low oil pressure LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 172 of 873

12ENGINE

14

REPAIR Refit

1.Clean sump, remove all traces of gasket from

mating faces of sump and cylinder block.

Visually check sump for damage.

2.Apply beads of RTV sealant to front main

bearing cap.

3.Position new gasket to sump, ensuring that

location pips on gasket are located in sump.

Check gasket lays flat on sump flange.

4.Fit sump. Fit bolts, ensuring that longest bolt is

inserted at position 7.

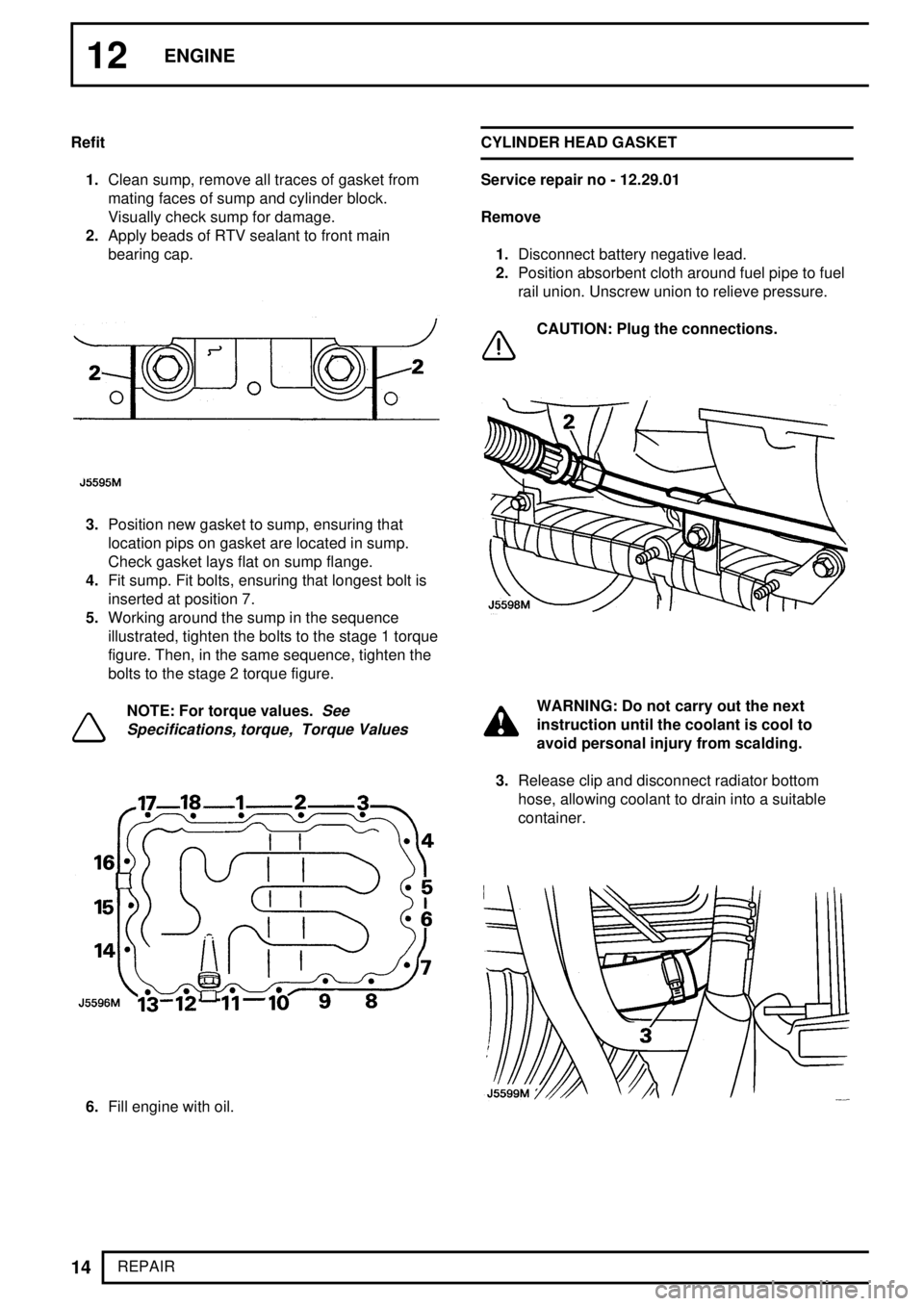

5.Working around the sump in the sequence

illustrated, tighten the bolts to the stage 1 torque

figure. Then, in the same sequence, tighten the

bolts to the stage 2 torque figure.

NOTE: For torque values.See

Specifications, torque, Torque Values

6.Fill engine with oil.CYLINDER HEAD GASKET

Service repair no - 12.29.01

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve pressure.

CAUTION: Plug the connections.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

3.Release clip and disconnect radiator bottom

hose, allowing coolant to drain into a suitable

container.

