display LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 31 of 1529

CONTENTS

28 CONTENTS

DRIVING AIDS .......................................................................................... 86-8-1

DESCRIPTION AND OPERATION

Park Distance Control – Component Location................................................................................ 86-8-1

Park Distance Control – Control Diagram....................................................................................... 86-8-2

Description ...................................................................................................................................... 86-8-4

Operation ........................................................................................................................................ 86-8-11

REPAIRS

Control unit (ECU) - park distance control (PDC) ........................................................................... 86-8-13

Sounder - parking aid rear ............................................................................................................. 86-8-14

Sensor - parking aid - rear - inner ................................................................................................... 86-8-15

Sensor - parking aid - rear - outer .................................................................................................. 86-8-16

NAVIGATION SYSTEM ............................................................................ 87-1

DESCRIPTION AND OPERATION

Harman/Becker Navigation System Component Location.............................................................. 87-1

Description ...................................................................................................................................... 87-2

DESCRIPTION AND OPERATION

CARiN III Navigation and Trafficmaster System Component Location........................................... 87-12

Description ...................................................................................................................................... 87-14

Operation ........................................................................................................................................ 87-20

REPAIRS

Interface electronic control unit (ECU) - remote control ................................................................. 87-29

Display unit .................................................................................................................................... 87-30

INSTRUMENTS ......................................................................................... 88-1

DESCRIPTION AND OPERATION

Instrument pack .............................................................................................................................. 88-1

Instrument component location - Engine compartment / underneath vehicle ................................. 88-2

Instrument component location - Passenger compartment ............................................................ 88-3

Instrument block diagram ............................................................................................................... 88-4

Description ...................................................................................................................................... 88-5

Interior rear view mirror with compass (where fitted) ..................................................................... 88-42

REPAIRS

Clock ............................................................................................................................................... 88-45

Instrument pack ............................................................................................................................ 88-45

Page 35 of 1529

INTRODUCTION

01-4

λLambda

lc Low compression

LCD Liquid Crystal Display

LED Light Emitting Diode

LH Left-Hand

LHD Left-Hand Drive

LVS Liquid Vapour Separator

mMetre

µMicro

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MFU Multi-Function Unit

MFL Multi-Function Logic

max. Maximum

MEMS Modular Engine Management

System

MIL Malfunction Indicator Lamp

min. Minimum

MPa MegaPascal

- Minus (tolerance)

' Minute (angle)

mm Millimetre

mph Miles per hour

MPi Multi-Point injection

MY Model Year

NAS North American Specification

(-) Negative (electrical)

Nm Newton metre

No. Number

NO

2Nitrogen Dioxide

NO

xOxides of Nitrogen

NTC Negative Temperature

Coefficient

OBD On Board Diagnostics

o.dia. Outside diameter

ORM Off-road Mode

ΩOhm

PAS Power Assisted Steering

PCV Positive Crankcase Ventilation

PDC Parking Distance Control

% Percentage

+ Plus (tolerance) or Positive

(electrical)

±Plus or minus (tolerance)

PTC Positive Temperature Coefficient

PTFE Polytetrafluorethylene

PWM Pulse Width Modulation

rRadius

:Ratio

ref Reference

RES Rover Engineering Standards

rev/min Revolutions per minute

RF Radio Frequency

RH Right-Hand

RHD Right-Hand Drive

ROM Read Only Memory

RON Research Octane Number

ROV Roll Over ValveROW Rest Of World

SAE Society of Automotive Engineers

" Second (angle)

