Gear ratio LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 351 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-52 DESCRIPTION AND OPERATION

Evaporative emission control

Due to increasing legislation, all new vehicles must be able to limit evaporative emissions (fuel vapour) from the fuel

tank.

The ECM controls the emission control system using the following components:

lEVAP canister.

lPurge valve.

lCanister vent solenoid (CVS) valve – (NAS vehicles with vacuum type EVAP system leak detection capability

only)

lFuel tank pressure sensor – (NAS vehicles with vacuum type EVAP system leak detection capability only)

lFuel leak detection pump – (NAS vehicles with positive pressure type EVAP system leak detection capability

only)

lInterconnecting pipe work.

Refer to Emissions section for operating conditions of evaporative emission systems.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative Emission Control

Operation.

On-Board Diagnostics (OBD) - North American Specification vehicles only

The ECM monitors performance of the engine for misfires, catalyst efficiency, exhaust leaks and evaporative control

loss. If a fault occurs, the ECM stores the relevant fault code and warns the driver of component failure by illuminating

the Malfunction Indicator Light in the instrument pack.

On vehicles fitted with automatic gearbox, the ECM combines with the Electronic Automatic Transmission (EAT) ECU

to provide the OBD strategy.

Conditions

If the OBD function of the ECM flags a fault during its operation, it falls into one of the following categories:

lmin = minimum value of the signal exceeded.

lmax = maximum value of the signal exceeded.

lsignal = signal not present.

lplaus = an implausible condition has been diagnosed.

Function

All of the ECM's internal diagnostic fault paths are monitored by the OBD system. Specific faults have their own

numeric code relating to certain sensors or actuators etc. These specific faults fall into two types, error codes (E xxx)

or cycle codes (Z xxx). E codes represent instantaneous faults and Z codes relate to codes generated after completion

of a drive cycle.

If an emission relevant fault occurs on a drive cycle, the ECM stores a temporary fault code, if the fault does not occur

on subsequent drive cycles the fault code stays as a temporary fault code. If the fault recurs on subsequent drive

cycles the ECM stores the fault code as a permanent code, and depending on which component has failed the ECM

will illuminate the MIL.

Immobilisation system

The ECM and the body control unit (BCU) security system comprise the immobilisation system.

The ECM and the BCU combine to prevent the engine from running unless the appropriate security criteria are met.

The ECM and the BCU are a matched pair, if either one is replaced for any reason, the system will not operate unless

the replaced unit is correctly matched to its original specification. TestBook must be used to reconfigure the

immobilisation system.

Conditions

The ECM operates immobilisation in three states:

l'New'.

l'Secure'.

l'No Code'.

Page 352 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-53

Function

With the ECM operating in the 'New' state, TestBook is required to instruct the ECM to learn the new BCU code. If the

ECM is in delivery state (i.e. direct from the supplier), it will not run the vehicle and will store a new ECM fault code

when it is fitted. This code must be cleared after instructing the ECM to learn the BCU code using TestBook.

When the ECM is in the 'Secure' state, no further action is required as the ECM has successfully learned the BCU

code. A 'Secure' ECM can not be configured to a 'No Code' state.

If the vehicle is fitted with an ECM with a valid code, the engine will start and the MIL will go out.

However, if the ECM has an invalid BCU security code the engine will crank, start, and then immediately stall. The

status of the security system can only be interrogated using TestBook.

