oil change LAND ROVER DISCOVERY 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 486 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-15

32.Remove 3 bolts securing oil cooling pipe

housing to gearbox, release housing and

discard 'O' rings.

33.Using a second jack support the weight of the

engine.

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing. 5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 490 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties.

13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox. 17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 522 of 1529

MANUAL GEARBOX - R380

OVERHAUL 37-51

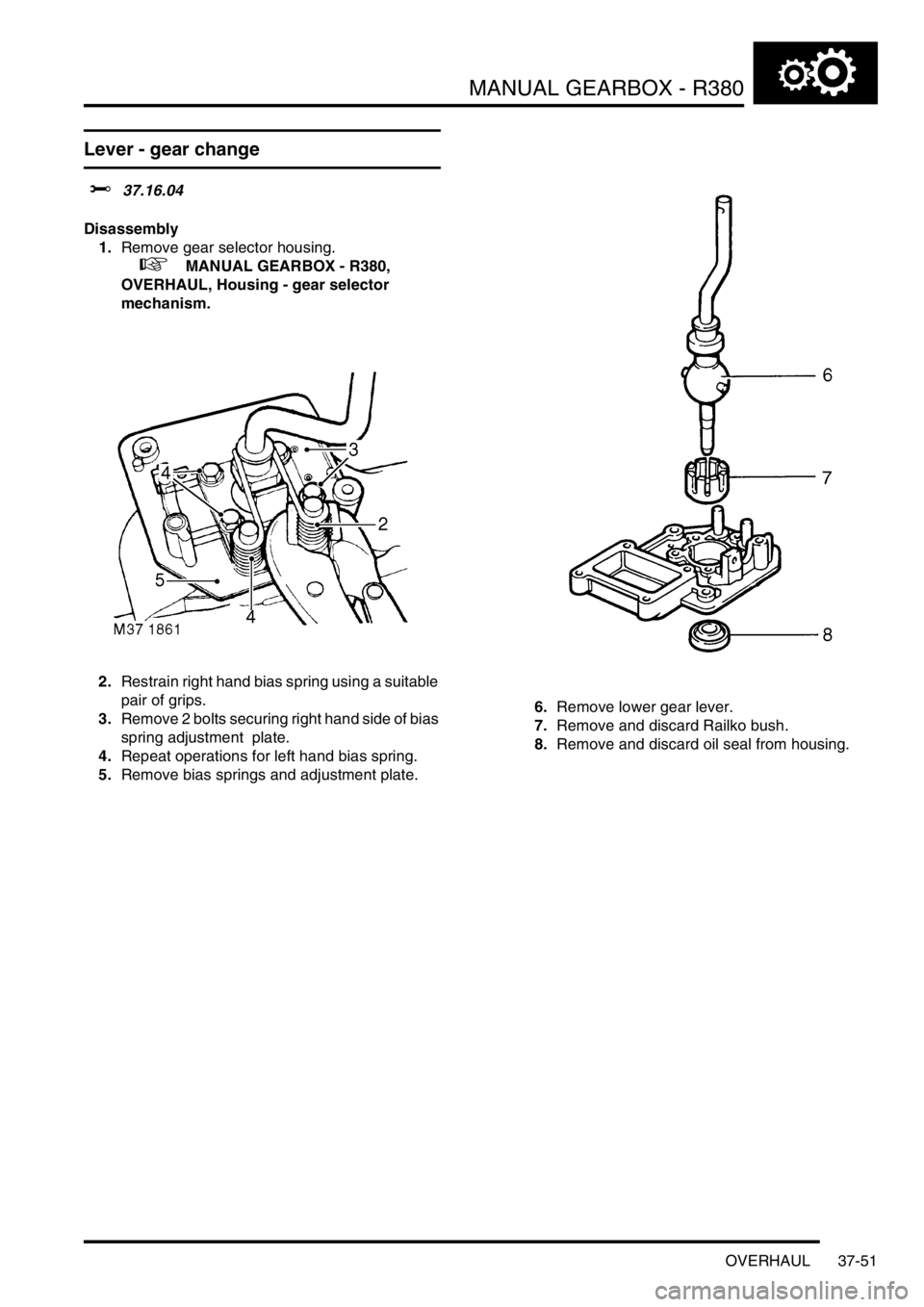

Lever - gear change

$% 37.16.04

Disassembly

1.Remove gear selector housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Housing - gear selector

mechanism.