SLABS Self Levelling and Anti-Lock

Brake System

SLS Self Levelling Suspension

SOHC Single Overhead Camshaft

sp.gr Specific gravity

SRS Supplementary Restraint System

std. Standard

synchro Synchronizer or synchromesh

TDC Top Dead Centre

TMAP Temperature, Manifold Absolute

Pressure

TP Throttle Position

TPS Throttle Position Sensor

TV Torsional Vibration

TXV Thermostatic Expansion Valve

UK United Kingdom

US United States

V Volt

Var. Variable

VIN Vehicle Identification Number

VIS Variable Intake System

VRS Variable Reluctance Sensor

VSS Vehicle Speed Signal

WWatt

Page 57 of 1529

GENERAL INFORMATION

03-22

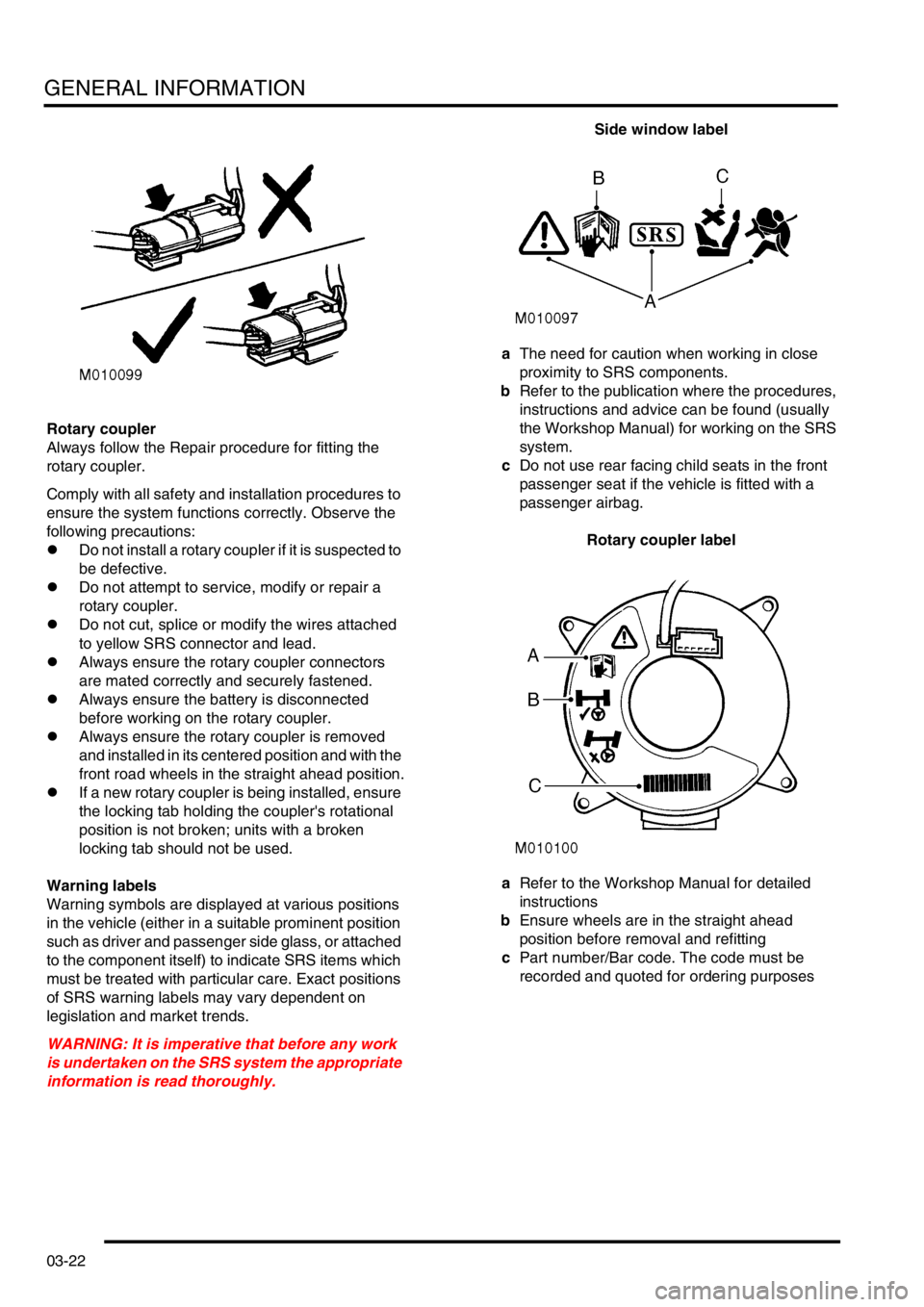

Rotary coupler

Always follow the Repair procedure for fitting the

rotary coupler.