Page 182 of 873

Mpi

1

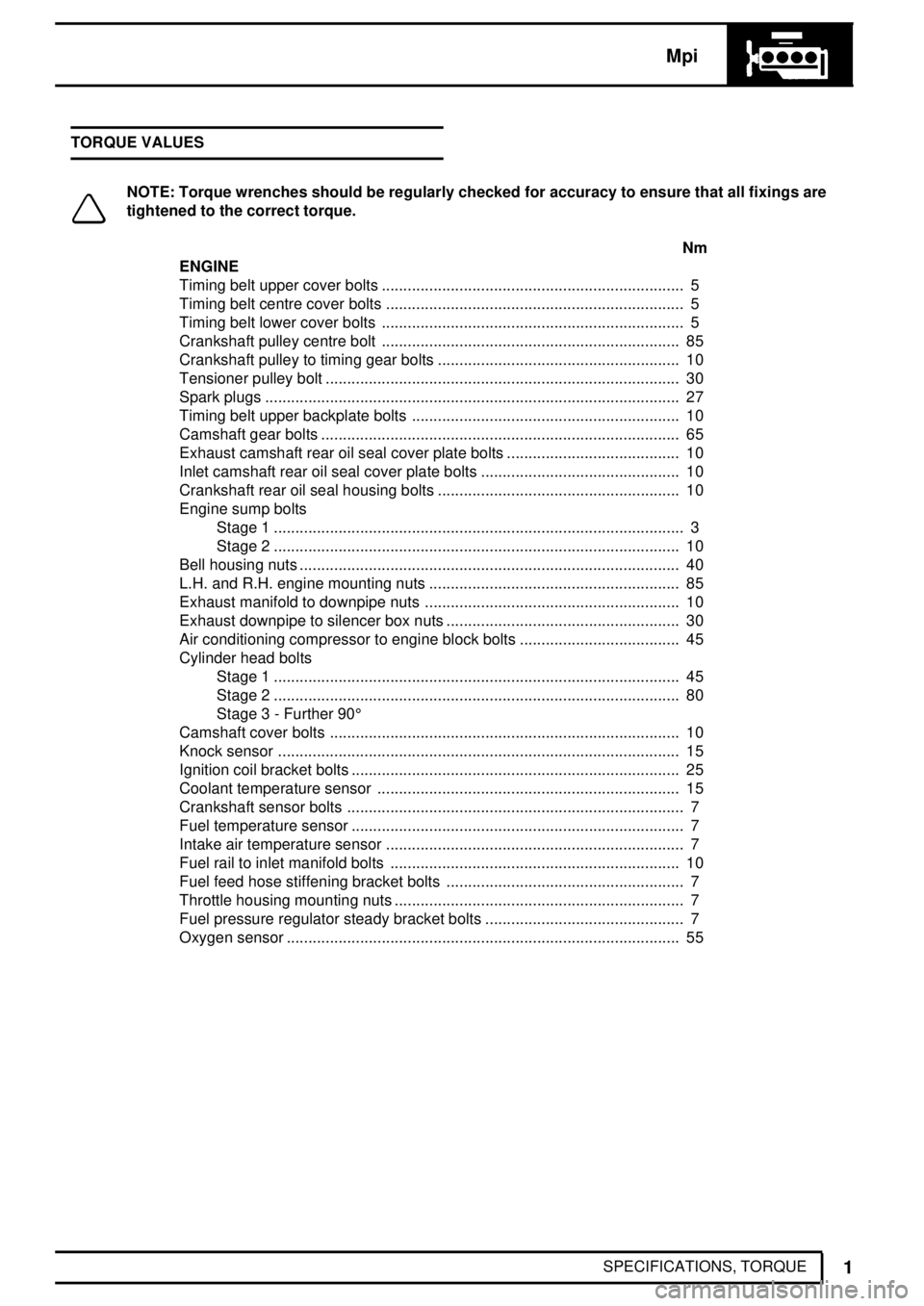

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

ENGINE

Timing belt upper cover bolts 5......................................................................

Timing belt centre cover bolts 5.....................................................................

Timing belt lower cover bolts 5......................................................................

Crankshaft pulley centre bolt 85.....................................................................

Crankshaft pulley to timing gear bolts 10........................................................

Tensioner pulley bolt 30..................................................................................

Spark plugs 27................................................................................................

Timing belt upper backplate bolts 10..............................................................

Camshaft gear bolts 65...................................................................................

Exhaust camshaft rear oil seal cover plate bolts 10........................................

Inlet camshaft rear oil seal cover plate bolts 10..............................................

Crankshaft rear oil seal housing bolts 10........................................................

Engine sump bolts

Stage 1 3...............................................................................................

Stage 2 10..............................................................................................

Bell housing nuts 40........................................................................................

