lock LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 70 of 873

10MAINTENANCE

8

MAINTENANCE

CLEAN PLENUM CHAMBER VENTILATION

PASSAGEWAY - V8i

Cleaning plenum chamber ventilation passageway

can be carried out without removing plenum chamber

from ram housing.

CAUTION: Care must be taken to prevent

debris from passageway passing beyond

throttle butterfly disc.

WARNING: Safety glasses must be worn

when performing this operation. Ensure

that debris is not blown into atmosphere

which could be harmful to other persons closeby.

1.Disconnect battery negative lead.

2.Release hose clamp and remove hose from

plenum chamber inlet.

3.Remove crankcase ventilation hose from side of

plenum chamber.

4.Insert a piece of lint free cloth down throttle

butterfly bore to prevent debris passing throttle

butterfly.

5.Place a cloth over tube protruding from side of

plenum from which ventilation hose was

removed to prevent debris from passageway

being blown into atmosphere.

6.Use a compressed air line with a slim bent

nozzle to enable passageway to be cleaned out

from within throttle butterfly bore.

7.Any remaining matter can be dislodged using

soft bent wire or pipe cleaner. Finally blow out

passageway again to remove remaining debris.

8.Remove small 'T' piece between crankcase

ventilation hoses and check it is free from

blockages, clean as necessary.

9.Refit 'T' piece and hoses, tighten hose clamps

securely.

RENEW CHARCOAL CANISTER - V8i- Mpi

Charcoal canister

Remove

1.Disconnect battery negative lead.

2.Pry out purge valve.

3.Disconnect pipe.

4.Loosen bolt.

5.Remove charcoal canister.

Refit

6.Reverse removal procedure.

