steering wheel LAND ROVER DISCOVERY 1995 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 557 of 873

STEERING

15

REPAIR STEERING COLUMN LOCK ASSEMBLY

Service repair no - 57.40.31

Remove

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit airbag module - if fitted.

1.Disconnect battery negative lead.

2.Remove steering column shroud.

See Steering

Column Shroud

3.Release turnbuckles, lower driver's access

panel.

4.If fitted, remove 4 screws securing knee pad,

remove bolster.

5.Disconnect ignition switch multiplug from fuse

box.

6.Disconnect ignition switch main feed multiplug.

Page 560 of 873

![LAND ROVER DISCOVERY 1995 Service Manual 57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joi LAND ROVER DISCOVERY 1995 Service Manual 57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joi](/img/64/57248/w960_57248-559.png)

57STEERING

18

REPAIR TRACK ROD AND LINKAGE

Service repair no - 57.55.09

Remove track rod

1.Site vehicle on a ramp [hoist].

2.Disconnect steering damper at track rod.

3.Disconnect track rod at ball joints, using

extractor LRT-57-018.

4.Remove track rod.

Remove linkage

5.Loosen clamp bolts.

6.Unscrew ball joints.

7.Unscrew track rod adjuster. (left hand thread).

Refit linkage

8.Fit replacement parts. Loosely fit clamp pinch

bolts.

9.Screw in ball joint to full extent of threads.

10.Set adjuster to track rod distance to 9mm as

shown.

11.Set adjuster end ball joint distance to 28.5mm as

shown.

12.Track rod effective length of 1230.0mm is

subject to adjustment during wheel alignment

check.

Refit track rod

CAUTION: Fit a new track rod if existing is

damaged or bent. No attempt should be

made to repair it.

13.Fit track rod and tighten ball joint nuts to

40 Nm.

14.Check front wheel alignment.See Adjustment,

Front Wheel Alignment

15.Connect steering damper to track rod.

16.Remove vehicle from hoist, or axle stands.