L.H. and R.H. engine mounting nuts 85..........................................................

Exhaust manifold to downpipe nuts 10...........................................................

Exhaust downpipe to silencer box nuts 30......................................................

Air conditioning compressor to engine block bolts 45.....................................

Cylinder head bolts

Stage 1 45..............................................................................................

Stage 2 80..............................................................................................

Stage 3 - Further 90°

Camshaft cover bolts 10.................................................................................

Knock sensor 15.............................................................................................

Ignition coil bracket bolts 25............................................................................

Coolant temperature sensor 15......................................................................

Crankshaft sensor bolts 7..............................................................................

Fuel temperature sensor 7.............................................................................

Intake air temperature sensor 7.....................................................................

Fuel rail to inlet manifold bolts 10...................................................................

Fuel feed hose stiffening bracket bolts 7.......................................................

Throttle housing mounting nuts 7...................................................................

Fuel pressure regulator steady bracket bolts 7..............................................

Oxygen sensor 55...........................................................................................

Page 187 of 873

EMISSION CONTROL

1

DESCRIPTION AND OPERATION REV: 09/95 EMISSION CONTROL

Three systems are used to control the vehicle

atmospheric emissions these are:

Engine crankcase fume emissions.

Fuel tank Evaporative emissions

Engine exhaust gas emissions.

Crankcase ventilation system - 3.9 MFi models

only

The crankcase ventilation system which is an integral

part of the air supply to the engine combustion

chambers, is often overlooked when diagnosing

problems associated with engine performance. A

blocked ventilation pipe or filter or excessive air leak

into the inlet system through a damaged pipe or

leaking gasket can effect the mixture, performance

and economy of the engine.

1. Three way connector

2. Air filter

3. Oil separatorThe purpose of the crankcase ventilation system is to

ensure that any noxious gas generated in the engine

crankcase is rendered harmless by burning in the

combustion chambers as follows:

Oil laden noxious gas in the engine crankcase is

drawn through an oil separator 3 located on the right

cylinder head rocker cover, where the oil is separated

and returned to the sump. The gas flows through a

restrictor in the three way connection 1 and into the

inlet plenum chamber where it is drawn into the

combustion chambers and burned. The volume of

fresh air which is drawn from the atmospheric side of

the throttle butterfly to mix with the gas, depends on

the position of the throttle and the engine speed.

The air filter 2 fitted to the left cylinder head rocker

cover, must be maintained in clean condition to

ensure sufficient air enters the crankcase under

varying throttle openings and manifold depression, to

prevent excessive crankcase pressure or depression

developing.

