ABS LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 272 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-39

Evaporative Emission Control Operation

Fuel vapour is stored in the activated charcoal (EVAP) canister for retention when the vehicle is not operating. When

the vehicle is operating, fuel vapour is drawn from the canister into the engine via a purge control valve. The vapour

is then delivered to the intake plenum chamber to be supplied to the engine cylinders where it is burned in the

combustion process.

During fuel filling the fuel vapour displaced from the fuel tank is allowed to escape to atmosphere, valves within the

fuel filler prevent any vapour escaping through to the EVAP canister as this can adversely affect the fuel cut-off height.

Only fuel vapour generated whilst driving is prevented from escaping to atmosphere by absorption into the charcoal

canister. The fuel filler shuts off to leave the tank approximately 10% empty to ensure the ROVs are always above

the fuel level and so vapour can escape to the EVAP canister and the tank can breathe. The back pressures normally

generated during fuel filling are too low to open the pressure relief valve, but vapour pressures accumulated during

driving are higher and can open the pressure relief valve. Should the vehicle be overturned, the ROVs shut off to

prevent any fuel spillage.

Fuel vapour generated from within the fuel tank as the fuel heats up is stored in the tank until the pressure exceeds

the operating pressure of the two-way valve. When the two-way valve opens, the fuel vapour passes along the vent

line from the fuel tank (via the fuel tank vapour separator) to the evaporation inlet port of the EVAP canister. The fuel

tank vents between 5.17 and 6.9 kPa.

Fuel vapour evaporating from the fuel tank is routed to the EVAP canister through the fuel vapour separator and vent

line. Liquid fuel must not be allowed to contaminate the charcoal in the EVAP canister. To prevent this, the fuel vapour

separator fitted to the fuel neck allows fuel to drain back into the tank. As the fuel vapour cools, it condenses and is

allowed to flow back into the fuel tank from the vent line by way of the two-way valve.

The EVAP canister contains charcoal which absorbs and stores fuel vapour from the fuel tank while the engine is not

running. When the canister is not being purged, the fuel vapour remains in the canister and clean air exits the canister

via the air inlet port.

The engine management ECM controls the electrical output signal to the purge valve. The system will not work

properly if there is leakage or clogging within the system or if the purge valve cannot be controlled.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

When the engine is running, the ECM decides when conditions are correct for vapour to be purged from the EVAP

canister and opens the canister purge valve. This connects a manifold vacuum line to the canister and fuel vapour

containing the hydrocarbons is drawn from the canister's charcoal element to be burned in the engine. Clean air is

drawn into the canister through the atmosphere vent port to fill the displaced volume of vapour.

The purge valve remains closed below preset coolant and engine speed values to protect the engine tune and

catalytic converter performance. If the EVAP canister was purged during cold running or at idling speed, the additional

enrichment in the fuel mixture would delay the catalytic converter light off time and cause erratic idle. When the purge

valve is opened, fuel vapour from the EVAP canister is drawn into the plenum chamber downside of the throttle

housing, to be delivered to the combustion chambers for burning.

The purge valve is opened and closed in accordance with a pulse width modulated (PWM) signal supplied from the

engine management ECM. The system will not work properly if the purge valve cannot be controlled. Possible failure

modes associated with the purge valve are listed below:

lValve drive open circuit.

lShort circuit to vehicle supply or ground.

lPurge valve or pipework blocked or restricted.

lPurge valve stuck open.

lPipework joints leaking or disconnected.

Possible symptoms associated with a purge valve or associated pipework failure is listed below:

lEngine may stall on return to idle if purge valve is stuck open.

lPoor idling quality if the purge valve is stuck open

lFuelling adaptions forced excessively lean if the EVAP canister is clear and the purge valve is stuck open.

lFuelling adaptions forced excessively rich if the EVAP canister is saturated and the purge valve is stuck open.

lSaturation of the EVAP canister if the purge valve is stuck closed.

Page 285 of 1529

EMISSION CONTROL - V8

17-2-52 REPAIRS

Canister - EVAP - Models with Fuel Leak

Detection Pump - up to 03MY

$% 17.15.13

Remove

1.Raise vehicle on lift.

