oil change LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 13 of 1529

CONTENTS

10 CONTENTS

MANUAL GEARBOX - R380 .................................................................... 37-1

DESCRIPTION AND OPERATION

R380 gearbox ................................................................................................................................. 37-1

Gearbox casings, gear change and oil pump ................................................................................ 37-2

Selector shaft and forks, synchromesh assemblies and gear train ............................................... 37-4

R380 gearbox cross section ........................................................................................................... 37-6

Description ...................................................................................................................................... 37-7

Operation ........................................................................................................................................ 37-8

ADJUSTMENTS

Spring - gear lever bias .................................................................................................................. 37-9

REPAIRS

Housing - gear selector .................................................................................................................. 37-11

Gearbox - V8 .................................................................................................................................. 37-12

Gearbox - Diesel ............................................................................................................................. 37-16

Seal - gearbox mainshaft ............................................................................................................... 37-20

Seal - input shaft ............................................................................................................................ 37-21

Cooler - oil - gearbox - Diesel ......................................................................................................... 37-23

Cooler - oil - gearbox - V8............................................................................................................... 37-24

Switch - Reverse light ................................................................................................................... 37-25

OVERHAUL

Shaft - output ................................................................................................................................. 37-27

Synchroniser - gearbox - set ......................................................................................................... 37-32

Fork - set - selector shaft .............................................................................................................. 37-34

Shaft - gearbox - input .................................................................................................................. 37-35

Extension - gearbox rear ............................................................................................................... 37-38

Pump - gearbox oil ......................................................................................................................... 37-41

Filter - gearbox oil ......................................................................................................................... 37-41

Gear - 5th gear set ........................................................................................................................ 37-42

Synchronizer assembly - 5th/reverse ........................................................................................... 37-43

5th gear - layshaft ......................................................................................................................... 37-44

Bearing - layshaft rear support ..................................................................................................... 37-46

Bearing - output shaft rear support ............................................................................................... 37-47

Shaft - reverse idler ...................................................................................................................... 37-48

Housing - gear selector mechanism ............................................................................................. 37-50

Lever - gear change ...................................................................................................................... 37-51

Housing - clutch ............................................................................................................................ 37-52

Cover - front ................................................................................................................................... 37-53

Page 41 of 1529

GENERAL INFORMATION

03-6

General Fitting Instructions

Component removal

Whenever possible, clean components and

surrounding area before removal.

lBlank off openings exposed by component

removal.

lImmediately seal fuel, oil or hydraulic lines when

apertures are exposed; use plastic caps or

plugs to prevent loss of fluid and ingress of dirt.

lClose the open ends of oilways exposed by

component removal with tapered hardwood

plugs or conspicuous plastic plugs.

lImmediately a component is removed, place it in

a suitable container; use a separate container

for each component and its associated parts.

lClean bench and provide marking materials,

labels and containers before dismantling a

component.

Dismantling

Observe scrupulous cleanliness when dismantling

components, particularly when brake, fuel or

hydraulic system parts are being worked on. A

particle of dirt or a cloth fragment could cause a

serious malfunction if trapped in these systems.

lBlow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

'O' rings used for sealing are correctly replaced

or renewed, if disturbed during the process.

lUse marking ink to identify mating parts and

ensure correct reassembly. Do not use a centre

punch or scriber to mark parts, they could

initiate cracks or distortion in marked

components.

lWire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

lWire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

lDo not discard a part due for renewal until after

comparing it with a new part, to ensure that its

correct replacement has been obtained.Cleaning components

Always use the recommended cleaning agent or

equivalent. Ensure that adequate ventilation is

provided when volatile degreasing agents are being

used. Do not use degreasing equipment for

components containing items which could be

damaged by the use of this process.

General inspection

All components should be inspected for wear or

damage before being reassembled.

lNever inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an

incipient failure.

lWhen a component is to be checked

dimensionally against recommended values,

use the appropriate measuring equipment

(surface plates, micrometers, dial gauges etc.).