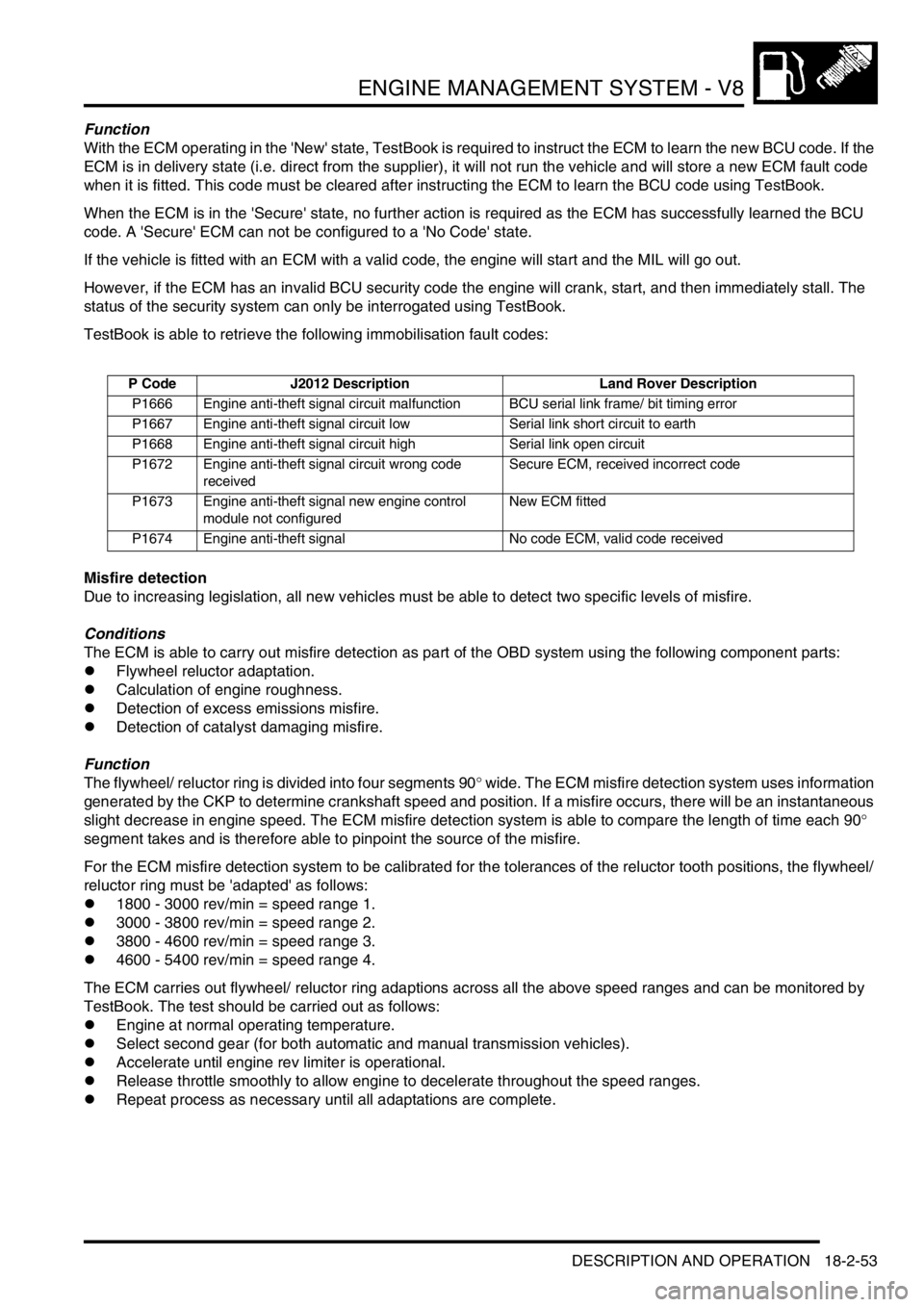

TestBook is able to retrieve the following immobilisation fault codes:

Misfire detection

Due to increasing legislation, all new vehicles must be able to detect two specific levels of misfire.

Conditions

The ECM is able to carry out misfire detection as part of the OBD system using the following component parts:

lFlywheel reluctor adaptation.

lCalculation of engine roughness.

lDetection of excess emissions misfire.

lDetection of catalyst damaging misfire.

Function

The flywheel/ reluctor ring is divided into four segments 90° wide. The ECM misfire detection system uses information

generated by the CKP to determine crankshaft speed and position. If a misfire occurs, there will be an instantaneous

slight decrease in engine speed. The ECM misfire detection system is able to compare the length of time each 90°

segment takes and is therefore able to pinpoint the source of the misfire.

For the ECM misfire detection system to be calibrated for the tolerances of the reluctor tooth positions, the flywheel/

reluctor ring must be 'adapted' as follows:

l1800 - 3000 rev/min = speed range 1.

l3000 - 3800 rev/min = speed range 2.

l3800 - 4600 rev/min = speed range 3.

l4600 - 5400 rev/min = speed range 4.