Page 71 of 873

MAINTENANCE

9

MAINTENANCE

CHECK CONDITION OF DRIVE BELT - V8i - Tdi -

Mpi

RENEW - V8i - Tdi

Renew drive belt V8i.See ENGINE, Repair, Drive

Belt Renew

Renew drive belt Tdi.See ENGINE, Repair, Drive

Belt Renew

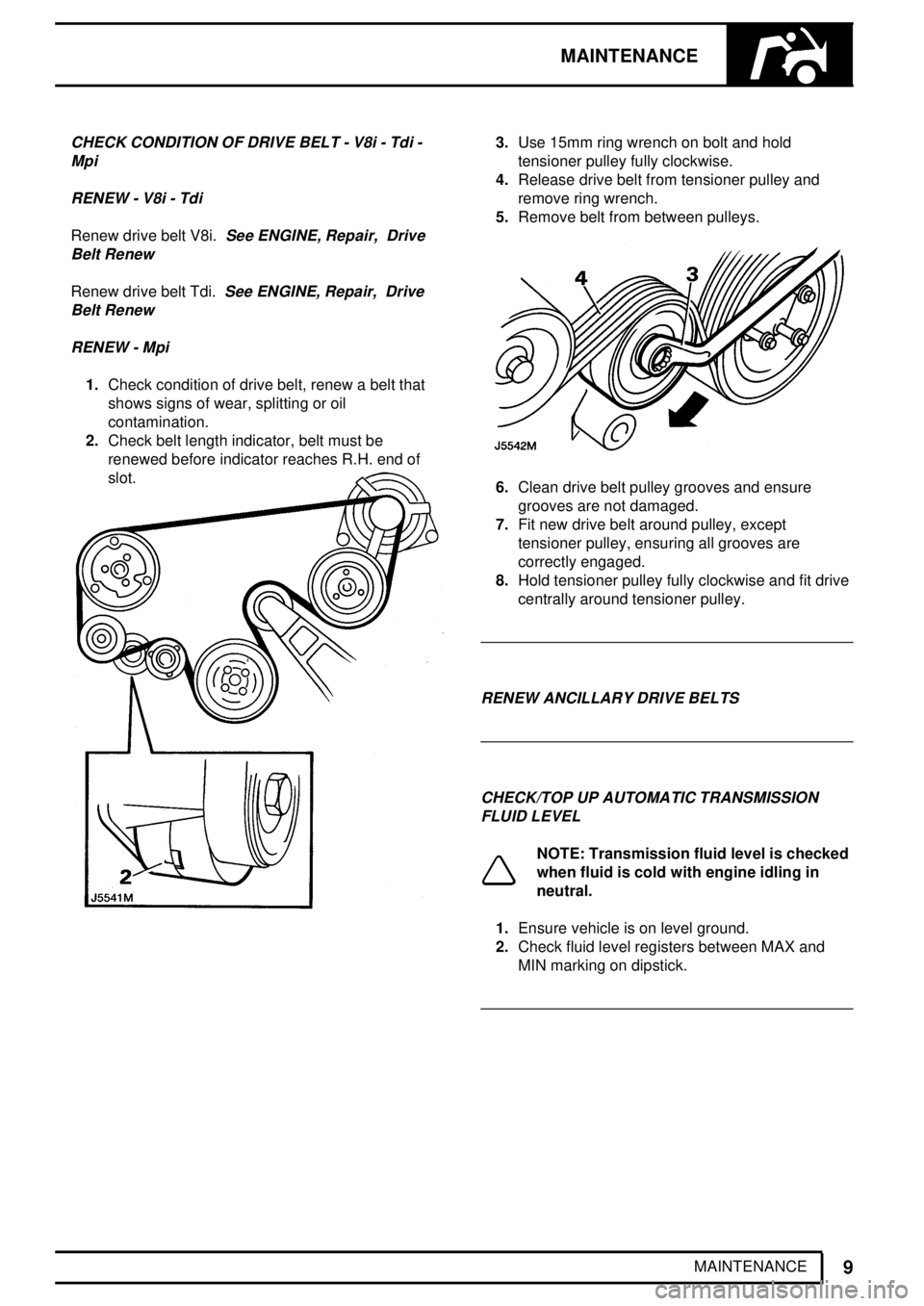

RENEW - Mpi

1.Check condition of drive belt, renew a belt that

shows signs of wear, splitting or oil

contamination.

2.Check belt length indicator, belt must be

renewed before indicator reaches R.H. end of

slot.

3.Use 15mm ring wrench on bolt and hold

tensioner pulley fully clockwise.

4.Release drive belt from tensioner pulley and

remove ring wrench.

5.Remove belt from between pulleys.

6.Clean drive belt pulley grooves and ensure

grooves are not damaged.

7.Fit new drive belt around pulley, except

tensioner pulley, ensuring all grooves are

correctly engaged.

8.Hold tensioner pulley fully clockwise and fit drive

centrally around tensioner pulley.

RENEW ANCILLARY DRIVE BELTS

CHECK/TOP UP AUTOMATIC TRANSMISSION

FLUID LEVEL

NOTE: Transmission fluid level is checked

when fluid is cold with engine idling in

neutral.

1.Ensure vehicle is on level ground.

2.Check fluid level registers between MAX and

MIN marking on dipstick.

