ECU LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 589 of 1529

TRANSFER BOX - LT230SE

41-64 OVERHAUL

Dog clutch - differential lock

$% 41.20.23

Disassembly

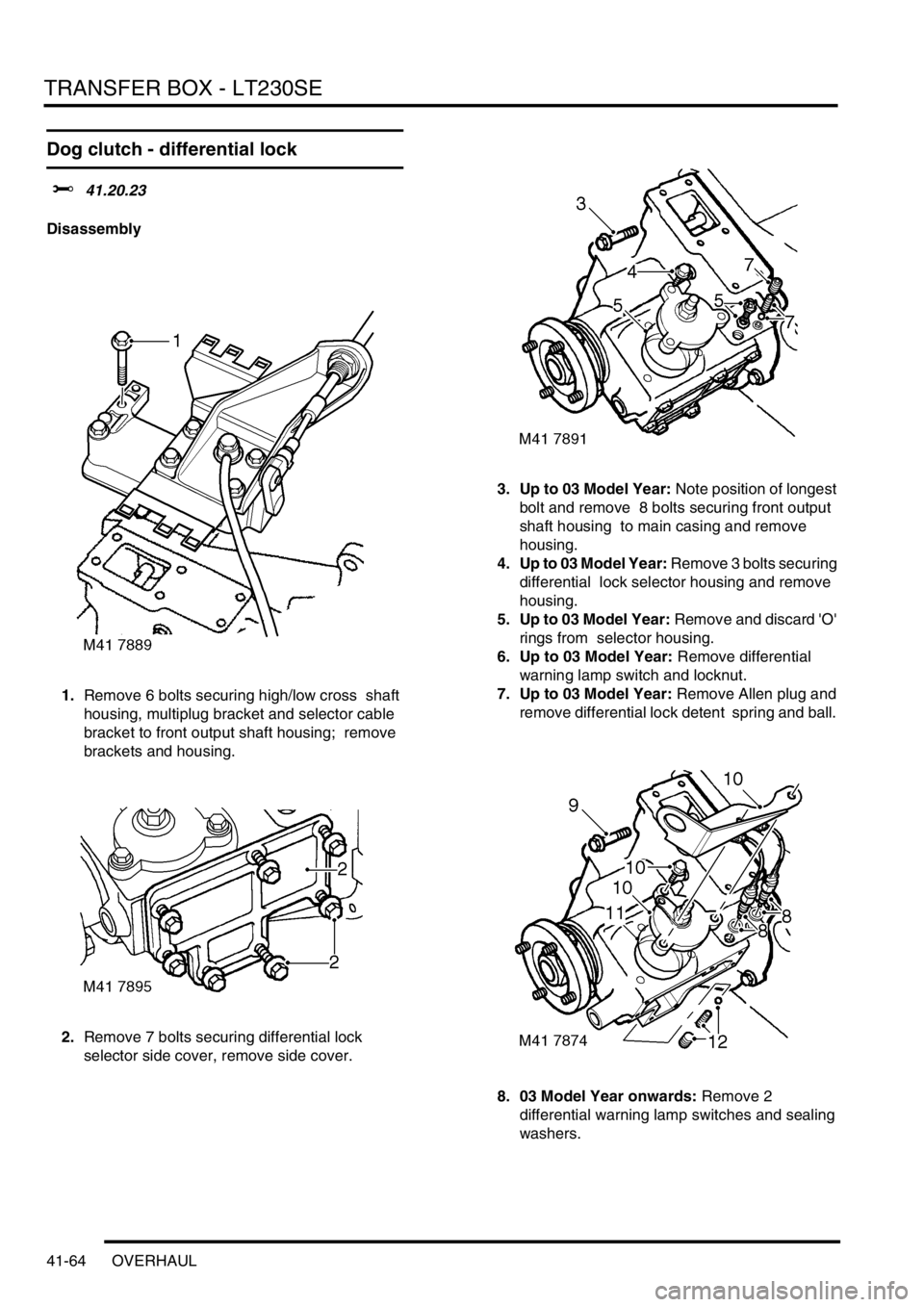

1.Remove 6 bolts securing high/low cross shaft

housing, multiplug bracket and selector cable

bracket to front output shaft housing; remove

brackets and housing.

