gearbox LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 114 of 1529

LIFTING AND TOWING

08-1

LIFTING AND TOWING

LIFTING

The following instructions must be carried out before

raising the vehicle off the ground.

lUse a solid level ground surface.

lApply hand brake.

lSelect 'P' (Automatic gearbox) or 1st gear

(Manual gearbox) in main gearbox.

lSelect Low range in transfer gearbox.

To avoid damage occurring to the under body

components of the vehicle the following jacking

procedures must be adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS:

lBody structure

lBumpers

lFuel lines

lBrake lines

lFront radius arms

lPanhard rod

lSteering linkage

lRear trailing arms

lFuel tank

lEngine sump

lGearbox bell housing

Vehicle jack

The jack provided with the vehicle is only intended for

use in an emergency, for changing a tyre. DO NOT

use the jack for any other purpose. Refer to Owner's

Handbook for vehicle jack location points and

procedure. Never work under a vehicle supported

solely by the vehicle jack.

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used. Do not commence

work on the underside of the vehicle until

suitable axle stands have been positioned under

the axle.

WARNING: Always chock the wheels when

jacking. The hand brake acts on the

transmission, not the rear wheels, and may be

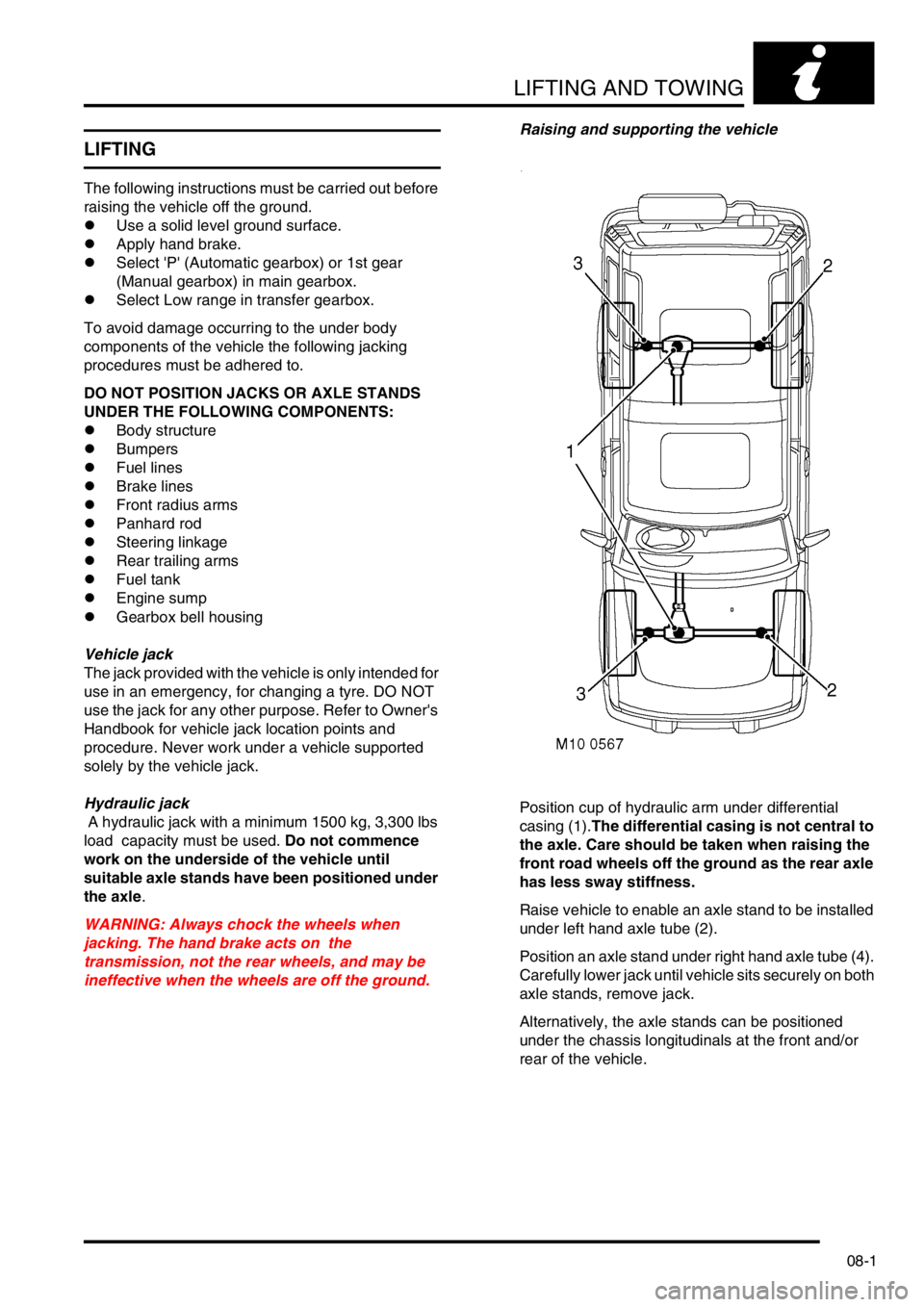

ineffective when the wheels are off the ground.Raising and supporting the vehicle