Page 72 of 873

10MAINTENANCE

10

MAINTENANCE

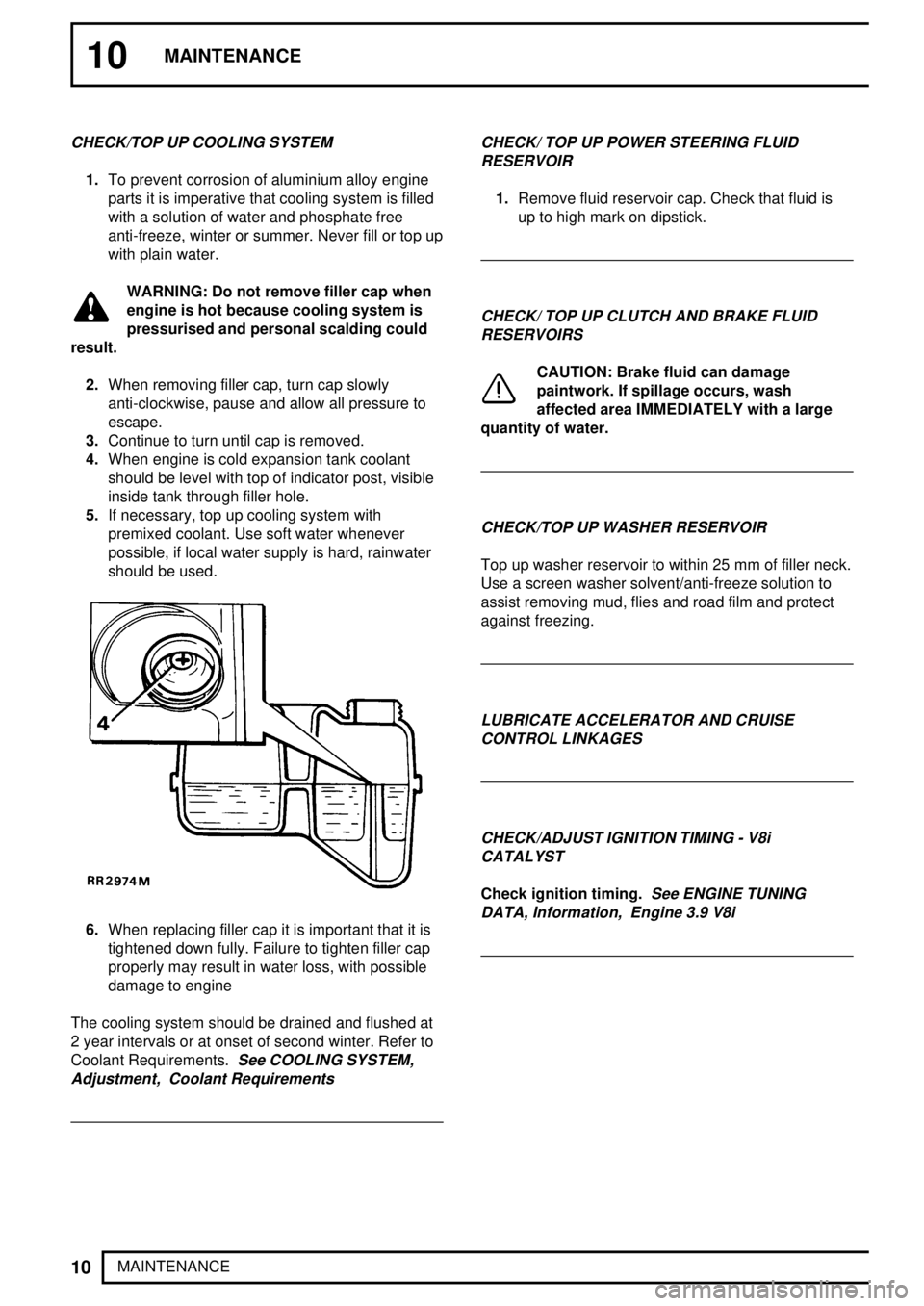

CHECK/TOP UP COOLING SYSTEM

1.To prevent corrosion of aluminium alloy engine

parts it is imperative that cooling system is filled

with a solution of water and phosphate free

anti-freeze, winter or summer. Never fill or top up

with plain water.

WARNING: Do not remove filler cap when

engine is hot because cooling system is

pressurised and personal scalding could

result.

2.When removing filler cap, turn cap slowly

anti-clockwise, pause and allow all pressure to

escape.

3.Continue to turn until cap is removed.

4.When engine is cold expansion tank coolant

should be level with top of indicator post, visible

inside tank through filler hole.

5.If necessary, top up cooling system with

premixed coolant. Use soft water whenever

possible, if local water supply is hard, rainwater

should be used.

6.When replacing filler cap it is important that it is

tightened down fully. Failure to tighten filler cap

properly may result in water loss, with possible

damage to engine

The cooling system should be drained and flushed at

2 year intervals or at onset of second winter. Refer to

Coolant Requirements.

See COOLING SYSTEM,

Adjustment, Coolant RequirementsCHECK/ TOP UP POWER STEERING FLUID

RESERVOIR

1.Remove fluid reservoir cap. Check that fluid is

up to high mark on dipstick.

CHECK/ TOP UP CLUTCH AND BRAKE FLUID

RESERVOIRS

CAUTION: Brake fluid can damage

paintwork. If spillage occurs, wash

affected area IMMEDIATELY with a large

quantity of water.

CHECK/TOP UP WASHER RESERVOIR

Top up washer reservoir to within 25 mm of filler neck.

Use a screen washer solvent/anti-freeze solution to

assist removing mud, flies and road film and protect

against freezing.