2.Remove 7 bolts securing differential lock

selector side cover, remove side cover.3. Up to 03 Model Year: Note position of longest

bolt and remove 8 bolts securing front output

shaft housing to main casing and remove

housing.

4. Up to 03 Model Year: Remove 3 bolts securing

differential lock selector housing and remove

housing.

5. Up to 03 Model Year: Remove and discard 'O'

rings from selector housing.

6. Up to 03 Model Year: Remove differential

warning lamp switch and locknut.

7. Up to 03 Model Year: Remove Allen plug and

remove differential lock detent spring and ball.

8. 03 Model Year onwards: Remove 2

differential warning lamp switches and sealing

washers.

Page 590 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-65

9. 03 Model Year onwards:Note position of

longest bolt and remove 8 bolts securing front

output shaft housing to main casing; remove

housing.

10. 03 Model Year onwards:Remove 3 bolts

securing differential lock selector housing and

bracket, remove housing.

11. 03 Model Year onwards:Remove and discard

'O' rings from selector housing.

12. 03 Model Year onwards:Remove differential

lock detent plug, recover spring and ball.

13.Compress differential lock selector fork spring

and remove retaining clips from each end of

spring.

14.Withdraw differential lock selector shaft from

front output housing, recover spring and

remove selector fork.

15.Position tool LRT-51-003 to output shaft drive

flange, remove and discard nut. 16.Remove and discard steel and felt washers.

Remove output shaft drive flange.

17.Using a copper mallet, drive output shaft from

housing.

18.Noting its fitted position, remove bearing

spacer from output shaft.

19.Noting its fitted position, remove dog clutch

from output shaft.

20.Remove and discard oil seal from housing.

Reassembly

1.Clean differential lock components. Remove all

traces of sealant from mating faces of

housings, side cover, bolt threads, detent plugs

and differential lock warning lamp switches.

2.Lubricate components with gearbox oil.

3.Using tool LRT-41-012, fit new output shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Page 593 of 1529

TRANSFER BOX - LT230SE

41-68 OVERHAUL

Input gear/bearing

$% 41.20.60

Disassembly

1.Make alignment marks between cover plate/

bearing housing and main casing.

2.Remove 5 bolts and stud nut securing cover/

bearing housing to main casing. Remove cover

and bearing housing.

3.Remove input gear assembly. 4.Remove and discard oil seal from main casing.

5.Drift out bearing track from main casing.

Page 594 of 1529

TRANSFER BOX - LT230SE

OVERHAUL 41-69

6.Drift out bearing track from housing and collect

selective shim.

7.Position tool LRT-99-002 to vice.

8.Assemble tool LRT-41-003 to bearing, position

input gear to hand press and remove bearing.

9.Repeat procedure for remaining bearing. Reassembly

1.Clean input gear, cover/bearing housing and

main casing.

2.Using tool LRT-99-002 and LRT-41-003 fit

new bearings to input gear.

3.Using a suitable mandrel, fit bearing track to

main casing.

4.Fit a 3.15 mm (0.12 in) thick shim to bearing

housing and using a suitable mandrel fit

bearing track to housing.

5.Position input gear to main casing.

6.Fit bearing housing, ensuring reference marks

are aligned, secure bearing housing with 2

bolts and tighten to 25 Nm (18 lbf.ft).

Page 595 of 1529

TRANSFER BOX - LT230SE

41-70 OVERHAUL

7.Position dial gauge with stylus contacting input

gear, push input gear rearwards and zero

gauge.

8.Push input gear forwards and note gauge

reading.

