oil temperature LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 20 of 873

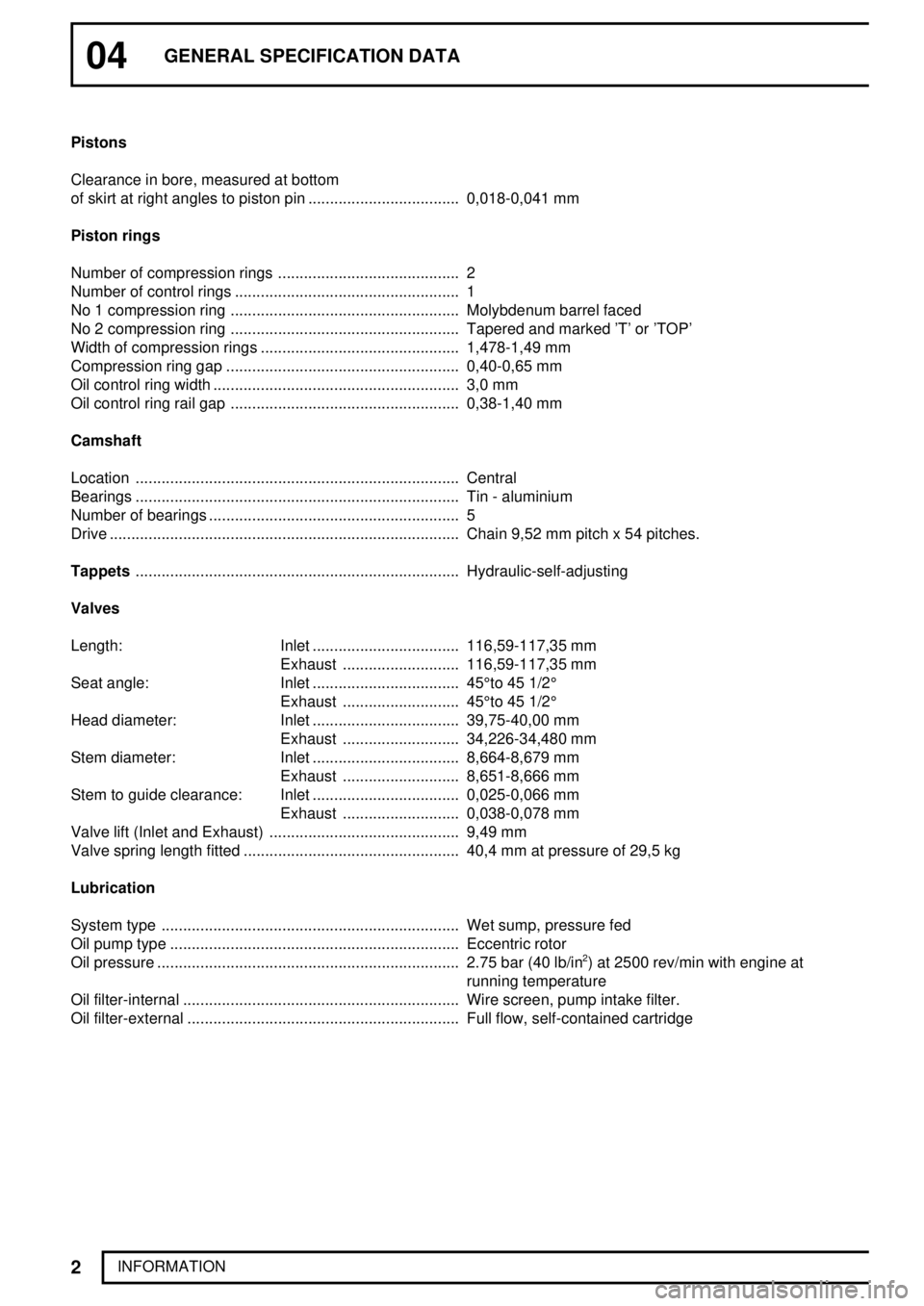

04GENERAL SPECIFICATION DATA

2

INFORMATION Pistons

Clearance in bore, measured at bottom

of skirt at right angles to piston pin 0,018-0,041 mm...................................

Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Molybdenum barrel faced.....................................................

No 2 compression ring Tapered and marked 'T' or 'TOP'.....................................................

Width of compression rings 1,478-1,49 mm..............................................

Compression ring gap 0,40-0,65 mm......................................................

Oil control ring width 3,0 mm.........................................................

Oil control ring rail gap 0,38-1,40 mm.....................................................

Camshaft

Location Central...........................................................................

Bearings Tin - aluminium...........................................................................

Number of bearings 5..........................................................

Drive Chain 9,52 mm pitch x 54 pitches..................................................................................

TappetsHydraulic-self-adjusting ...........................................................................

Valves

Length: Inlet 116,59-117,35 mm..................................

Exhaust 116,59-117,35 mm...........................

Seat angle: Inlet 45°to 45 1/2° ..................................

Exhaust 45°to 45 1/2° ...........................

Head diameter: Inlet 39,75-40,00 mm..................................

Exhaust 34,226-34,480 mm...........................

Stem diameter: Inlet 8,664-8,679 mm..................................

Exhaust 8,651-8,666 mm...........................

Stem to guide clearance: Inlet 0,025-0,066 mm..................................

Exhaust 0,038-0,078 mm...........................

Valve lift (Inlet and Exhaust) 9,49 mm............................................

Valve spring length fitted 40,4 mm at pressure of 29,5 kg..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Eccentric rotor...................................................................