Ensure the measuring equipment is calibrated

and in good serviceable condition.

lReject a component if its dimensions are

outside the specified tolerances, or if it appears

to be damaged.

lA part may be refitted if its critical dimension is

exactly to its tolerance limit and it appears to be

in satisfactory condition. Use 'Plastigauge' 12

Type PG-1 for checking bearing surface

clearances.

Page 101 of 1529

TORQUE WRENCH SETTINGS

06-10

Manual gearbox - R380

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Bias spring adjustment plate bolts + 25 Nm (18 lbf.ft)

Gearbox to engine bolts 45 Nm (33 lbf.ft)

Coolant pipe housing bolts 25 Nm (18 lbf.ft)

Breather pipe banjo bolt 15 Nm (11 lbf.ft)

Gear lever extension clamp bolt 25 Nm (18 lbf.ft)

Gearbox mounting bolts 85 Nm (63 lbf.ft)

Gearbox mounting nuts 48 Nm (37 lbf.ft)

Seal housing bolts 18 Nm (13 lbf.ft)

Bearing sleeve bolts 25 Nm (18 lbf.ft)

Fork bolt7 Nm (5.2 lbf.ft)

Reverse light switch 24 Nm (18 lbf.ft)

Extension housing bolts + 25 Nm (18 lbf.ft)

Gear selector housing bolts + 25 Nm (18 lbf.ft)

Oil pump to housing Torx screws 6 Nm (4.4 lbf.ft)

Gear change lever yoke Allen screw + 25 Nm (18 lbf.ft)

5th gear stake nut 350 Nm (258 lbf.ft)

Spool retainer bolts 8 Nm (6 lbf.ft)

Centre plate detent spring and ball Torx screw 25 Nm (18 lbf.ft)

Selector lever to housing bolts + 25 Nm (18 lbf.ft)

Clutch \ Bell housing bolts 73 Nm (54 lbf.ft)