Comply with all safety and installation procedures to

ensure the system functions correctly. Observe the

following precautions:

lDo not install a rotary coupler if it is suspected to

be defective.

lDo not attempt to service, modify or repair a

rotary coupler.

lDo not cut, splice or modify the wires attached

to yellow SRS connector and lead.

lAlways ensure the rotary coupler connectors

are mated correctly and securely fastened.

lAlways ensure the battery is disconnected

before working on the rotary coupler.

lAlways ensure the rotary coupler is removed

and installed in its centered position and with the

front road wheels in the straight ahead position.

lIf a new rotary coupler is being installed, ensure

the locking tab holding the coupler's rotational

position is not broken; units with a broken

locking tab should not be used.

Warning labels

Warning symbols are displayed at various positions

in the vehicle (either in a suitable prominent position

such as driver and passenger side glass, or attached

to the component itself) to indicate SRS items which

must be treated with particular care. Exact positions

of SRS warning labels may vary dependent on

legislation and market trends.

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.Side window label

aThe need for caution when working in close

proximity to SRS components.

bRefer to the publication where the procedures,

instructions and advice can be found (usually

the Workshop Manual) for working on the SRS

system.

cDo not use rear facing child seats in the front

passenger seat if the vehicle is fitted with a

passenger airbag.