Oil pressure 2.75 bar (40 lb/in

2) at 2500 rev/min with engine at ......................................................................

running temperature

Oil filter-internal Wire screen, pump intake filter.................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

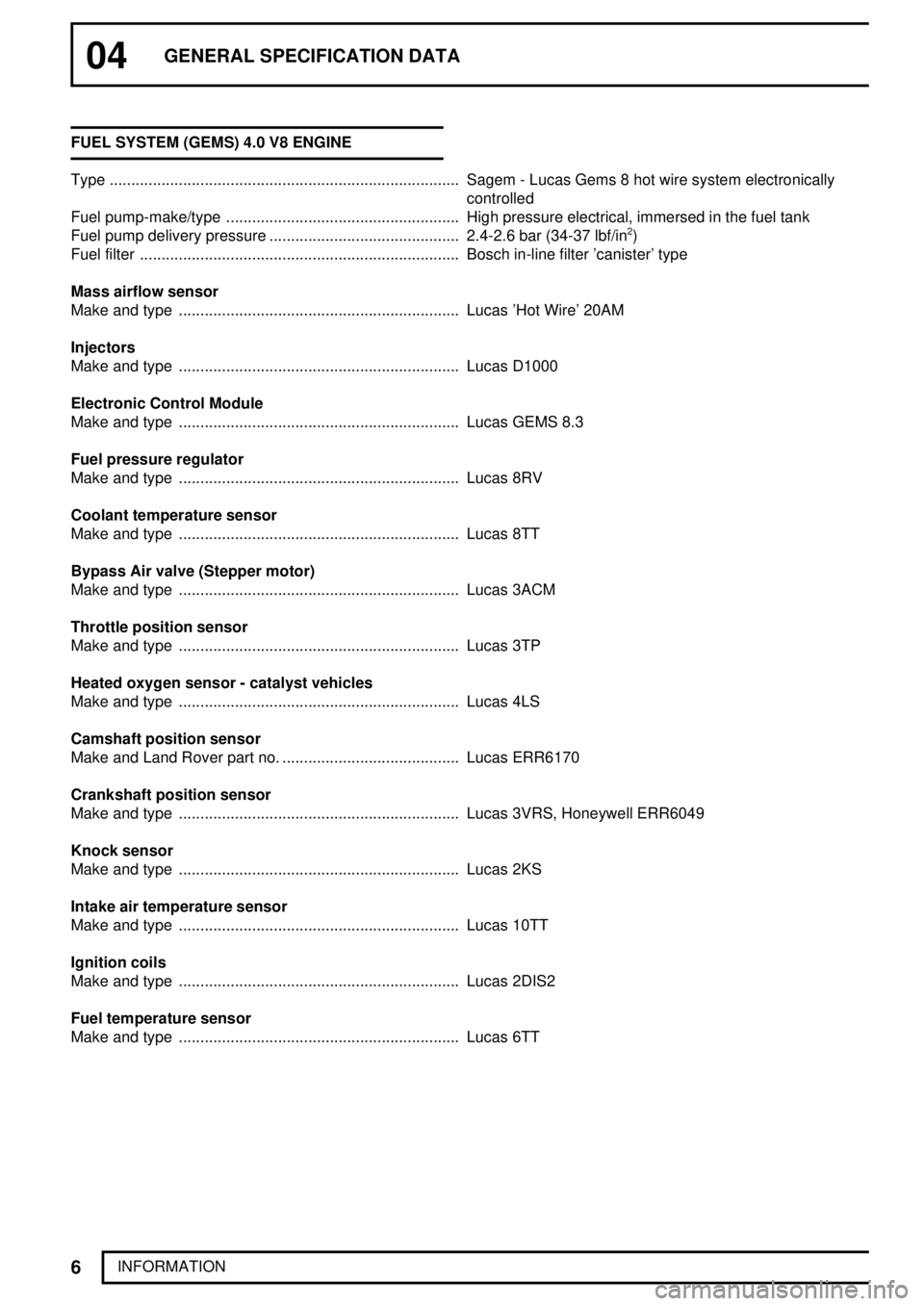

Page 24 of 873

04GENERAL SPECIFICATION DATA

6

INFORMATION FUEL SYSTEM (GEMS) 4.0 V8 ENGINE

Type Sagem - Lucas Gems 8 hot wire system electronically.................................................................................

controlled

Fuel pump-make/type High pressure electrical, immersed in the fuel tank......................................................

Fuel pump delivery pressure 2.4-2.6 bar (34-37 lbf/in

2) ............................................

Fuel filter Bosch in-line filter 'canister' type..........................................................................

Mass airflow sensor

Make and type Lucas 'Hot Wire' 20AM.................................................................

Injectors

Make and type Lucas D1000.................................................................

Electronic Control Module

Make and type Lucas GEMS 8.3.................................................................

Fuel pressure regulator

Make and type Lucas 8RV.................................................................

Coolant temperature sensor

Make and type Lucas 8TT.................................................................

Bypass Air valve (Stepper motor)

Make and type Lucas 3ACM.................................................................

Throttle position sensor

Make and type Lucas 3TP.................................................................

Heated oxygen sensor - catalyst vehicles

Make and type Lucas 4LS.................................................................

Camshaft position sensor

Make and Land Rover part no. Lucas ERR6170.........................................

Crankshaft position sensor

Make and type Lucas 3VRS, Honeywell ERR6049.................................................................

Knock sensor

Make and type Lucas 2KS.................................................................

Intake air temperature sensor

Make and type Lucas 10TT.................................................................

Ignition coils

Make and type Lucas 2DIS2.................................................................

Fuel temperature sensor

Make and type Lucas 6TT.................................................................