Page 118 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-1

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

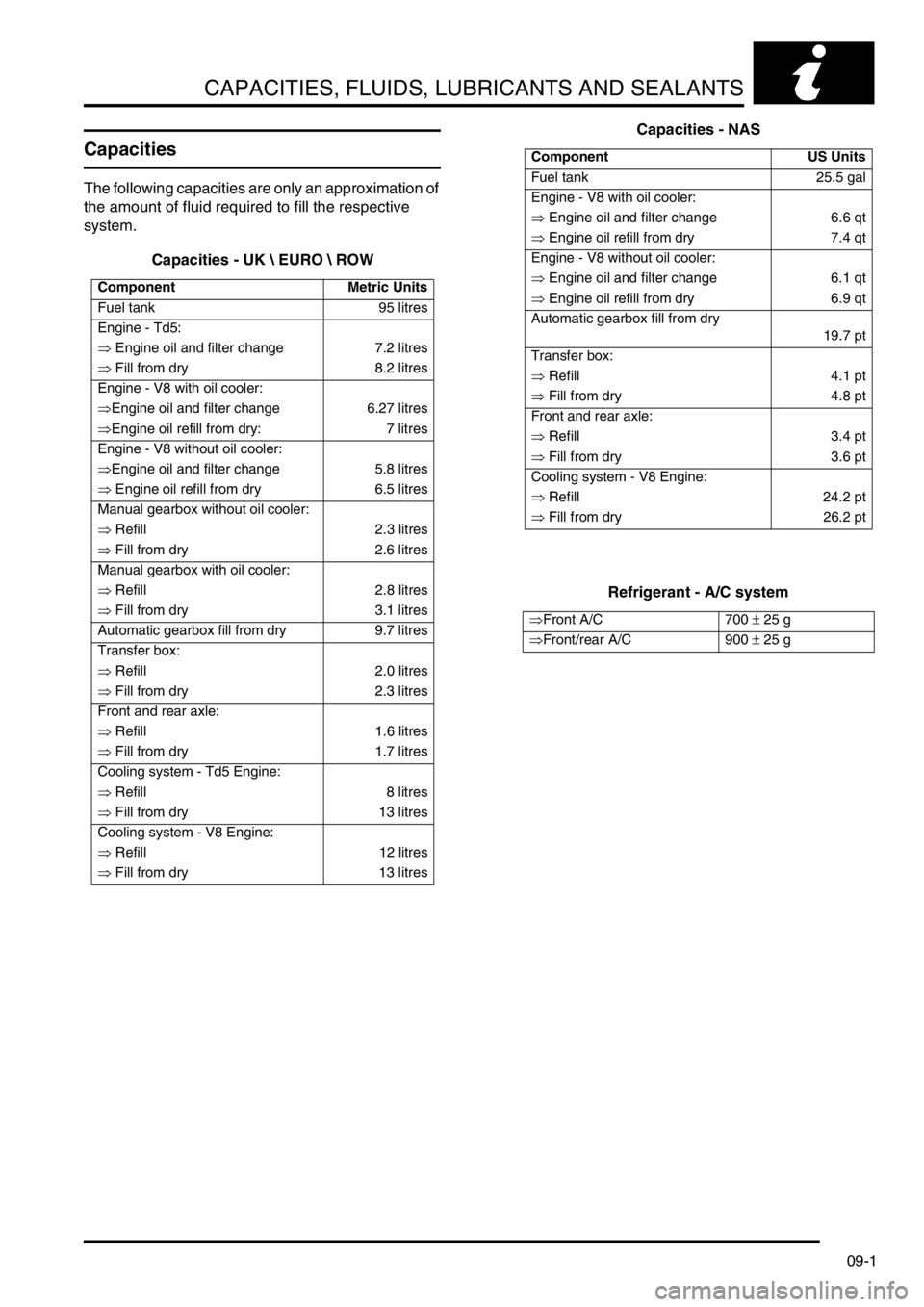

Capacities

The following capacities are only an approximation of

the amount of fluid required to fill the respective

system.

Capacities - UK EURO ROWCapacities - NAS

Refrigerant - A/C system

Component Metric Units

Fuel tank 95 litres

Engine - Td5:

⇒ Engine oil and filter change 7.2 litres

⇒ Fill from dry 8.2 litres

Engine - V8 with oil cooler:

⇒Engine oil and filter change 6.27 litres

⇒Engine oil refill from dry: 7 litres

Engine - V8 without oil cooler:

⇒Engine oil and filter change 5.8 litres

⇒ Engine oil refill from dry 6.5 litres

Manual gearbox without oil cooler:

⇒ Refill 2.3 litres

⇒ Fill from dry 2.6 litres

Manual gearbox with oil cooler:

⇒ Refill 2.8 litres

⇒ Fill from dry 3.1 litres

Automatic gearbox fill from dry 9.7 litres

Transfer box:

⇒ Refill 2.0 litres

⇒ Fill from dry 2.3 litres

Front and rear axle:

⇒ Refill 1.6 litres

⇒ Fill from dry 1.7 litres

Cooling system - Td5 Engine:

⇒ Refill 8 litres

⇒ Fill from dry 13 litres

Cooling system - V8 Engine:

⇒ Refill 12 litres

⇒ Fill from dry 13 litres

Component US Units

Fuel tank 25.5 gal

Engine - V8 with oil cooler:

⇒ Engine oil and filter change 6.6 qt

⇒ Engine oil refill from dry 7.4 qt

Engine - V8 without oil cooler:

⇒ Engine oil and filter change 6.1 qt

⇒ Engine oil refill from dry 6.9 qt

Automatic gearbox fill from dry

19.7 pt

Transfer box:

⇒ Refill 4.1 pt

⇒ Fill from dry 4.8 pt

Front and rear axle:

⇒ Refill 3.4 pt

⇒ Fill from dry 3.6 pt

Cooling system - V8 Engine:

⇒ Refill 24.2 pt

⇒ Fill from dry 26.2 pt

⇒Front A/C 700 ± 25 g

⇒Front/rear A/C 900 ± 25 g

Page 276 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-43

Secondary Air Injection System

Operation

When the engine is started, the engine control module checks the engine coolant temperature and if it is below 55°

C, the ECM grounds the electrical connection to the coil of the secondary air injection (SAI) pump relay.