Page 273 of 873

19FUEL SYSTEM

2

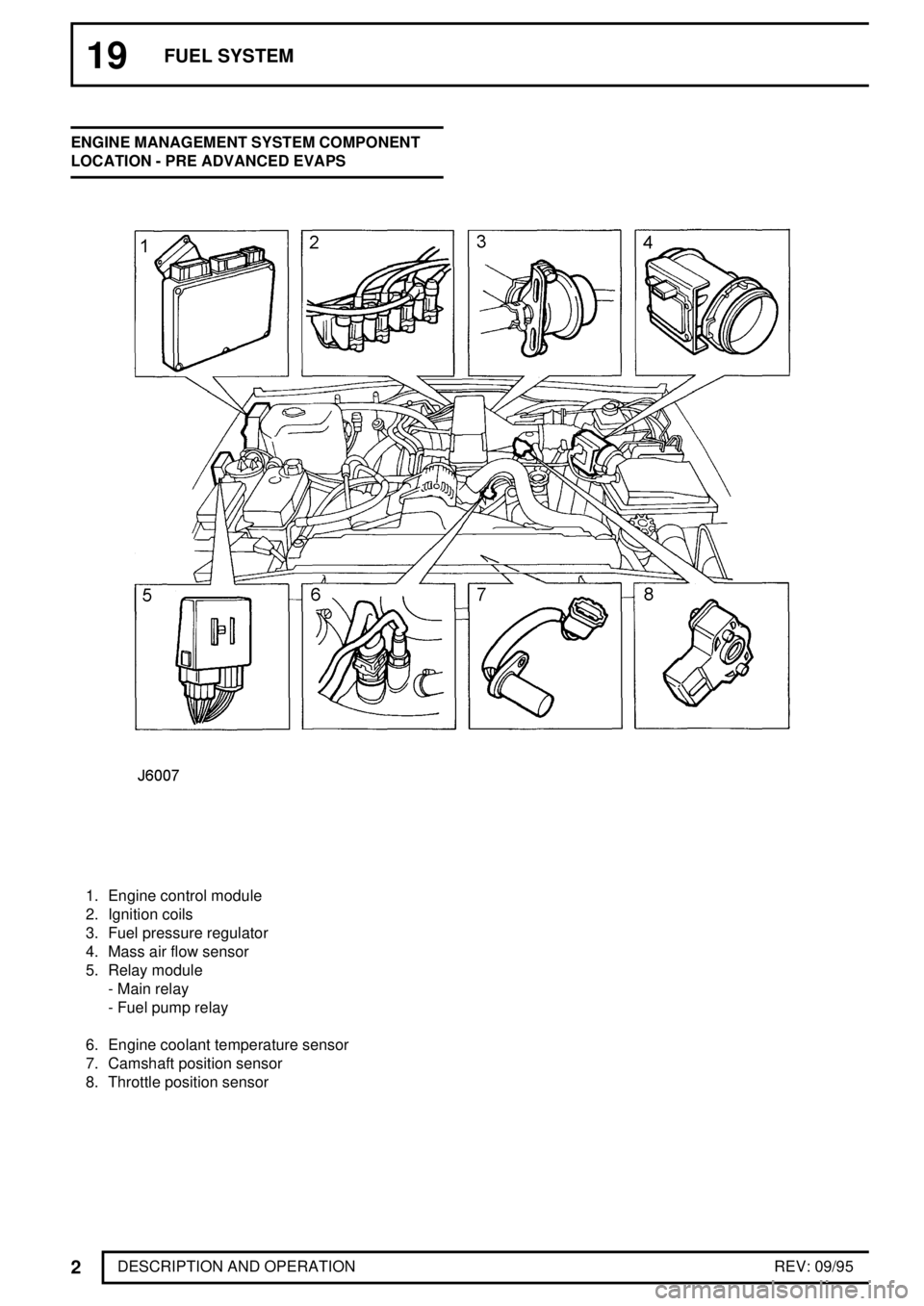

DESCRIPTION AND OPERATION REV: 09/95 ENGINE MANAGEMENT SYSTEM COMPONENT

LOCATION - PRE ADVANCED EVAPS

1. Engine control module

2. Ignition coils

3. Fuel pressure regulator

4. Mass air flow sensor

5. Relay module

- Main relay

- Fuel pump relay

6. Engine coolant temperature sensor

7. Camshaft position sensor

8. Throttle position sensor

Page 276 of 873

SFI

5

DESCRIPTION AND OPERATION REV: 09/95 Engine fuel temperature sensor (EFT Sensor)

This is another resistive sensor. Located on the fuel

rail it measures temperature of the rail rather than the

fuel. The resistance varies with changes in

temperature. The signal is used to increase the

injection pulse time when undergoing hot restarts.

When the fuel is hot, vapourisation occurs in the rail

and bubbles can occur in the injectors. Increasing the

pulse time flushes the bubbles away, and cools the

fuel rail with fuel from the tank. The fault may not be

evident to the driver, there may be a hot restart

problem. The fault is indicated by illumination of the

malfunction indicator light (MIL) on North American

specification vehicles.

Knock sensors

The knock sensor produces an output voltage in

proportion to mechanical vibration caused by the

engine. A sensor is located in each cylinder bank

between 2/4 and 3/5 cylinders. The ECM calculates if

the engine is knocking due to camshaft and

crankshaft sensor signals regarding the position of the

engine in the cycle. The ECM can also work out

exactly which cylinder is knocking and retards the

ignition on that particular cylinder until the knock

disappears. It then advances the ignition to find the

optimum ignition timing for that cylinder. The ECM can

adjust the timing of each cylinder for knock

simultaneously. It is possible that all eight cylinders

could have different advance angles at the same time.

If the camshaft sensor fails, the knock sensor will

continue to work, but as the engine may be running

one revolution out of sychronisation the ECM may

retard the wrong cylinder of the pair e.g. 1 instead of

6. If the knock sensor fails engine knock will not be

detected and corrected. The fault is indicated by

illumination of the malfunction indicator light (MIL) on

North American specification vehicles.Ignition coils

The electronic ignition system uses four double ended

coils. They are mounted on a bracket fitted to the rear

of the engine. The circuit to each coil is completed by

switching within the ECM, allowing each coil to charge

up and fire. Sparks are produced in two cylinders

simultaneously, one on compression stroke, the other

on exhaust stroke. Note that coil 1 feeds cylinders 1

and 6, coil 2 feeds cylinders 5 and 8, coil 3 feeds

cylinders 4 and 7, and coil 4 feeds cylinders 2 and 3.

Due to the ease of combustion in the cylinder on the

compression stroke, more energy is dissipated in that

cylinder. Coil failure will result in a lack of sparks and

misfire in the affected cylinders. The fault is indicated

by illumination of the malfunction indicator light (MIL)

on North American specification vehicles.

