fuel LAND ROVER DISCOVERY 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 40 of 1529

GENERAL INFORMATION

03-5

Checklist

Always adhere to the following.

Electricity and heating:

lkeep doors and windows closed in the winter;

lswitch off machinery or lights when not needed;

luse energy efficient heating systems;

lswitch off computers and photocopiers when

not needed.

Fuel:

ldon't run engines unnecessarily;

lthink about whether journeys are necessary and

drive to conserve fuel.

Water:

ldon't leave taps and hose pipes running;

lmend leaks quickly, don't be wasteful.

Compressed air:

ldon't leave valves open;

lmend leaks quickly;

ldon't leave the compressor running when not

needed.

Use of environmentally damaging materials:

lcheck whether a less toxic material is available.

Handling and storage of materials:

lhave the correct facilities available for handling

liquids to prevent spillage and wastage as listed

above;

lprovide suitable locations for storage to prevent

frost damage or other deterioration.

Waste Management

One of the major ways that pollution can be reduced

is by the careful handling, storage and disposal of all

waste materials that occur on sites. Legislation

makes it illegal to dispose of waste materials other

than to licensed waste carriers and disposal sites.

This means that it is necessary to not only know what

the waste materials are, but also to have the

necessary documentation and licenses.

Handling and storage of waste

Ensure that waste materials are not poured down the

drain or onto soils. They should be stored in such a

way as to prevent the escape of the material to land,

water or air.

They must also be segregated into different types of

waste e.g. oil, metals, batteries, used vehicle

components. This will prevent any reaction between

different materials and assist in disposal.Disposal of waste

Disposal of waste materials must only be to waste

carriers who are licensed to carry those particular

waste materials and all the necessary

documentation must be completed. The waste

carrier is responsible for ensuring that the waste is

taken to the correct disposal sites.

Dispose of waste in accordance with the following

guidelines.

lFuel, hydraulic fluid, anti-freeze and oil: keep

separate and dispose of to specialist contractor.

lRefrigerant: collect in specialist equipment and

reuse.

lDetergents: safe to pour down the foul drain if

diluted.

lPaint, thinners: keep separate and dispose of

to specialist contractor.

lComponents: send back to supplier for

refurbishment, or disassemble and reuse any

suitable parts. Dispose of the remainder in

ordinary waste.

lSmall parts: reuse any suitable parts, dispose

of the remainder in ordinary waste.

lMetals: can be sold if kept separate from

general waste.

lTyres: keep separate and dispose of to

specialist contractor.

lPackaging: compact as much as possible and

dispose of in ordinary waste.

lAsbestos-containing: keep separate and

dispose of to specialist contractor.

lOily and fuel wastes (e.g. rags, used spill kit

material): keep separate and dispose of to

specialist contractor.

lAir filters: keep separate and dispose of to

specialist contractor.

lRubber/plastics: dispose of in ordinary waste.

lHoses: dispose of in ordinary waste.

lBatteries: keep separate and dispose of to

specialist contractor.

lAirbags - explosives: keep separate and

dispose of to specialist contractor.

lElectrical components: send back to supplier

for refurbishment, or disassemble and reuse

any suitable parts. Dispose of the remainder in

ordinary waste.

lElectronic components: send back to supplier

for refurbishment, or disassemble and reuse

any suitable parts. Dispose of the remainder in

ordinary waste.

lCatalysts: can be sold if kept separate from

general waste

lUsed spill-absorbing material: keep separate

and dispose of to specialist contractor.

lOffice waste: recycle paper and toner and ink

cartridges, dispose of the remainder in ordinary

waste.