2.Restrain right hand bias spring using a suitable

pair of grips.

3.Remove 2 bolts securing right hand side of bias

spring adjustment plate.

4.Repeat operations for left hand bias spring.

5.Remove bias springs and adjustment plate.6.Remove lower gear lever.

7.Remove and discard Railko bush.

8.Remove and discard oil seal from housing.

Page 601 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-4 DESCRIPTION AND OPERATION

Description

General

The automatic gearbox is a four speed unit with electronic control of gear selection, shift quality and torque converter

lock-up. Selections on the selector lever assembly are transmitted to the gearbox by a selector cable. A gear position

switch on the gearbox transmits the gear selection to an Electronic Automatic Transmission (EAT) ECU, which

outputs the appropriate control signals to an electro-hydraulic valve block in the gearbox. A mode switch enables the

driver to change the control mode of the EAT ECU. The EAT ECU operates warning lamps in the instrument pack to

indicate the control mode and system status.

The gearbox features a pressure lubrication system and is cooled by pumping the lubricant through an oil cooler.

On NAS market vehicles from 03 model year, the ZF 4HP24 transmission unit is introduced for use with the 4.6 litre

V8 engine. This transmission is required to accomodate the increased power output of the larger engine. The ZF

4HP22 transmission remains in use on vehicles with Td5 and 4.0 litre V8 engines.

Both transmission units are of similar construction, with the ZF 4HP24 unit being 15 mm longer than the 4HP22 unit

to accomodate a larger fluid pump. The operation of both transmission units is the same.

Page 610 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-13

Oil cooler

1Inlet connection

2Fixing bracket

3Outlet connection4Fixing bracket

5Temperature sensor

Transmission fluid from the gearbox is circulated through a cooler attached to the front of the radiator. Quick release

connectors on the transmission fluid lines attach to connections on each end tank of the cooler. A temperature sensor

on the RH end tank provides the instrument pack with an input of transmission fluid temperature. If the temperature

exceeds a preset limit, the instrument pack illuminates the transmission temperature warning lamp. The warning lamp

remains illuminated until the temperature of the fluid returns within limits.

EAT ECU

The EAT ECU operates the solenoid valves in the gearbox to provide automatic control of gear shifts and torque

converter lock-up. The EAT ECU is attached to a protective bracket which is secured to the cabin floor below the LH

front seat. A 55 pin connector links the EAT ECU to the vehicle wiring.

Software in the EAT ECU monitors hard wired inputs and exchanges information with the ECM on a Controller Area

Network (CAN) bus to determine gear shift and torque converter lock-up requirements. Resultant control signals are

then output to the gearbox solenoid valves.

Page 760 of 1529

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-15

The two solenoid operated directional control valves (DCV's) are fitted to ports in the top face of the valve block. The

DCV's are screwed into the valve block and sealed with O ring seals. Each DCV has a solenoid for electrical operation

of the valve. The solenoid is sealed to the DCV with two O ring and secured with a cap. The cap, coil and O rings are

serviceable items. The DCV's are non-serviceable and failure of a DCV requires the replacement of the valve block

assembly.

The pressure control valve is fitted to a port in the rear face of the valve block. The pressure control valve is screwed

into the valve block and sealed with O rings. The pressure control valve has a coil for electrical operation. The coil is

sealed to the pressure control valve with two O rings and secured with a cap. The cap, coil and O rings are serviceable

items. The pressure control valve is non-serviceable and failure requires replacement of the valve block assembly.

The pressure transducer is fitted to a port in the forward face of the valve block. The pressure transducer is screwed

into the valve block and sealed with an O ring seal. The pressure transducer is a serviceable item.

The high pressure filter locates in a port on the lower face of the valve block. The gauze and fibre filter is sealed in

the port with O ring seals. A threaded cap secures the filter in the valve block and is also sealed with an O ring seal.

A threaded hole on the lower face of the filter allows a bolt to be fitted to remove the filter from the port. If a system

component is replaced, the filter must be changed.

Four ports are located on the forward face of the valve block and two ports on the rear. Each port is fitted with a seal

pack which contains two O ring seals and backing rings. The ACE pipes locate and seal in the seal packs and are

secured to the valve block with the studs and nuts located on the forward and rear faces.