9.Calculate thickness of shim required using the

formula - A+B+C=D where:

lA= Thickness of installed shim - 3.15 mm

(0.12 in)

lB= Recorded end-float.

lC= Required pre-load - 0.05 mm (0.002 in).

lD= Thickness of shim required.

10.If an alternative shim is required to establish

correct pre-load, fit an alternative shim. Shims

are available from 3.15 to 4.00 mm (0.12 to

0.16 in) thickness, in increments of 0.05 mm

(0.002 in).

11.Remove 2 bolts, remove bearing housing and

input gear.

12.Lubricate input gear and bearings with

recommended oil.

13.Position input gear into main casing.

14.Apply sealant, Part No. STC 4600to bearing

housing and cover.

15.Apply sealant, Part No. STC 50552 to threads

of cover bolts and stud nut.

16.Position bearing housing/cover, align reference

marks and tighten bolts and stud nut by

diagonal selection to 45 Nm (33 lbf.ft).

17.Using tool LRT-37-014 fit new input shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Low gear - differential

$% 41.20.62

Disassembly

1.Remove differential.

+ TRANSFER BOX - LT230SE,

OVERHAUL, Dog clutch - differential lock.

2.Secure differential in a soft jawed vice.

3.Release staking from bearing retaining nut.

4.Using tool LRT-41-007 remove and discard

bearing retaining nut.

5.Position tool LRT-99-002. to a vice.

6.Position tool LRT-41-001 around rear

differential bearing, position differential to tool

LRT-99-002 and press off bearing.

Page 598 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-1

AUTOMATIC GE ARBOX - ZF4HP22 - 24 DESCRIPTION AND OPERAT ION

Automatic gearbox component layout

1Selector lever assembly

2Gearbox

3Electronic automatic transmission ECU

4Selector position switch5Oil cooler

6Fluid lines

7Breather tube

8Selector cable

Page 600 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-3

1Transmission high/low switch

2Mode switch

3Gear position switch connector

4Solenoid valve/speed sensor connector

5Electronic automatic transmission ECU

6Engine control module

7Diagnostic socket

8Instrument pack

9Transmission fluid temperature sensor

10Body control unit

11Battery power supply

12Ignition power supply

Page 601 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-4 DESCRIPTION AND OPERATION

Description

General

The automatic gearbox is a four speed unit with electronic control of gear selection, shift quality and torque converter

lock-up. Selections on the selector lever assembly are transmitted to the gearbox by a selector cable. A gear position

switch on the gearbox transmits the gear selection to an Electronic Automatic Transmission (EAT) ECU, which

outputs the appropriate control signals to an electro-hydraulic valve block in the gearbox. A mode switch enables the

driver to change the control mode of the EAT ECU. The EAT ECU operates warning lamps in the instrument pack to

indicate the control mode and system status.

The gearbox features a pressure lubrication system and is cooled by pumping the lubricant through an oil cooler.

On NAS market vehicles from 03 model year, the ZF 4HP24 transmission unit is introduced for use with the 4.6 litre

V8 engine. This transmission is required to accomodate the increased power output of the larger engine. The ZF

4HP22 transmission remains in use on vehicles with Td5 and 4.0 litre V8 engines.

Both transmission units are of similar construction, with the ZF 4HP24 unit being 15 mm longer than the 4HP22 unit

to accomodate a larger fluid pump. The operation of both transmission units is the same.

Page 602 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-5

Selector lever assembly

1Release button

2Mode switch

3Electrical connector

4Interlock solenoid (where fitted)

5Base6Gasket

7Securing bolt

8Lever

9Cover

10Position indicators

The selector lever assembly consists of a lever and a cover attached to a base. The base is located on a gasket and

secured to the transmission tunnel. The lever is hinged to the base. A latch in the lever engages with detents in the

base to provide the lever positions P, R, N, D, 3, 2, 1. The latch is disengaged by pressing a release button on the

lever knob. Except for lever movement between positions D and 3, the button must be pressed before the lever can

be moved. In some markets, vehicles incorporate an interlock solenoid at the bottom of the lever, which prevents the

lever being moved from P unless the ignition switch is in position II and the foot brake is applied. If the battery

becomes flat, the interlock system will prevent selector lever movement and removal of the ignition key.