A 12V battery supply is fed to the inertia switch via fuse 13 in the engine compartment fusebox. When the inertia

switch contacts are closed, the feed passes through the switch and is connected to the coil of the Main relay. An earth

connection from the Main relay coil is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the Main relay.

The Main and Secondary Air Injection (SAI) pump relays are located in the engine compartment fusebox. When the

contacts of the Main relay are closed, a 12V battery supply is fed to the coil of the SAI pump relay. An earth connection

from the coil of the SAI pump relay is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the SAI pump relay to supply 12V to the SAI pump via fusible link 2 in the engine

compartment fusebox. The SAI pump starts to operate, and will continue to do so until the ECM switches off the earth

connection to the coil of the SAI pump relay.

The SAI pump remains operational for a period determined by the ECM and depends on the starting temperature of

the engine, or for a maximum operation period determined by the ECM if the target engine coolant temperature has

not been reached in the usual time.

When the contacts of the main relay are closed, a 12V battery supply is fed to the SAI solenoid valve via Fuse 2 in

the engine compartment fusebox.

The ECM grounds the electrical connection to the SAI vacuum solenoid valve at the same time as it switches on the

SAI pump motor. When the SAI vacuum solenoid valve is energised, a vacuum is provided to the operation control

ports on both of the vacuum operated SAI control valves at the exhaust manifolds. The control vacuum is sourced

from the intake manifold depression and routed to the SAI control valves via a vacuum reservoir and the SAI vacuum

solenoid valve.

The vacuum reservoir is included in the vacuum supply circuit to prevent vacuum fluctuations caused by changes in

the intake manifold depression affecting the operation of the SAI control valves.

When a vacuum is applied to the control ports of the SAI control valves, the valves open to allow pressurised air from

the SAI pump to pass through to the exhaust ports in the cylinder heads for combustion.

When the ECM has determined that the SAI pump has operated for the desired duration, it switches off the earth paths

to the SAI pump relay and the SAI vacuum solenoid valve. With the SAI vacuum solenoid valve de-energised, the

valve closes, cutting off the vacuum supply to the SAI control valves. The SAI control valves close immediately and

completely to prevent any further pressurised air from the SAI pump entering the exhaust manifolds.

The engine coolant temperature sensor incurs a time lag in respect of detecting a change in temperature and the SAI

pump automatically enters a 'soak period' between operations to prevent the SAI pump overheating. The ECM also

compares the switch off and start up temperatures, to determine whether it is necessary to operate the SAI pump.

This prevents the pump running repeatedly and overheating on repeat starts.

Other factors which may prevent or stop SAI pump operation include the prevailing engine speed / load conditions.

Page 350 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-51

Conditions

The ECM calculates ignition timing using input from the following:

lCKP sensor.

lKnock sensors (KS).

lMAF sensor.

lTP sensor (idle only).

lECT sensor.

Function

At engine start up, the ECM sets ignition timing dependent on ECT information and starting rev/min from the CKP. As

the running characteristics of the engine change, the ignition timing changes. The ECM compares the CKP signal to

stored values in its memory, and if necessary advances or retards the spark via the ignition coils.

Ignition timing is used by the ECM for knock control.

Knock control

The ECM uses active knock control to prevent possible engine damage due to pre-ignition. This is achieved by

converting engine block noise into a suitable electrical signal that can be processed by the ECM. A major contributing

factor to engine 'knock' is fuel quality, the ECM can function satisfactorily on 91 RON fuel as well as the 95 RON fuel

that it is calibrated for.