The ECM carries out flywheel/ reluctor ring adaptions across all the above speed ranges and can be monitored by

TestBook. The test should be carried out as follows:

lEngine at normal operating temperature.

lSelect second gear (for both automatic and manual transmission vehicles).

lAccelerate until engine rev limiter is operational.

lRelease throttle smoothly to allow engine to decelerate throughout the speed ranges.

lRepeat process as necessary until all adaptations are complete.

P Code J2012 Description Land Rover Description

P1666 Engine anti-theft signal circuit malfunction BCU serial link frame/ bit timing error

P1667 Engine anti-theft signal circuit low Serial link short circuit to earth

P1668 Engine anti-theft signal circuit high Serial link open circuit

P1672 Engine anti-theft signal circuit wrong code

receivedSecure ECM, received incorrect code

P1673 Engine anti-theft signal new engine control

module not configuredNew ECM fitted

P1674 Engine anti-theft signal No code ECM, valid code received

Page 354 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-55

Vehicle Speed Signal (VSS)

The VSS is used, by the ECM, to control idle speed and overrun cut off. The ECM receives the signal through a hard

wired connection direct from the SLABS ECU.

For vehicles fitted with an automatic gearbox, two vehicle speed signals are received by the ECM. The second signal

is derived from the main gearbox output shaft speed, and is sent to the ECM by the Electronic Automatic Transmission

(EAT) ECU though the Controller Area Network (CAN). The ECM compares the vehicle speed signal generated by

the SLABS ECU with that supplied via the CAN.

The ECM also receives transfer box information. This allows the ECM to take in to account the vehicle being driven

using low range gearing and compensate as necessary.

On vehicles with manual transmission, the SLABS signal is checked against a threshold value stored in ECM memory.

If other engine parameters indicate the engine is at high load and the VSS is below the threshold, a fault condition is

registered in the diagnostic memory.

The vehicle speed signal generated by the SLABS ECU is in the form of a pulse width modulated signal (PWM).

Pulses are generated at 8000 per mile, and the frequency of the signal changes in accordance with road speed. At

zero road speed the ECU outputs a reference signal at a frequency of 2Hz for diagnostic purposes.

Function

The input signal for the SLABS ECU is measured via pin 22 of connector C0637 of the ECM. The SLABS ECU

generates a PWM signal switching between 0 and 12 volts at a frequency of 8000 pulses per mile. For vehicles with

automatic gearbox the input signal for the EAT ECU is measured via pins 36 and 37 of connector C0637 of the ECM.

These pin numbers provide a bi-directional communications link using the CAN data bus.

In the case of a VSS failure on vehicles with automatic gearboxes, the ECM applies default values derived from the

EAT ECU. There are no default values for manual gearbox vehicles.

The VSS can fail in the following ways:

lWiring short circuit to vehicle supply.

lWiring short circuit to vehicle earth.

lWiring open circuit.

In the event of a VSS failure, any of the following symptoms may be observed:

lMIL illuminated after 2 driving cycles (NAS only).

lVehicle speed limiting disabled (manual transmission vehicles only).

lSLABS/HDC warning lamp on and audible warning.