LUBRICATE ACCELERATOR AND CRUISE

CONTROL LINKAGES

CHECK/ADJUST IGNITION TIMING - V8i

CATALYST

Check ignition timing.See ENGINE TUNING

DATA, Information, Engine 3.9 V8i

Page 74 of 873

10MAINTENANCE

12

MAINTENANCE

EXTERNALLY CHECK INTERCOOLER FOR

OBSTRUCTION - Tdi

Clear any trapped dirt or flies from vanes of

intercooler

CLEAN INTERCOOLER ELEMENT - Tdi

Remove

1.Remove intercooler element.

2.Flush intercooler with ICI 'GENKLENE'or

à oD-SOLVE' propriety cleaner, following the

manufacturer's instructions.

3.Dry the intercooler completely ensuring that no

liquid remains in the element.

Refit

4.Refit intercooler element.UNDER VEHICLE MAINTENANCE

Vehicles operating under severe conditions of dust,

sand, mud and water should have oils changed and

lubrication carried out at more frequent intervals than

is recommended in maintenance schedules.

RENEW ENGINE OIL AND FILTER - Tdi

CAUTION: Serious damage to the

turbocharger will result if engine is run

above idling speed before oil pressure is

restored.

RENEW ENGINE OIL - V8i

RENEW ENGINE OIL AND FILTER - V8i

CAUTION: To prevent an airlock occuring

after removing filter, fill new filter with oil

and fit immediately after removing old

filter. If airlock does occur fill oil pump with

petroleum jelly.

RENEW ENGINE OIL AND FILTER - Mpi

CHECK/TOP UP MANUAL GEARBOX OIL - V8i

1.Site vehicle on lift or level ground.

2.Remove oil filler level plug. If necessary, inject

new oil into the gearbox until it runs out of filler

hole. Fit plug. Tighten to

30 Nm.

RENEW MANUAL GEARBOX OIL - Tdi - Mpi

RENEW MANUAL GEARBOX OIL - V8i

Page 80 of 873

10MAINTENANCE

18

MAINTENANCE

ABS VEHICLES - CHECK ROAD WHEEL SPEED

SENSOR ELECTRICAL HARNESS FOR DAMAGE

RENEW OXYGEN SENSORS

See EMISSION CONTROL, Repair, Heated

Oxygen Sensor (HO2S)

RENEW CATALYTIC CONVERTERS

See MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust System Complete

REPORT ANY UNUSUAL FEATURES OF VEHICLE

CONDITION AND ADDITIONAL WORK REQUIREDCARRY OUT ROAD TEST

For details of dynamometer testing.See

INTRODUCTION, Information, Dynamometer

Testing - Non Anti-lock brake vehicles See

INTRODUCTION, Information, Dynamometer

Testing - Vehicles with Anti-lock brakes (ABS)

Check following items:

1.Inhibitor switch only operates in P and N.

2.Engine for excessive noise.

3.Clutch for slip, judder or spin.

4.Automatic gear selection/shift speeds.

5.Gear selection/noise - high/low range.

6.Steering for abnormal noise/effort.

7.Steering for free play.

8.All instruments, gauges and warning indicators.

9.Heater and air conditioning systems.

10.Heated rear screen.

11.Shock absorbers - ride irregularities.

12.Foot brake, on emergency stop, pulling to one

side, binding, pedal effort.

13.Parkbrake efficiency.

14.Seat reclining and latching.

15.Fully extend seat belt, check operation of

retraction and latching. Inertia belts lock when

snatched or vehicle on slope.

16.Road wheel balance.

17.Transmission for vibrations.

18.Body noises, squeaks and rattles.

19.Excessive exhaust smoke.

20.Engine idle speed.

21.Endorse service record.

22.Report any unusual features of vehicle condition

and additional work required.