Actuators

Two actuators are used for the ACE system and are attached to the front and rear torsion bars. The actuators apply

hydraulically generated force to the torsion bar to oppose lateral forces caused by the vehicle cornering.

Each actuator is a conventional double-acting cylinder. A piston is attached to a rod and moves within the cylinder

when hydraulic pressure is applied. The rod is sealed at the point where it exits the cylinder. The outer end of the rod

is threaded and locates in a bush in the ACE long arm and secured with a nut. A rubber gaiter covers the rod and

prevents dirt and moisture from damaging the rod surface and cylinder seals. The cylinder has a forked attachment

which locates on the short arm bush and secured with a bolt and nut.

Two banjo connections provide for the attachment of the hydraulic hoses from the ACE valve block. The connections

provide hydraulic flow to each side of the piston to extend or retract the rod.

Page 1193 of 1529

AIR CONDITIONING

82-4DESCRIPTION AND OPERATION

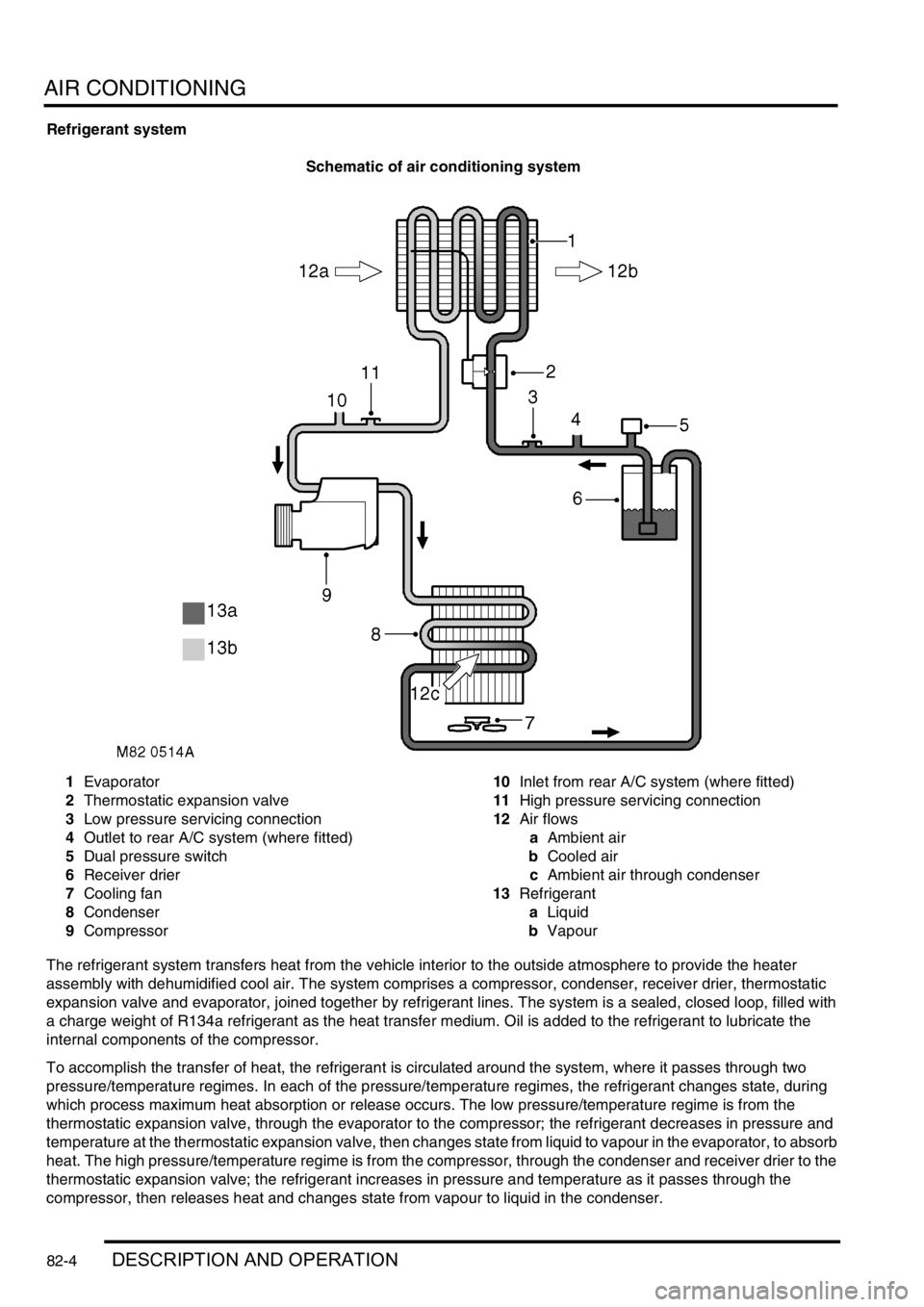

Refrigerant system

Schematic of air conditioning system

1Evaporator

2Thermostatic expansion valve

3Low pressure servicing connection

4Outlet to rear A/C system (where fitted)

5Dual pressure switch

6Receiver drier

7Cooling fan

8Condenser

9Compressor10Inlet from rear A/C system (where fitted)

11High pressure servicing connection

12Air flows

aAmbient air

bCooled air

cAmbient air through condenser

13Refrigerant

aLiquid

bVapour

The refrigerant system transfers heat from the vehicle interior to the outside atmosphere to provide the heater

assembly with dehumidified cool air. The system comprises a compressor, condenser, receiver drier, thermostatic

expansion valve and evaporator, joined together by refrigerant lines. The system is a sealed, closed loop, filled with

a charge weight of R134a refrigerant as the heat transfer medium. Oil is added to the refrigerant to lubricate the

internal components of the compressor.

To accomplish the transfer of heat, the refrigerant is circulated around the system, where it passes through two

pressure/temperature regimes. In each of the pressure/temperature regimes, the refrigerant changes state, during

which process maximum heat absorption or release occurs. The low pressure/temperature regime is from the

thermostatic expansion valve, through the evaporator to the compressor; the refrigerant decreases in pressure and

temperature at the thermostatic expansion valve, then changes state from liquid to vapour in the evaporator, to absorb

heat. The high pressure/temperature regime is from the compressor, through the condenser and receiver drier to the

thermostatic expansion valve; the refrigerant increases in pressure and temperature as it passes through the

