glove box LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 226 of 873

Tdi

9

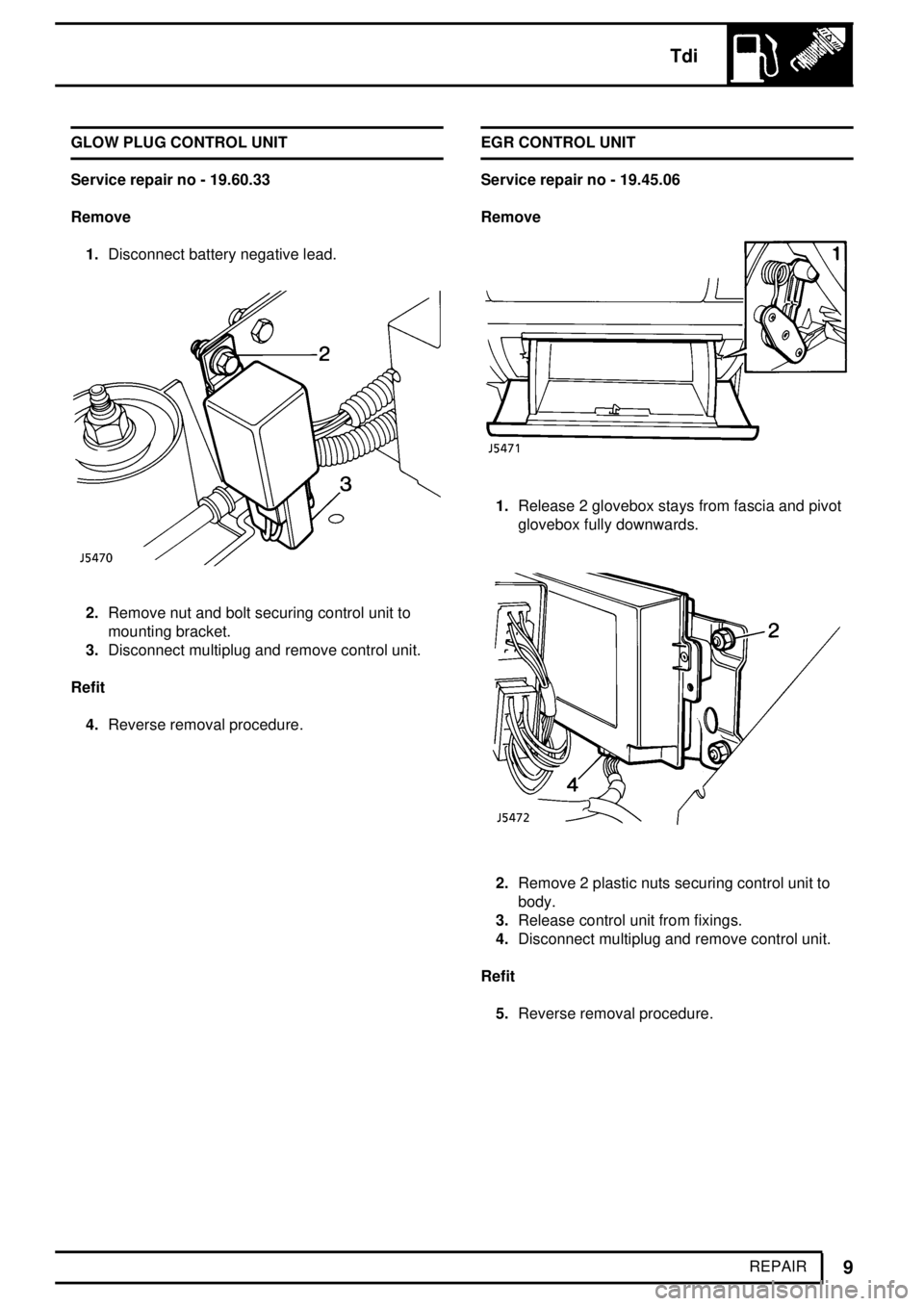

REPAIR GLOW PLUG CONTROL UNIT

Service repair no - 19.60.33

Remove

1.Disconnect battery negative lead.

2.Remove nut and bolt securing control unit to

mounting bracket.

3.Disconnect multiplug and remove control unit.

Refit

4.Reverse removal procedure.EGR CONTROL UNIT

Service repair no - 19.45.06

Remove

1.Release 2 glovebox stays from fascia and pivot

glovebox fully downwards.

2.Remove 2 plastic nuts securing control unit to

body.

3.Release control unit from fixings.

4.Disconnect multiplug and remove control unit.

Refit

5.Reverse removal procedure.

