar to mating faces of bell housing.

Lubricate splines of gearbox primary pinion with

Rocol MV 3.

If automatic transmission, coat the four drive

plate to torque convertor bolts with Loctite 290.

Tighten to

39 Nm.

43.Lower engine and locate with transmission.

If manual transmission locate primary pinion into

clutch and engage bell housing dowels. Fit

engine to bell housing fixings. Tighten to

40 Nm.

If automatic transmission fixings. Tighten to46

Nm.

44.Raise engine, refit front engine mounting

brackets to cylinder block and bell housing.

45.Remove gearbox support and lower engine.

46.Tighten front engine mountings to chassis

fixings. Tighten to

45 Nm.

47.Reverse removal procedure. 1 to 37.

Page 89 of 873

12ENGINE

8

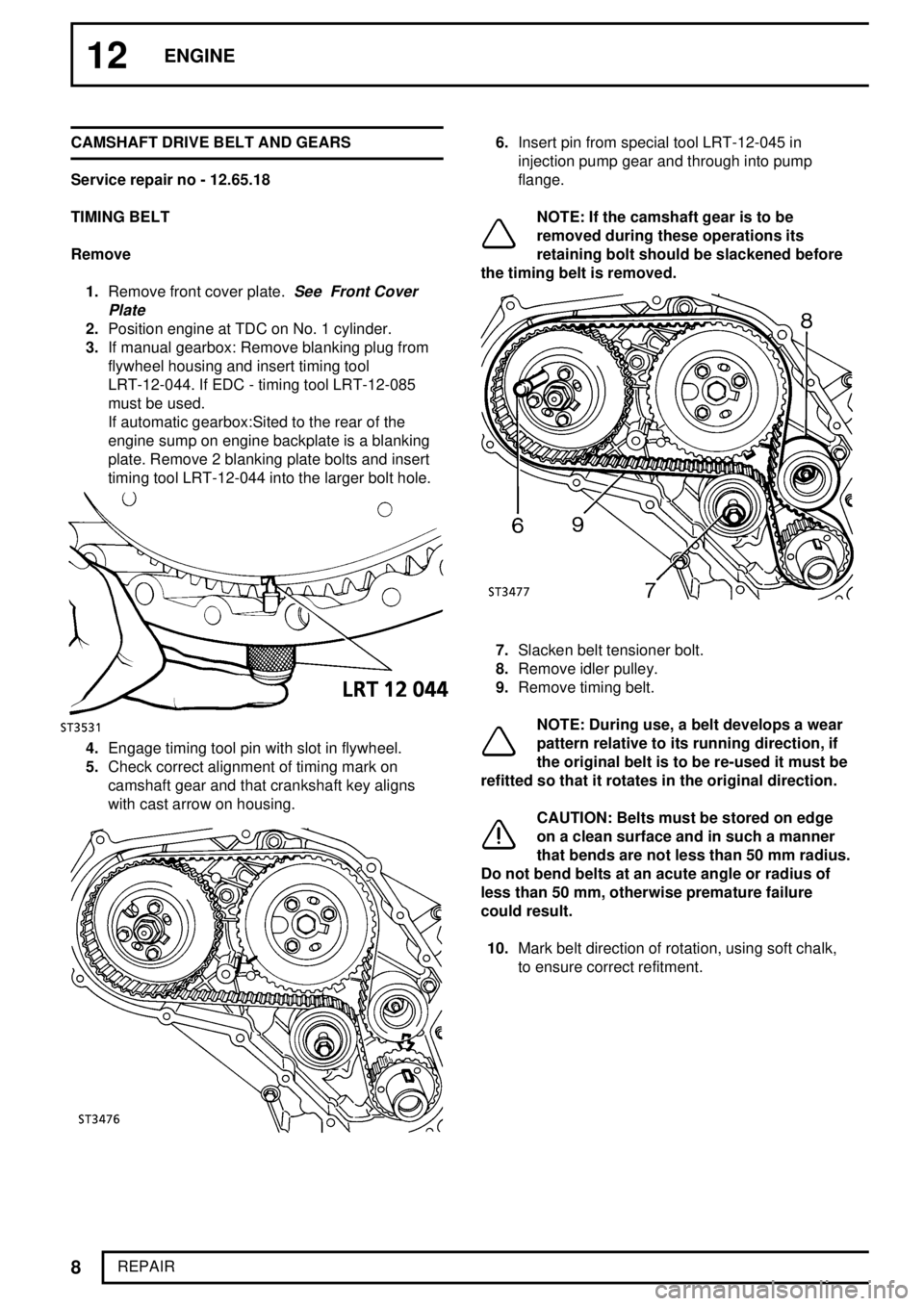

REPAIR CAMSHAFT DRIVE BELT AND GEARS

Service repair no - 12.65.18

TIMING BELT

Remove

1.Remove front cover plate.