Conditions

The ECM knock control system operates as follows:

lHot running engine.

l91 or 95 RON fuel.

Function

The ECM knock control uses two sensors located one between the centre two cylinders of each bank. The knock

sensors consist of piezo ceramic crystals that oscillate to create a voltage signal. During pre-ignition, the frequency

of crystal oscillation increases which alters the signal output to the ECM.

If the knock sensors detect pre-ignition in any of the cylinders, the ECM retards the ignition timing by 3° for that

particular cylinder. If this action stops the engine knock, the ignition timing is restored to its previous figure in

increments of 0.75°. If this action does not stop engine knock then the ECM retards the ignition timing a further 3° up

to a maximum of -15° and then restores it by 0.75° and so on until the engine knock is eliminated.

The ECM also counteracts engine knock at high intake air temperatures by retarding the ignition as above. The ECM

uses the IAT signal to determine air temperature.

Idle speed control

The ECM regulates the engine speed at idling. The ECM uses the idle air control valve (IACV) to compensate for the

idle speed drop that occurs when the engine is placed under greater load than usual. When the throttle is in the rest

position i.e. it has not been pressed, the majority of intake air that the engine consumes comes from the idle air control

valve.

IACV control idle speed

Conditions in which the ECM operates the IACV control idle speed is as follows:

lIf any automatic transmission gears other than P or N are selected.

lIf air conditioning is switched on.

lIf cooling fans are switched on.

lAny electrical loads activated by the driver.

Function

The idle air control valve utilises two coils that use opposing pulse width modulated (PWM) signals to control the

position of a rotary valve. If one of the circuits that supplies the PWM signal fails, the ECM closes down the remaining

signal preventing the idle air control valve from working at its maximum/ minimum setting. If this should occur, the idle

air control valve assumes a default idle position at which the engine idle speed is raised to 1200 rev/min with no load

placed on the engine.

Page 473 of 1529

MANUAL GEARBOX - R380

37-2 DESCRIPTION AND OPERATION

Gearbox casings, gear change and oil

pump

Page 474 of 1529

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-3

1Front cover

2Input shaft oil seal

3Oil filler/level plug

4Sealing washer

5Oil drain plug

6Gear case

7Interlock spool retainer, bolt and 'O' ring

8Centre plate

9Locating dowels

10Selector plug, detent balls and spring

11Splash shield and retaining bolt

12Extension housing

13Gate plate and retaining bolt

14Interlock spool retainer, retaining bolt and 'O'

ring – if fitted – extension housing

15Inhibitor cam spring

16Inhibitor cam

17Reverse inhibitor shaft

18Output shaft oil seal

19Oil seal collar

20Oil pump and retaining bolt

21'O' ring

22Reverse lamp switch23Oil by-pass block - UK and European models

24Bolt - oil by-pass block

25'O' ring - oil by-pass block

26Thermostat and housing - non UK and non

European models

27'O' ring - thermostat housing

28Bolt - thermostat housing

29Oil pick-up pipe

30Oil filter

31Oil pick-up ring

32Rubber gaiter

33Cable tie

34Upper gear lever

35Clamp bolt

36Bias springs

37Bolts and washers - bias adjusting plate and

housing

38Bias adjusting plate

39Lower gear lever and ball

40Railko bush

41Oil seal

42Gear change housing

Page 477 of 1529

MANUAL GEARBOX - R380

37-6 DESCRIPTION AND OPERATION

R380 gearbox cross section

1Input shaft

2Breather

3Input shaft 4th gear

4Selector shaft

53rd/4th selector fork

6Output shaft 3rd gear

7Output shaft 2nd gear

81st/2nd selector fork

9Output shaft 1st gear

10Selective shims - output shaft and layshaft end-

float

11Selective shim - reverse gear idler shaft end-

float

125th/reverse selector fork

13Selector yoke14Gear change assembly

15Railko bush

16Output shaft 5th gear

17Output shaft oil seal

18Output shaft

19Oil pump

205th/reverse gear synchromesh assembly

21Output shaft reverse gear

22Centre plate

23Oil filter

241st/2nd synchromesh assembly

25Layshaft

263rd/4th gear synchromesh assembly

27Input shaft oil seal

Page 478 of 1529

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-7

Description

General

The R380 all synchromesh gearbox has five forward speeds and reverse and is mounted in line with the engine. The