Page 346 of 873

CRUISE CONTROL

9

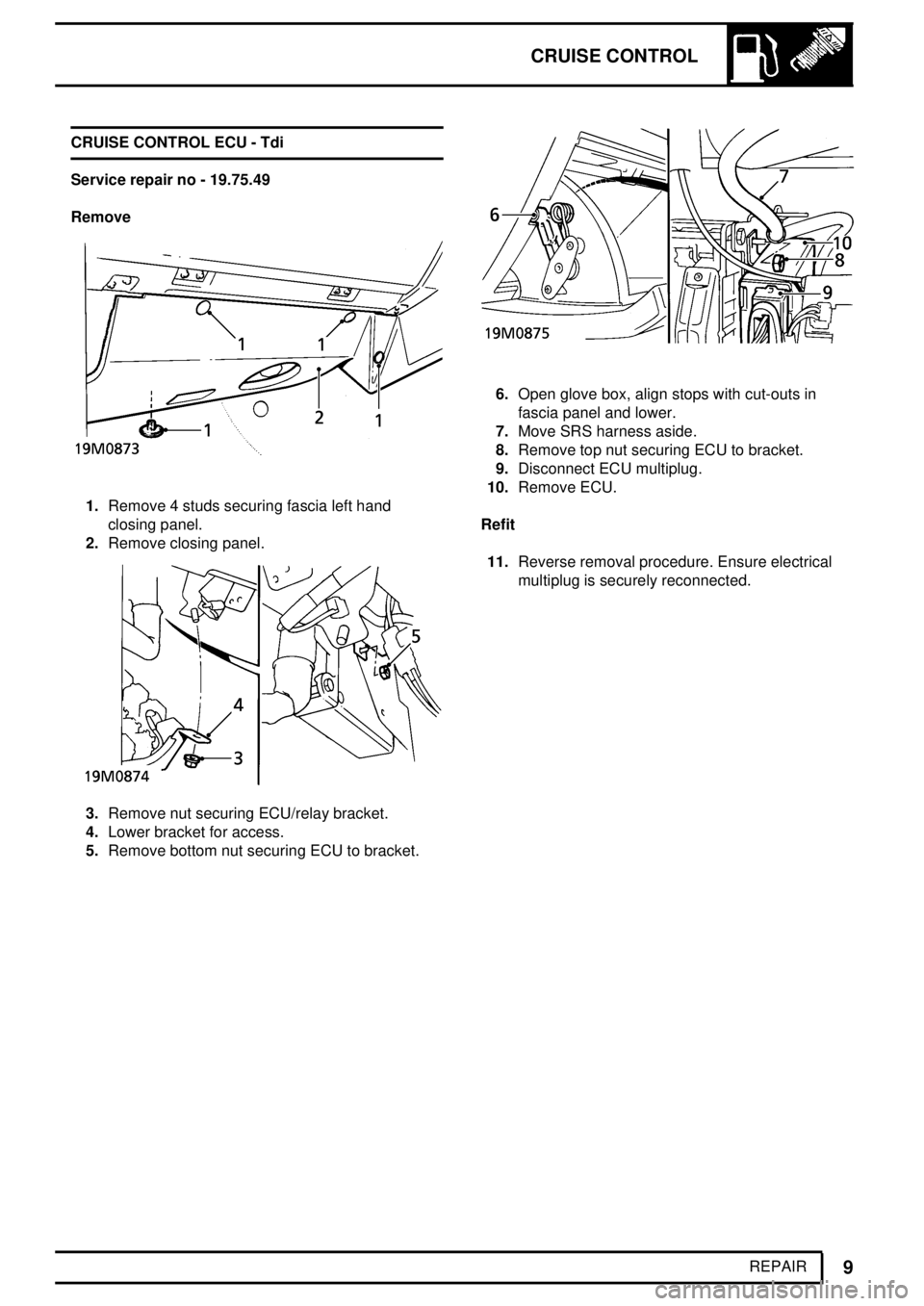

REPAIR CRUISE CONTROL ECU - Tdi

Service repair no - 19.75.49

Remove

1.Remove 4 studs securing fascia left hand

closing panel.

2.Remove closing panel.

3.Remove nut securing ECU/relay bracket.

4.Lower bracket for access.

5.Remove bottom nut securing ECU to bracket.

6.Open glove box, align stops with cut-outs in

fascia panel and lower.

7.Move SRS harness aside.

8.Remove top nut securing ECU to bracket.

9.Disconnect ECU multiplug.

10.Remove ECU.

Refit

11.Reverse removal procedure. Ensure electrical

multiplug is securely reconnected.