See Front Cover

Plate

2.Position engine at TDC on No. 1 cylinder.

3.If manual gearbox: Remove blanking plug from

flywheel housing and insert timing tool

LRT-12-044. If EDC - timing tool LRT-12-085

must be used.

If automatic gearbox:Sited to the rear of the

engine sump on engine backplate is a blanking

plate. Remove 2 blanking plate bolts and insert

timing tool LRT-12-044 into the larger bolt hole.

4.Engage timing tool pin with slot in flywheel.

5.Check correct alignment of timing mark on

camshaft gear and that crankshaft key aligns

with cast arrow on housing.

6.Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

NOTE: If the camshaft gear is to be

removed during these operations its

retaining bolt should be slackened before

the timing belt is removed.

7.Slacken belt tensioner bolt.

8.Remove idler pulley.

9.Remove timing belt.

NOTE: During use, a belt develops a wear

pattern relative to its running direction, if

the original belt is to be re-used it must be

refitted so that it rotates in the original direction.

CAUTION: Belts must be stored on edge

on a clean surface and in such a manner

that bends are not less than 50 mm radius.

Do not bend belts at an acute angle or radius of

less than 50 mm, otherwise premature failure

could result.

10.Mark belt direction of rotation, using soft chalk,

to ensure correct refitment.