compressor, then releases heat and changes state from vapour to liquid in the condenser.

Page 1195 of 1529

AIR CONDITIONING

82-6DESCRIPTION AND OPERATION

Condenser

1Condenser matrix

2Outlet connection

3Inlet connection

The condenser transfers heat from the refrigerant to the surrounding air.

The condenser is installed immediately in front of the oil coolers. Rubber mounting bushes are used to mount the

condenser to the chassis sidemembers and brackets on the headlamp panels.

Ambient air, passing through the condenser matrix due to ram effect and/or the cooling fan, absorbs heat from the

refrigerant, which changes state from a vapour to a liquid.

Page 1289 of 1529

BODY CONTROL UNIT

86-3-2 DESCRIPTION AND OPERATION

Power supply

Battery supply to the BCU and the IDM is provided through a 10 A fuse located in the engine compartment fuse box.

The BCU unit receives an ignition switched power supply (ignition switch position II) input via a 10 A fuse in the

passenger compartment fuse box.

The BCU receives a signal when the ignition switch is turned to the crank position, it then supplies an earth path to

the starter relay coil, to enable the crank operation by supplying power through the starter relay contacts to the starter

motor.

Battery voltage is monitored and BCU operation will function normally between 8 and 18 volts. Between 5.7 and 8

volts the BCU is in the 'under volts' state. The status of the battery is used to determine which outputs may be driven.

If a voltage supply above 18 volts is experienced, outputs will not normally be driven except for those functions which

are required during cranking (robust immobilisation, antenna coil, crank enable relay and feed to gear position switch

contacts W, X, Y, Z). In the over voltage state the vehicle can be driven, but all other functions are disabled and

outputs are switched off (power windows, heated screen, direction indicators etc.).

All functions are disabled on power up until communications between the BCU and IDM have been established. If

communications cannot be established, operation will commence with degraded functionality.

Battery supply to the IDM is provided through the inertia switch and a 10 A fuse in the engine compartment fuse box.

If the inertia switch contacts are closed battery voltage is available at the IDM; if the inertia switch contacts are open

there is no battery supply to the IDM. The supply condition of the IDM is signalled to the BCU via the serial bus. If the

inertia switch is operated (contacts open) the change in state is detected by the BCU which unlocks the doors if the

ignition switch is in position II and the alarm is not set.

The BCU is earthed through a hard-wire connection.