Page 594 of 873

BRAKES

3

DESCRIPTION AND OPERATION Description of components

1. ABS Modulator unit

To provide the ABS function a Modulator is positioned

within the system between the master cylinder and the

calipers. On both LHD and RHD vehicles it is sited on

the left inner wing [fender]. The Modulator has 8

solenoid valves, 2 for each wheel, 2 expanders and a

recirculation pump. It is non serviceable.

2. Servo/master cylinder

Actuation of the system is provided by a combined

master cylinder and servo assembly attached to the

pedal box, this provides pressure to opposed piston

calipers at each brake pad Twin piston at the front

axle, single piston at the rear.

3. Pressure reducing valve

To maintain the braking balance, pressure to the rear

axle is regulated by a Pressure Reducing Valve (PRV)

This PRV is of the failure bypass type, allowing full

system pressure to the rear axle in the event of a front

circuit failure. It is sited on the left inner wing [fender].

4. Electronic control unit - ECU

ABS control is provided by an electronic control unit

which is positioned on the passenger side of the

vehicle behind the dash panel/glove box.

The ECU, which is non-serviceable, is connected to

the ABS harness by a 35 way connector. non

serviceable.

The ECU continually monitors the brake system,

providing diagnostics in the event of a system

malfunction. Details of how to access the ECU

diagnostics are provided in the Electrical

Troubleshooting Manual.

5.& 6. Front and rear sensors/exciter rings - 4 off

A sensor is sited at each wheel, sensing a 60 tooth

exciter ring. When vehicle is in motion inductive

sensors send signals to ECU. Front exciter ring is

fitted to outside diameter of constant velocity joint

inside each front hub assembly. The rear exciter ring

is bolted to the rear of each brake disc bell.7. Diagnostic plug connection

A diagnostic plug is located behind the dash. To the

left of the steering column on LHD vehicles. To the

right of the steering column on RHD vehicles. It is a 5

way blue connector.

The location and identification of ABS electrical relays

are given in the Electrical Troubleshooting Manual.

For location and identification of ABS electrical fuses.

See ELECTRICAL, Repair, Fuse Box - Interioror.

See ELECTRICAL, Repair, Fuse Box - Engine

Compartment

ANTI-LOCK BRAKE SYSTEM - ABS

Manufactured by WABCO

Introduction

The purpose of ABS is to prevent vehicle wheels

locking during brake application, thus maintaining

vehicle steerability and stability. This allows vehicle to

be steered whilst brakes are applied, even under

emergency conditions, and to avoid obstacles where

there is sufficient space to redirect the vehicle.

WARNING: ABS is an aid to retaining

steering control and stability while

braking.

·ABS cannot defy the natural laws of physics

acting on the vehicle.

·ABS will not prevent accidents resulting from

excessive cornering speeds, following

another vehicle too closely or aquaplaning,

i.e. where a layer of water prevents adequate

contact between tyre and road surface.

·The additional control provided by ABS must

never be exploited in a dangerous or

reckless manner which could jeopardise the

safety of driver or other road users.

·The fitting of ABS does not imply that the

vehicle will always stop in a shorter stopping

distance.

Page 654 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

9

REPAIR PASSENGER'S AIRBAG MODULE

Service repair no - 76.74.02

WARNING: All the airbag system

components, including the wiring harness,

MUST be renewed after the airbags have

deployed.

Remove

1.Switch off ignition.

2.Disconnect battery negative lead and then

positive lead.

3.Open glovebox and disconnect harness

connector from airbag module.

4.Use special socket and long extension, remove

2 torx head screws securing front of airbag

module to fascia panel.

5.Use special socket, remove 2 torx head screws

securing rear of airbag module to fascia panel.

6.Release airbag module from fascia panel.

CAUTION: Do not allow the airbag module

to hang by the airbag harness.

7.Carefully and without pulling on connector

remove airbag module.

CAUTION: Store the airbag module in

accordance with the storage procedures

described in Description and Operation.

NOTE: If airbag module is to be replaced

the serial number must be recorded in the

vehicle service record.

Refit

8.Reverse removal procedure.

9.Tighten airbag module securing screws to

8Nm

(6 lbf ft).

CAUTION: Take care not to cross thread

screws.

10.Check Supplementary Restraint System using

Testbook.