Page 57 of 873

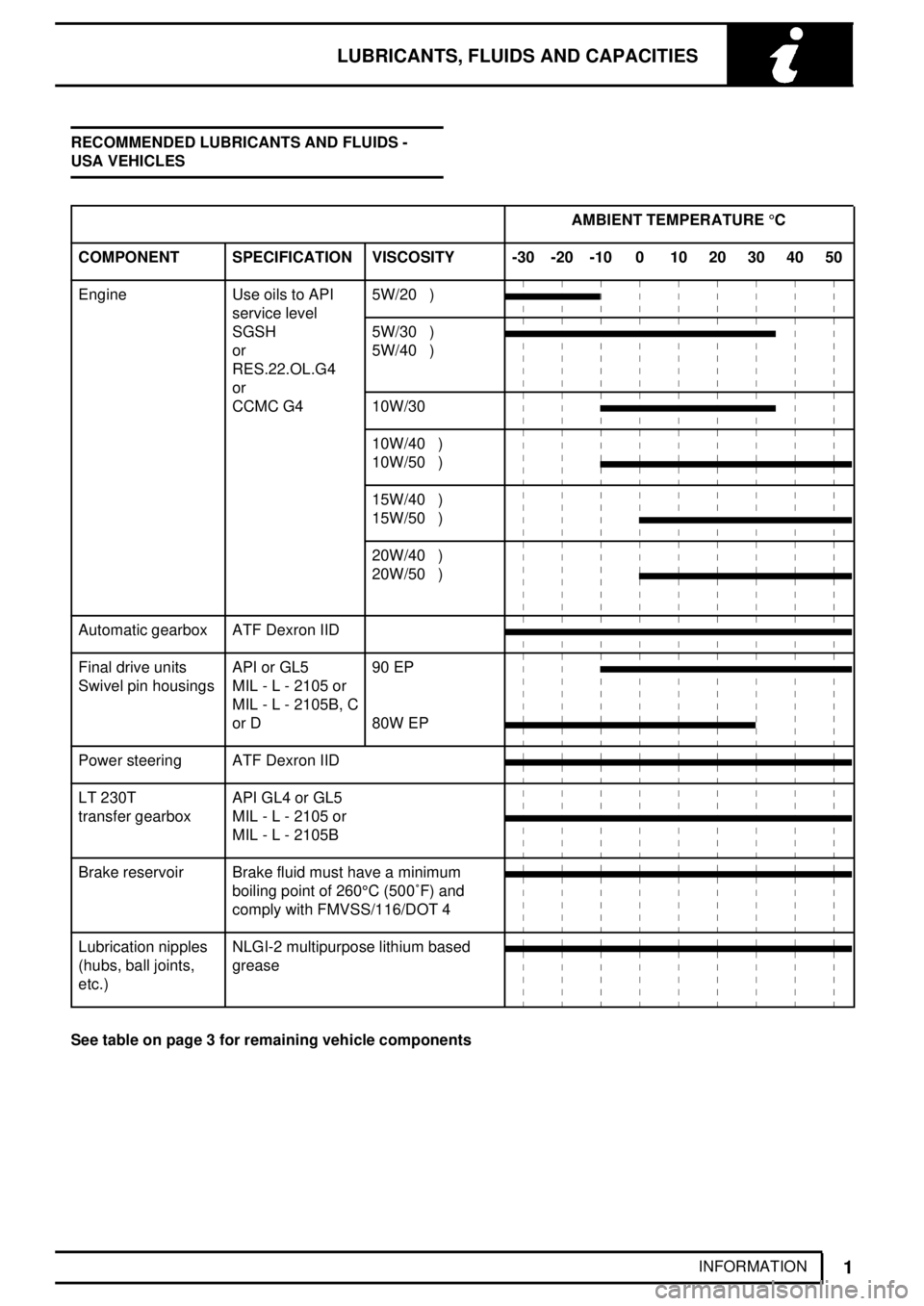

LUBRICANTS, FLUIDS AND CAPACITIES

1

INFORMATION RECOMMENDED LUBRICANTS AND FLUIDS -

USA VEHICLES

AMBIENT TEMPERATURE°C

COMPONENT SPECIFICATION VISCOSITY -30 -20 -10 0 10 20 30 40 50

Engine Use oils to API 5W/20 )

service level

SGSH 5W/30 )

or 5W/40 )

RES.22.OL.G4

or

CCMC G4 10W/30

10W/40 )

10W/50 )

15W/40 )

15W/50 )

20W/40 )

20W/50 )