ENDORSE SERVICE RECORD

Page 82 of 873

Tdi

1

REPAIR DRIVE BELT INFORMATION

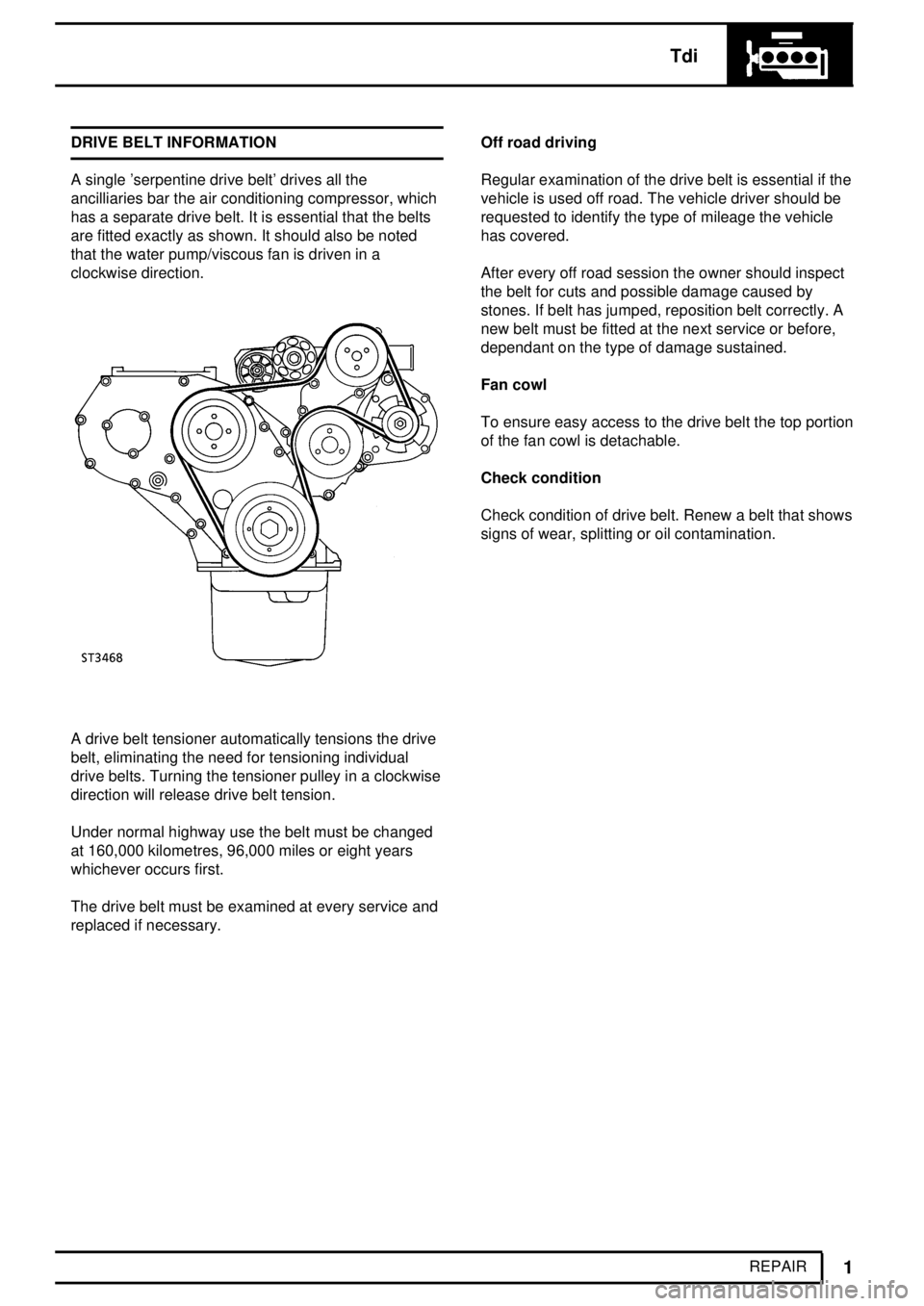

A single 'serpentine drive belt' drives all the

ancilliaries bar the air conditioning compressor, which

has a separate drive belt. It is essential that the belts

are fitted exactly as shown. It should also be noted

that the water pump/viscous fan is driven in a

clockwise direction.

A drive belt tensioner automatically tensions the drive

belt, eliminating the need for tensioning individual

drive belts. Turning the tensioner pulley in a clockwise

direction will release drive belt tension.

Under normal highway use the belt must be changed

at 160,000 kilometres, 96,000 miles or eight years

whichever occurs first.

The drive belt must be examined at every service and

replaced if necessary.Off road driving

Regular examination of the drive belt is essential if the

vehicle is used off road. The vehicle driver should be

requested to identify the type of mileage the vehicle

has covered.

After every off road session the owner should inspect

the belt for cuts and possible damage caused by

stones. If belt has jumped, reposition belt correctly. A

new belt must be fitted at the next service or before,

dependant on the type of damage sustained.

Fan cowl

To ensure easy access to the drive belt the top portion

of the fan cowl is detachable.