Page 714 of 873

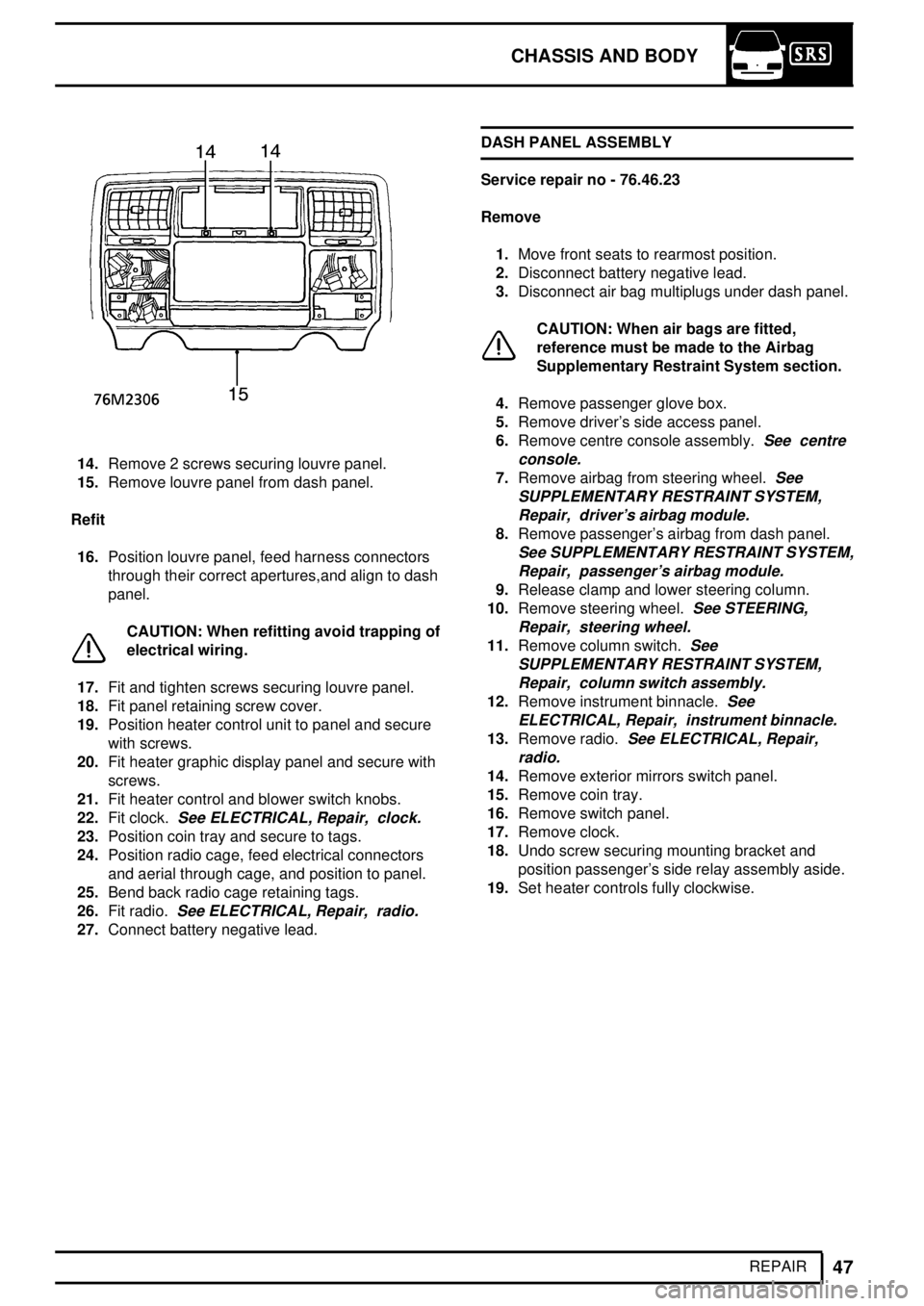

CHASSIS AND BODY

47

REPAIR

14.Remove 2 screws securing louvre panel.

15.Remove louvre panel from dash panel.

Refit

16.Position louvre panel, feed harness connectors

through their correct apertures,and align to dash

panel.

CAUTION: When refitting avoid trapping of

electrical wiring.

17.Fit and tighten screws securing louvre panel.

18.Fit panel retaining screw cover.

19.Position heater control unit to panel and secure

with screws.

20.Fit heater graphic display panel and secure with

screws.

21.Fit heater control and blower switch knobs.

22.Fit clock.

See ELECTRICAL, Repair, clock.

23.Position coin tray and secure to tags.

24.Position radio cage, feed electrical connectors

and aerial through cage, and position to panel.

25.Bend back radio cage retaining tags.

26.Fit radio.

See ELECTRICAL, Repair, radio.

27.Connect battery negative lead.DASH PANEL ASSEMBLY

Service repair no - 76.46.23

Remove

1.Move front seats to rearmost position.

2.Disconnect battery negative lead.