Automatic gearbox ATF Dexron IID

Final drive units API or GL5 90 EP

Swivel pin housings MIL - L - 2105 or

MIL - L - 2105B, C

or D 80W EP

Power steering ATF Dexron IID

LT 230T API GL4 or GL5

transfer gearbox MIL - L - 2105 or

MIL - L - 2105B

Brake reservoir Brake fluid must have a minimum

boiling point of 260°C (500ÊF) and

comply with FMVSS/116/DOT 4

Lubrication nipples

(hubs, ball joints,

etc.)NLGI-2 multipurpose lithium based

grease

See table on page 3 for remaining vehicle components

Page 58 of 873

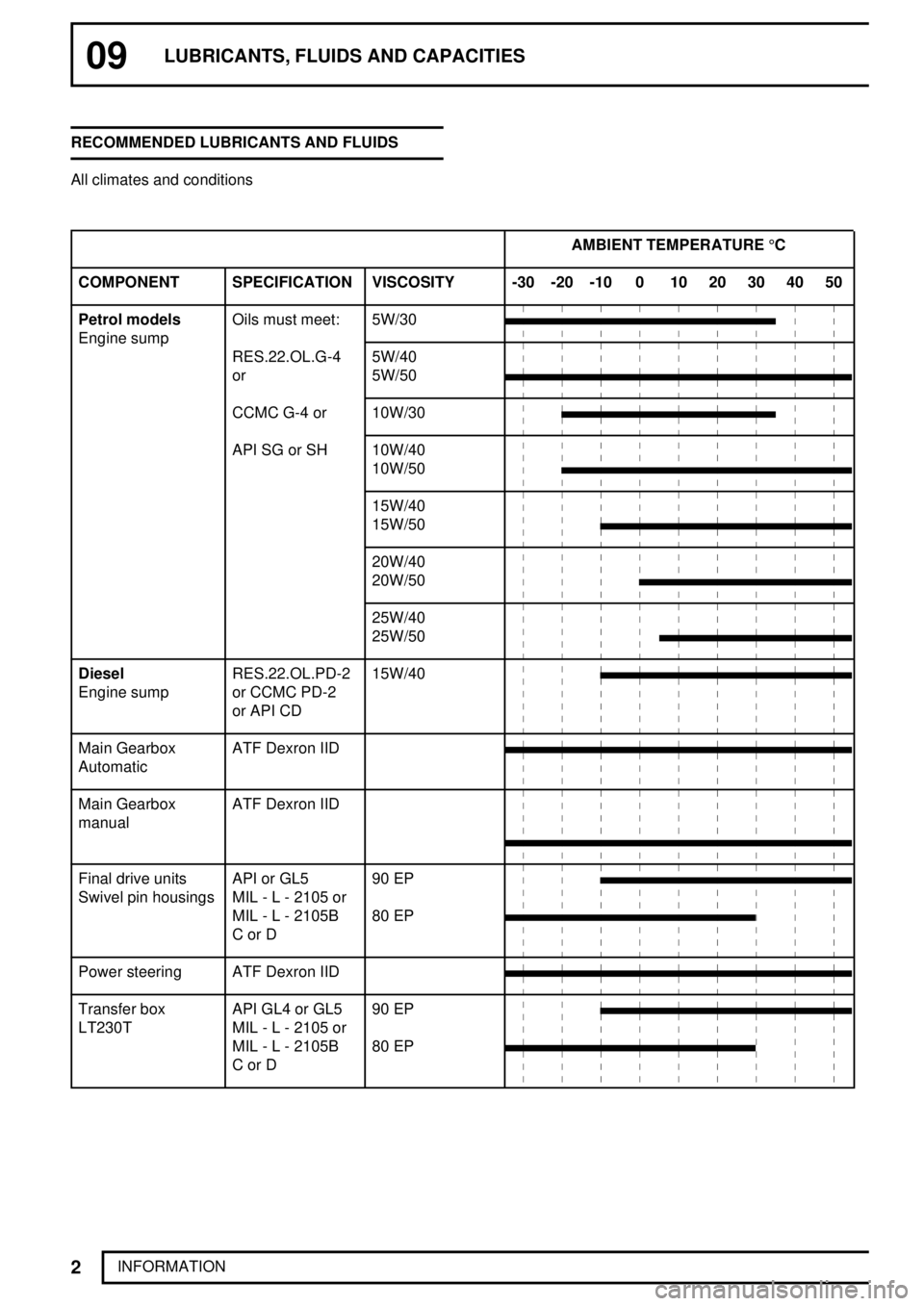

09LUBRICANTS, FLUIDS AND CAPACITIES

2

INFORMATION RECOMMENDED LUBRICANTS AND FLUIDS

All climates and conditions

AMBIENT TEMPERATURE°C

COMPONENT SPECIFICATION VISCOSITY -30 -20 -10 0 10 20 30 40 50

Petrol modelsOils must meet: 5W/30

Engine sump

RES.22.OL.G-4 5W/40

or 5W/50

CCMC G-4 or 10W/30

API SG or SH 10W/40

10W/50

15W/40

15W/50

20W/40

20W/50

25W/40

25W/50

DieselRES.22.OL.PD-2 15W/40

Engine sump or CCMC PD-2

or API CD

Main Gearbox

AutomaticATF Dexron IID

Main Gearbox

manualATF Dexron IID

Final drive units API or GL5 90 EP

Swivel pin housings MIL - L - 2105 or

MIL - L - 2105B 80 EP

CorD

Power steering ATF Dexron IID

Transfer box API GL4 or GL5 90 EP

LT230T MIL - L - 2105 or

MIL - L - 2105B 80 EP

CorD

Page 61 of 873

LUBRICANTS, FLUIDS AND CAPACITIES

5

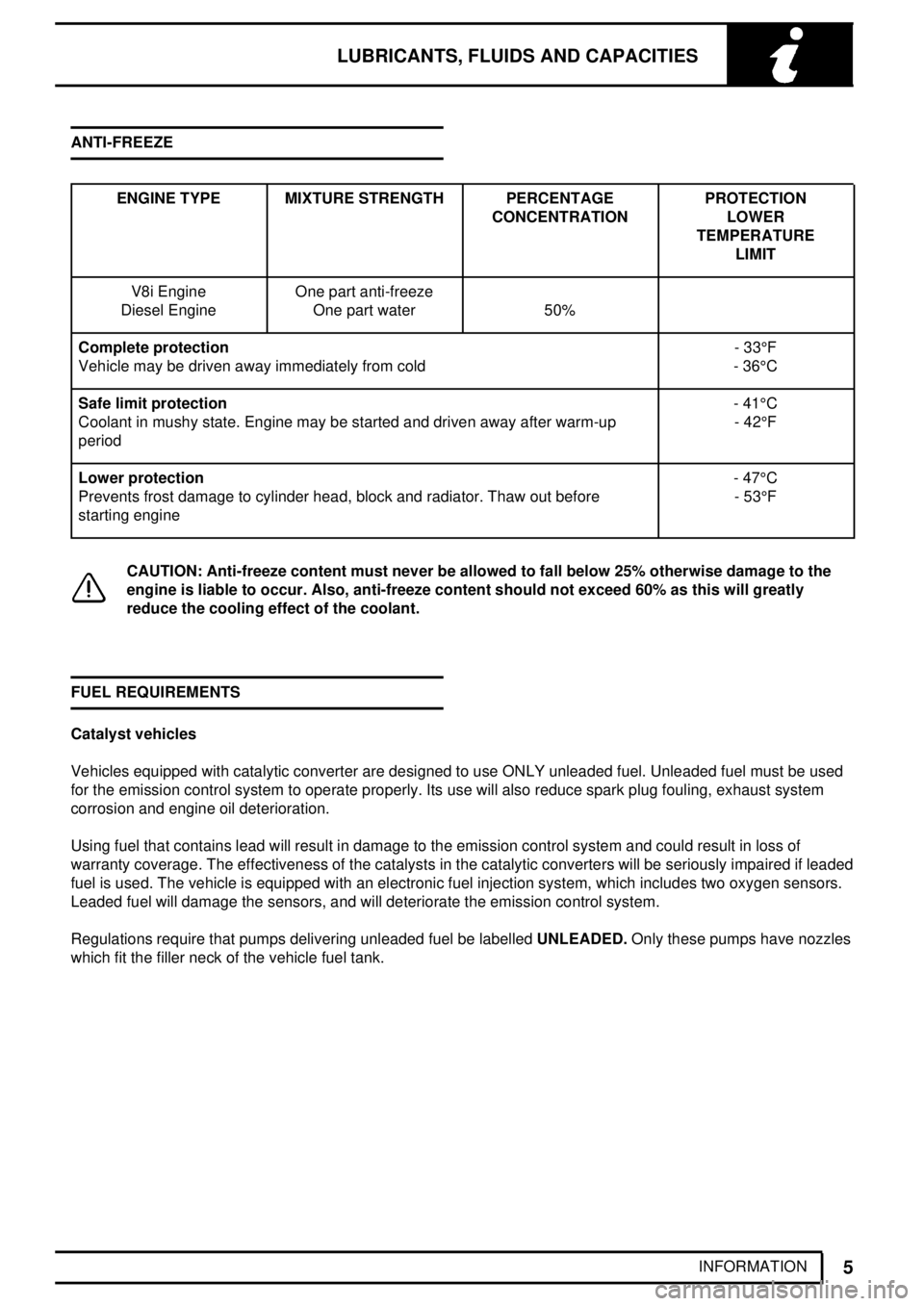

INFORMATION ANTI-FREEZE

ENGINE TYPE MIXTURE STRENGTH PERCENTAGE PROTECTION

CONCENTRATION LOWER

TEMPERATURE

LIMIT

V8i Engine One part anti-freeze

Diesel Engine One part water 50%

Complete protection-33°F

Vehicle may be driven away immediately from cold - 36°C

Safe limit protection-41°C

Coolant in mushy state. Engine may be started and driven away after warm-up

period-42°F

Lower protection-47°C

Prevents frost damage to cylinder head, block and radiator. Thaw out before

starting engine-53°F

CAUTION: Anti-freeze content must never be allowed to fall below 25% otherwise damage to the