2.Remove 3 Torx screws securing fuel leak

detection pump to mounting bracket.

3.Remove 3 bolts securing EVAP canister

mounting bracket to chassis longitudinal.4.Remove 2 bolts securing EVAP canister to

mounting bracket and collect clamp.

5.Remove mounting bracket.

6.Position cloth to absorb any fuel spillage.

7.Release purge and tank vent pipes from EVAP

canister.

8.Remove clip securing fuel leak detection pump

pipe to EVAP canister.

9.Release pipe from EVAP canister and remove

canister.

CAUTION: Plug the connections.

Refit

1.Remove plugs and ensure all connections are

clean.

2.Connect fuel leak detection pump pipe to EVAP

canister and secure with clip.

3.Connect purge and tank vent pipes to EVAP

canister.

4.Position mounting bracket to EVAP canister

and secure with bolts.

5.Position mounting bracket to chassis

longitudinal and tighten bolts.

6.Fit Torx screws securing fuel leak detection

pump to mounting bracket.

7.Lower vehicle.

M17 02192

M17 0220

M17 0221

4

4

4

9

7

7

5

8

Page 297 of 1529

EMISSION CONTROL - V8

17-2-64 REPAIRS

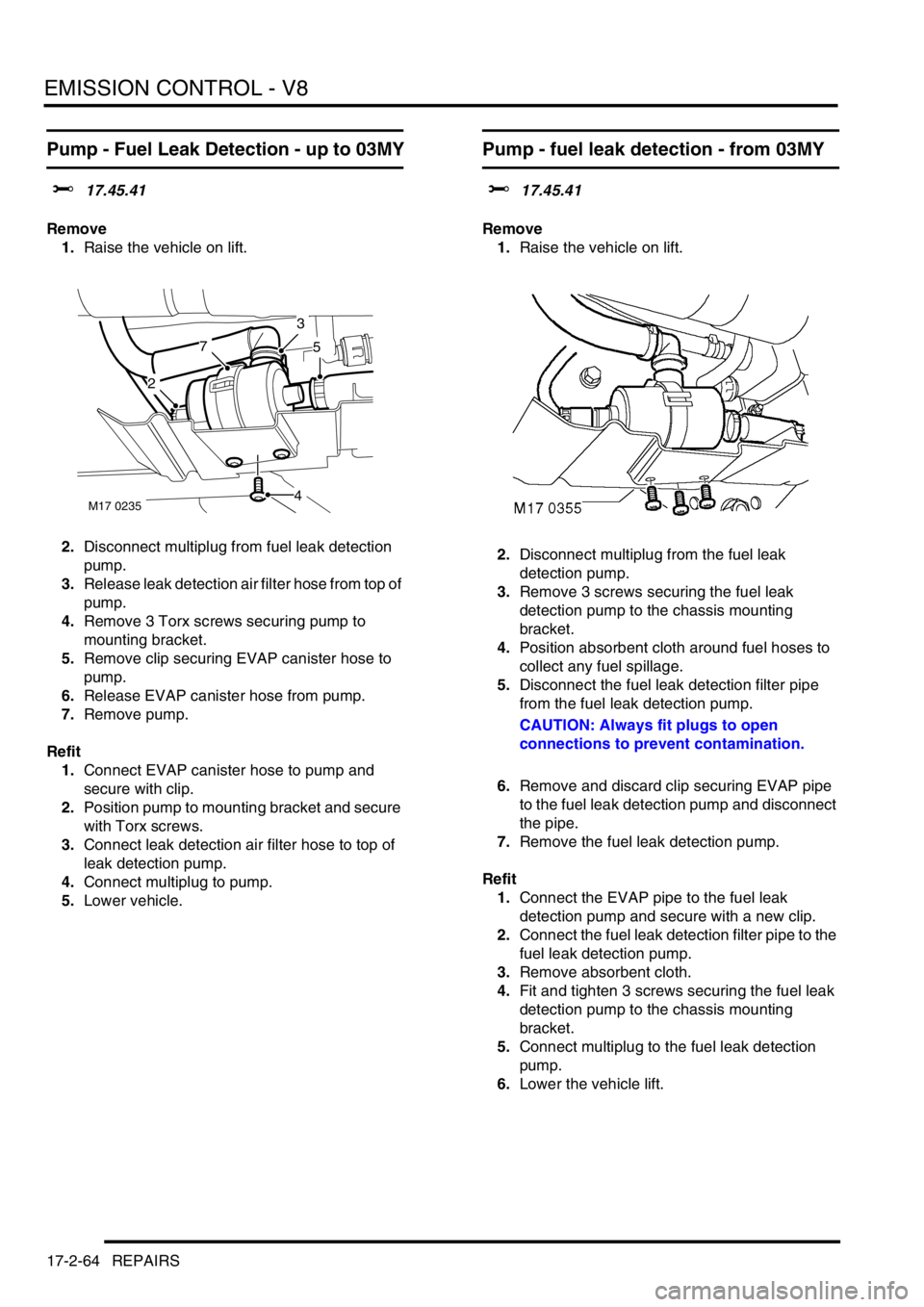

Pump - Fuel Leak Detection - up to 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from fuel leak detection

pump.

3.Release leak detection air filter hose from top of

pump.

4.Remove 3 Torx screws securing pump to

mounting bracket.

5.Remove clip securing EVAP canister hose to

pump.

6.Release EVAP canister hose from pump.

7.Remove pump.

Refit

1.Connect EVAP canister hose to pump and

secure with clip.

2.Position pump to mounting bracket and secure

with Torx screws.

3.Connect leak detection air filter hose to top of

leak detection pump.

4.Connect multiplug to pump.

5.Lower vehicle.

Pump - fuel leak detection - from 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from the fuel leak

detection pump.

3.Remove 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

4.Position absorbent cloth around fuel hoses to

collect any fuel spillage.

5.Disconnect the fuel leak detection filter pipe

from the fuel leak detection pump.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove and discard clip securing EVAP pipe

to the fuel leak detection pump and disconnect

the pipe.

7.Remove the fuel leak detection pump.

Refit

1.Connect the EVAP pipe to the fuel leak

detection pump and secure with a new clip.