3.Disconnect air bag multiplugs under dash panel.

CAUTION: When air bags are fitted,

reference must be made to the Airbag

Supplementary Restraint System section.

4.Remove passenger glove box.

5.Remove driver's side access panel.

6.Remove centre console assembly.

See centre

console.

7.Remove airbag from steering wheel.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, driver's airbag module.

8.Remove passenger's airbag from dash panel.

See SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, passenger's airbag module.

9.Release clamp and lower steering column.

10.Remove steering wheel.

See STEERING,

Repair, steering wheel.

11.Remove column switch.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, column switch assembly.

12.Remove instrument binnacle.See

ELECTRICAL, Repair, instrument binnacle.

13.Remove radio.See ELECTRICAL, Repair,

radio.

14.Remove exterior mirrors switch panel.

15.Remove coin tray.

16.Remove switch panel.

17.Remove clock.

18.Undo screw securing mounting bracket and

position passenger's side relay assembly aside.

19.Set heater controls fully clockwise.

Page 716 of 873

CHASSIS AND BODY

49

REPAIR Refit

CAUTION: When refitting avoid trapping

electrical wiring.

29.Reverse removal procedure.

30.With assistance: Position dash panel and

connect dash harness multiplugs to fusebox and

main harness.

31.Reverse removal procedure. Ensure dash panel

upper bracket studs are located before the 4

lower brackets.

32.Reverse removal procedure. Disconnect

glovebox switch Lucars to ease fitting of relay

bracket.WINDSCREEN GLASS

Service repair no - 76.81.01

Information

The following equipment is required:

·Cutting wire and handles

·Windscreen repair kit (see Technical

Bulletin).

See Electrical Trouble Shooting

Manual.Windscreen Glass Replacement.

·Sealant applicator gun.

·Suction cup lifters.

The following materials are included in the windscreen

repair kit:

·Glass cleaning solvent - 'Betawipe' Glass

activator (yellow cap).

·Cotton buds.

·Glass primer - 'Betaprime'(green cap).

·Body primer - 'Betaprime' paint/plastic

primer (red cap).

·Betaseal Adhesive sealant.

NOTE: The adhesive sealant cures in 6 to 8

hours

CAUTION: Once existing sealant is cut, the

exposed surfaces oxidises in

approximately 90 minutes. The refit

procedure must be completed within this time

span to prevent the sealant oxidising, to effect a

satisfactory joint.

CAUTION: If the windscreen aperture body

flange shows signs of corrosion it must be

treated with anti corrosion primer and

repainted. Newly painted areas must then be left

for 8 hours or more before applying adhesive

sealant.

Page 744 of 873

80HEATING AND VENTILATION

2

REPAIR 8.Disconnect 4 multiplugs and position harness

aside.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

9. Fan speed switch:remove fan speed switch

slide and push out fan speed switch.

10.Pull out light bulb disconnect terminals and

remove fan speed light strip.

11.Unclip 3 heater control cables from control unit.

12. Microswitch:Unclip 3 micro switches.

13.Cut cable tie and release wiring harness from

control unit.

14.Remove heater control unit.