engine is liable to occur. Also, anti-freeze content should not exceed 60% as this will greatly

reduce the cooling effect of the coolant.

FUEL REQUIREMENTS

Catalyst vehicles

Vehicles equipped with catalytic converter are designed to use ONLY unleaded fuel. Unleaded fuel must be used

for the emission control system to operate properly. Its use will also reduce spark plug fouling, exhaust system

corrosion and engine oil deterioration.

Using fuel that contains lead will result in damage to the emission control system and could result in loss of

warranty coverage. The effectiveness of the catalysts in the catalytic converters will be seriously impaired if leaded

fuel is used. The vehicle is equipped with an electronic fuel injection system, which includes two oxygen sensors.

Leaded fuel will damage the sensors, and will deteriorate the emission control system.

Regulations require that pumps delivering unleaded fuel be labelledUNLEADED.Only these pumps have nozzles

which fit the filler neck of the vehicle fuel tank.

Page 100 of 873

Tdi

19

REPAIR OIL TEMPERATURE CONTROL VALVE

Service repair no - 12.60.69

Remove

1.Disconnect oil cooler pipes.

2.Remove two bolts and carefully withdraw

thermostat extension housing (1) complete with

O ring seal (2), thermostat (3), two washers (4)

and spring (5).

3.Clean adaptor housing.

4.Inspect all parts and renew as necessary.

Refit

5.Fit thermostat to extension housing ensuring pin

locates in hole.

6.Fit two washers and spring to thermostat.

7.Fit a new 'O' ring to extension housing.

8.Insert spring into adaptor and secure extension

housing to adaptor with bolts. Tighten to

9 Nm.

OIL FILTER HEAD GASKET

Service repair no - 12.60.03

Renew

1.Disconnect oil cooler pipes.

2.Disconnect pressure switch lead.

3.Remove securing bolts and withdraw head

complete with gasket.

4.Clean mating faces.

5.Refit head with new gasket.

6.Secure with bolts. Tighten to

45 Nm.

7.Refit pipes and reconnect pressure switch.