2.Connect the fuel leak detection filter pipe to the

fuel leak detection pump.

3.Remove absorbent cloth.

4.Fit and tighten 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

5.Connect multiplug to the fuel leak detection

pump.

6.Lower the vehicle lift.

M17 0235

2

3

4

57

Page 304 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-5

1Engine control module

2Crankshaft speed and position sensor

3Camshaft position sensor

4Engine coolant temperature sensor

5Mass air flow/ inlet air temperature sensor

6Throttle position sensor

7Heated oxygen sensors

8Fuel injectors

9Idle air control valve

10Fuel pump relay

11EVAP canister

12EVAP canister vent valve

13EVAP canister purge valve

14Fuel tank pressure sensor15Ignition coils

16Knock sensor

17Spark plugs

18High/ Low ratio switch

19Malfunction indication lamp

20Diagnostic connector

21Air temperature control clutch relay

22Air temperature control cooling fan relay

23ATC ECU

24CAN link to EAT

25SLABS ECU

26BCU

27Instrument cluster

28Thermostat monitoring sensor (where fitted)

Page 306 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-7

The ECM controls the following outputs:

lFuel injectors (1 per cylinder).

lIgnition coils/ high tension leads/ spark plugs.

lFuel pump relay.

lIdle air control valve.

lHeated oxygen sensors.

lEVAP canister purge valve.

lEVAP canister vent solenoid (CVS) valve (where fitted).

lMalfunction Indicator Lamp (MIL)/ service engine soon lamp (where fitted).

lHill descent control (via SLABS interface).

lEVAP system fuel leak detection pump (where fitted)

lSecondary air injection pump (where fitted)

The ECM also interfaces with the following:

lDiagnostics via diagnostic connector with TestBook.

lController Area Network (CAN) link to EAT ECU.

lAir conditioning system.

lSelf Levelling & Anti-lock Braking System (SLABS) ECU.

lImmobilisation system via the body control unit (BCU).

lInstrument cluster.

lCruise control ECU

lActive Cornering Enhancement (ACE) ECU

Page 327 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-28 DESCRIPTION AND OPERATION

Throttle Position (TP) sensor (C0175)

The TP sensor is located on the throttle body assembly in the engine compartment. The ECM is able to determine the

position of the throttle plate and the rate of change of its angle. The ECM processes the signal received from the TP

sensor.