Refit

15.Reverse removal procedure. Check the

satisfactory function of the controls before fitting

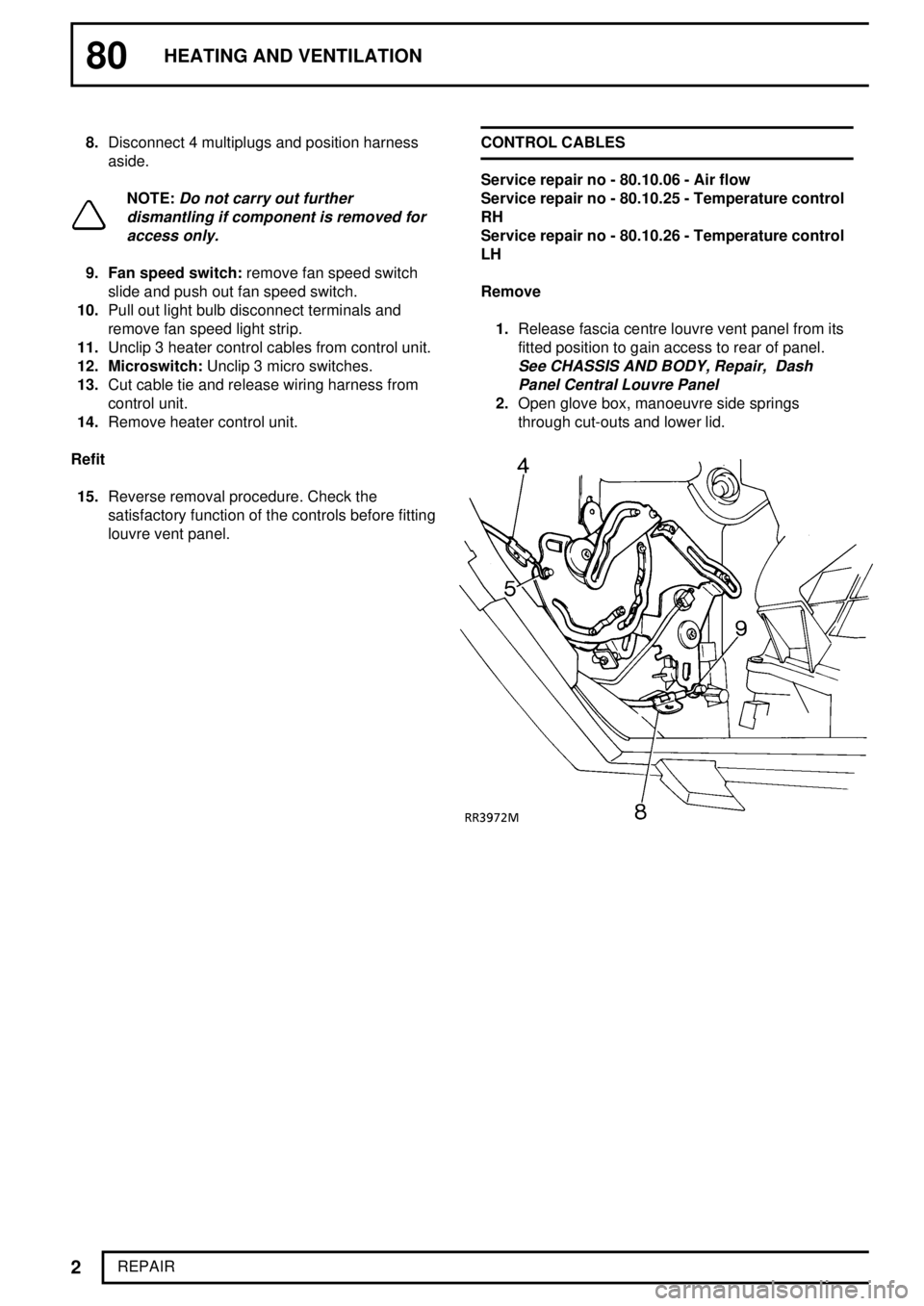

louvre vent panel.CONTROL CABLES

Service repair no - 80.10.06 - Air flow

Service repair no - 80.10.25 - Temperature control

RH

Service repair no - 80.10.26 - Temperature control

LH

Remove

1.Release fascia centre louvre vent panel from its

fitted position to gain access to rear of panel.

See CHASSIS AND BODY, Repair, Dash

Panel Central Louvre Panel

2.Open glove box, manoeuvre side springs

through cut-outs and lower lid.