Injectors

A multiport fuel injection system (MFI) is used, one

injector per cylinder. Each injector consists of a small

solenoid which is activated by the ECM to allow a

metered amount of fuel to pass into the combustion

chamber. Due to the pressure in the fuel rail and the

shape of the injector orifice, the fuel squirts into the

cylinder in a fine spray to aid combustion. In the

unlikely event of injector failure a misfire will occur as

there will be no fuel to the affected cylinder. The fault

is indicated by illumination of the malfunction indicator

light (MIL) on North American specification vehicles.

Page 279 of 873

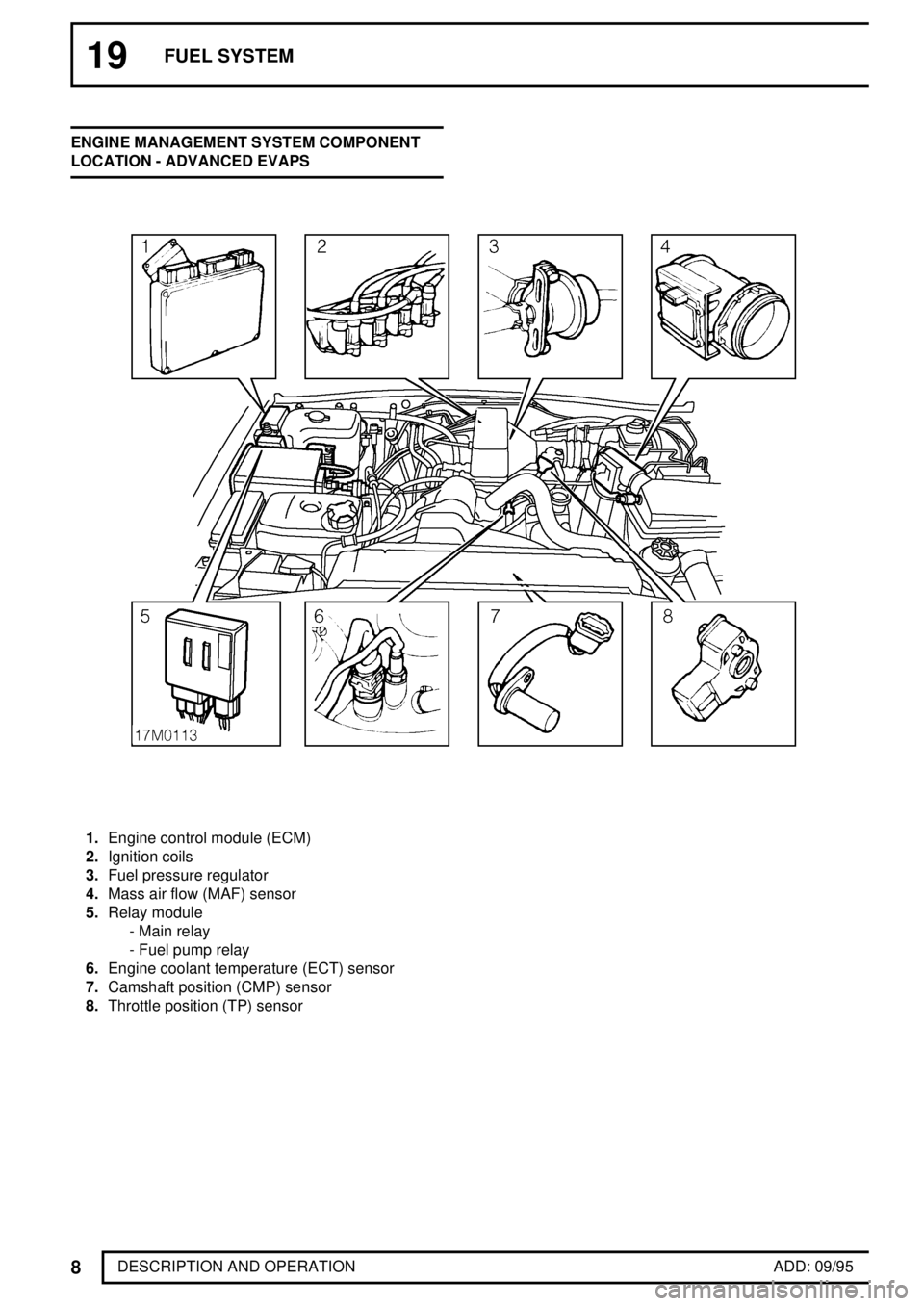

19FUEL SYSTEM

8

DESCRIPTION AND OPERATION ADD: 09/95 ENGINE MANAGEMENT SYSTEM COMPONENT

LOCATION - ADVANCED EVAPS

1.Engine control module (ECM)