The TP sensor consists of a resistance track and a sliding contact connected to the throttle plate assembly. As the

throttle is opened and closed the sliding contact moves along the resistance track to change the output voltage of the

sensor. The ECM determines throttle plate position by processing this output voltage. The connection of the sensor

to the throttle plate assembly is via a shaft.

The ECM is able to determine the closed throttle position, this enables the TP sensor to be fitted without the need for

prior adjustment. The TP sensor signal has input into the ECM's fuelling strategy and also to determine closed throttle

position for idle speed control. The TP sensor also supplies the ECM with information to enable the overrun fuel cut

off strategy to be implemented. When the ECM receives closed throttle information from the TP sensor it closes the

injectors for the duration of the closed throttle time.

The TP sensor signal is also used by the Electronic Automatic Transmission (EAT) ECU to determine the correct point

for gear shifts and acceleration kickdown. The ECM also supplies the SLABS ECU with this TP sensor information as

a PWM signal.

Input/Output

The TP sensor has electrical input and output. Input is a 5 volt supply via pin 10 of connector C0636 of the ECM. The

signal output is via pin 24 of connector C0636 and is a varying voltage, less than 0.5V (closed throttle) and greater

than 4.5V (wide open throttle) depending on throttle plate position. The TP sensor earth is via pin 25 of connector

C0636 of the ECM, this acts as a screen to protect the integrity of the TP sensor signal.

The connector and sensor terminals are gold plated for corrosion and temperature resistance, care must be exercised

while probing the connector and sensor terminals.

If the TP sensor signal fails, the ECM uses a default value derived from engine load and speed.

The TP sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lSignal out of parameters.

lBlocked air filter (load monitoring, ratio of the TP sensor to air flow).

lRestriction in air inlet (load monitoring, ratio of the TP sensor to air flow).

lVacuum leak

Page 354 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-55

Vehicle Speed Signal (VSS)

The VSS is used, by the ECM, to control idle speed and overrun cut off. The ECM receives the signal through a hard

wired connection direct from the SLABS ECU.

For vehicles fitted with an automatic gearbox, two vehicle speed signals are received by the ECM. The second signal

is derived from the main gearbox output shaft speed, and is sent to the ECM by the Electronic Automatic Transmission

(EAT) ECU though the Controller Area Network (CAN). The ECM compares the vehicle speed signal generated by

the SLABS ECU with that supplied via the CAN.

The ECM also receives transfer box information. This allows the ECM to take in to account the vehicle being driven

using low range gearing and compensate as necessary.

On vehicles with manual transmission, the SLABS signal is checked against a threshold value stored in ECM memory.

If other engine parameters indicate the engine is at high load and the VSS is below the threshold, a fault condition is

registered in the diagnostic memory.

The vehicle speed signal generated by the SLABS ECU is in the form of a pulse width modulated signal (PWM).

Pulses are generated at 8000 per mile, and the frequency of the signal changes in accordance with road speed. At

zero road speed the ECU outputs a reference signal at a frequency of 2Hz for diagnostic purposes.

Function

The input signal for the SLABS ECU is measured via pin 22 of connector C0637 of the ECM. The SLABS ECU

generates a PWM signal switching between 0 and 12 volts at a frequency of 8000 pulses per mile. For vehicles with

automatic gearbox the input signal for the EAT ECU is measured via pins 36 and 37 of connector C0637 of the ECM.

These pin numbers provide a bi-directional communications link using the CAN data bus.

In the case of a VSS failure on vehicles with automatic gearboxes, the ECM applies default values derived from the

EAT ECU. There are no default values for manual gearbox vehicles.