Page 114 of 873

V8i

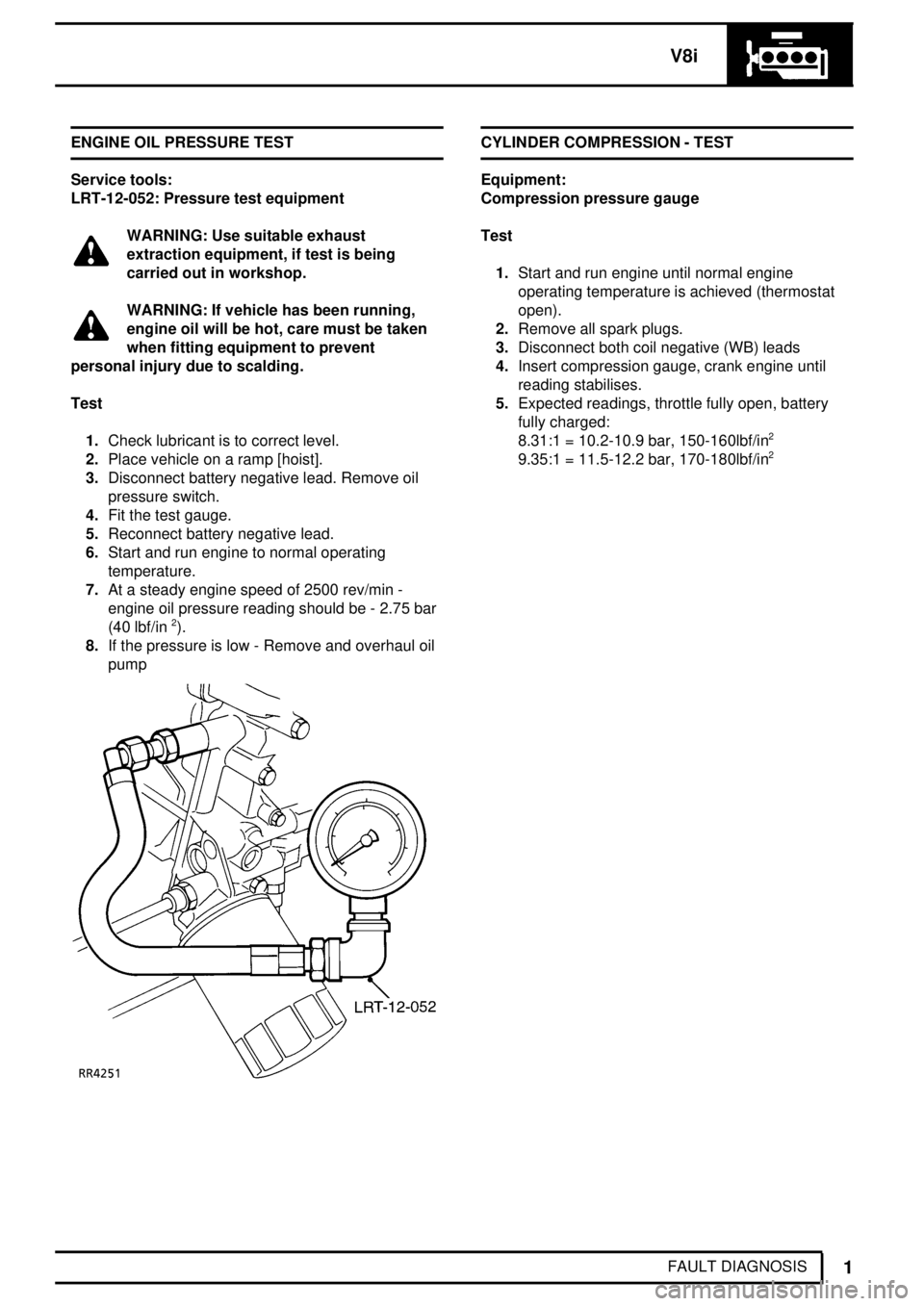

1

FAULT DIAGNOSIS ENGINE OIL PRESSURE TEST

Service tools:

LRT-12-052: Pressure test equipment

WARNING: Use suitable exhaust

extraction equipment, if test is being

carried out in workshop.

WARNING: If vehicle has been running,

engine oil will be hot, care must be taken

when fitting equipment to prevent

personal injury due to scalding.

Test

1.Check lubricant is to correct level.

2.Place vehicle on a ramp [hoist].

3.Disconnect battery negative lead. Remove oil

pressure switch.

4.Fit the test gauge.

5.Reconnect battery negative lead.

6.Start and run engine to normal operating

temperature.

7.At a steady engine speed of 2500 rev/min -

engine oil pressure reading should be - 2.75 bar

(40 lbf/in

2).

8.If the pressure is low - Remove and overhaul oil

pump

CYLINDER COMPRESSION - TEST

Equipment:

Compression pressure gauge

Test

1.Start and run engine until normal engine

operating temperature is achieved (thermostat

open).

2.Remove all spark plugs.

3.Disconnect both coil negative (WB) leads

4.Insert compression gauge, crank engine until

reading stabilises.

5.Expected readings, throttle fully open, battery

fully charged:

8.31:1 = 10.2-10.9 bar, 150-160lbf/in

2

9.35:1 = 11.5-12.2 bar, 170-180lbf/in2

Page 131 of 873

V8i

13

REPAIR

NOTE: Release bolts securing compressor

mounting bracket to engine and remove

bracket to enable temporary lifting eye

ETC 5964 to be fitted. Secure lifting eye to

mounting bracket fixing points with suitable bolts

of equivalent size, pitch and thread. Leave lifting

eye attached until engine is reinstalled in vehicle.

15.Place drain tray underneath vehicle.

16.Disconnect hose from reservoir to power

steering pump. Secure hose end above level of

fluid reservoir to avoid unnecessary loss of fluid.