Page 95 of 873

12ENGINE

14

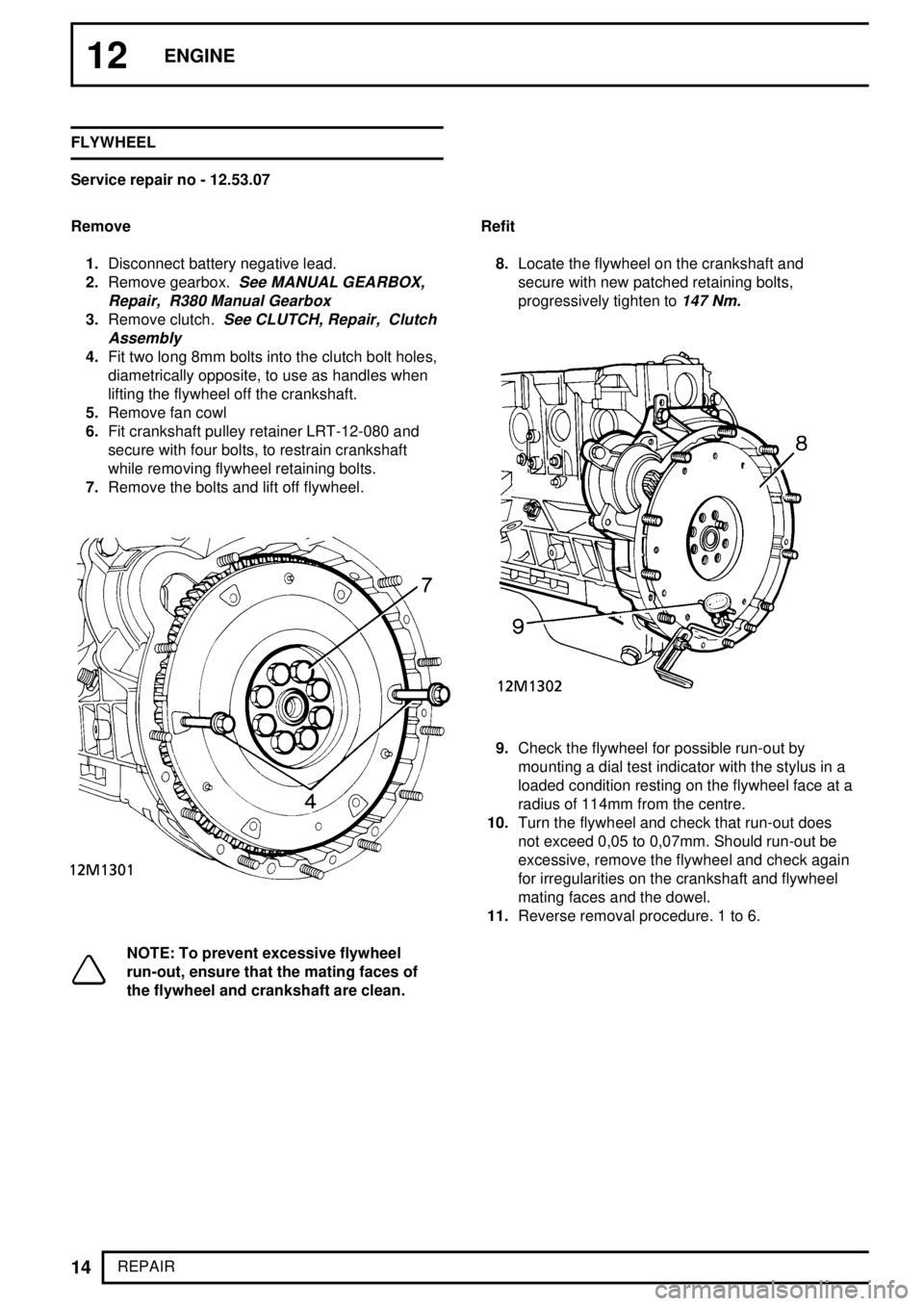

REPAIR FLYWHEEL

Service repair no - 12.53.07

Remove

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Fit two long 8mm bolts into the clutch bolt holes,

diametrically opposite, to use as handles when

lifting the flywheel off the crankshaft.

5.Remove fan cowl

6.Fit crankshaft pulley retainer LRT-12-080 and

secure with four bolts, to restrain crankshaft

while removing flywheel retaining bolts.

7.Remove the bolts and lift off flywheel.

NOTE: To prevent excessive flywheel

run-out, ensure that the mating faces of

the flywheel and crankshaft are clean.Refit

8.Locate the flywheel on the crankshaft and

secure with new patched retaining bolts,

progressively tighten to

147 Nm.

9.Check the flywheel for possible run-out by

mounting a dial test indicator with the stylus in a

loaded condition resting on the flywheel face at a

radius of 114mm from the centre.

10.Turn the flywheel and check that run-out does

not exceed 0,05 to 0,07mm. Should run-out be

excessive, remove the flywheel and check again

for irregularities on the crankshaft and flywheel

mating faces and the dowel.

11.Reverse removal procedure. 1 to 6.

Page 96 of 873

Tdi

15

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

NOTE: The crankshaft rear oil seal is

retained in its own housing, if the seal

requires replacing the housing and seal

assembly (1) must be renewed complete with the

housing seal (3). Housing and seal assemblies are

supplied with their own former/seal guide (2)

already fitted. This former must not be removed

before fitting the assembly to the engine. If a seal

and housing assembly is received without a

former/guide fitted it must be returned to the

supplier. Used formers/guides must be discarded

immediately after use, under no circumstances

should they be reused on other assemblies.

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove five bolts and withdraw seal housing

and seal assembly complete with gasket.

Refit

6.Insert slave studs to seal housing mounting face.

7.Position new seal housing gasket over slave

studs and crankshaft flange onto cylinder block.