The VSS can fail in the following ways:

lWiring short circuit to vehicle supply.

lWiring short circuit to vehicle earth.

lWiring open circuit.

In the event of a VSS failure, any of the following symptoms may be observed:

lMIL illuminated after 2 driving cycles (NAS only).

lVehicle speed limiting disabled (manual transmission vehicles only).

lSLABS/HDC warning lamp on and audible warning.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

Rough road signal

When the vehicle travels across rough terrain, or on rough roads instability becomes evident in the drive train. The

ECM could interpret these vibrations as a 'false misfire'. To counteract this 'false misfire' the SLABS ECU generates

a rough road signal, sends it to the ECM so that the ECM can suspend misfire detection for as long as the vehicle is

travelling on the 'rough road'.

P Code J2012 Description Land Rover Description

P0500 Vehicle speed sensor malfunction VSS short or open circuit

P0501 Vehicle speed sensor range/performance VSS implausible

Page 355 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-56 DESCRIPTION AND OPERATION

Function

Input for the rough road signal is measured via pin 34 of connector C0637 of the ECM. The SLABS ECU generates

a PWM signal that varies in accordance with changing road conditions. The rough road PWM signal operates at a

frequency of 2.33 Hz ± 10%. The significance of changes in the PWM signal are shown in the following table:

The rough road signal can fail in the following ways:

lHarness or connector damage

lSLABS failure — wheel speed sensor

A rough road signal failure may be evident from the following:

lHDC / ABS warning light on

Should a malfunction of the rough road signal occur, the following fault codes may be evident and can be retrieved

by TestBook:

Hill Descent Control (HDC) signal

The ECM transmits throttle angle, engine torque, engine identification (Td5 or V8), and transmission type (automatic

or manual) data to the SLABS ECU to support the Hill Descent Control system. The information is transmitted via a

0 – 12V pulse width modulated (PWM) signal at a frequency of 179.27 Hz.

Function

The HDC signal output from the ECM is via pin 29 of connector C0636. The ECM generates a PWM signal that varies

in pulse width in accordance with changing throttle angle or engine torque. The throttle angle data is transmitted on

pulses 1, 3, 5 and 37. The engine torque data is transmitted on pulses 2,4,6 and 38. The engine and transmission

information is transmitted on pulse 39. A synchronising pulse is transmitted after every 39th pulse.

The HDC signal can fail in the following ways:

lHarness or connector damage

A HDC signal failure may be evident from the following:

lHDC / ABS warning light on

lHDC inoperative

lAudible warning

Should a malfunction of the HDC signal occur, the following fault codes may be evident and can be retrieved by

TestBook:

PWM signal Indication

<10% Electrical short circuit to ground

25% ± 5 % Smooth road

50% ± 5 % SLABS error

75% ± 5% Rough road

>90% Electrical short circuit to battery voltage

P Code J2012 Description Land Rover Description

P1590 ABS rough road signal circuit malfunction Hardware is OK, but SLABS ECU is sending an error

signal

P1591 ABS rough road signal circuit low Signal from SLABS ECU short circuit to earth

P1592 ABS rough road signal circuit high Signal from SLABS ECU short circuit to vehicle battery

supply

P Code J2012 Description Land Rover Description

P1663 Throttle angle/Torque signal circuit malfunction SLABS HDC link open circuit

P1664 Throttle angle/Torque signal circuit low SLABS HDC link short circuit to ground

P1665 Throttle angle/Torque signal circuit high SLABS HDC link short circuit to battery voltage

Page 360 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-61

DESCRIPTION AND OPERAT ION

Cruise control component layout

1Cruise control ECU

2Cruise control master switch

3SET+ switch

4RES switch

5Brake pedal switch

6Clutch pedal switch7BCU

8Vacuum pump assembly

9Pneumatic actuator

10SLABS ECU

11Automatic gear selector lever

Page 361 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-62 DESCRIPTION AND OPERATION