Page 561 of 873

STEERING

19

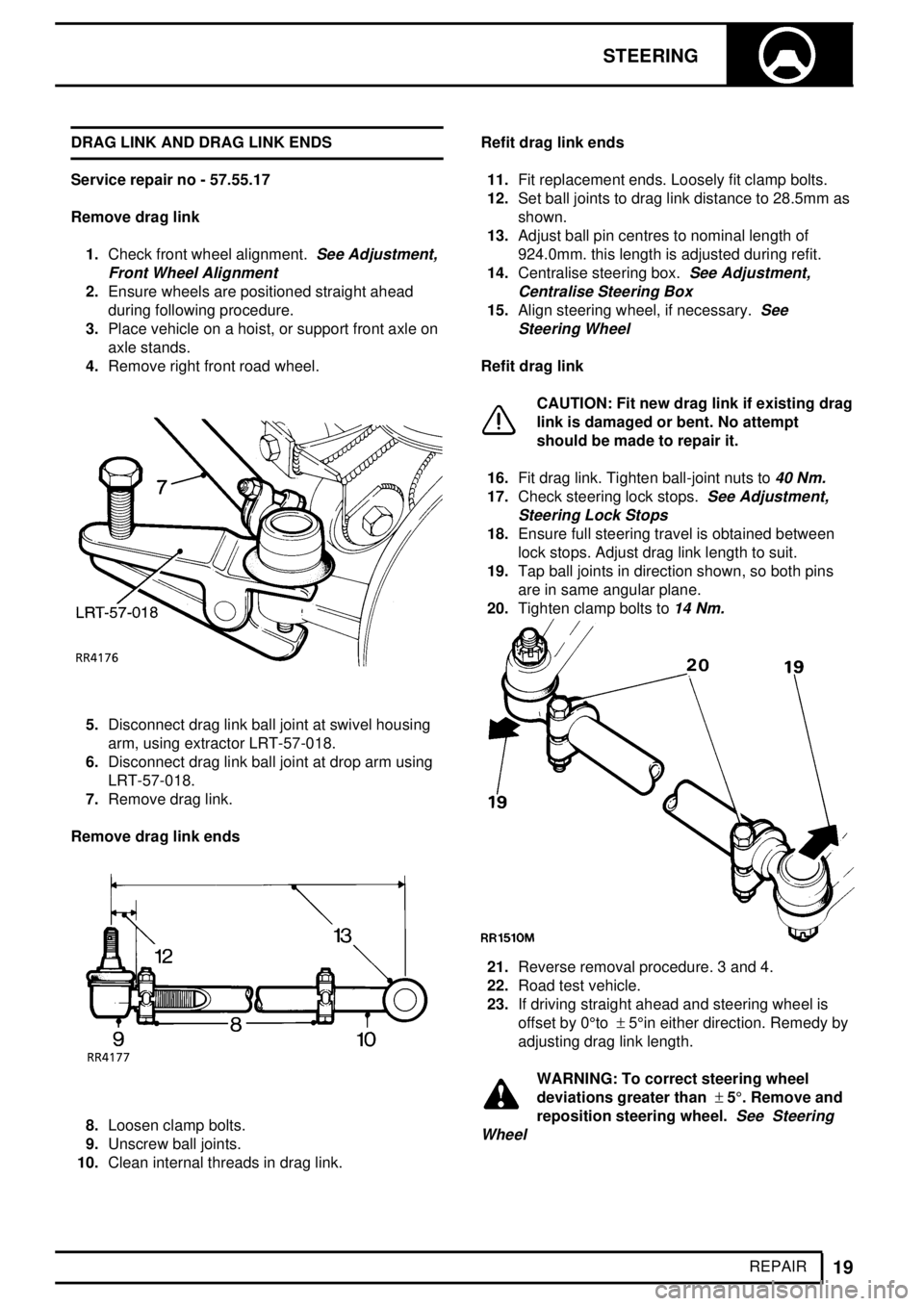

REPAIR DRAG LINK AND DRAG LINK ENDS

Service repair no - 57.55.17

Remove drag link

1.Check front wheel alignment.

See Adjustment,

Front Wheel Alignment

2.Ensure wheels are positioned straight ahead

during following procedure.

3.Place vehicle on a hoist, or support front axle on

axle stands.

4.Remove right front road wheel.

5.Disconnect drag link ball joint at swivel housing

arm, using extractor LRT-57-018.

6.Disconnect drag link ball joint at drop arm using

LRT-57-018.

7.Remove drag link.

Remove drag link ends

8.Loosen clamp bolts.

9.Unscrew ball joints.

10.Clean internal threads in drag link.Refit drag link ends

11.Fit replacement ends. Loosely fit clamp bolts.

12.Set ball joints to drag link distance to 28.5mm as

shown.

13.Adjust ball pin centres to nominal length of

924.0mm. this length is adjusted during refit.

14.Centralise steering box.

See Adjustment,

Centralise Steering Box

15.Align steering wheel, if necessary.See

Steering Wheel

Refit drag link

CAUTION: Fit new drag link if existing drag

link is damaged or bent. No attempt

should be made to repair it.

16.Fit drag link. Tighten ball-joint nuts to

40 Nm.

17.Check steering lock stops.See Adjustment,

Steering Lock Stops

18.Ensure full steering travel is obtained between

lock stops. Adjust drag link length to suit.

19.Tap ball joints in direction shown, so both pins

are in same angular plane.

20.Tighten clamp bolts to

14 Nm.

21.Reverse removal procedure. 3 and 4.

22.Road test vehicle.

23.If driving straight ahead and steering wheel is

offset by 0°to±5°in either direction. Remedy by

adjusting drag link length.

WARNING: To correct steering wheel

deviations greater than±5°. Remove and

reposition steering wheel.

See Steering

Wheel

Page 572 of 873

57STEERING

2

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Ball joint nuts 40..............................................................................................

Clamp bolt nuts 14..........................................................................................

Steering column bracket nuts 22....................................................................

Steering wheel nut 50.....................................................................................

Tie bar to mounting nut 110.............................................................................

Universal joint pinch bolt 25............................................................................

PAS box

Adjuster locknut 60.................................................................................

Drop arm nut 176....................................................................................

Sector shaft cover to steering box 75.....................................................

Steering box to chassis 81.....................................................................

Steering box fluid pipes 14mm thread 15...............................................

Steering box fluid pipes 16mm thread 20...............................................

Tie bar 81...............................................................................................

PAS pump

High pressure fluid pipe 20.....................................................................

Power steering pump mounting 35.........................................................

Pulley bolts, power steering pump 10....................................................

Hose clamp 3........................................................................................

Front mounting plate bolts 9..................................................................

PAS reservoir

Hose clamp 3........................................................................................

* Torque values below are for all screws and bolts used except for those that are specified otherwise.

METRIC Nm

M5 6......................................................................................................

M6 9......................................................................................................

M8 25.....................................................................................................

M10 45...................................................................................................

M12 90...................................................................................................

M14 105..................................................................................................

M16 180..................................................................................................

UNC / UNF

1/4 9......................................................................................................

5/16 24...................................................................................................

3/8 39.....................................................................................................

7/16 78...................................................................................................

1/2 90.....................................................................................................

5/8 136....................................................................................................