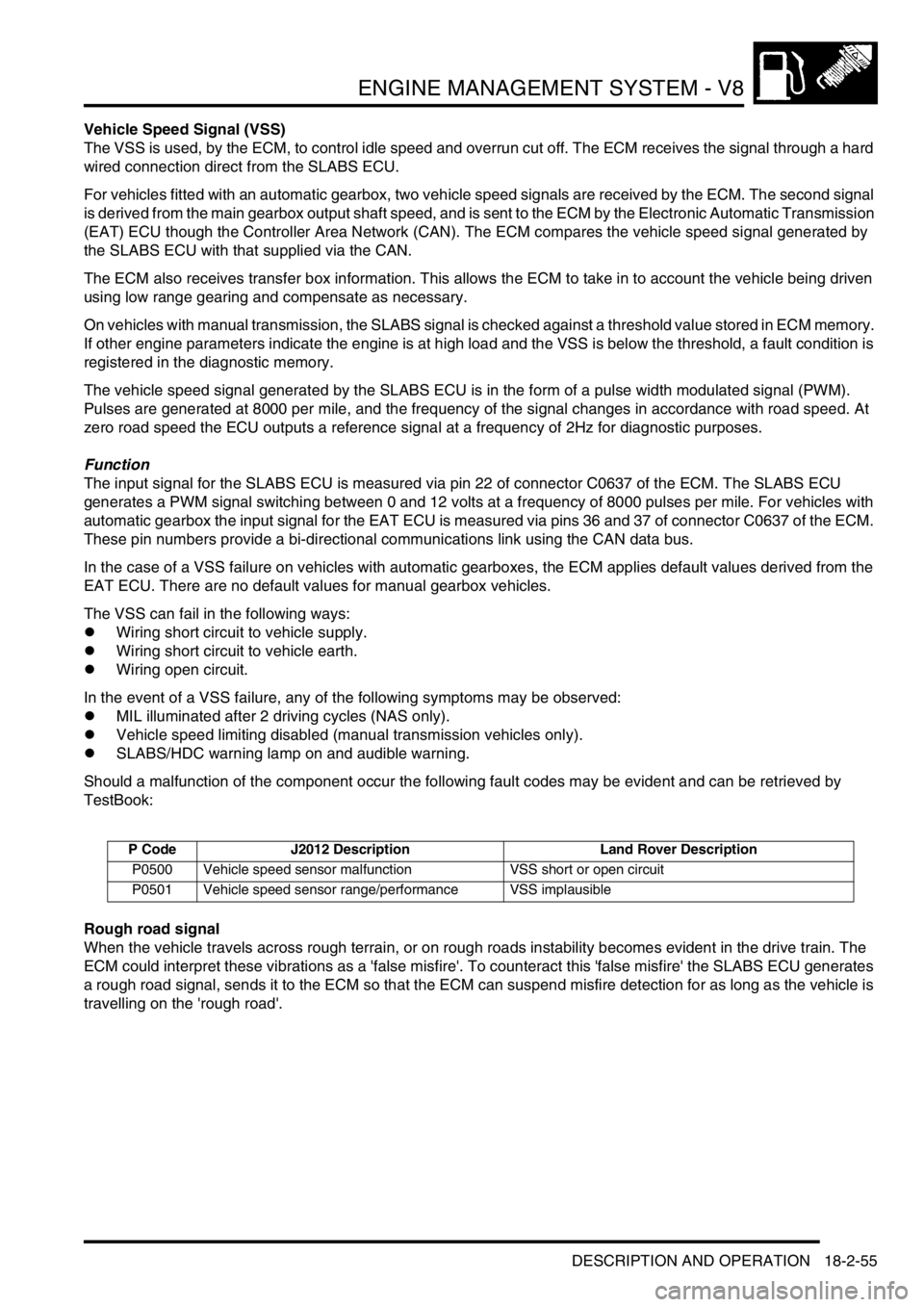

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

Rough road signal

When the vehicle travels across rough terrain, or on rough roads instability becomes evident in the drive train. The

ECM could interpret these vibrations as a 'false misfire'. To counteract this 'false misfire' the SLABS ECU generates

a rough road signal, sends it to the ECM so that the ECM can suspend misfire detection for as long as the vehicle is

travelling on the 'rough road'.

P Code J2012 Description Land Rover Description

P0500 Vehicle speed sensor malfunction VSS short or open circuit

P0501 Vehicle speed sensor range/performance VSS implausible

Page 357 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-58 DESCRIPTION AND OPERATION

Conditions

The CAN system is used by the EAT ECU and the ECM for transmission of the following information:

lGearshift torque control information.

lEAT OBD information.

lMIL request.

lVehicle speed signal.

lEngine temperature.

lEngine torque and speed.

lGear selected.

lGear change information.

lAltitude adaptation factor

lAir intake temperature

lThrottle angle / pedal position

Function

The CAN system uses a twisted pair of wires to form the 'data bus' to minimise electrical interference. This method of

serial interface is very reliable and very fast. The information messages are structured so that each of the receivers

(ECM or EAT ECU) is able to interpret and react to the messages sent.