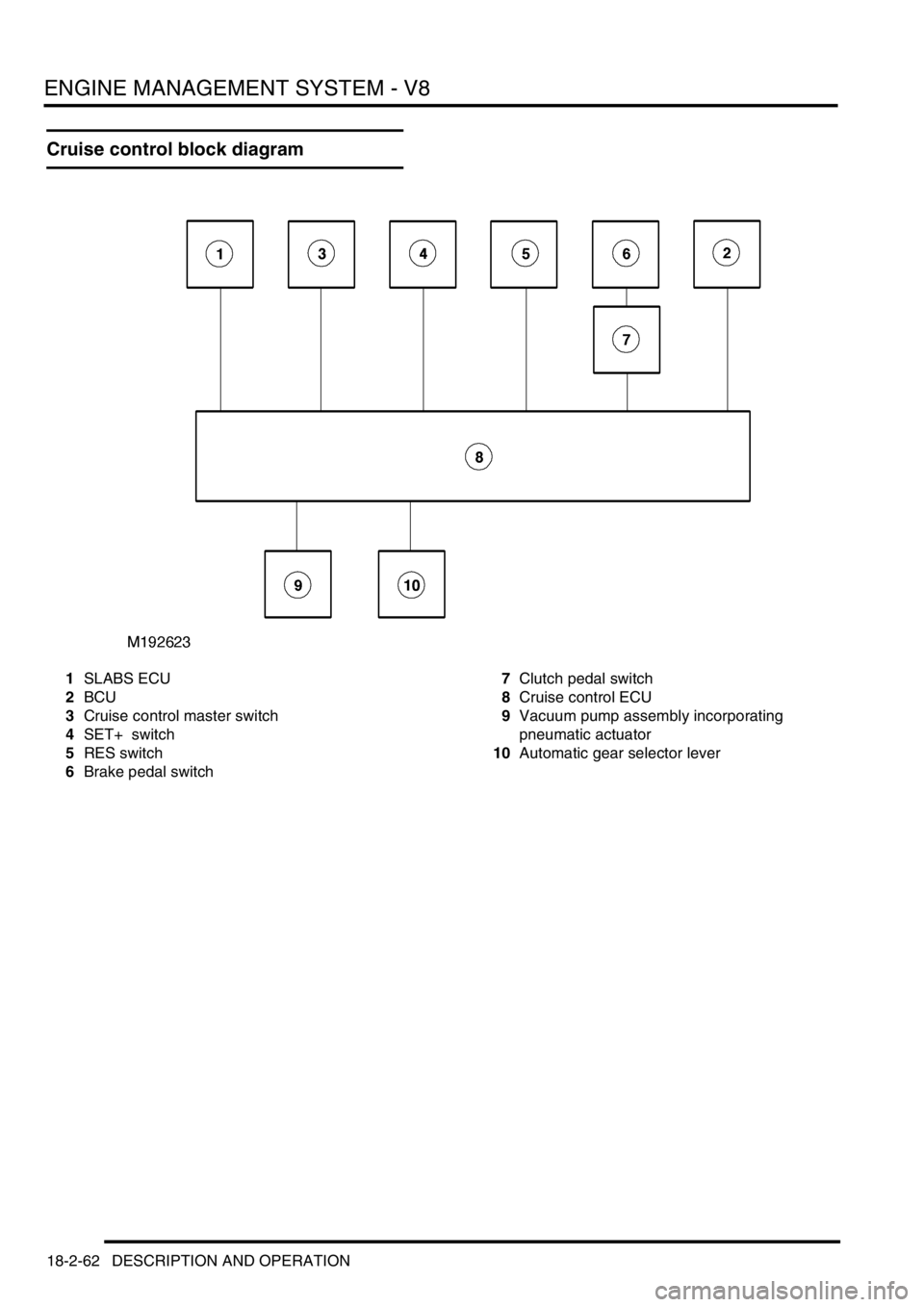

Cruise control block diagram

1SLABS ECU

2BCU

3Cruise control master switch

4SET+ switch

5RES switch

6Brake pedal switch7Clutch pedal switch

8Cruise control ECU

9Vacuum pump assembly incorporating

pneumatic actuator

10Automatic gear selector lever