2.Ignition coils

3.Fuel pressure regulator

4.Mass air flow (MAF) sensor

5.Relay module

- Main relay

- Fuel pump relay

6.Engine coolant temperature (ECT) sensor

7.Camshaft position (CMP) sensor

8.Throttle position (TP) sensor

Page 313 of 873

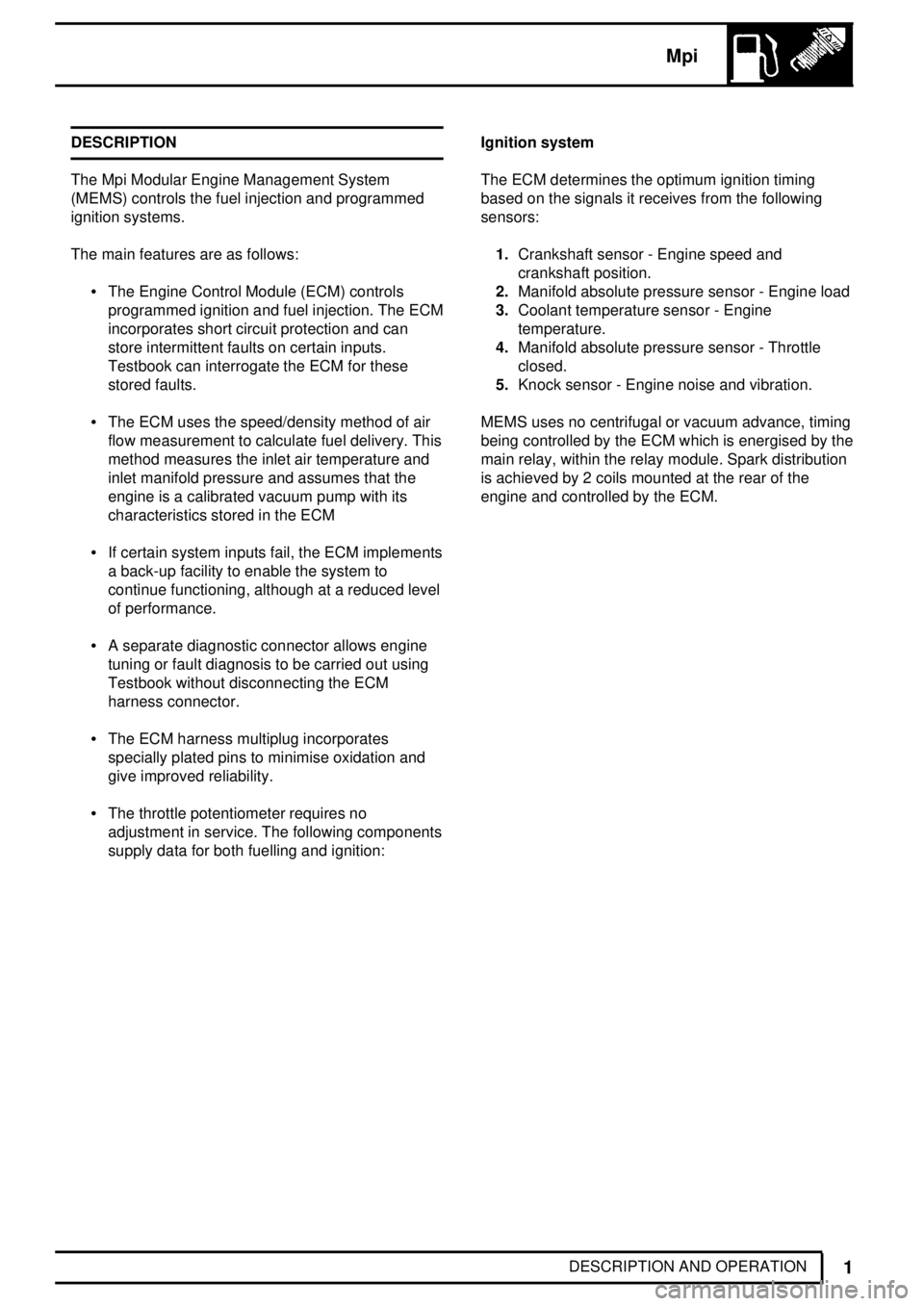

Mpi

1

DESCRIPTION AND OPERATION DESCRIPTION

The Mpi Modular Engine Management System

(MEMS) controls the fuel injection and programmed

ignition systems.

The main features are as follows:

·The Engine Control Module (ECM) controls

programmed ignition and fuel injection. The ECM

incorporates short circuit protection and can

store intermittent faults on certain inputs.

Testbook can interrogate the ECM for these

stored faults.

·The ECM uses the speed/density method of air

flow measurement to calculate fuel delivery. This

method measures the inlet air temperature and

inlet manifold pressure and assumes that the

engine is a calibrated vacuum pump with its

characteristics stored in the ECM

·If certain system inputs fail, the ECM implements

a back-up facility to enable the system to

continue functioning, although at a reduced level

of performance.

·A separate diagnostic connector allows engine

tuning or fault diagnosis to be carried out using

Testbook without disconnecting the ECM

harness connector.