Page 41 of 1529

GENERAL INFORMATION

03-6

General Fitting Instructions

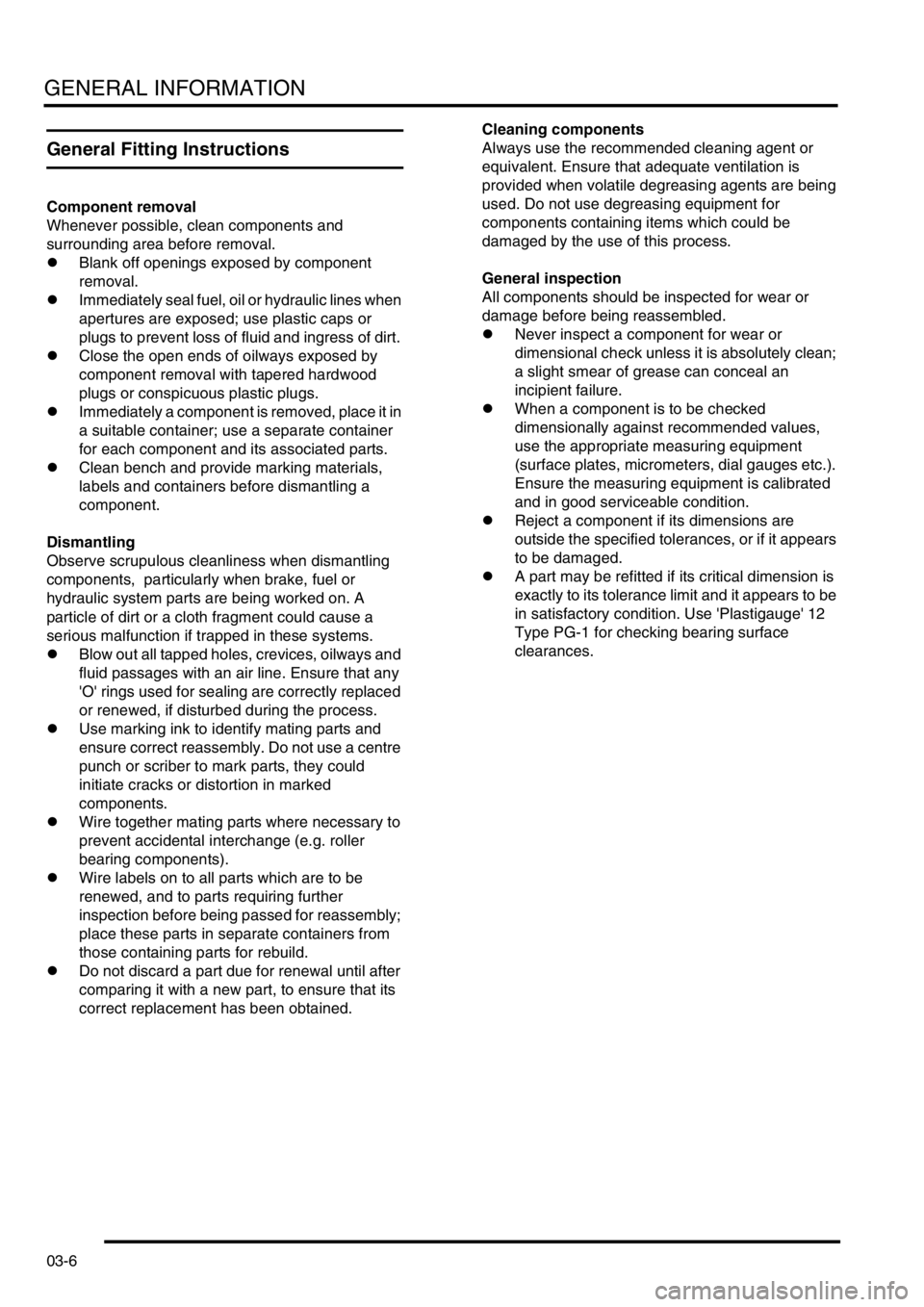

Component removal

Whenever possible, clean components and

surrounding area before removal.

lBlank off openings exposed by component

removal.

lImmediately seal fuel, oil or hydraulic lines when

apertures are exposed; use plastic caps or

plugs to prevent loss of fluid and ingress of dirt.

lClose the open ends of oilways exposed by

component removal with tapered hardwood

plugs or conspicuous plastic plugs.

lImmediately a component is removed, place it in

a suitable container; use a separate container

for each component and its associated parts.

lClean bench and provide marking materials,

labels and containers before dismantling a

component.

Dismantling

Observe scrupulous cleanliness when dismantling

components, particularly when brake, fuel or

hydraulic system parts are being worked on. A

particle of dirt or a cloth fragment could cause a

serious malfunction if trapped in these systems.

lBlow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

'O' rings used for sealing are correctly replaced

or renewed, if disturbed during the process.

lUse marking ink to identify mating parts and

ensure correct reassembly. Do not use a centre

punch or scriber to mark parts, they could

initiate cracks or distortion in marked

components.

lWire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

lWire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

lDo not discard a part due for renewal until after

comparing it with a new part, to ensure that its

correct replacement has been obtained.Cleaning components

Always use the recommended cleaning agent or

equivalent. Ensure that adequate ventilation is

provided when volatile degreasing agents are being

used. Do not use degreasing equipment for

components containing items which could be

damaged by the use of this process.

General inspection

All components should be inspected for wear or

damage before being reassembled.

lNever inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an

incipient failure.

lWhen a component is to be checked

dimensionally against recommended values,

use the appropriate measuring equipment

(surface plates, micrometers, dial gauges etc.).

Ensure the measuring equipment is calibrated

and in good serviceable condition.

lReject a component if its dimensions are

outside the specified tolerances, or if it appears

to be damaged.

lA part may be refitted if its critical dimension is

exactly to its tolerance limit and it appears to be

in satisfactory condition. Use 'Plastigauge' 12

Type PG-1 for checking bearing surface

clearances.