Page 745 of 873

HEATING AND VENTILATION

3

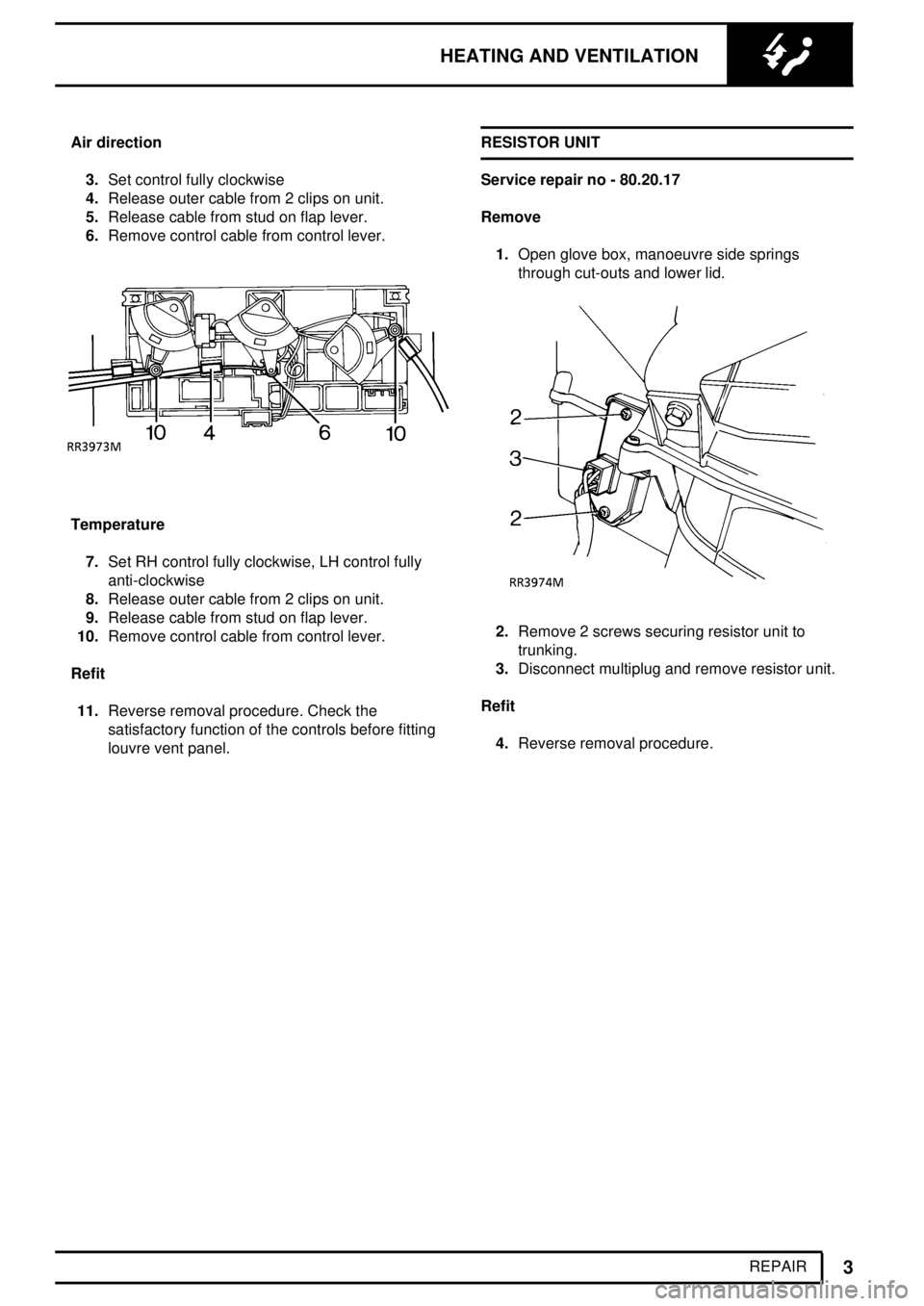

REPAIR Air direction

3.Set control fully clockwise

4.Release outer cable from 2 clips on unit.

5.Release cable from stud on flap lever.

6.Remove control cable from control lever.

Temperature

7.Set RH control fully clockwise, LH control fully

anti-clockwise

8.Release outer cable from 2 clips on unit.

9.Release cable from stud on flap lever.

10.Remove control cable from control lever.

Refit

11.Reverse removal procedure. Check the

satisfactory function of the controls before fitting

louvre vent panel.RESISTOR UNIT

Service repair no - 80.20.17

Remove

1.Open glove box, manoeuvre side springs

through cut-outs and lower lid.

2.Remove 2 screws securing resistor unit to

trunking.

3.Disconnect multiplug and remove resistor unit.

Refit

4.Reverse removal procedure.