Page 97 of 873

12ENGINE

16

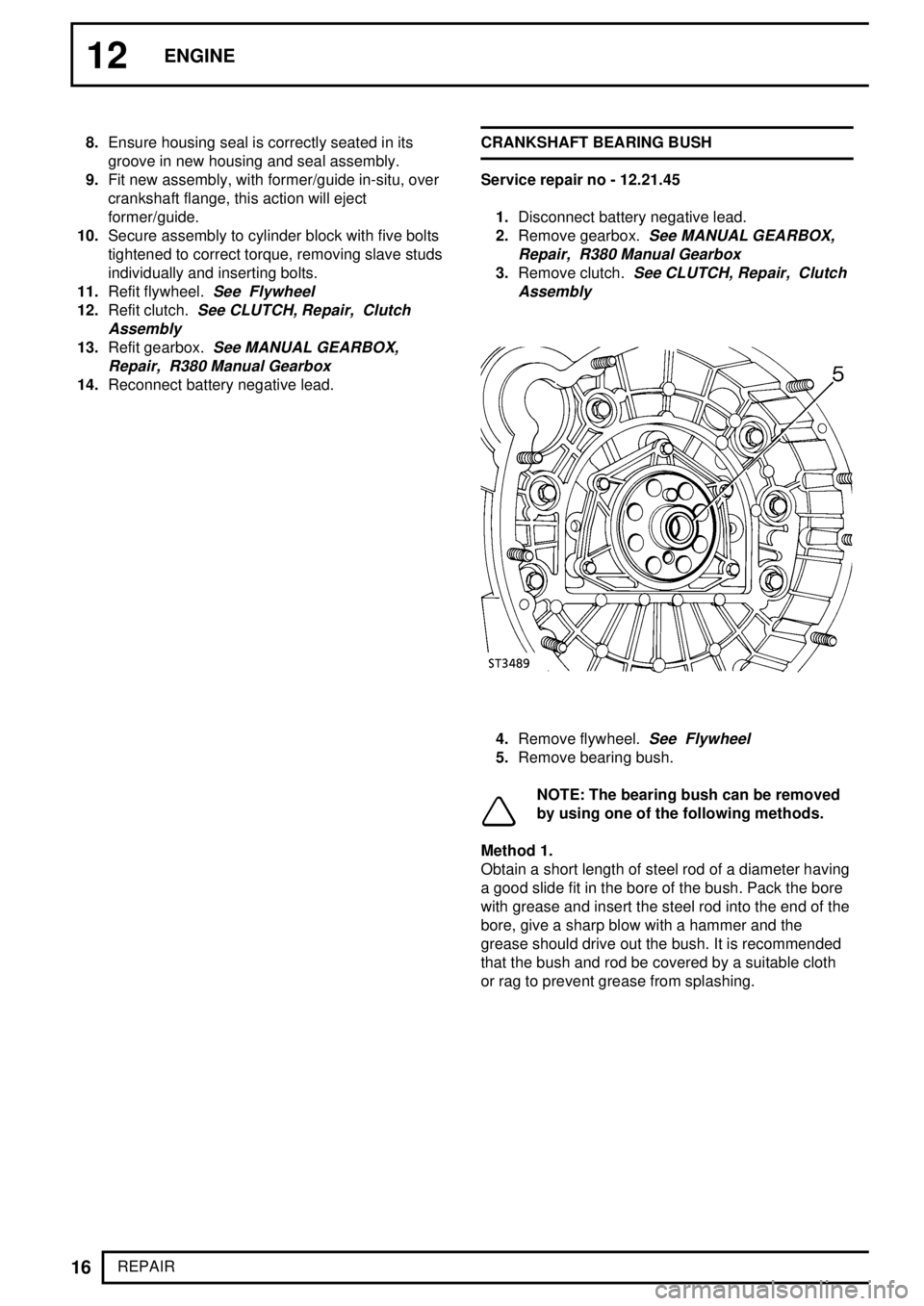

REPAIR 8.Ensure housing seal is correctly seated in its

groove in new housing and seal assembly.

9.Fit new assembly, with former/guide in-situ, over

crankshaft flange, this action will eject

former/guide.

10.Secure assembly to cylinder block with five bolts

tightened to correct torque, removing slave studs

individually and inserting bolts.

11.Refit flywheel.

See Flywheel

12.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

13.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

14.Reconnect battery negative lead.CRANKSHAFT BEARING BUSH

Service repair no - 12.21.45

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove bearing bush.

NOTE: The bearing bush can be removed

by using one of the following methods.

Method 1.

Obtain a short length of steel rod of a diameter having

a good slide fit in the bore of the bush. Pack the bore

with grease and insert the steel rod into the end of the

bore, give a sharp blow with a hammer and the

grease should drive out the bush. It is recommended

that the bush and rod be covered by a suitable cloth

or rag to prevent grease from splashing.

Page 98 of 873

Tdi

17

REPAIR Method 2.

Thread the bore of the existing bush and using a

suitable bolt extract the bush. Thoroughly clean bush

location ensuring all swarf is removed.