Page 44 of 1529

GENERAL INFORMATION

03-9

Joints and Joint Faces

General

Fit joints dry unless specified otherwise.

lAlways use the correct gaskets as specified.

lWhen jointing compound is used, apply in a thin

uniform film to metal surfaces; take care to

prevent jointing compound from entering

oilways, pipes or blind tapped holes.

lIf gaskets and/or jointing compound is

recommended for use; remove all traces of old

jointing material prior to reassembly. Do not use

a tool which will damage the joint faces and

smooth out any scratches or burrs using an oil

stone. Do not allow dirt or jointing material to

enter any tapped holes or enclosed parts.

lPrior to reassembly, blow through any pipes,

channels or crevices with compressed air.

Locking Devices

General

Always replace locking devices with one of the same

design.

Tab washers

Always release locking tabs and fit new locking

washers. Do not re-use locking tabs.

Locking nuts

Always use a backing spanner when loosening or

tightening locking nuts, brake and fuel pipe unions.

Roll pins

Always fit new roll pins of an interference fit in the

hole.

Circlips

Always fit new circlips of the correct size for the

groove.

Keys and keyways

Remove burrs from edges of keyways with a fine file

and clean thoroughly before attempting to refit key.

Clean and inspect key closely; keys are suitable for

refitting only if indistinguishable from new, as any

indentation may indicate the onset of wear.

Page 49 of 1529

GENERAL INFORMATION

03-14

Fuel system hoses

All fuel hoses are made up of two laminations, an

armoured rubber outer sleeve and an inner viton

core. If any of the fuel system hoses have been

disconnected, it is imperative that the internal bore is

inspected to ensure that the viton lining has not

become separated from the armoured outer sleeve.

A new hose must be fitted if separation is evident.

Cooling system hoses

The following precautions MUST be followed to

ensure that integrity of cooling hoses and their

connections to system components are

maintained. Hose orientation and connection

Correct orientation of cooling hoses is important in

ensuring that the hose does not become fatigued or

damaged through contact with adjacent

components. Where 'timing' marks (2) are provided

on the hose and corresponding connection, these

must be used to ensure correct orientation. Hoses

must be pushed fully onto their connection points.

Usually, a moulded form (3) on the stub pipe

provides a positive indicator.

Page 51 of 1529

GENERAL INFORMATION

03-16

Fuel Handling Precautions

Fuel vapour is highly flammable and in confined

spaces is also explosive and toxic. The vapour is

heavier than air and will always fall to the lowest

level. The vapour can be easily distributed

throughout a workshop by air currents;

consequently, even a small spillage of fuel is

potentially very dangerous.

The following information provides basic precautions

which must be observed if fuel is to be handled

safely. It also outlines other areas of risk which must

not be ignored. This information is issued for basic

guidance only, if in doubt consult your local Fire

Officer.

General

Always have a fire extinguisher containing FOAM,

CO

2, GAS or POWDER close at hand when handling

or draining fuel or when dismantling fuel systems.

Fire extinguishers should also be located in areas

where fuel containers are stored.

Always disconnect the vehicle battery before

carrying out dismantling or draining work on a fuel

system.

Whenever fuel is being handled, drained or stored, or

when fuel systems are being dismantled, all forms of

ignition must be extinguished or removed; any

leadlamps must be flameproof and kept clear of

spillage.

WARNING: No one should be permitted to repair

components associated with fuel without first

having specialist training.

WARNING: Do not remove fuel system

components while the vehicle is over a pit.

Fuel tank draining

Fuel tank draining should be carried out in

accordance with the procedure outlined in the FUEL

DELIVERY section of this manual and observing the

following precautions.

WARNING: Fuel must not be extracted or drained

from any vehicle while it is over a pit. Extraction

or draining of fuel must be carried out in a well

ventilated area.

The capacity of containers must be more than

adequate for the amount of fuel to be extracted or

drained. The container should be clearly marked

with its contents and placed in a safe storage

area which meets the requirements of local

authority regulations.Fuel tank removal

When the fuel line is secured to the fuel tank outlet by

a spring steel clip, the clip must be released before

the fuel line is disconnected or the fuel tank is

removed. This procedure will avoid the possibility of

fumes in the fuel tank being ignited when the clip is

released.

As an added precaution, fuel tanks should have a

'FUEL VAPOUR' warning label attached to them as

soon as they are removed from the vehicle.

Fuel tank repairs - plastic tank

No attempt should be made to repair a plastic fuel

tank. If the structure of the tank is damaged, a new

tank must be fitted.

Body repairs

Plastic fuel pipes are particularly susceptible to heat,

even at relatively low temperature, and can be

melted by heat conducted from some distance away.