The CAN 'data bus' is directly connected between pin 36 of connector C0637 of the ECM and pin 16 of connector

C0193 at the EAT ECU, and pin 37 of connector C0637 of the ECM and pin 44 of connector C0193 at the EAT ECU.

The CAN system can fail in the following ways:

lCAN data bus wiring open circuit.

lCAN data bus wiring short circuit.

In the event of a CAN data bus failure any of the following symptoms may be observed:

lMIL illuminated after 2 drive cycles (NAS only).

lEAT defaults to 3rd gear only.

lHarsh gearshifts.

l'Sport' and 'manual' lights flash alternately.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

Drive cycles

The following are the TestBook drive cycles:

⇒ Drive cycle A:

1Switch on the ignition for 30 seconds.

2Ensure engine coolant temperature is less than 60°C (140°F).

3Start the engine and allow to idle for 2 minutes.

4Connect TestBook and check for fault codes.

⇒ Drive cycle B:

1Switch ignition on for 30 seconds.

2Ensure engine coolant temperature is less than 60°C (140°F).

3Start the engine and allow to idle for 2 minutes.

4Perform 2 light accelerations (0 to 35 mph (0 to 60 km/h) with light pedal pressure).

5Perform 2 medium accelerations (0 to 45 mph (0 to 70 km/h) with moderate pedal pressure).

6Perform 2 hard accelerations (0 to 55 mph (0 to 90 km/h) with heavy pedal pressure).

7Allow engine to idle for 2 minutes.

8Connect TestBook and with the engine still running, check for fault codes.

P Code J2012 Description Land Rover Description

P0600 Serial communication link malfunction CAN time out

P1776 Transmission control system torque interface

malfunctionEAT torque interface error

Page 360 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-61

DESCRIPTION AND OPERAT ION

Cruise control component layout

1Cruise control ECU

2Cruise control master switch

3SET+ switch

4RES switch

5Brake pedal switch

6Clutch pedal switch7BCU

8Vacuum pump assembly

9Pneumatic actuator

10SLABS ECU

11Automatic gear selector lever

Page 361 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-62 DESCRIPTION AND OPERATION