Fitting

6.Fit new bush using a suitable shouldered drift,

inserting bush flush with end of crankshaft.

7.Refit flywheel.

See Flywheel

8.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

9.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

10.Reconnect battery negative lead.FLYWHEEL HOUSING

Service repair no - 12.53.01

Remove

1.Disconnect battery negative lead.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

Assembly

4.Remove flywheel.See Flywheel

5.Remove starter motor.

6.Remove two bolts from top of flywheel housing.

7.Remove four bolts from bottom of flywheel

housing.

8.Remove six inner bolts and lift off flywheel

housing.

Refit

9.Clean rear face of housing and mating face on

block, ensuring all old sealant is removed.

Page 99 of 873

12ENGINE

18

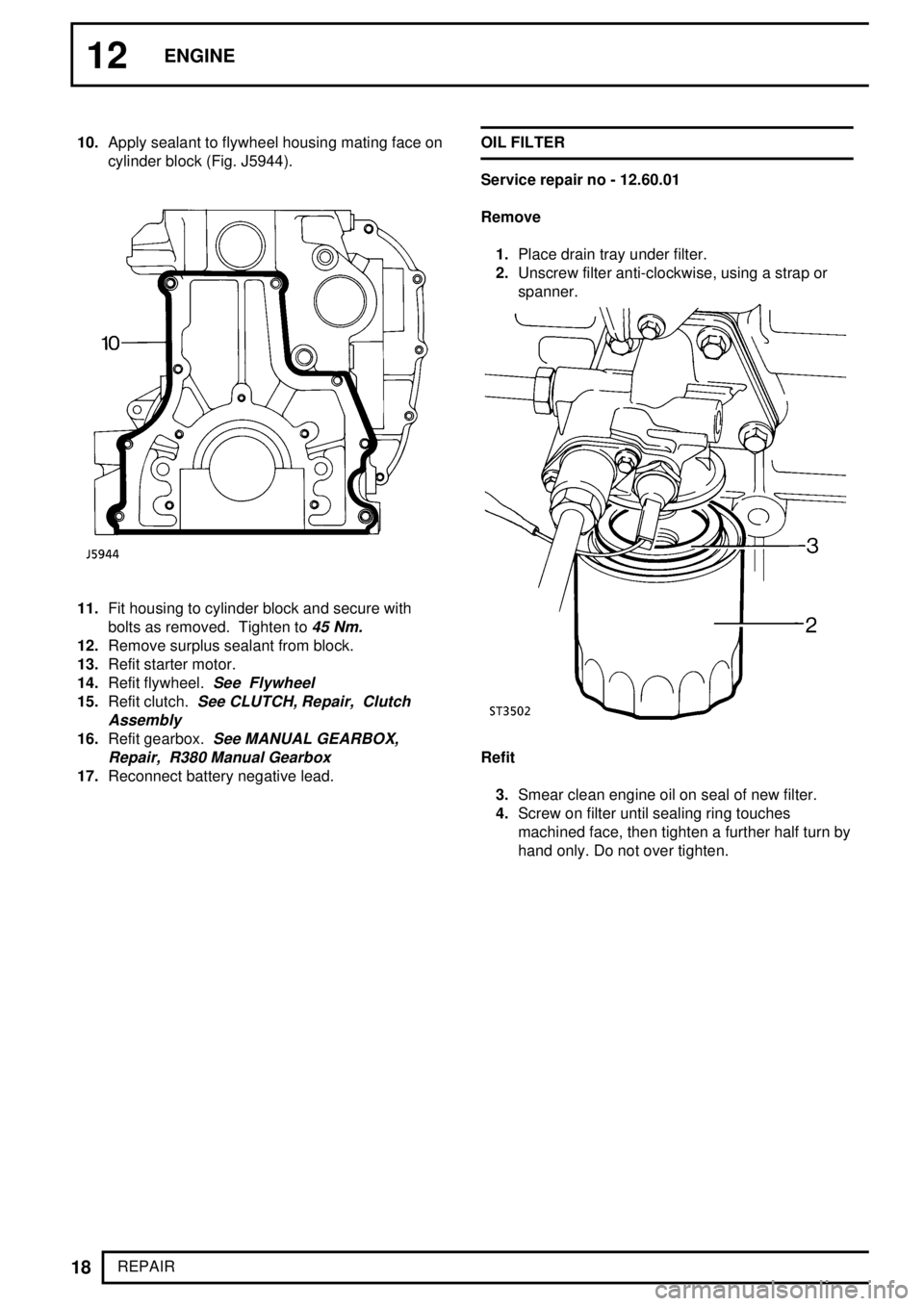

REPAIR 10.Apply sealant to flywheel housing mating face on

cylinder block (Fig. J5944).