clutch bell housing is bolted to the front of the gearbox and the transfer box is mounted at the rear.

Gearbox casings

Gearbox casings consist of a front cover, gearcase, centre plate and extension housing. All casings with the exception

of the front cover are located to each other by dowels and sealed. Gearbox filler/level and drain plugs are located in

the gearcase.

Reverse lamp switch

A reverse lamp switch is inserted into the extension housing. Selection of reverse gear will close the switch allowing

current from fuse 25 to flow through the switch to illuminate the reverse lamps. The switch also provides a feed to the

BCU and the electrochromic automatic interior mirror - if fitted; the mirror moving from the dimmed position if

applicable.

Gearchange assembly

The gearchange assembly is bolted to the top of the gearcase, the upper gear lever being attached to the lower gear

lever by means of a clamp bolt. The lower gear lever ball is housed in a Railko bush inserted in the gear change

housing, the end of the lever locating in the selector yoke which is attached to the end of the selector shaft. Bias

springs provide a positive return of the gear lever to the neutral position with selection of 1st/2nd and 5th/reverse gears

being against bias spring pressure. Spring loaded detent balls fitted in the centre plate locate in grooves in the selector

shaft to provide positive gear and neutral selection.

Lubrication

Lubrication is by an oil pump located in the extension housing and driven by the layshaft with additional lubrication

being provided by splash. The pump directs oil via a filter and internal drillings in the output shaft to lubricate the

components. On non UK and non European models, provision for oil cooling is by means of a thermostat housed in

a cover bolted to the side of the extension housing. The cover incorporates tappings for connections to an oil cooler.

On UK and European models, the thermostat and cover are replaced by an oil by-pass block.

Internal pressures produced within the gearbox are vented to atmosphere via a plastic breather pipe. The pipe is

attached to the extension housing and is routed across the top of the gearcase and secured at the open end by a clip

attached to the engine cylinder block.

Selector shaft and forks

Selector forks for 1st/2nd, 3rd/4th and 5th/reverse gears are located on a single selector shaft; the 1st/2nd and 3rd/

4th selector forks are inside the main gearcase whilst the 5th/reverse selector fork is inside the extension housing.

Each of the selector forks locates inside its corresponding synchromesh hub.

Synchromesh assemblies

Each synchromesh assembly is located on the output shaft adjacent to its corresponding gears and comprises a

synchromesh ring, hub, slippers and sleeve. The hubs and slippers are retained in the sleeves by means of spring

clips. 1st/2nd and 3rd synchromesh assemblies are fitted with double synchromesh rings whilst 4th, 5th and reverse

assemblies are fitted with single rings.

The gear train

The gear train comprises an input shaft, output shaft, layshaft and reverse idler shaft together with their appropriate

gears and synchromesh assemblies.

The gear train input shaft, output shaft and layshaft are supported by taper roller bearings with all gears on the input

and output shafts running on caged needle roller bearings. Layshaft gears are integral with the shaft with the

exception of reverse/5th gears which are splined to the shaft and retained with a nut. 1st, 2nd, 3rd and 4th gears are

shot peened to improve durability. The reverse idler shaft and gear are supported in the centre plate by a caged

needle roller bearing. End-float of the output shaft and layshaft is controlled by selective shims located in the centre

plate whilst reverse idler shaft end-float is controlled by a selective shim located behind reverse gear.