Check condition

Check condition of drive belt. Renew a belt that shows

signs of wear, splitting or oil contamination.

Page 85 of 873

12ENGINE

4

REPAIR 22.Disconnect feed pipe and spill return pipe from

injector pump.

23.Disconnect both pipes from fuel lift pump.

24.Disconnect servo hose from vacuum pump.

25.Remove three retaining nuts and disconnect

exhaust down pipe.

26.Remove oil cooler pipes from oil filter adaptor.

27.If automatic transmission is fitted, disconnect

feed and return pipes at gearbox oil cooler.

Remove retaining bracket from LH side of

cylinder block and release both oil cooler pipes.

28.Support gearbox.

29.Disconnect ground strap from starter motor.

30.On vehicles with automatic transmission, remove

fixings and detach drive plate housing access

panel and gasket.31.Working through drive plate housing aperture

mark the torque convertor and drive plate to

facilitate reassembly.

32.Remove the four convertor to flexible drive

securing bolts, rotating crankshaft to gain access

to each individual bolt.

33.Fit engine lifting bracket to the two RH rear

cylinder head fixing bolts.

34.Using suitable hoist, fit lifting chains to engine.

35.Remove four bolts, from both sides, securing

front engine mounting brackets to cylinder block.

36.Remove two bolts, from both sides, securing

front engine mounting bracket to bell housing.