·The ECM harness multiplug incorporates

specially plated pins to minimise oxidation and

give improved reliability.

·The throttle potentiometer requires no

adjustment in service. The following components

supply data for both fuelling and ignition:Ignition system

The ECM determines the optimum ignition timing

based on the signals it receives from the following

sensors:

1.Crankshaft sensor - Engine speed and

crankshaft position.

2.Manifold absolute pressure sensor - Engine load

3.Coolant temperature sensor - Engine

temperature.

4.Manifold absolute pressure sensor - Throttle

closed.

5.Knock sensor - Engine noise and vibration.

MEMS uses no centrifugal or vacuum advance, timing

being controlled by the ECM which is energised by the

main relay, within the relay module. Spark distribution

is achieved by 2 coils mounted at the rear of the

engine and controlled by the ECM.

Page 321 of 873

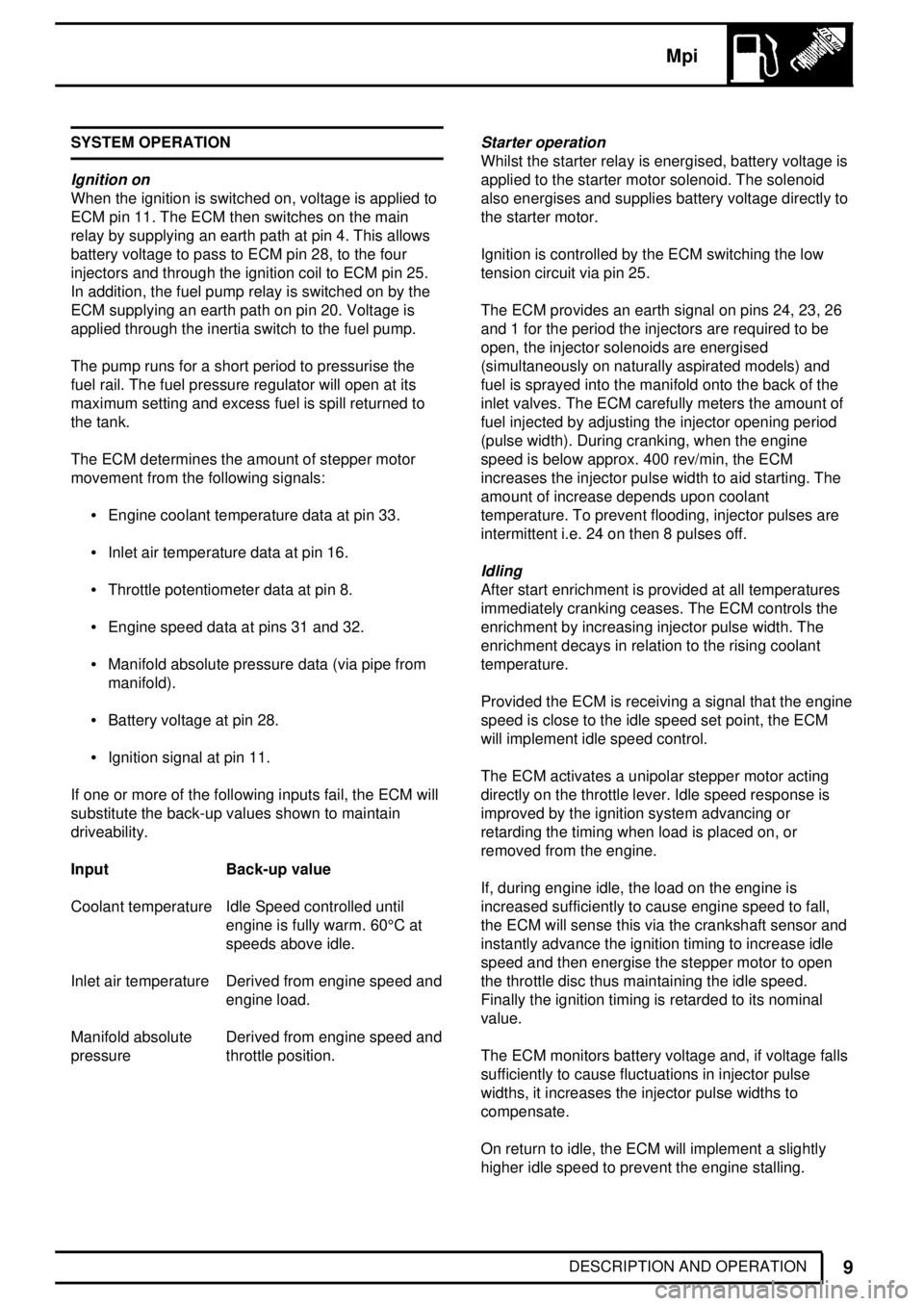

Mpi

9

DESCRIPTION AND OPERATION SYSTEM OPERATION

Ignition on

When the ignition is switched on, voltage is applied to

ECM pin 11. The ECM then switches on the main

relay by supplying an earth path at pin 4. This allows

battery voltage to pass to ECM pin 28, to the four

injectors and through the ignition coil to ECM pin 25.