Rotary coupler label

aRefer to the Workshop Manual for detailed

instructions

bEnsure wheels are in the straight ahead

position before removal and refitting

cPart number/Bar code. The code must be

recorded and quoted for ordering purposes

Page 83 of 1529

GENERAL DATA

04-20

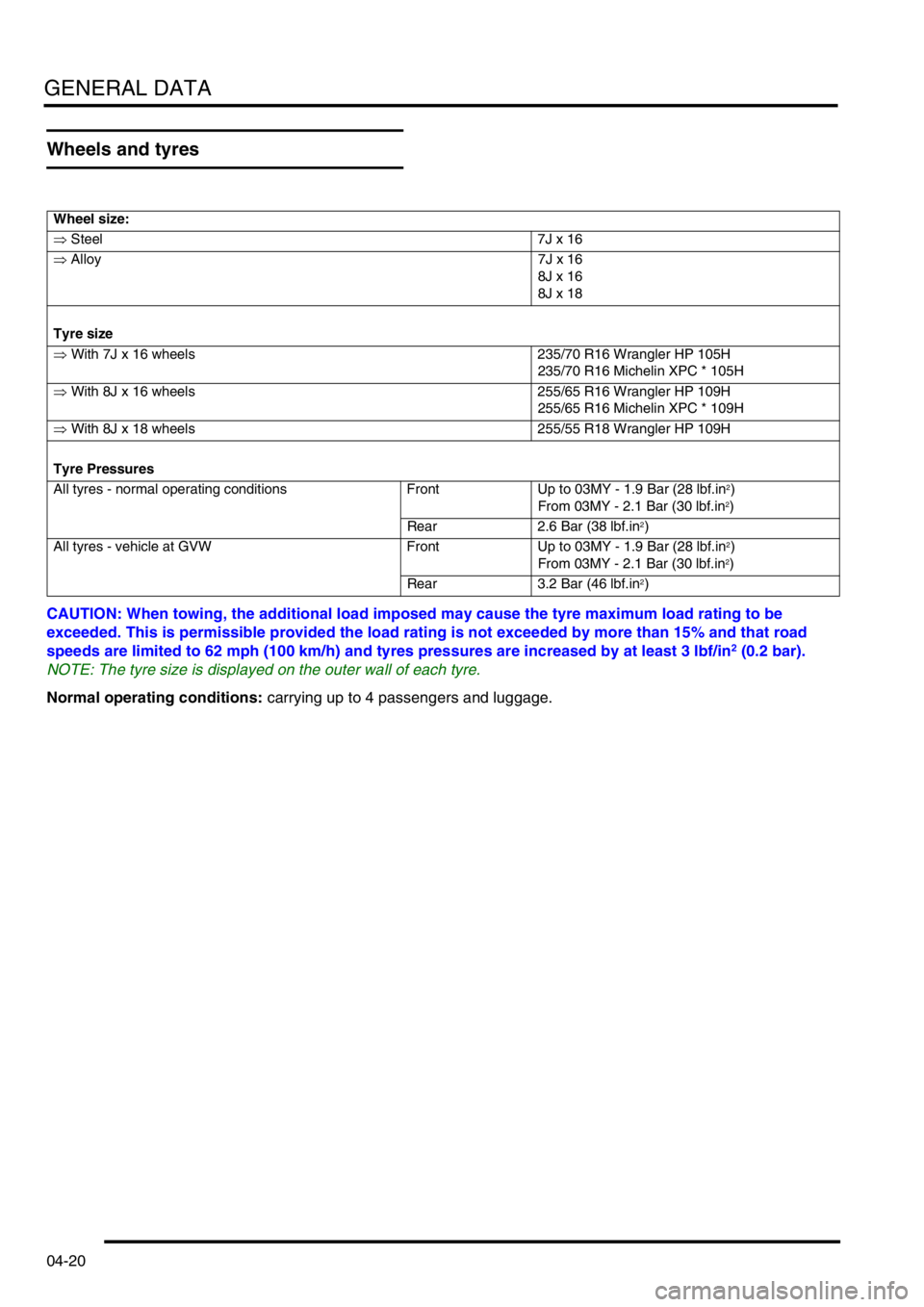

Wheels and tyres

CAUTION: When towing, the additional load imposed may cause the tyre maximum load rating to be

exceeded. This is permissible provided the load rating is not exceeded by more than 15% and that road

speeds are limited to 62 mph (100 km/h) and tyres pressures are increased by at least 3 lbf/in

2 (0.2 bar).

NOTE: The tyre size is displayed on the outer wall of each tyre.

Normal operating conditions: carrying up to 4 passengers and luggage.

Wheel size:

⇒ Steel 7J x 16

⇒ Alloy 7J x 16

8J x 16

8J x 18

Tyre size

⇒ With 7J x 16 wheels 235/70 R16 Wrangler HP 105H

235/70 R16 Michelin XPC * 105H

⇒ With 8J x 16 wheels 255/65 R16 Wrangler HP 109H

255/65 R16 Michelin XPC * 109H

⇒ With 8J x 18 wheels 255/55 R18 Wrangler HP 109H

Tyre Pressures

All tyres - normal operating conditions Front Up to 03MY - 1.9 Bar (28 lbf.in

2)

From 03MY - 2.1 Bar (30 lbf.in2)

Rear 2.6 Bar (38 lbf.in

2)

All tyres - vehicle at GVW Front Up to 03MY - 1.9 Bar (28 lbf.in

2)

From 03MY - 2.1 Bar (30 lbf.in2)

Rear 3.2 Bar (46 lbf.in

2)

Page 1200 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-11

ATC ECU

The ATC ECU is installed in the centre of the fascia, below the radio. An integral control panel on the ATC ECU

contains switches for system control inputs and a LCD to provide system status information.

Inputs from sensors and the control panel switches are processed by the ATC ECU, which then outputs the

appropriate control signals.