The cover incorporates lever position indicators and the mode switch. The lever position indicators illuminate to show

the position of the selector lever. Illumination is controlled by the Body Control Unit (BCU). The mode switch is a non-

latching hinged switch that, when pressed, connects an earth to the EAT ECU to request a change of mode.

An electrical connector at the rear of the cover connects the selector lever assembly to the vehicle wiring.

Selector cable

The selector cable is a Bowden type cable that connects the selector lever assembly to a selector lever on the

gearbox. 'C' clips secure the ends of the outer cable to brackets on the selector lever assembly and the selector lever.

The inner cable is adjustable at the connection of the inner cable with the gearbox selector lever.

Page 607 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-10 DESCRIPTION AND OPERATION

The lock-up and brake clutches are operated by pressurised transmission fluid from the valve block in the sump. A

manual valve and four solenoid valves, also known as Motorised Valves (MV), control the supply of pressurised

transmission fluid from the valve block:

lThe manual valve controls the supply in P, R, N and D.

lSolenoid valves MV 1 and MV 2 control the supplies that operate the brake clutches for shift control.

lSolenoid valve MV 3 controls the supply that operates the lock-up clutch.

lSolenoid valve MV 4 modulates the pressure of the supplies to the brake clutches, to control shift quality.

Operation of the manual valve is controlled by the selector lever assembly. In the gearbox, a selector shaft engages

with the manual valve. The selector shaft is connected to the selector lever assembly via the selector cable and a

selector lever on the left side of the gearbox. The selector shaft also operates a mechanism that locks the output shaft

when P is selected.

Operation of the solenoid valves is controlled by the EAT ECU.

An output shaft speed sensor in the gearbox housing outputs a signal to the EAT ECU. The EAT ECU compares

output shaft speed with engine speed to determine the engaged gear, and output shaft speed with vehicle speed to

confirm the range selected on the transfer box.

A bayonet lock electrical connector in the gearbox casing, to the rear of the selector lever, connects the solenoid

valves and the output shaft speed sensor to the vehicle wiring.

A pressed steel sump encloses the valve block and collects transmission fluid draining from the gearbox housing. A

suction pipe and filter on the underside of the valve block connect to the inlet side of the fluid pump. A magnet is

installed in the sump to collect any magnetic particles that may be present. A level plug and a drain plug are installed

in the sump for servicing.

Rear extension housing

The rear extension housing provides the interface between the gearbox housing and the transfer box. A splined

extension shaft, secured to the gearbox output shaft by a bolt, transmits the drive from the gearbox to the transfer

box. A seal in the rear of the housing prevents leakage past the extension shaft. A breather pipe, attached to the left

side of the rear extension housing, ventilates the interior of the gearbox and rear extension housings to atmosphere.

The open end of the breather pipe is located in the engine compartment at the right front corner of the engine sump

on gearboxes fitted to early vehicles and is clipped to the top of the gearbox on later vehicles.

Gearbox power flows

The following Figures show the power flow through the gearbox for each forward gear when D is selected, and for

reverse. The key to the Item numbers on the Figures, and in parenthesis in the accompanying text, can be found on

the 'Sectioned view of gearbox' Figure, above.

1st Gear (D selected)

Clutches (4) and (11) are engaged. The front planet gear carrier of gear set (9) locks against the gearbox housing

through freewheel (15) when the engine powers the vehicle, and freewheels when the vehicle is coasting. Gear set

(10) rotates as a solid unit with the front planet gear carrier. In 1st gear hold brake clutch (8) is applied to provide

overrun braking.