Page 594 of 873

BRAKES

3

DESCRIPTION AND OPERATION Description of components

1. ABS Modulator unit

To provide the ABS function a Modulator is positioned

within the system between the master cylinder and the

calipers. On both LHD and RHD vehicles it is sited on

the left inner wing [fender]. The Modulator has 8

solenoid valves, 2 for each wheel, 2 expanders and a

recirculation pump. It is non serviceable.

2. Servo/master cylinder

Actuation of the system is provided by a combined

master cylinder and servo assembly attached to the

pedal box, this provides pressure to opposed piston

calipers at each brake pad Twin piston at the front

axle, single piston at the rear.

3. Pressure reducing valve

To maintain the braking balance, pressure to the rear

axle is regulated by a Pressure Reducing Valve (PRV)

This PRV is of the failure bypass type, allowing full

system pressure to the rear axle in the event of a front

circuit failure. It is sited on the left inner wing [fender].

4. Electronic control unit - ECU

ABS control is provided by an electronic control unit

which is positioned on the passenger side of the

vehicle behind the dash panel/glove box.

The ECU, which is non-serviceable, is connected to

the ABS harness by a 35 way connector. non

serviceable.

The ECU continually monitors the brake system,

providing diagnostics in the event of a system

malfunction. Details of how to access the ECU

diagnostics are provided in the Electrical

Troubleshooting Manual.

5.& 6. Front and rear sensors/exciter rings - 4 off

A sensor is sited at each wheel, sensing a 60 tooth

exciter ring. When vehicle is in motion inductive

sensors send signals to ECU. Front exciter ring is

fitted to outside diameter of constant velocity joint

inside each front hub assembly. The rear exciter ring

is bolted to the rear of each brake disc bell.7. Diagnostic plug connection

A diagnostic plug is located behind the dash. To the

left of the steering column on LHD vehicles. To the

right of the steering column on RHD vehicles. It is a 5

way blue connector.

The location and identification of ABS electrical relays

are given in the Electrical Troubleshooting Manual.

For location and identification of ABS electrical fuses.

See ELECTRICAL, Repair, Fuse Box - Interioror.

See ELECTRICAL, Repair, Fuse Box - Engine

Compartment

ANTI-LOCK BRAKE SYSTEM - ABS

Manufactured by WABCO

Introduction

The purpose of ABS is to prevent vehicle wheels

locking during brake application, thus maintaining

vehicle steerability and stability. This allows vehicle to

be steered whilst brakes are applied, even under

emergency conditions, and to avoid obstacles where

there is sufficient space to redirect the vehicle.

WARNING: ABS is an aid to retaining

steering control and stability while

braking.

·ABS cannot defy the natural laws of physics

acting on the vehicle.

·ABS will not prevent accidents resulting from

excessive cornering speeds, following

another vehicle too closely or aquaplaning,

i.e. where a layer of water prevents adequate

contact between tyre and road surface.

·The additional control provided by ABS must

never be exploited in a dangerous or

reckless manner which could jeopardise the

safety of driver or other road users.

·The fitting of ABS does not imply that the

vehicle will always stop in a shorter stopping

distance.

Page 601 of 873

BRAKES

1

FAULT DIAGNOSIS ABS FAULT DIAGNOSIS

If a fault has occurred, or has been identified by ECU

self diagnostic function and ABS warning light is

illuminated. The system and components must be

checked to locate and rectify fault, using Testbook

diagnostics.

NOTE: If warning lamp has indicated a

fault in system, and no fault code has been

stored in memory, cause of fault is:

a) Failure in electrical supply

b) Bad ECU ground

c) Faulty warning light relay

d) ECU not connected

Before commencing fault diagnosis procedure

following items must be checked:

1.Inspect all exposed cables for damage or

abrasion.

2.Check ground on ABS system.

3.Battery - state of charge.

4.Check hub end-float.

5.All ABS fuses and electrical connections.

Fault rectification

1.Complete harness should be replaced if faults

are found in wiring harness.

2.DO NOT use unspecified cables or connectors,

as this could jeopardise safe function of ABS.

3.DO NOT attempt to open sealed 35 way

connector to ECU.FAULT DIAGNOSIS PROCEDURE

NOTE: If ABS warning light illuminates due

to large sensor air gap, fault will be

retained by the ECU memory. Where wheel

sensors have been pushed fully home prior to

test, The ECU will indicate a fault that has been

rectified.

NOTE: After any steering adjustment,

bearing replacement/adjustment, brake

disc replacement: Check hub end-float and

sensor clearance.

RELAYS AND FUSES ABS

The location and identification of ABS electrical relays

are given in the Electrical Troubleshooting Manual

For location and identification of ABS electrical fuses.

See ELECTRICAL, Repair, Fuse Box - Interioror.