When body repairs involve the use of heat, all fuel

pipes which run in the vicinity of the repair area must

be removed, and the tank outlet plugged.

WARNING: If welding is to be carried out in the

vicinity of the fuel tank, the fuel system must be

drained and the tank removed before welding

commences.

Page 67 of 1529

GENERAL DATA

04-4

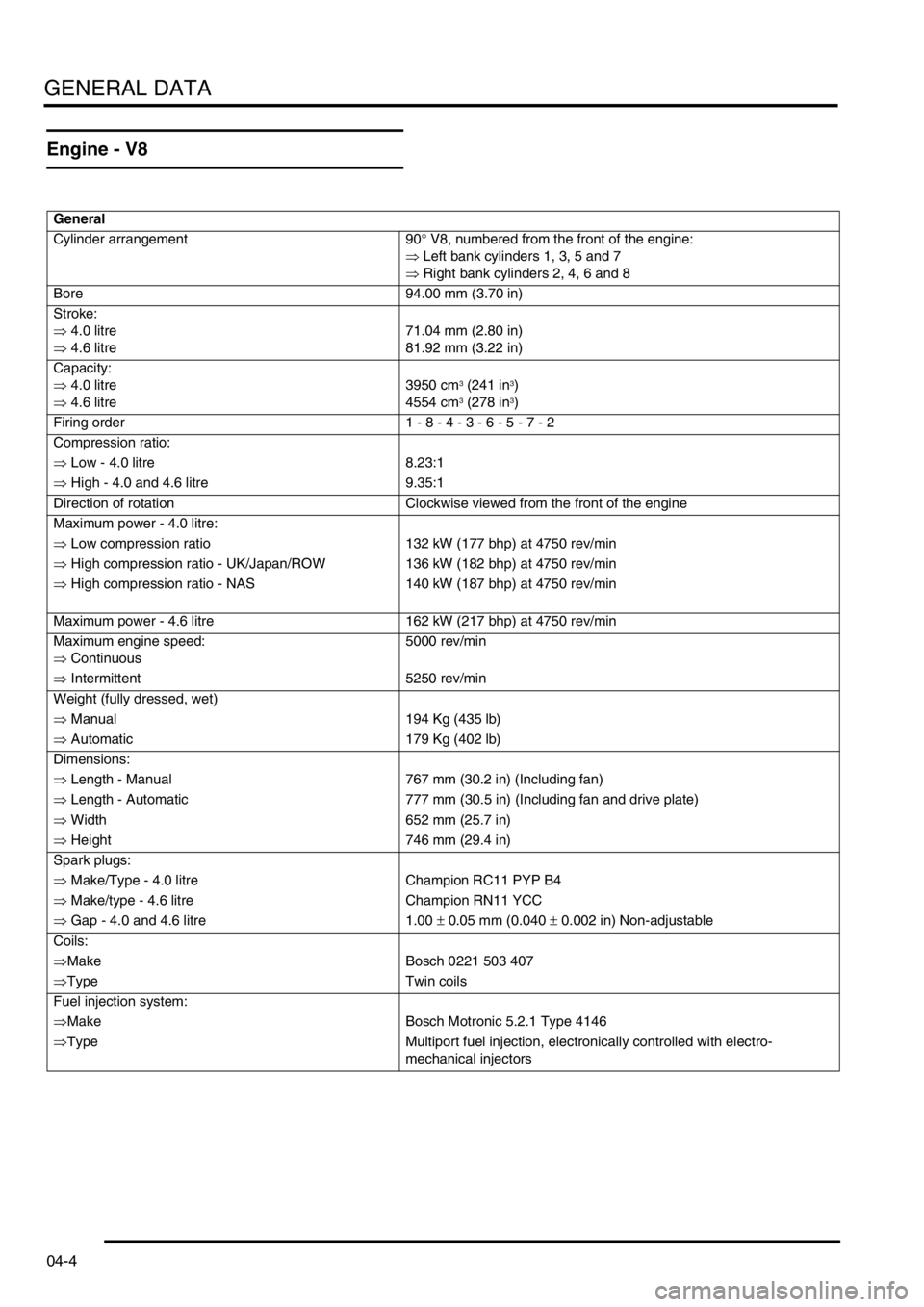

Engine - V8

General

Cylinder arrangement 90° V8, numbered from the front of the engine:

⇒ Left bank cylinders 1, 3, 5 and 7

⇒ Right bank cylinders 2, 4, 6 and 8

Bore 94.00 mm (3.70 in)

Stroke:

⇒ 4.0 litre

⇒ 4.6 litre71.04 mm (2.80 in)

81.92 mm (3.22 in)

Capacity:

⇒ 4.0 litre

⇒ 4.6 litre3950 cm

3 (241 in3)

4554 cm3 (278 in3)

Firing order 1 - 8 - 4 - 3 - 6 - 5 - 7 - 2

Compression ratio:

⇒ Low - 4.0 litre 8.23:1

⇒ High - 4.0 and 4.6 litre 9.35:1

Direction of rotation Clockwise viewed from the front of the engine

Maximum power - 4.0 litre:

⇒ Low compression ratio 132 kW (177 bhp) at 4750 rev/min

⇒ High compression ratio - UK/Japan/ROW 136 kW (182 bhp) at 4750 rev/min

⇒ High compression ratio - NAS 140 kW (187 bhp) at 4750 rev/min

Maximum power - 4.6 litre 162 kW (217 bhp) at 4750 rev/min

Maximum engine speed:

⇒ Continuous5000 rev/min

⇒ Intermittent 5250 rev/min

Weight (fully dressed, wet)

⇒ Manual 194 Kg (435 lb)

⇒ Automatic 179 Kg (402 lb)

Dimensions:

⇒ Length - Manual 767 mm (30.2 in) (Including fan)

⇒ Length - Automatic 777 mm (30.5 in) (Including fan and drive plate)

⇒ Width 652 mm (25.7 in)

⇒ Height 746 mm (29.4 in)

Spark plugs:

⇒ Make/Type - 4.0 litre Champion RC11 PYP B4

⇒ Make/type - 4.6 litre Champion RN11 YCC

⇒ Gap - 4.0 and 4.6 litre 1.00 ± 0.05 mm (0.040 ± 0.002 in) Non-adjustable

Coils:

⇒Make Bosch 0221 503 407

⇒Type Twin coils

Fuel injection system:

⇒Make Bosch Motronic 5.2.1 Type 4146

⇒Type Multiport fuel injection, electronically controlled with electro-

mechanical injectors

Page 68 of 1529

GENERAL DATA

04-5

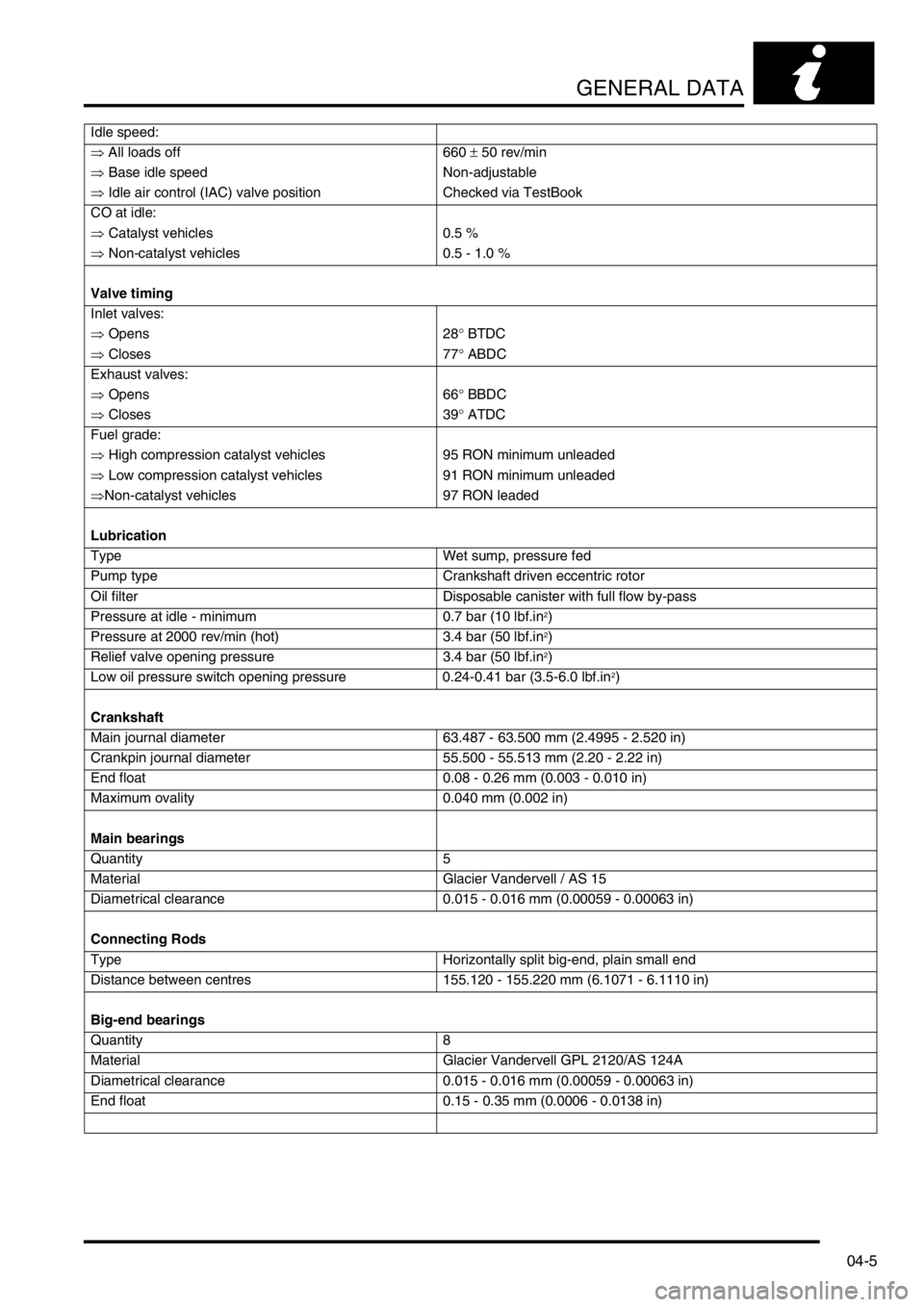

Idle speed:

⇒ All loads off 660 ± 50 rev/min

⇒ Base idle speed Non-adjustable

⇒ Idle air control (IAC) valve position Checked via TestBook

CO at idle:

⇒ Catalyst vehicles 0.5 %

⇒ Non-catalyst vehicles 0.5 - 1.0 %

Valve timing

Inlet valves:

⇒ Opens 28° BTDC

⇒ Closes 77° ABDC

Exhaust valves:

⇒ Opens 66° BBDC

⇒ Closes 39° ATDC

Fuel grade:

⇒ High compression catalyst vehicles 95 RON minimum unleaded

⇒ Low compression catalyst vehicles 91 RON minimum unleaded

⇒Non-catalyst vehicles 97 RON leaded

Lubrication

Type Wet sump, pressure fed

Pump type Crankshaft driven eccentric rotor

Oil filter Disposable canister with full flow by-pass

Pressure at idle - minimum 0.7 bar (10 lbf.in

2)

Pressure at 2000 rev/min (hot) 3.4 bar (50 lbf.in

2)

Relief valve opening pressure 3.4 bar (50 lbf.in

2)

Low oil pressure switch opening pressure 0.24-0.41 bar (3.5-6.0 lbf.in

2)

Crankshaft

Main journal diameter 63.487 - 63.500 mm (2.4995 - 2.520 in)

Crankpin journal diameter 55.500 - 55.513 mm (2.20 - 2.22 in)

End float 0.08 - 0.26 mm (0.003 - 0.010 in)

Maximum ovality 0.040 mm (0.002 in)

Main bearings

Quantity 5

Material Glacier Vandervell / AS 15

Diametrical clearance 0.015 - 0.016 mm (0.00059 - 0.00063 in)

Connecting Rods

Type Horizontally split big-end, plain small end

Distance between centres 155.120 - 155.220 mm (6.1071 - 6.1110 in)

Big-end bearings

Quantity 8

Material Glacier Vandervell GPL 2120/AS 124A

Diametrical clearance 0.015 - 0.016 mm (0.00059 - 0.00063 in)

End float 0.15 - 0.35 mm (0.0006 - 0.0138 in)