In addition, the fuel pump relay is switched on by the

ECM supplying an earth path on pin 20. Voltage is

applied through the inertia switch to the fuel pump.

The pump runs for a short period to pressurise the

fuel rail. The fuel pressure regulator will open at its

maximum setting and excess fuel is spill returned to

the tank.

The ECM determines the amount of stepper motor

movement from the following signals:

·Engine coolant temperature data at pin 33.

·Inlet air temperature data at pin 16.

·Throttle potentiometer data at pin 8.

·Engine speed data at pins 31 and 32.

·Manifold absolute pressure data (via pipe from

manifold).

·Battery voltage at pin 28.

·Ignition signal at pin 11.

If one or more of the following inputs fail, the ECM will

substitute the back-up values shown to maintain

driveability.

Input Back-up value

Coolant temperature Idle Speed controlled until

engine is fully warm. 60°Cat

speeds above idle.

Inlet air temperature Derived from engine speed and

engine load.

Manifold absolute Derived from engine speed and

pressure throttle position.

Starter operation

Whilst the starter relay is energised, battery voltage is

applied to the starter motor solenoid. The solenoid

also energises and supplies battery voltage directly to

the starter motor.

Ignition is controlled by the ECM switching the low

tension circuit via pin 25.

The ECM provides an earth signal on pins 24, 23, 26

and 1 for the period the injectors are required to be

open, the injector solenoids are energised

(simultaneously on naturally aspirated models) and

fuel is sprayed into the manifold onto the back of the

inlet valves. The ECM carefully meters the amount of

fuel injected by adjusting the injector opening period

(pulse width). During cranking, when the engine

speed is below approx. 400 rev/min, the ECM

increases the injector pulse width to aid starting. The

amount of increase depends upon coolant

temperature. To prevent flooding, injector pulses are

intermittent i.e. 24 on then 8 pulses off.

Idling

After start enrichment is provided at all temperatures

immediately cranking ceases. The ECM controls the

enrichment by increasing injector pulse width. The

enrichment decays in relation to the rising coolant

temperature.

Provided the ECM is receiving a signal that the engine

speed is close to the idle speed set point, the ECM

will implement idle speed control.

The ECM activates a unipolar stepper motor acting

directly on the throttle lever. Idle speed response is

improved by the ignition system advancing or

retarding the timing when load is placed on, or

removed from the engine.

If, during engine idle, the load on the engine is

increased sufficiently to cause engine speed to fall,

the ECM will sense this via the crankshaft sensor and

instantly advance the ignition timing to increase idle

speed and then energise the stepper motor to open

the throttle disc thus maintaining the idle speed.

Finally the ignition timing is retarded to its nominal

value.

The ECM monitors battery voltage and, if voltage falls

sufficiently to cause fluctuations in injector pulse

widths, it increases the injector pulse widths to

compensate.

On return to idle, the ECM will implement a slightly

higher idle speed to prevent the engine stalling.

Page 350 of 873

Tdi

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Compressor

Drive Belt

YES - Continue.

3.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant

NO - Continue.

4.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

5.Are there any external leaks, from water pump,

engine gaskets, fast idle thermostat or the heater

unit?

YES - Investigate and rectify.

See Adjustment,

Coolant

NO - Continue.

6.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue

7.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting.

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 10,

otherwise: Continue.8.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.

NO - Rectify.

YES - Continue.

9.Is temperature sender and gauge giving

accurate readings?

NO - Sustitute parts and compare readings.

YES - Continue.

10.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If only the coolant system is contaminated suspect a

cylinder head gasket.

If both systems are contaminated, suspect the

radiator.

If only the lubrication system is contaminated with

coolant, suspect leakage past cylinder liner seals or

cylinder head gasket.

Page 360 of 873

V8i

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Drive Belt -

Check Tension

YES - Continue.

3.Is ignition timing correct?

NO -

See ELECTRICAL, Adjustment,

Ignition Timing

YES - Continue.

4.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant Requirements

NO - Continue.

5.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

6.Are there any external leaks, from water pump,

engine gaskets or the heater unit?

YES - Investigate and rectify.

See Adjustment,

Coolant Requirements

NO - Continue.

7.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue.8.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 11,

otherwise: Continue.

9.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.K5

NO - Rectify.

YES - Continue.

10.Is temperature sender and gauge giving

accurate readings?

NO - Substitute parts and compare readings.

YES - Continue.

11.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If the coolant only, or both systems are contaminated,

suspect cylinder head gaskets or radiator.

If only the lubrication stystem is contaminated with

coolant, suspect inlet manifold or front cover gaskets.