Page 86 of 873

Tdi

5

REPAIR

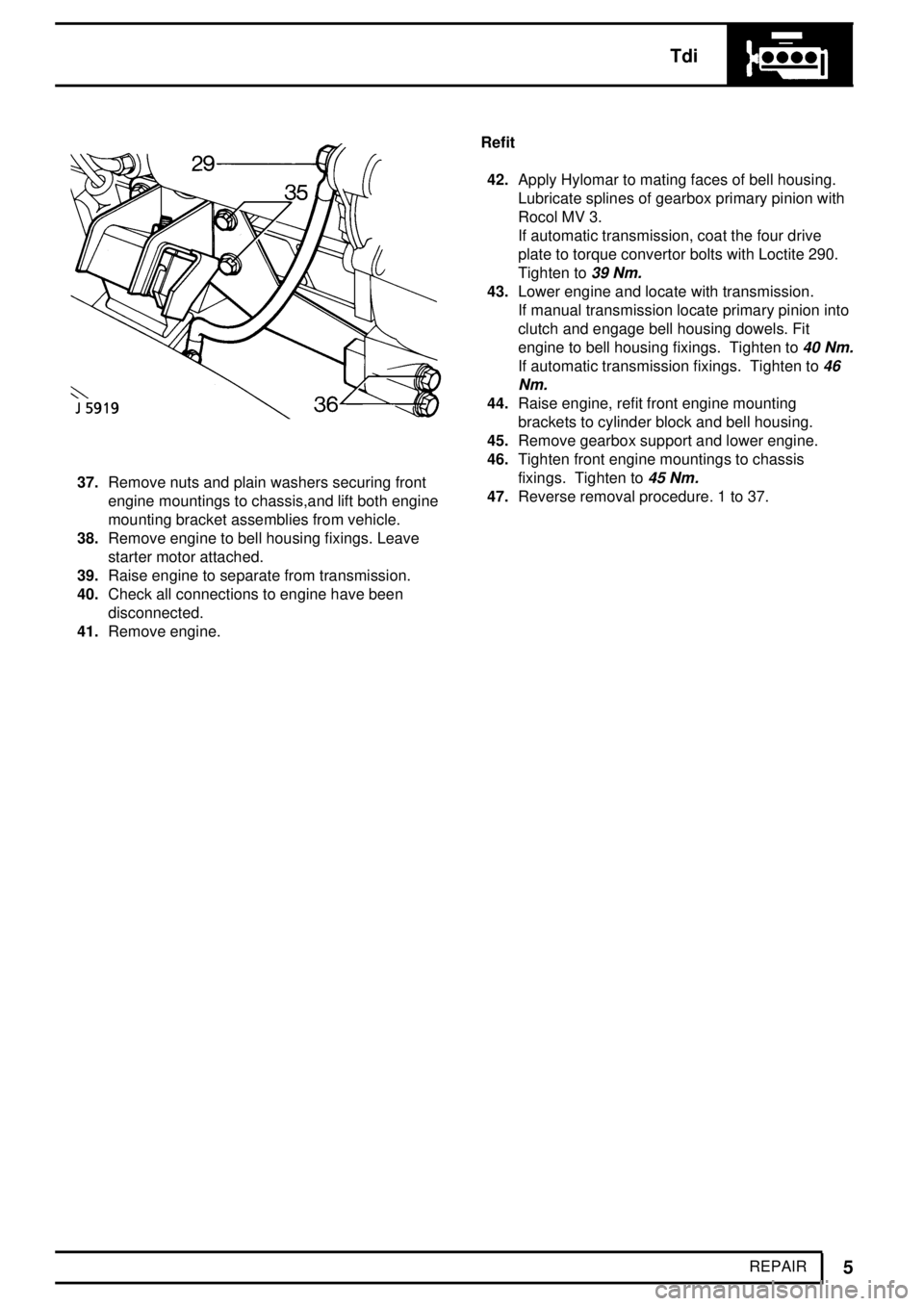

37.Remove nuts and plain washers securing front

engine mountings to chassis,and lift both engine

mounting bracket assemblies from vehicle.

38.Remove engine to bell housing fixings. Leave

starter motor attached.

39.Raise engine to separate from transmission.

40.Check all connections to engine have been

disconnected.

41.Remove engine.Refit

42.Apply Hylomar to mating faces of bell housing.

Lubricate splines of gearbox primary pinion with

Rocol MV 3.

If automatic transmission, coat the four drive

plate to torque convertor bolts with Loctite 290.

Tighten to

39 Nm.

43.Lower engine and locate with transmission.

If manual transmission locate primary pinion into

clutch and engage bell housing dowels. Fit

engine to bell housing fixings. Tighten to

40 Nm.

If automatic transmission fixings. Tighten to46

Nm.

44.Raise engine, refit front engine mounting

brackets to cylinder block and bell housing.

45.Remove gearbox support and lower engine.

46.Tighten front engine mountings to chassis

fixings. Tighten to

45 Nm.

47.Reverse removal procedure. 1 to 37.

Page 91 of 873

12ENGINE

10

REPAIR

21.With lip side leading, drive-in seal squarely using

special tool LRT-12-082.

22.Refit gear.

FUEL INJECTION PUMP GEAR

Service repair no - 19.30.06

Remove

23.Slacken the three bolts on front of gear.

CAUTION: It is important to ensure that

when the injection pump is locked no

attempt must be made to rotate it. Take

care not to allow the crankshaft to be turned.24.Remove special tool pin from gear.

25.Remove three bolts and withdraw plate and

gear.

Refit

26.Fit gear and plate and secure with three bolts.