Page 71 of 1529

GENERAL DATA

04-8

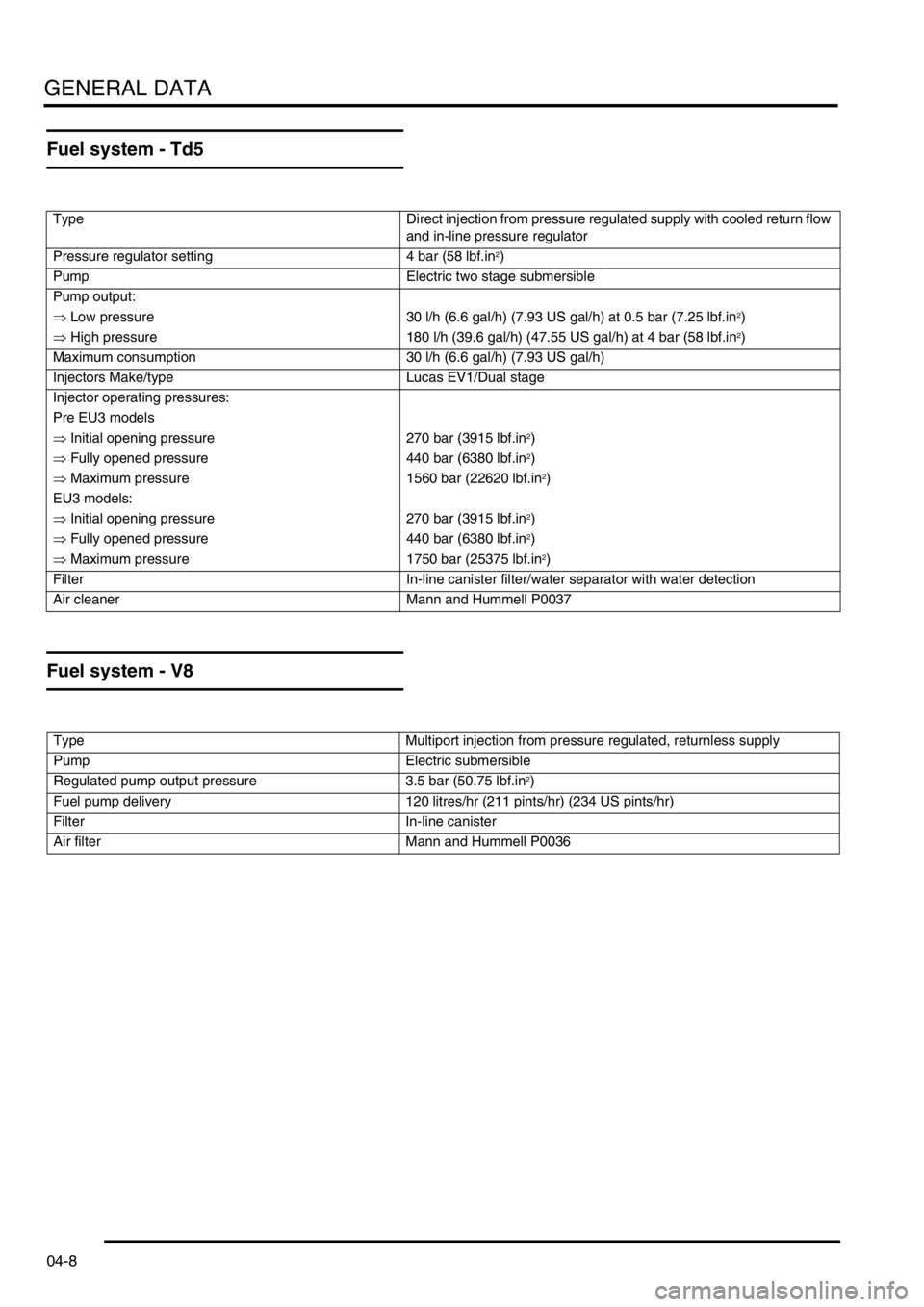

Fuel system - Td5

Fuel system - V8

Type Direct injection from pressure regulated supply with cooled return flow

and in-line pressure regulator

Pressure regulator setting 4 bar (58 lbf.in

2)

Pump Electric two stage submersible

Pump output:

⇒ Low pressure 30 l/h (6.6 gal/h) (7.93 US gal/h) at 0.5 bar (7.25 lbf.in

2)

⇒ High pressure 180 l/h (39.6 gal/h) (47.55 US gal/h) at 4 bar (58 lbf.in

2)

Maximum consumption 30 l/h (6.6 gal/h) (7.93 US gal/h)

Injectors Make/type Lucas EV1/Dual stage

Injector operating pressures:

Pre EU3 models

⇒ Initial opening pressure 270 bar (3915 lbf.in

2)

⇒ Fully opened pressure 440 bar (6380 lbf.in

2)

⇒ Maximum pressure 1560 bar (22620 lbf.in

2)

EU3 models:

⇒ Initial opening pressure 270 bar (3915 lbf.in

2)

⇒ Fully opened pressure 440 bar (6380 lbf.in

2)

⇒ Maximum pressure 1750 bar (25375 lbf.in

2)

Filter In-line canister filter/water separator with water detection

Air cleaner Mann and Hummell P0037

Type Multiport injection from pressure regulated, returnless supply

Pump Electric submersible

Regulated pump output pressure 3.5 bar (50.75 lbf.in

2)

Fuel pump delivery 120 litres/hr (211 pints/hr) (234 US pints/hr)

Filter In-line canister

Air filter Mann and Hummell P0036

Page 72 of 1529

GENERAL DATA

04-9

Cooling system - Td5

Type Pressurised, spill return partial flow, thermostatically controlled

Cooling fans 11 blade axial flow on viscous coupling and 11 blade axial flow electric

Electric cooling fan switching points:

For A/C system:

⇒ On When vehicle speed is 50 mph (80 km/h) or less and ambient

temperature is 28 °C (82 °F) or more

⇒ Off When vehicle speed increases to 62.5 mph (100 km/h) or ambient

temperature decreases to 25 °C (77 °F)

For engine cooling during normal running:

⇒ On 110 °C (230 °F)