11.Fit housing to cylinder block and secure with

bolts as removed. Tighten to

45 Nm.

12.Remove surplus sealant from block.

13.Refit starter motor.

14.Refit flywheel.

See Flywheel

15.Refit clutch.See CLUTCH, Repair, Clutch

Assembly

16.Refit gearbox.See MANUAL GEARBOX,

Repair, R380 Manual Gearbox

17.Reconnect battery negative lead.OIL FILTER

Service repair no - 12.60.01

Remove

1.Place drain tray under filter.

2.Unscrew filter anti-clockwise, using a strap or

spanner.

Refit

3.Smear clean engine oil on seal of new filter.

4.Screw on filter until sealing ring touches

machined face, then tighten a further half turn by

hand only. Do not over tighten.

Page 116 of 873

V8i

3

FAULT DIAGNOSIS ENGINE STARTING PROBLEMS

Engine fails to crank in park or neutral (Automatic

Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES - Continue.

2.Is automatic transmission inhibitor switch faulty

or gear selection linkage incorrectly adjusted?

YES -

See AUTOMATIC GEARBOX, Repair,

Inhibitor Switch

,

NO -

See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine fails to crank (Manual Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES -See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine cranks but fails to start

1.Is the cranking speed fast enough (120 rpm)?

NO -

See INTRODUCTION, Information,

Jump Starting

If necessary also.See Electrical Trouble

Shooting Manual.

YES - Continue.

2.Is there combustion in any cylinder?

NO -

See ELECTRICAL, Fault diagnosis,

Lucas Constant Energy Ignition

System - V8i See Electrical Trouble

Shooting Manual.

YES - Continue.

3.Are the fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission control

If problem is not diagnosed repeat tests, starting

at 2.ENGINE RUNNING PROBLEMS

Engine runs at high speed but will not idle (stops)

Engine idle speed erratic Engine starts but stops

immediately

Engine stalls Engine misfires/hesitation

1.Multiport fuel injection.

See Electrical Trouble

Shooting Manual. See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy Ignition

System - V8i

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

If problem is not diagnosed continue.

2.Are HT leads correctly routed and clipped?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission Control

If problem is not diagnosed repeat tests, starting

at 1.

Engine lacks power/poor performance

1.Is throttle travel restricted or cable incorrectly

adjusted?

YES - Check thickness of carpets.

See FUEL

SYSTEM, Repair, Throttle Cable See

FUEL SYSTEM, Repair, Accelerator

Pedal

NO - Continue.

2.Are the Ignition and Multiport Fuel Injection

systems in order?

NO -

See Electrical Trouble Shooting

Manual.A1 See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy

Ignition System - V8i See

ELECTRICAL, Repair, Distributor - V8i

YES - Continue.

Page 128 of 873

12ENGINE

10

REPAIR TIMING CHAIN AND CHAINWHEELS

Service repair no - 12.65.12

Remove

1.Remove front cover.

See Front Cover Gasket

2.Remove retaining bolt and washer, remove

distributor drive gear and spacer.

3.Ensure number one piston is at TDC.

4.Remove chainwheels and chain as an assembly.

See V8i Overhaul Manual.

Refit

5.Clean chainwheels and chain.

6.Fit chainwheels to chain, aligning timing marks.

7.Ensure camshaft key is fitted parallel to shaft

axis to ensure adequate lubrication to distributor

drive gear.

8.Engage chainwheel assembly on camshaft and

crankshaft keys, ensure chain wheels are fully

located.

9.Check alignment of timing marks with straight

edge.

10.Fit spacer with flange to front,

11.Fit distributor drive gear with groove towards

spacer.