ATC ECU connectors

ATC ECU connector pin details

Connector/Pin

No.Description Input/Output

C0791

1 Battery power supply Input

2 Ignition power supply Input

3 Sensor power supply Output

4Earth -

5 Display illumination Input

6 Not used -

7 Not used -

8 Sensor earth -

C0792

1 Night lighting/dimming Input

2 Vehicle speed Input

3 Hand of drive Input

4 Distribution flaps position Input

5 Heater coolant temperature Input

6 External air temperature Input

7 In-car air temperature Input

8 Blower power transistor collector voltage Input

9 Not used -

10 Not used -

11 Windscreen heater status Input

12 Rear screen heater status Input

13 Rear air conditioning ON Input

Page 1201 of 1529

AIR CONDITIONING

82-12DESCRIPTION AND OPERATION

Control panel

1LH temperature switch

2Economy mode (ECON) switch

3Blower switch

4Display

5Distribution switch

6External air temperature (EXT) switch7RH temperature switch

8Fresh/Recirculated air switch

9Defrost mode switch

10Automatic mode (AUTO) switch

11A/C on/off switch

14 Driver's blend flaps position Input

15 Passenger's blend flaps position Input

16 LH solar heating load Input

17 RH solar heating load Input

18 Evaporator Input

19 Not used -

20 Not used -

C0793

1 Blower power transistor base current Output

2 Blower relay Output

3 Windscreen heater request Output

4 Rear screen heater request Output

5 Passenger's blend flaps servo motor, drive to hot Output

6 Driver's blend flaps servo motor, drive to hot Output

7 Distribution flaps servo motor, drive to windscreen and side

windows demistOutput

8 Fresh/Recirculated air servo motor, drive to recirculated air Output

9 Cooling fan request (diesel models) Output

10 Power relay Output

11 Compressor clutch request Output

12 Cooling fan request (V8 models) Output

13 Passenger's blend flaps servo motor, drive to cold Output

14 Driver's blend flaps servo motor, drive to cold Output

15 Distribution flaps servo motor, drive to footwells Output

16 Fresh/Recirculated air servo motor, drive to fresh air Output Connector/Pin

No.Description Input/Output

Page 1202 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-13

The control panel switches are all non-latching pushswitches except for the LH and RH temperature switches, which

are centre-off rocker switches. The switches have the following functions:

LH and RH temperature switches. Enabled only while the system is on:

lEach press increases or decreases the related temperature setting, in steps of 1 °C (2 °F), between 16 and 28

°C (60 and 84 °F).

lIf the decrease side of the switch is pressed when a temperature of 16 °C (60 °F) is set, the display changes to

LO (maximum cold).

lIf the increase side of the switch is pressed when a temperature of 28 °C (84 °F) is set, the display changes to

HI (maximum hot).

lIf a switch is kept depressed, step changes occur every 0.4 seconds.

A/C on/off switch. Switches the system on and off. When used to switch the system on, the system resumes the

configuration in use prior to the previous off selection.

Blower switch. Enabled only while the system is on. Provides manual control of blower speed:

lEach press changes the blower speed, in sequence, through off (only available if economy mode is selected on)

and five incremental speeds.

lIf the switch is kept depressed, after 1 second subsequent speed increments occur every 0.4 second until blower

reaches high speed. Releasing and then pressing the switch again changes blower back to off or low speed.

Distribution switch. Enabled only while the system is on. Provides manual control of air distribution:

lEach press changes the air distribution, in sequence, through footwells only, footwells and windscreen/side

windows demist, windscreen/side windows demist only, face level only, face level and footwells.

lIf the switch is kept depressed, after 1 second subsequent distribution changes occur every 0.4 seconds until

distribution reaches face level and footwells. Releasing and then pressing the switch again changes distribution

back to footwells only.

External air temperature (EXT) switch. Enabled while the system is on or off. Switches the external temperature output

on and off:

lIf the system is already on, the temperature output overrides the system outputs for approximately 7 seconds,

then the display reverts to system outputs.

lIf the system is switched on while the external temperature output is on, the system outputs override the external

temperature output.

Fresh/Recirculated air switch. Enabled only while the system is on. Provides manual control of inlet air selection.

Defrost mode switch. Starts the system in, or switches the system to and from, defrost mode.

Automatic mode (AUTO) switch. Starts the system in, or switches the system to and from, the automatic mode.