27.Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

Page 92 of 873

Tdi

11

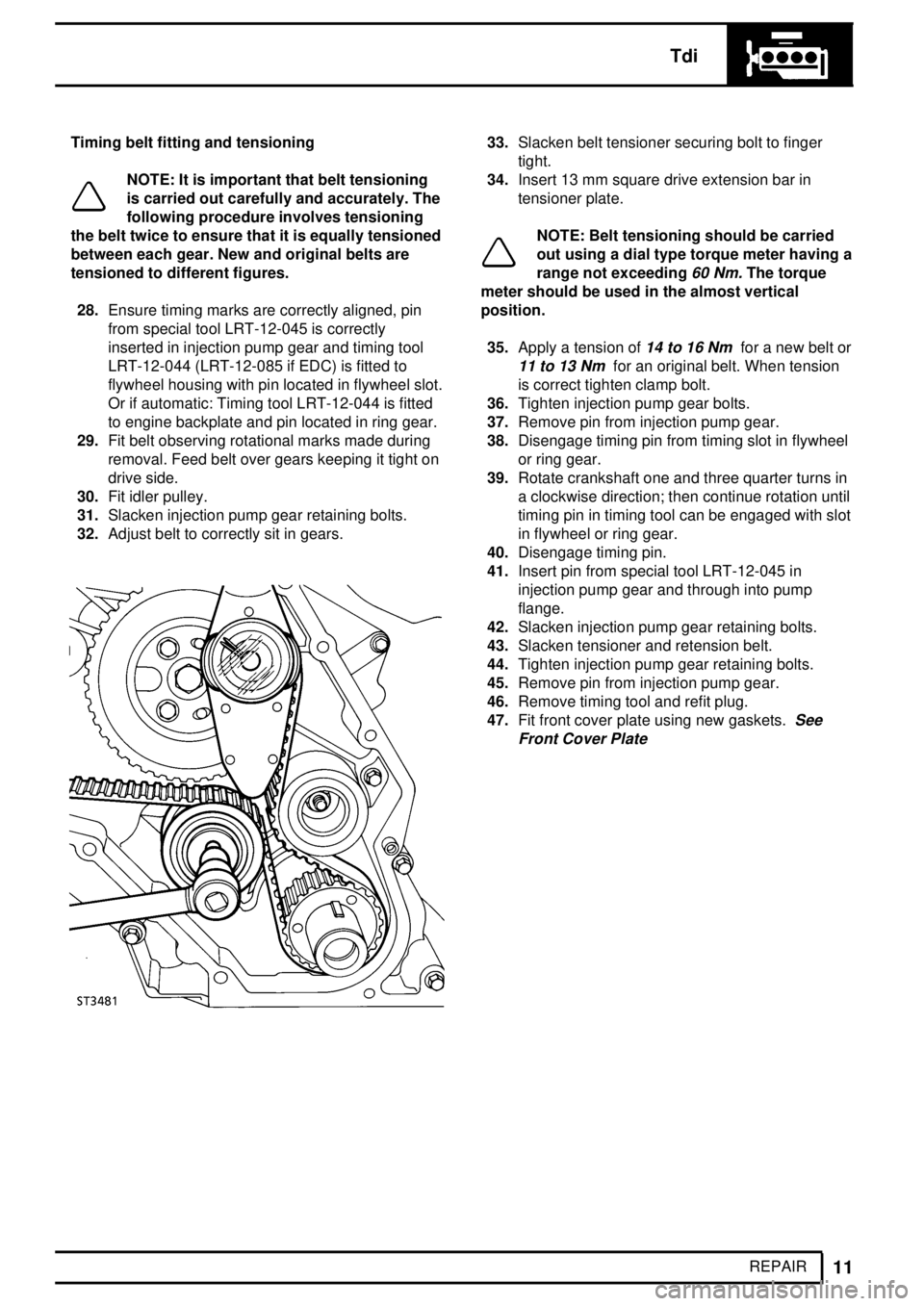

REPAIR Timing belt fitting and tensioning

NOTE: It is important that belt tensioning

is carried out carefully and accurately. The

following procedure involves tensioning

the belt twice to ensure that it is equally tensioned

between each gear. New and original belts are

tensioned to different figures.

28.Ensure timing marks are correctly aligned, pin

from special tool LRT-12-045 is correctly

inserted in injection pump gear and timing tool

LRT-12-044 (LRT-12-085 if EDC) is fitted to

flywheel housing with pin located in flywheel slot.

Or if automatic: Timing tool LRT-12-044 is fitted

to engine backplate and pin located in ring gear.

29.Fit belt observing rotational marks made during

removal. Feed belt over gears keeping it tight on

drive side.

30.Fit idler pulley.

31.Slacken injection pump gear retaining bolts.

32.Adjust belt to correctly sit in gears.

33.Slacken belt tensioner securing bolt to finger

tight.

34.Insert 13 mm square drive extension bar in

tensioner plate.

NOTE: Belt tensioning should be carried

out using a dial type torque meter having a

range not exceeding

60 Nm.The torque

meter should be used in the almost vertical

position.

35.Apply a tension of

14 to 16 Nmfor a new belt or

11 to 13 Nmfor an original belt. When tension

is correct tighten clamp bolt.

36.Tighten injection pump gear bolts.

37.Remove pin from injection pump gear.

38.Disengage timing pin from timing slot in flywheel

or ring gear.

39.Rotate crankshaft one and three quarter turns in

a clockwise direction; then continue rotation until

timing pin in timing tool can be engaged with slot

in flywheel or ring gear.

40.Disengage timing pin.

41.Insert pin from special tool LRT-12-045 in

injection pump gear and through into pump

flange.

42.Slacken injection pump gear retaining bolts.

43.Slacken tensioner and retension belt.

44.Tighten injection pump gear retaining bolts.

45.Remove pin from injection pump gear.

46.Remove timing tool and refit plug.

47.Fit front cover plate using new gaskets.

See

Front Cover Plate