⇒ Off 105 °C (221 °F)

For engine cooling at ignition off (to counteract heat

soak):

⇒ On If, within 10 seconds of ignition off, engine coolant temperature is 105

°C (221 °F) or more

⇒ Off After 10 minutes or if engine coolant temperature decreases to 100 °C

(212 °F)

Coolant pump Centrifugal impeller, belt driven from crankshaft

Thermostat Waxstat with pressure relief valve

Thermostat opening temperature:

⇒ Initial opening 82 °C (179 °F)

⇒ Fully open 96 °C (204 °F)

Expansion tank cap relief valve - system operating

pressure1.4 bar (20.3 lbf.in

2)

Fuel cooler thermostat opening temperature 82°C (179°F)

Page 93 of 1529

TORQUE WRENCH SETTINGS

06-2

Engine Td5

TORQUE DESCRIPTION METRIC IMPERIAL

ACE pump bolts25 Nm (18 lbf.ft)

A/C compressor bolts 25 Nm (18 lbf.ft)

Alternator support bracket to cylinder head bolts 25 Nm (18 lbf.ft)

Alternator/vacuum pump oil feed pipe union 10 Nm (7 lbf.ft)

Camshaft cover to camshaft carrier bolts 10 Nm (7 lbf.ft)

Camshaft sprocket to camshaft bolts 37 Nm (27 lbf.ft)

Centrifuge cover bolts 10 Nm (7 lbf.ft)

Centrifuge oil drain pipe to sump bolts (or nuts) 10 Nm (7 lbf.ft)

Centrifuge to oil drain pipe bolts 10 Nm (7 lbf.ft)

Centrifuge to oil cooler housing bolts 25 Nm (18 lbf.ft)

CKP sensor bolt10 Nm (7 lbf.ft)

Coolant pipe bolt50 Nm (37 lbf.ft)

Connecting rod bolts, then a further 80°20 Nm (15 lbf.ft)

Crankshaft pulley bolt 460 Nm (340 lbf.ft)

Crankshaft pulley TV damper bolts 80 Nm (59 lbf.ft)

Crankshaft rear oil seal housing bolts 10 Nm (7 lbf.ft)

Cylinder head bolts initial tighten 30 Nm (22 lbf.ft)

Cylinder head bolts final tighten, then a further 90°, then a further 180° and finally a

further 45°65 Nm (48 lbf.ft)

Dipstick tube to camshaft carrier bolt 10 Nm (7 lbf.ft)

Drive plate (automatic transmission) to crankshaft bolts 115 Nm (85 lbf.ft)

EGR pipe clamp to cylinder head bolt - if fitted 25 Nm (18 lbf.ft)

EGR pipe Allen screws 10 Nm (7 lbf.ft)

Engine mounting (front) to cylinder block bolts 48 Nm (35 lbf.ft)

Engine mounting (front) to chassis nuts 85 Nm (63 lbf.ft)

Engine mounting bracket (rear, LH & RH) to gearbox bolts 85 Nm (63 lbf.ft)

Engine mounting bracket (rear, LH & RH) nuts 45 Nm (33 lbf.ft)

Flywheel to crankshaft (manual transmission) bolts, then a further 90°40 Nm (30 lbf.ft)

Front crossmember bolts 26 Nm (20 lbf.ft)

Fuel connector block bolts 25 Nm (18 lbf.ft)

Fuel cooler to inlet manifold bolts 25 Nm (18 lbf.ft)

Gearbox housing to engine bolts 50 Nm (37 lbf.ft)

Heater pipe to cylinder head bolts 25 Nm (18 lbf.ft)

Main bearing cap bolts then a further 90°33 Nm (24 lbf.ft)

Oil cooler housing to cylinder block bolts 25 Nm (18 lbf.ft)

Oil cooler pipe clip bolts 10 Nm (7 lbf.ft)

Oil filter adaptor housing to oil cooler housing bolts 25 Nm (18 lbf.ft)

Oil pick-up strainer Torx screws + 10 Nm (7 lbf.ft)

Oil pressure switch 15 Nm (11 lbf.ft)

Oil pump drive sprocket bolt + 25 Nm (18 lbf.ft)

Oil pump pressure relief valve plug + 25 Nm (18 lbf.ft)

Oil pump and stiffener assembly to cylinder block bolts 13 Nm (10 lbf.ft)

Oil sump to cylinder block bolts 25 Nm (18 lbf.ft)

Oil sump to gearbox bell housing bolts 13 Nm (10 lbf.ft)

PAS pump bracket bolts 27 Nm (20 lbf.ft)

PAS pump pulley bolts 27 Nm (20 lbf.ft)

Rocker arm adjusting screw locknuts 16 Nm (12 lbf.ft)