Economy mode (ECON) switch. Enabled only while the system is on. Provides manual on/off control of the refrigerant

system compressor, to reduce fuel consumption when there is no requirement for cool or dehumidified air, e.g. when

the ambient temperature is lower than the LH and RH temperature settings.

Temperature settings: The LH and RH temperature settings are reference inputs used by the control system and give

an approximation of the temperatures that will be established in the cabin. They are not necessarily actual distribution

outlet temperatures, or the temperatures at specific points in the cabin.

Audible warning: A 'beep' is emitted from the ATC ECU each time it receives a control switch input. This audible

warning can be switched off and on by pressing and holding the AUTO switch, then pressing and holding the A/C on/

off switch until the audible warning sounds (approximately 3 seconds). While switched off, the audible warning still

sounds when:

lSwitching between °F and °C on the display.

lSwitching the audible warning from off to on.

lSwitching the timed feet function on and off.

lSwitching the timed recirculated inlet air on and off.

lSwitching the latched recirculated inlet air on and off.

lWhen there is a fault warning.

lRunning the self diagnostic routine.

Page 1203 of 1529

AIR CONDITIONING

82-14DESCRIPTION AND OPERATION

Display outputs

1LH temperature

2Economy mode

3Recirculated air

4Automatic mode5Manual distribution

6RH temperature

7Blower speed

8External air temperature

Outputs on the display are shown at full brightness when the exterior lights are off, and dimmed when the exterior

lights are on.

LH temperature. Illuminates to show the LH temperature selection, the temperature scale or that the ATC ECU is in

diagnostic mode.

Economy mode. Illuminates when the compressor is manually selected off with the ECON switch.

Recirculated air. Illuminates when the inlet air is manually selected to recirculated mode.

Automatic mode. Illuminates the AUTO legend and related symbol(s) when the blower speed, air distribution or

temperature control are in the automatic mode.

Manual distribution. Illuminates the appropriate symbol(s) to show the manually selected air distribution. Also

illuminates in the automatic modes when one of the temperatures is set to LO or HI.

RH temperature. Illuminates to show the RH temperature selection, external air temperature or diagnostic fault code.

Blower speed. Illuminates when the blower speed is manually selected. Also illuminates in the automatic modes when

one of the temperatures is set to LO or HI.

External air temperature. EXT illuminates to show that external air temperature is selected on.

All temperature indications on the display are in either °C or °F. For 1 second after the system is first switched on, the

display shows only °C or °F, in the LH temperature window, to indicate which temperature scale is in use. After 1

second, the °C or °F indication goes off and the display shows all relevant outputs.

Temperature conversion: While the system is on, the temperature indications on the display can be switched between

the two scales by pressing and holding the fresh/recirculated air switch, then pressing and holding the A/C on/off

switch until the audible warning sounds (approximately 3 seconds).

Page 1208 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-19

Diagnostics

The ATC ECU performs a diagnostic check each time the ignition is switched on. To avoid nuisance fault indications

at low light levels, the sunlight sensor is omitted from the diagnostic check. If a fault is detected, the audible warning

sounds three times and the AUTO window on the control panel display flashes for 20 seconds. The ATC ECU then

reverts to normal control but uses a default value or strategy for the detected fault. Faults are identified by performing

a manual diagnostic check of the system.

A manual diagnostic check includes a check of the sunlight sensor, and is initiated by pressing and holding the AUTO

switch and the air distribution switch, then turning the ignition switch from off to on. The audible warning sounds once

and the indications on the control panel display illuminate. FC is shown in the LH temperature window and the results

of the check are shown as a two digit fault code in the RH temperature window. If a fault is detected, the audible

warning sounds three times and the AUTO window on the display flashes on and off for 20 seconds. If more than one

fault is detected, the fault codes cycle in numerical order, at 1 Hz. The audible warning sounds as each fault code is

shown. In low light conditions, to avoid false sunlight sensor fault indications, the sunlight sensor should be illuminated

with a strong light source.