12.Fit retaining bolt and washer. Tighten to

58 Nm.

13.Fit front cover.See Front Cover Gasket

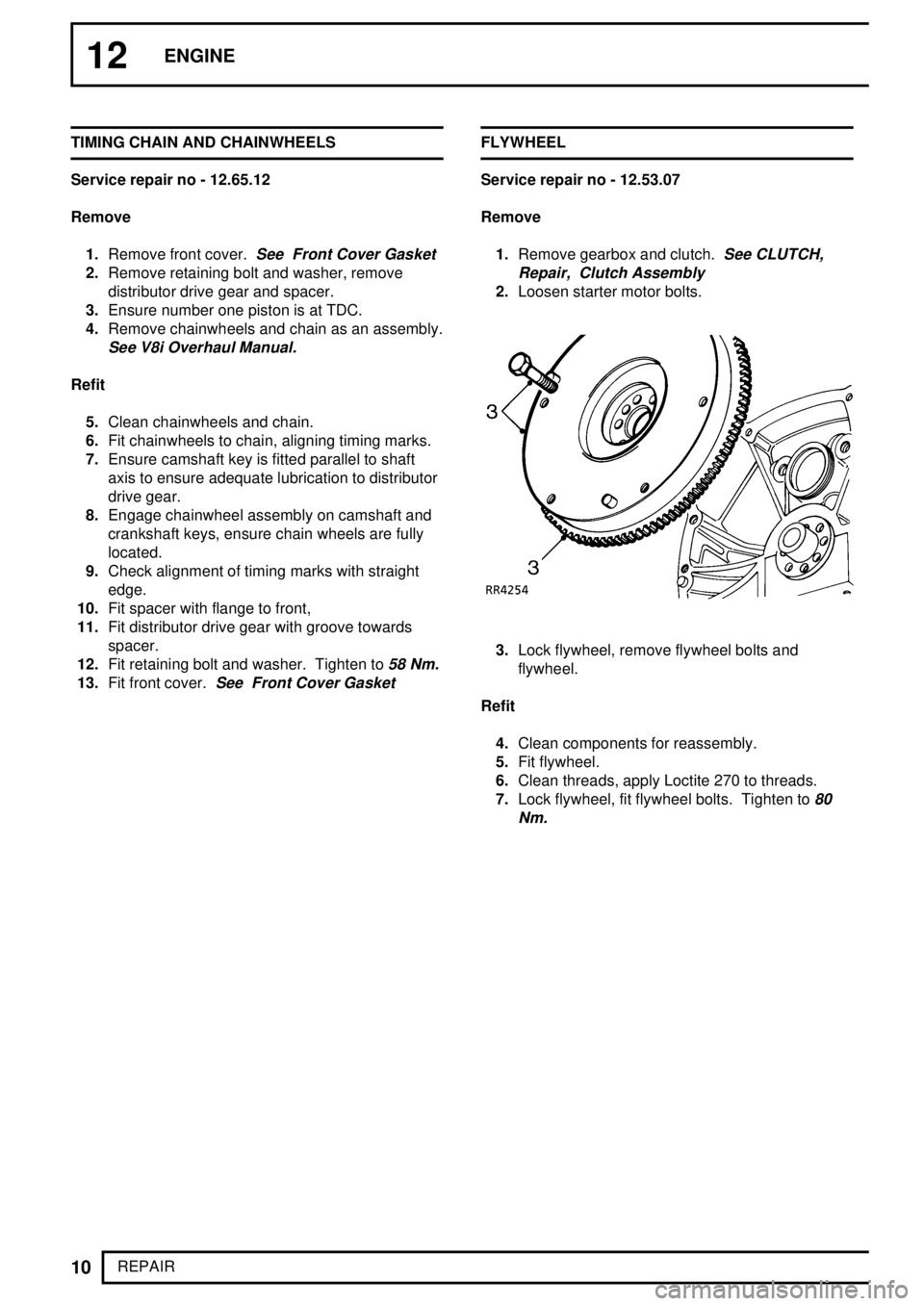

FLYWHEEL

Service repair no - 12.53.07

Remove

1.Remove gearbox and clutch.

See CLUTCH,

Repair, Clutch Assembly

2.Loosen starter motor bolts.

3.Lock flywheel, remove flywheel bolts and

flywheel.

Refit

4.Clean components for reassembly.

5.Fit flywheel.

6.Clean threads, apply Loctite 270 to threads.

7.Lock flywheel, fit flywheel bolts. Tighten to

80

Nm.