Inputs and outputs

The BCU and IDM process inputs and provide the necessary outputs for control and operation of the vehicle's 'body'

systems.

BCU inputs

The BCU processes signals received from the following components:

lDoor latch switches.

lDriver's door key lock/ unlock switches.

lBonnet activated security system.

lVolumetric sensors.

lCentral Door Locking (CDL) switches.

lRemote transmitter (via receiver unit).

lInertia fuel cut-off switch.

lIgnition switch.

lFuel flap release switch.

The input voltages (V

in) for BCU digital signals are defined as follows:

lLogic 1 when V

in ≥ 6V.

lLogic 0 when V

in ≤ 2V.

BCU input voltages between 2 and 6 volts are indeterminate and cannot be guaranteed.

Analogue input voltages are measured as a ratio with respect to battery voltage.

Page 1306 of 1529

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-19

Operation

For IDM inputs which are also inputs for BCU functions, the delay before the BCU recognises the change in input

status is less than 250 ms. The BCU uses a debounce algorithm to ignore changes in input having a duration less

than 100 ms with the exception of automatic gearbox W, X, Y, Z inputs, which have a debounce period of 33 ms.

Transit mode

To prevent excessive battery drain during transit to overseas markets, the vehicle is placed in a transit mode.

To exit the transit mode, simultaneously hold down the heated rear window switch and the rear fog lamp switch, turn

the ignition switch from 0 to II and, after a minimum of 2 seconds, release the switches.

Transit mode can be entered using TestBook. When TestBook communicates with the BCU for diagnostics related to

BCU operation, it first checks that the vehicle is not in transit mode.

Anti-theft system

The BCU uses the driver's door key lock and unlock switches to activate and deactivate the security system. The

driver's door lock is also used for entering the EKA.

+ ALARM SYSTEM AND HORN, DESCRIPTION AND OPERATION, Description.

Immobilisation

For immobilisation, the BCU disables the starter motor relay. When the engine is cranking, the ECM looks for a coded

signal from the BCU. If the signal is not received within one second of cranking, the fuel supply to the engine is

stopped and the injectors are disabled. This also prevents unburnt fuel from entering the catalyst.

If the BCU is disconnected, the engine starter motor will remain isolated by the starter motor relay and the ECM will

remain immobilised. The main wiring for the system is contained within the main harness which is relatively

inaccessible, so preventing intruders from disabling the system by cutting the wires for the immobilisation system.

Once the immobiliser has been activated, destruction of the trigger device or the wiring to it will not disarm the system.

The RF transmitter communicates to the BCU via the RF receiver using a 70 bit code. Pressing the unlock button on

the transmitter will re-mobilise the vehicle. The RF transponder is integrated into the metal key assembly, inserting

the key into the ignition switch will induce a signal in the exciter coil to re-mobilise the vehicle.

Anti-theft alarm

The alarm system provides a warning of unauthorised access to the vehicle and includes perimetric and volumetric

monitoring under the control of the BCU.

The perimetric protection system detects opening of all doors, tail door and bonnet and will also detect the operation

of the ignition key switch. The following conditions must be satisfied before the BCU will operate all of the functions

of perimetric protection:

lAll doors and hinged panels are in the closed position.

lIgnition key out of the ignition switch.

lInertia switch is not tripped.

If all conditions are not satisfied the BCU will enter a mislock condition.

The volumetric sensor uses two ultrasonic sensors mounted in the headlining to detect movement within the vehicle.

The alarm will trigger when the sensor signals the BCU for 200 ms or greater. Within a single setting period the alarm

system will allow a maximum of 10 triggers as a result of any combination of sensor inputs. It is possible to lock the

vehicle without enabling the volumetric alarm by using the key. The same conditions needed to satisfy enabling of the

perimetric protection system is also needed to enable volumetric protection.

When the alarm system is set the BCU checks the status of all the inputs from the door and bonnet switches to ensure

the integrity of the vehicle before setting the alarm system into operational mode. In some markets, when the alarm

is set the BCU sends a signal to the IDM which will cause the direction indicators to flash three times for a duration of

3 seconds.

If the sensors are triggered the BCU will activate an alarm sounder to provide an audible warning of a theft attempt.

The activation period of the alarm sounder is 25 to 30 seconds. The duty cycle of the alarm sounder is 50:50 ± 10%.