Diagnostic fault codes and fault descriptions

Code Component Fault Default value/strategy

00 - No fault found -

11 In-car temperature sensor Open or short circuit 25°C (77°F)

12 Ambient temperature sensor Open or short circuit 10°C (50°F)

Cooling fan permanently on

Display shows "- -" if external air

temperature selected

13 Thermistor Open or short circuit 0°C (32°F)

14 Heater coolant temperature sensor Open or short circuit 70°C (158°F)

21 Sunlight sensor, left output Open or short circuit No solar heating correction

22 Sunlight sensor, right output Open or short circuit No solar heating correction

31 LH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

32 RH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

33 Distribution servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

Page 1302 of 1529

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-15

Electric seats

The BCU controls the logical operation of the electrically operated front seats. Two modes of operation are available:

+ SEATS, DESCRIPTION AND OPERATION, Description - electric seats.

lElectric seat adjustment is enabled if the ignition is on or the driver's door is opened for a short time period.

lElectric seat adjustment is enabled if the ignition is on and the driver's door is closed.

The seats are operated by four electric motors which control the seat cushion rear up/ down, the seat cushion front

up/ down, seat cushion forward/ rearward and seat squab recline. The electrically powered lumbar adjustment in each

seat is operated by a single motorised air pump and a solenoid located on the seat squab frame. The air pump inflates

a cushion in the seat squab and the solenoid operates a valve to deflate the cushion. The seat squab and cushion

may also contain heater elements to provide heated seat operation.

The switches for electrically operated seats are located either side of the centre console.

Direction indicators and hazard warning lamps

The direction indicator lamps are operated from a three position direction indicator switch on the left hand, steering

column stalk. The BCU only allows the lamps to work as direction indicators when the ignition switch is in position II.

The BCU also controls the lamps to operate as hazard warning lamps and as a visual warning for the anti-theft system,

in which cases all lamps flash simultaneously irrespective of the ignition switch position.

System control of the direction indicators and hazard warning lamps is provided by the BCU operating with the IDM

and two electronic relays located in the passenger compartment fuse box. The IDM and relays are integral parts of

the passenger compartment fuse box and cannot be serviced individually. The serial data bus is used for

communication of status and operation requests between the BCU, IDM and instrument pack.

The hazard warning lamps are operated from a latching pushbutton switch located on the fascia.

All direction indicator/ hazard warning lamp bulbs are rated at 5 Watts.

Headlamps

The BCU contains a feature which allow the vehicle headlamps to be turned on when the remote transmitter is

pressed (courtesy headlamps).

For markets with daylight running lamps, the BCU controls the logical operation of the daylight running lamps. Options

are daylight running lamps are on if the main beam headlamps are off, or the daylight running lamps are on with main

and dipped beam off and the gearbox not in Park.

Front fog lamps

For markets with front fog lamps fitted, the BCU controls the operation of the front fog lamps. Options can be selected

so that the fog lamps will operate with or without the headlamps on main beam.

Instrument pack

The BCU communicates with the instrument pack via a serial data bus.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

lThe instrument pack provides the BCU and IDM with details of vehicle speed.

lSignals are provided from the IDM to the instrument pack and BCU when the direction indicator lamps are active.

lFor certain markets, the BCU provides a signal to the instrument pack for indicating when the transfer box is in

neutral.

lThe IDM can signal the instrument pack to illuminate a trailer warning lamp. This operates when the IDM senses

that the current drawn by the indicator circuit exceeds a preset threshold.

lThe odometer reading displayed on the instrument pack LCD screen is also stored in non volatile memory in the

BCU. Whenever the ignition is turned from position I to position II, the instrument pack and the BCU compare

their stored values.

lThe gear selector position is displayed on the instrument pack LCD screen under the direction of the BCU.

Starting

The starting system comprises a starter motor and solenoid located at the rear right hand side of the engine. A starter

relay controlled by the BCU is used to supply battery power for starter solenoid operation. The starter motor receives

its feed directly from the battery.