Position cup of hydraulic arm under differential

casing (1).The differential casing is not central to

the axle. Care should be taken when raising the

front road wheels off the ground as the rear axle

has less sway stiffness.

Raise vehicle to enable an axle stand to be installed

under left hand axle tube (2).

Position an axle stand under right hand axle tube (4).

Carefully lower jack until vehicle sits securely on both

axle stands, remove jack.

Alternatively, the axle stands can be positioned

under the chassis longitudinals at the front and/or

rear of the vehicle.

Page 115 of 1529

LIFTING AND TOWING

08-2

Before commencing work on underside of vehicle re-

check security of vehicle on stands.

WARNING: Always chock the wheels when

jacking. The hand brake acts on the the

transmission, not the rear wheels, and may be

ineffective when the wheels are off the ground.

Reverse procedure when removing vehicle from

stands.

Hydraulic ramps

Use only a 'drive on' type ramp which supports a

vehicle by it's own road wheels. If a 'wheel free'

condition is required, use a 'drive on' ramp

incorporating a 'wheel free' system that supports

under axle casings. Alternatively, place vehicle on a

firm, flat floor and support on axle stands.

TOWING

Towing

The vehicle has permanent four wheel drive. The

following towing instructions must be adhered

to:

Towing on 4 wheels with driver

Turn ignition key to position '1' to release steering

lock.

Select neutral in main gearbox and transfer gearbox.

Secure tow rope, chain or cable to towing eye.

Release the handbrake.

The brake servo and power assisted steering

system will not be functional without the engine

running. Greater pedal pressure will be required

to apply the brakes, the steering system will

require greater effort to turn the front road

wheels. The vehicle tow connection should be

used only in normal road conditions, 'snatch'

recovery should be avoided.

Suspended tow

To prevent vehicle damage, front or rear

propeller shaft MUST BE removed, dependent

upon which axle is being trailed.

Mark propeller shaft drive flanges at transfer box and

axles with identification lines to enable the propeller

shaft to be refitted in its original position.