17.Disconnect power steering pump to power

steering box hose. Seal hose and pump

openings with masking tape to prevent ingress of

dirt. Wipe away any fluid spillage from chassis or

steering box.

18.Disconnect fuel temperature and coolant

temperature sensor multi-plugs.

19.Disconnect leads from coil.

20.Identify each injector multi-plug for re-assembly

and disconnect plugs from injectors.

21.Manoeuvre harness from behind fuel rails and

place to one side clear of engine assembly.

22.Remove two clamps securing gearbox oil cooler

pipes to engine block.

23.Remove engine mounting fixings on both sides

of cylinder block.

24.Fit lifting chains to engine lifting eyes as shown

in illustration RR1780E.

1. L/H Front chain 356mm total overall length.

2. R/H Front chain 330mm total overall length.

3. R/H Rear chain 457mm total overall length.

NOTE: All chain dimensions are measured

from end of lifting hook to end of last link

in chain.

25.Fit chain lifting eye to a suitable engine hoist.

Raise hoist high enough to enable engine

mountings to be removed, and withdraw rubber

mountings.

26.Lower hoist until engine rests securely on engine

mounting brackets. Remove lifting chains and

hoist.

27.Disconnect two heater hoses located on top of

right hand rocker cover.

28.Remove ground strap from rear of left hand

cylinder head. DO NOT remove from retaining

clip.

29.Remove all electrical harnesses from retaining

clips at rear of engine.

30.Remove transmission breather pipes from

retaining clip on rear lifting eye.

31.Remove top two bolts securing bell housing to

cylinder block.

32.Raise front of vehicle, lower vehicle on to axle

stands.

33.Remove bell housing bottom cover. Remove

gasket from bell housing face.

34.Remove nuts securing exhaust downpipes to

manifolds, remove heat shield from right hand

side downpipe.

35.Remove electrical leads from starter motor

solenoid. Disconnect multi-plug from oil level

sensor on side of sump, if fitted.

NOTE: Instructions 37, 38 and 39 refer to

automatic vehicles only.

36.With assistance rotate engine at crankshaft

pulley until two access holes in drive plate/ring

gear assembly are visible.

37.Remove two bolts visible through access holes.

Mark one access hole and one bolt hole to

ensure unit is reassembled in its original position

38.Rotate crankshaft 180Ê until two remaining

access holes are visible, remove two bolts.

Page 139 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Rep LAND ROVER DISCOVERY 1995 Workshop Manual 4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Rep](/img/64/57248/w960_57248-138.png)

4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Repair, Radiator

4.Remove plenum chamber.See FUEL SYSTEM

SFI, Repair, Plenum Chamber

5.Remove mass air flow sensor.See FUEL

SYSTEM SFI, Repair, Mass Air Flow Sensor

(MAF Sensor)

6.Slacken hose clip securing bottom hose to

expansion tank.

7.Disconnect hose.

8.Remove 2 nuts securing expansion tank.

9.Remove nut and bolt securing expansion tank.

10.Remove expansion tank.

11.Disconnect servo vacuum hose from ram

housing.

12.Disconnect battery sensing lead Lucar from

generator.

13.Remove generator terminal cover.

14.Remove 2 terminal nuts and release leads from

terminals.

15.Release purge hose from ram pipe housing.

16.Position cloth to absorb fuel spillage.

17.Slacken clip securing fuel return hose to fuel rail.

18.Disconnect hose.

19.Plug connections.

20.Disconnect fuel feed hose union.

21.Plug connections. Position hoses aside.

22.Slacken clip securing heater return hose to pipe.

23.Disconnect hose.24.Slacken clip securing heater feed adaptor hose

to inlet manifold.

25.Remove bolt securing pipe bracket.

26.Disconnect feed hose from inlet manifold.

27.Disconnect hose/pipe assembly.

28.Disconnect leads from spark plugs and remove

ignition coils.

See FUEL SYSTEM SFI, Repair,

Ignition Coils

29.Disconnect fuel temperature sensor multiplug.

30.Disconnect coolant sensor multiplug.

31.Disconnect temperature gauge sensor lead.

32.Release camshaft sensor multiplug from bracket

and disconnect multiplug.

33.Disconnect oil pressure switch Lucar.

34.Disconnect air intake temperature sensor

multiplug.

35.Disconnect 8 injector multiplugs.

36.Remove 4 nuts securing harness brackets to

inlet manifold.

37.Release harness brackets.

38.Remove bolts securing gearbox breather pipes

to engine lifting bracket.

Page 143 of 873

4.0 V8

7

REPAIR 171.Route drive belt around pulleys.

172.Pivot tensioner downwards.

173.Align belt to tensioner and release tensioner.

174.Connect battery positive lead and tighten.

175.Secure terminal cover.

176.Align gearbox breather pipe, clip to engine lifting

eye and fit bolt. Tighten to

9 Nm.

177.Align and secure engine harness brackets to

inlet manifold and fit nuts. Tighten to

9 Nm.

178.Connect injector multiplugs.

179.Connect air intake temperature sensor multiplug.

180.Connect fuel temperature sensor multiplug.

181.Connect coolant temperature multiplug.

182.Connect temperature gauge connector.

183.Connect oil pressure switch Lucar.

184.Connect camshaft sensor multiplug and secure

to bracket.

185.Fit ignition coil bracket.

See FUEL SYSTEM

SFI, Repair, Ignition Coils

186.Position heater hose/pipe assembly.

187.Connect hose to inlet manifold.

188.Align pipe to bracket and fit bolt. Tighten to

9

Nm.

189.Tighten hose clip.

190.Connect heater return hose and tighten clip.