Page 747 of 873

HEATING AND VENTILATION

5

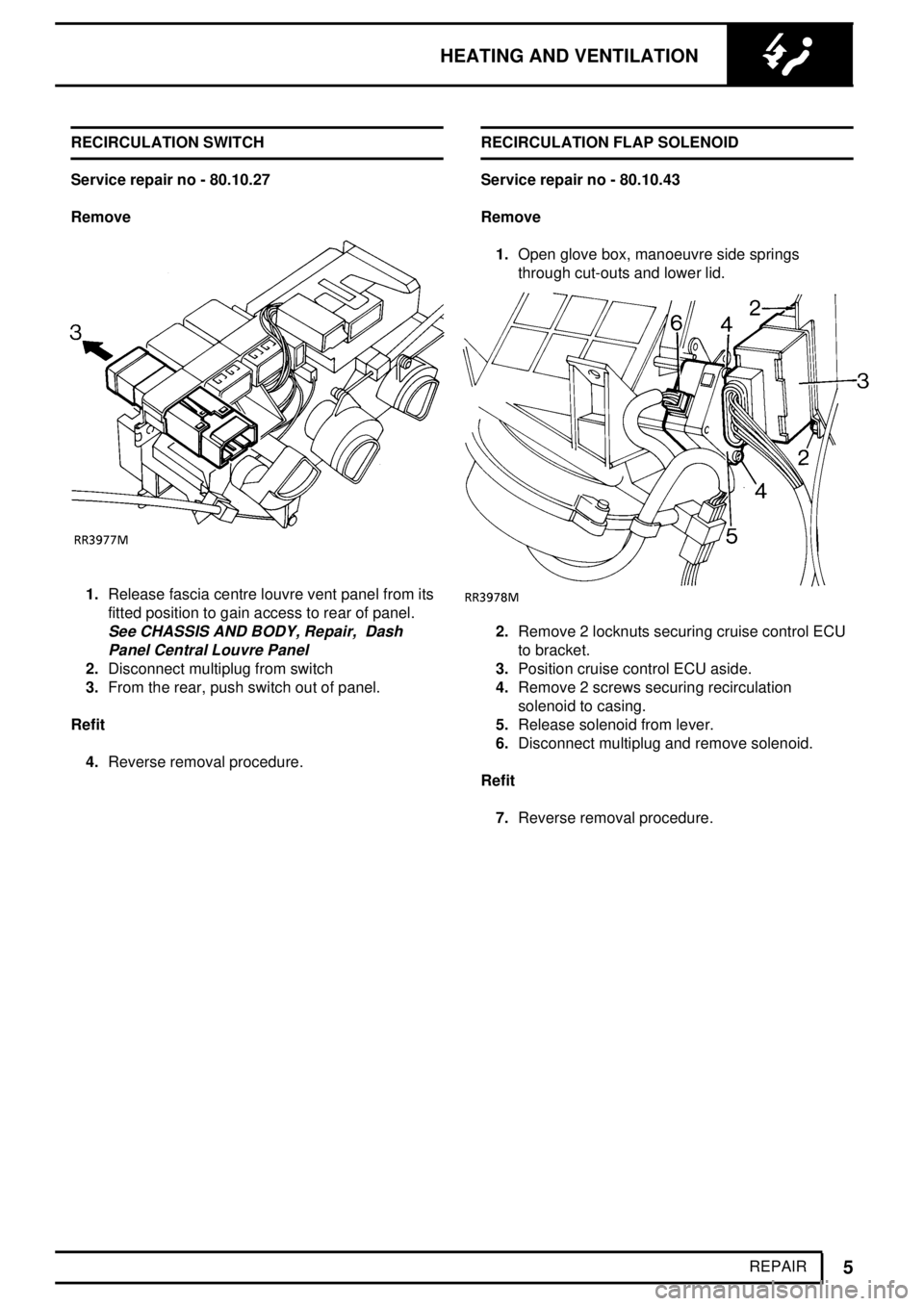

REPAIR RECIRCULATION SWITCH

Service repair no - 80.10.27

Remove

1.Release fascia centre louvre vent panel from its

fitted position to gain access to rear of panel.

See CHASSIS AND BODY, Repair, Dash

Panel Central Louvre Panel

2.Disconnect multiplug from switch

3.From the rear, push switch out of panel.

Refit

4.Reverse removal procedure.RECIRCULATION FLAP SOLENOID

Service repair no - 80.10.43

Remove

1.Open glove box, manoeuvre side springs

through cut-outs and lower lid.

2.Remove 2 locknuts securing cruise control ECU

to bracket.

3.Position cruise control ECU aside.

4.Remove 2 screws securing recirculation

solenoid to casing.

5.Release solenoid from lever.

6.Disconnect multiplug and remove solenoid.

Refit

7.Reverse removal procedure.

Page 860 of 873

86ELECTRICAL

40

REPAIR INSTRUMENT ILLUMINATION ELECTRONIC

DIMMER/RHEOSTAT

Service repair no - 86.65.07

Electronic dimming control switch is located in

instrument panel finisher. Rotate control to vary

intensity of illumination.

Remove

1.Disconnect the battery negative lead.

2.Remove instrument panel finisher.

See

CHASSIS AND BODY, Repair, Instrument

Panel Finisher

3.Remove 2 screws securing rheostat, remove

rheostat.

Refit

4.Reverse removal procedure.WINDOW LIFT/HEATED SEAT CUSHION

SWITCHES AND BULBS

Service repair no - 86.25.16 - Switches

Service repair no - 86.45.29 - Bulb

Switch Replacement

1.Disconnect the battery negative lead.

2.Carefully release rear of surround from centre

console.

3.Remove screws, pry window lift switch surround

from glove box.

4.Disconnect multi-plug(s) at rear of switch(es).

5.Apply pressure to rear of switch, push it through

surround.

Bulb replacement

6.Identify bulb to be replaced and remove

appropriate switch.

7.Rotate bulb holder 90°and withdraw it from

switch; discard bulb and holder.

Refit

8.Reverse removal procedure.