See ELECTRICAL, Repair, Fuse Box - Engine

Compartment

Page 628 of 873

WHEELS AND TYRES

1

FAULT DIAGNOSIS TYRE WEAR CHART

FAULT CAUSE REMEDY

Rapid wear at Tyres under-inflated Inflate to correct pressure

shoulders Worn suspension components Replace worn components

i.e. ball joints, panhard

rod bushes,steering damper

Excessive cornering speeds

Rapid wear at

centreTyres over-inflated Inflate to correct pressure

of tread

Wear at one

shoulderTrack out of adjustment Adjust track to correct figure

Bent panhard rod Check and replace worn or damaged

components

Bald spots or tyre Wheel out of balance Balance wheel and tyre

cupping assembly

Excessive radial runout Check runout and replace tyre

if necessary

Shock absorber worn Replace shock

Excessive braking

Tyre scalloped Track out of adjustment Adjust toe to correct figure

Worn suspension components Replace as necessary

Excessive cornering speeds

CAUTION: This diagnosis chart is for general guidance only and does not necessarily include

every cause of abnormal tyre wear.

Page 629 of 873

74WHEELS AND TYRES

2

FAULT DIAGNOSIS FAULT - SYMPTOMS

Vibration through steering wheel

1.Check tyre pressures.

See Repair, Tyre

Pressures

2.Check condition of tyres.See Tyre Wear Chart

3.Check front wheel alignment.See STEERING,

Adjustment, Front Wheel Alignment

4.Check wheel balance.See Repair, Wheel

Balancing

NOTE: In the event that any apparent

vibration is not eliminated at this stage.

See PROPELLER SHAFTS, Fault

diagnosis, Vibration Harshness

NOTE: In the event that any apparent

vibration is not eliminated at this stage, go

to steering Fault Diagnosis, Fault -

Symptom (Steering vibration, road wheel

shimmy/wobble).

See STEERING, Fault diagnosis,

Steering Faults

NOTE: Radial ply tyres have a flexible

sidewall, which produces a sidewall bulge

making the tyre appear under-inflated.

This is a normal condition for radial ply tyres. Do

not attempt to reduce this bulge by over-inflating

the tyre.

1. Correct inflation.

2. Under-inflation.

3. Over-inflation.

4. Tread contact with road.

Page 631 of 873

74WHEELS AND TYRES

2

REPAIR When the indicators appear in two or more adjacent

grooves, at three locations around the tyre, a new tyre

must be fitted.

NOTE: Do not attempt to interchange

tyres, e.g. from front to rear, as tyre wear

produces characteristic patterns

depending on their position. If tyre position is

changed after wear has occured, the performance

of the tyre will be adversely affected.

NOTE: Territorial vehicle regulations

governing tyre wear MUST be adhered to.

WHEELS INSPECTION

Regularly check the condition of the wheels. Replace

any wheel that is bent, cracked, dented or has

excessive runout.

VALVES INSPECTION

Check condition of inflation valve. Replace any valve

that is worn, cracked, loose, or leaking air.TYRE PRESSURES

Maximum tyre life and performance will be

obtained only if tyres are maintained at the correct

pressures.

Tyre pressures must be checked at least once a

month and at least once a week, preferably daily, if

the vehicle is used off road.

The tyre inflation pressure is calculated to give the

vehicle satisfactory ride and steering characteristics

without compromising tyre tread life. For

recommended tyre pressures in all conditions.

See

GENERAL SPECIFICATION DATA, Information,

Wheels and Tyres

American vehicles - A label attached to the inside

edge of the driver's door also provides tyre pressure

information.

Always check tyre inflation pressures using an

accurate gauge and inflate tyres to the

recommended pressures only.

Check and adjust tyre pressuresONLYwhen the

tyres are cold, vehicle parked for three hours or more,

or driven for less than 3.2 km (2 miles) at speeds

below 64 km/h (40 mph). Do not reduce inflation

pressures if the tyres are hot or the vehicle has been

driven for more than 3.2 km (2 miles) at speeds over

64 km/h (40 mph), as pressures can increase by 0.41

bars (6 p.s.i) over cold inflation pressures.

CheckALLtyre pressures including the spare. Refit

the valve caps as they form a positive seal and keep

dust out of the valve.

Page 645 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

3

FAULT DIAGNOSIS

4.Airbag modules

A- If defective, replace and dispose of the entire unit

as directed in the instructions. Under no

circumstances should a diagnosis be performed using

electrically powered test equipment or probing

devices.

B- Tampering or mishandling can result in personal

injury. For special handling instruction refer to the

Workshop manual. This airbag module cannot be

repaired. Use diagnostic instructions to determine if

the unit is defective.

C- ROVER Bar code - The code number must be

recorded if the airbag module is to be replaced.

5.Steering wheel

Refer to the Owner's Handbook for information

on the airbag system.