191.Remove plugs from fuel feed and return hose

connections.

192.Clean feed unions.

193.Connect return hose and tighten clip.

194.Connect feed hose union and tighten.

195.Remove cloth.

196.Connect purge hose.

197.Connect leads to generator, tighten terminal nuts

and fit cover.

198.Connect sensing Lucar.

199.Connect servo vacuum hose.

200.Position expansion tank and secure with fixings.

201.Connect hose and tighten clip.

202.Lower ramp.

203.Fit mass air flow sensor.

See FUEL SYSTEM

SFI, Repair, Mass Air Flow Sensor (MAF

Sensor)

204.Fit plenum chamber.See FUEL SYSTEM SFI,

Repair, Plenum Chamber

205.Fit radiator.See COOLING SYSTEM, Repair,

Radiator

206.Fit bonnet.See CHASSIS AND BODY, Repair,

Bonnet [Hood]

207.Reconnect battery negative lead.

208.Bleed power steering system.

See STEERING,

Repair, Power Steering System - Bleed

209.Drain engine oil and refill.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids - USA

Vehicles

210.Start engine. Check for fuel, coolant and oil

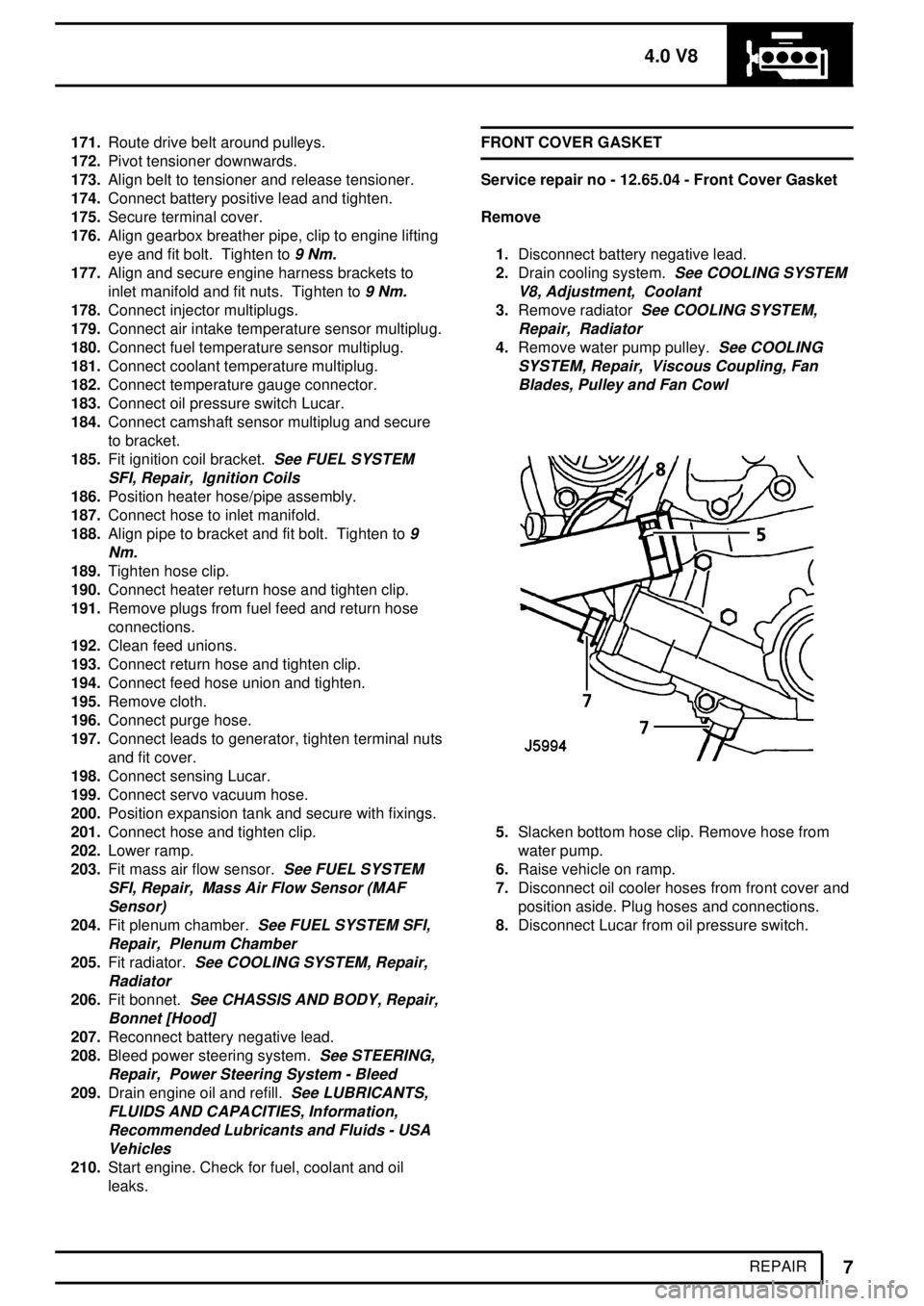

leaks.FRONT COVER GASKET

Service repair no - 12.65.04 - Front Cover Gasket

Remove

1.Disconnect battery negative lead.

2.Drain cooling system.

See COOLING SYSTEM

V8, Adjustment, Coolant

3.Remove radiatorSee COOLING SYSTEM,

Repair, Radiator

4.Remove water pump pulley.See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

5.Slacken bottom hose clip. Remove hose from

water pump.

6.Raise vehicle on ramp.

7.Disconnect oil cooler hoses from front cover and

position aside. Plug hoses and connections.

8.Disconnect Lucar from oil pressure switch.