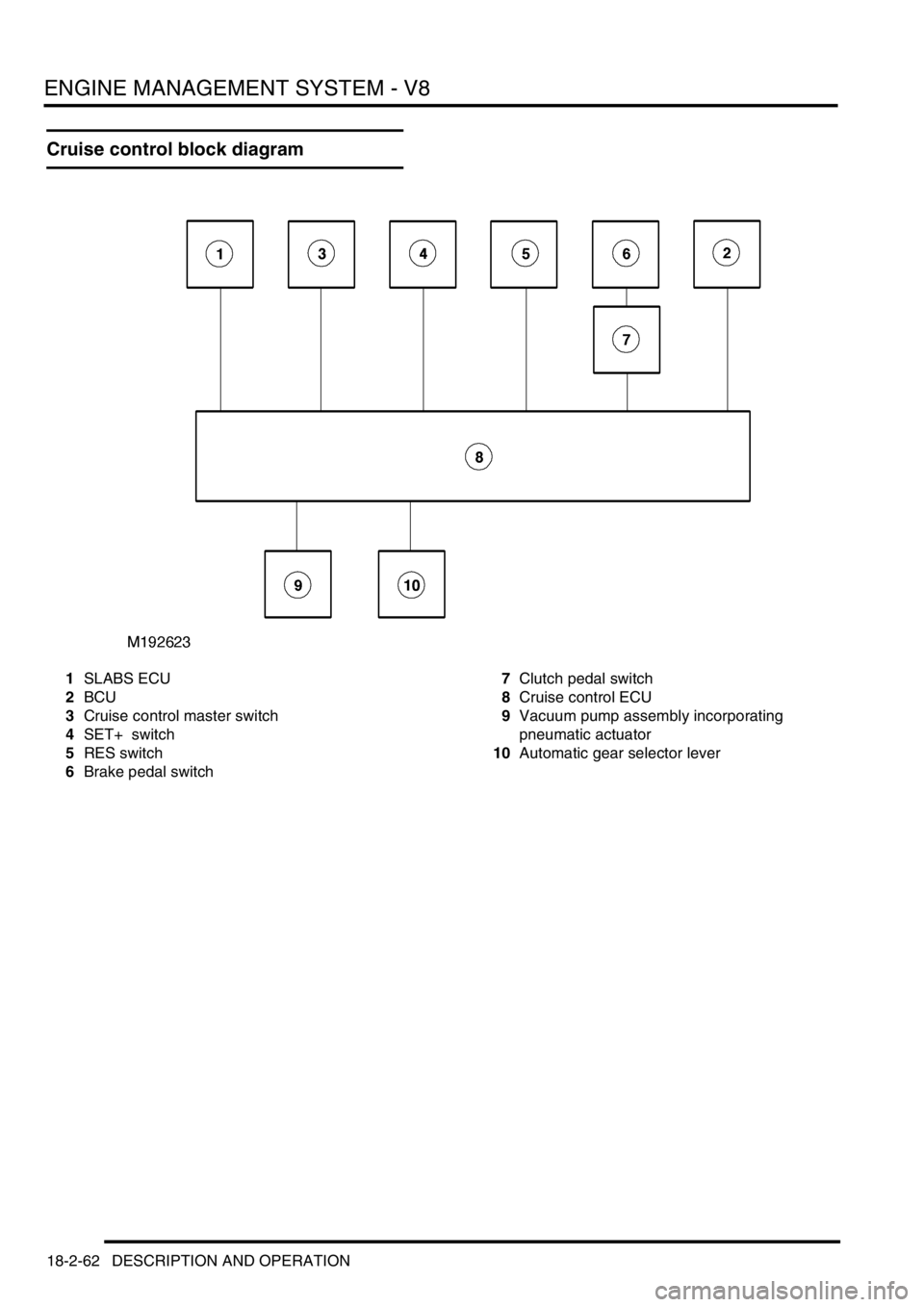

Cruise control block diagram

1SLABS ECU

2BCU

3Cruise control master switch

4SET+ switch

5RES switch

6Brake pedal switch7Clutch pedal switch

8Cruise control ECU

9Vacuum pump assembly incorporating

pneumatic actuator

10Automatic gear selector lever

Page 362 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-63

Description - cruise control

General

All markets have a common cruise control system. The cruise control system, when activated, regulates vehicle

speed. The system consists of an electrical sub-system and a mechanical sub-system.

The electrical sub-system consists of the following components:

lCruise control master switch (on/off switch).

lSET+ switch.

lRES switch.

lCruise control ECU.

lVacuum pump assembly.

lBrake pedal switch.

lClutch pedal switch (manual gearbox only).

lSLABS ECU (speed signal).

lBCU (brake pedal switch and automatic gearbox gear selector lever position signal).

The mechanical sub-system consists of the following components:

lPneumatic actuator.

lVacuum pump.

The cruise control ECU controls the cruise control system. It is located on the right hand A post.

The system has diagnostic capabilities through TestBook.

WARNING: To avoid the risk of losing control of the vehicle, do not use cruise control on winding, snow

covered or slippery roads, or in traffic conditions where a constant speed cannot be safely maintained. In

these conditions and at any time the system is not being used, ensure the cruise control switch is OFF.

Page 367 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-68 DESCRIPTION AND OPERATION

Brake pedal switch

The cruise control ECU has two inputs from the brake pedal switch that determine the position of the brake pedal.

One input comes through the BCU and is low when the brake pedal is not pressed. The second input comes directly

from the brake pedal switch. This input is high when the brake pedal is not pressed. On vehicles with a manual

gearbox, the input from the clutch pedal switch to the cruise control ECU is connected in series with the direct signal

from the brake pedal switch.

If the cruise control ECU receives a changed signal from either source, it deactivates cruise control, removing power

to the vacuum pump and activating the vacuum control valve releasing all vacuum in the system.