Page 117 of 1529

LIFTING AND TOWING

08-4

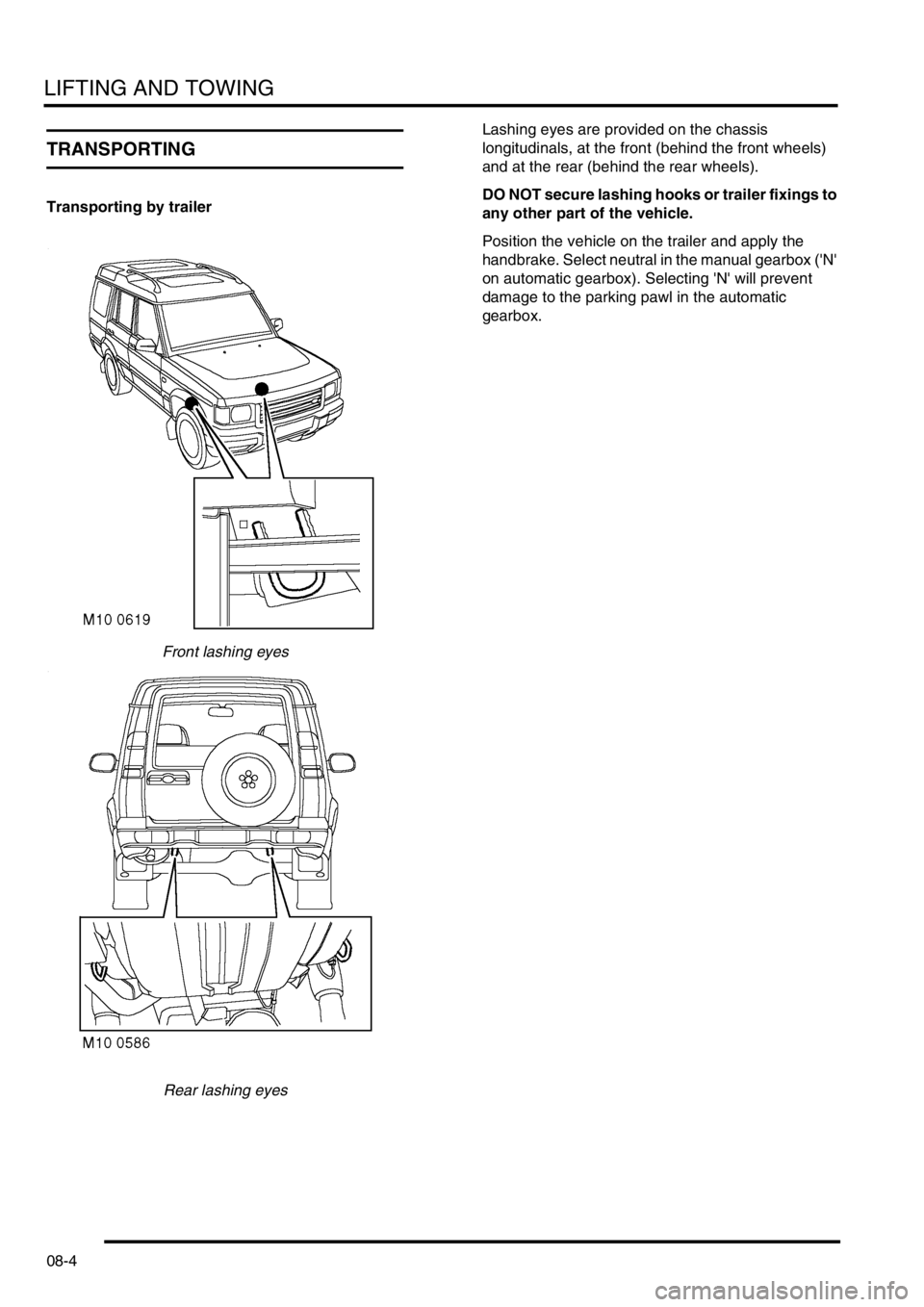

TRANSPORTING

Transporting by trailer

Front lashing eyes

Rear lashing eyesLashing eyes are provided on the chassis

longitudinals, at the front (behind the front wheels)

and at the rear (behind the rear wheels).

DO NOT secure lashing hooks or trailer fixings to

any other part of the vehicle.

Position the vehicle on the trailer and apply the

handbrake. Select neutral in the manual gearbox ('N'

on automatic gearbox). Selecting 'N' will prevent

damage to the parking pawl in the automatic

gearbox.