The brake pedal switch also provides the signal to illuminate the brake lamps and the brake input to the SLABS ECU.

Input/Output

With the brake pedal and the clutch pedal in the rest position, the cruise control ECU receives 12 Volts.

With the brake pedal pressed, the cruise control ECU receives 0 Volts and a low voltage logic signal from the BCU.

NOTE: If the clutch pedal is pressed, 0 Volts are present at the cruise control ECU irrespective of brake pedal position.

ECU operating parameters (connector connected)

Pin No. Condition Volts Ohms

1 Ignition in position II, brake pedal

released, clutch pedal released12

1 Ignition in position II, brake pedal

pressed, clutch pedal releasedMore than 10,000

1 Ignition in position II, brake pedal

released, clutch pedal pressedMore than 10,000

Page 369 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-70 DESCRIPTION AND OPERATION

Body control unit

On manual gearbox vehicles, the BCU provides cruise control lockout or suspend function as described under brake

pedal switch.

On vehicles with automatic gearbox, the BCU monitors the status of the brake pedal switch as well as the status of

the automatic gearbox gear selector lever. The BCU monitors the gear selector lever to determine which gearbox

position the driver has selected. If the BCU detects that the driver has selected park, reverse or neutral, it sends a

signal to the cruise control ECU which inhibits cruise operation or deactivates cruise control if it is activated.

Input/Output

If the BCU receives a brake pedal switch signal or an automatic gearbox gear selector lever position signal, the BCU

sends a HIGH signal to the cruise control ECU. The cruise control ECU cancels or inhibits cruise control functions.

Page 373 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-74 DESCRIPTION AND OPERATION

Operation - cruise control

Cruise control activation

Cruise control is a passive system. The driver must activate it. Switching on the cruise control master switch located

on the instrument panel activates cruise control. An LED in the switch illuminates, indicating cruise control is

available. The driver must accelerate the vehicle to the desired speed using the accelerator pedal. When the desired

speed is reached, pressing the SET+ switch activates cruise control. Cruise control will only activate if the following

conditions are met:

lVehicle speed is between 28 - 125 mph (45 - 200 km/h).

lThe brake pedal is not pressed.

lThe clutch pedal is not pressed (manual gearbox only).

lThe gearbox is not in park, reverse or neutral (automatic gearbox only).

Function

The cruise control ECU receives the set signal and determines the vehicle speed provided by the SLABS ECU. The

cruise control ECU activates the vacuum pump assembly to move the pneumatic actuator and the linkage to the

throttle disc to maintain set road speed. It does this by controlling the vacuum to the pneumatic actuator.

Cruise control cancellation

Cancelling cruise control enables the driver to regain control of the vehicle speed by using the accelerator pedal.

Cruise control is cancelled if any of the following conditions occur:

lThe brake pedal is pressed.

lThe RES switch button is pressed.

lThe clutch pedal is pressed (manual gearbox only).

lThe cruise control master switch is turned off.

lThe gearbox is placed in park, neutral, or reverse (automatic gearbox only).

Function

The cruise control ECU cancels cruise control operation by opening a vacuum control valve in the vacuum pump

assembly. This releases the throttle linkage from the control of the pneumatic actuator and returns it to the control of

the accelerator pedal.

The set speed will be stored in the cruise control ECU unless:

lThe cruise control master switch is turned off.

lThe ignition switch is turned off.

If cruise control is deactivated using either of the above methods, the set speed will be erased from the memory of

the cruise control ECU.

Cruise control resume

Cruise control can be resumed at the previously set speed, provided the set speed has not been erased from the

cruise control ECU memory as described above. To resume cruise control operation to the previously set speed,

depress the RES switch once when the following conditions are met:

lA set speed is stored in the cruise control ECU.

lVehicle speed is between 28 - 125 mph (45 - 200 km/h).

lThe brake pedal is not pressed.

lThe clutch pedal is not pressed (manual gearbox only).

lThe gearbox is not in park, reverse or neutral (automatic gearbox only).

Function

The cruise control ECU activates the vacuum pump assembly to move the pneumatic actuator. This moves the

throttle to the set speed by adjusting the position of the throttle disc.