Page 118 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-1

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

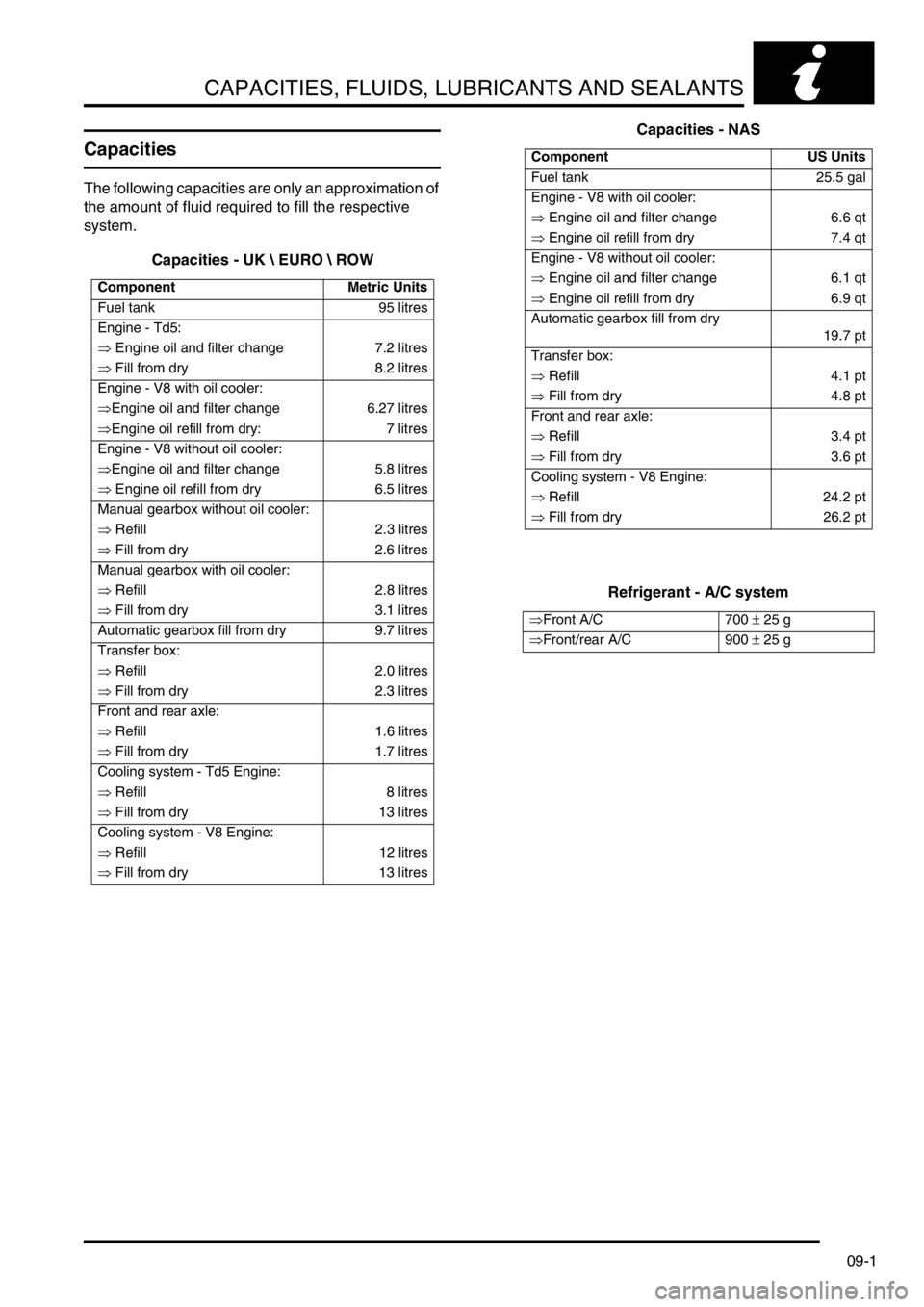

Capacities

The following capacities are only an approximation of

the amount of fluid required to fill the respective

system.

Capacities - UK EURO ROWCapacities - NAS

Refrigerant - A/C system

Component Metric Units

Fuel tank 95 litres

Engine - Td5:

⇒ Engine oil and filter change 7.2 litres

⇒ Fill from dry 8.2 litres

Engine - V8 with oil cooler:

⇒Engine oil and filter change 6.27 litres

⇒Engine oil refill from dry: 7 litres

Engine - V8 without oil cooler:

⇒Engine oil and filter change 5.8 litres

⇒ Engine oil refill from dry 6.5 litres

Manual gearbox without oil cooler:

⇒ Refill 2.3 litres

⇒ Fill from dry 2.6 litres

Manual gearbox with oil cooler:

⇒ Refill 2.8 litres

⇒ Fill from dry 3.1 litres

Automatic gearbox fill from dry 9.7 litres

Transfer box:

⇒ Refill 2.0 litres

⇒ Fill from dry 2.3 litres

Front and rear axle:

⇒ Refill 1.6 litres

⇒ Fill from dry 1.7 litres

Cooling system - Td5 Engine:

⇒ Refill 8 litres

⇒ Fill from dry 13 litres

Cooling system - V8 Engine:

⇒ Refill 12 litres

⇒ Fill from dry 13 litres

Component US Units

Fuel tank 25.5 gal

Engine - V8 with oil cooler:

⇒ Engine oil and filter change 6.6 qt

⇒ Engine oil refill from dry 7.4 qt

Engine - V8 without oil cooler:

⇒ Engine oil and filter change 6.1 qt

⇒ Engine oil refill from dry 6.9 qt

Automatic gearbox fill from dry

19.7 pt

Transfer box:

⇒ Refill 4.1 pt

⇒ Fill from dry 4.8 pt

Front and rear axle:

⇒ Refill 3.4 pt

⇒ Fill from dry 3.6 pt

Cooling system - V8 Engine:

⇒ Refill 24.2 pt

⇒ Fill from dry 26.2 pt

⇒Front A/C 700 ± 25 g

⇒Front/rear A/C 900 ± 25 g

Page 121 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-4

Gearbox oil

Manual Gearbox: Use Texaco MTF 94 oil for refill

and topping-up.

Automatic Gearbox: Use Texamatic 9226, ATF

Dexron 11D or Dexron 111 for refill and topping-up

Transfer box

Use Texaco Multi-Gear 75W/90R or oil meeting

specification API GL5.

Front and rear axles

Use Texaco Multi-Gear 75W/90R.

Air Conditioning

Use lubricating oil Nippon Denso ND-8.

General Greasing

Use Multipurpose Lithium Base Grease N.L.G.I.

consistency No. 2.

Bonnet latch

Lubricate cable and latch with oil.

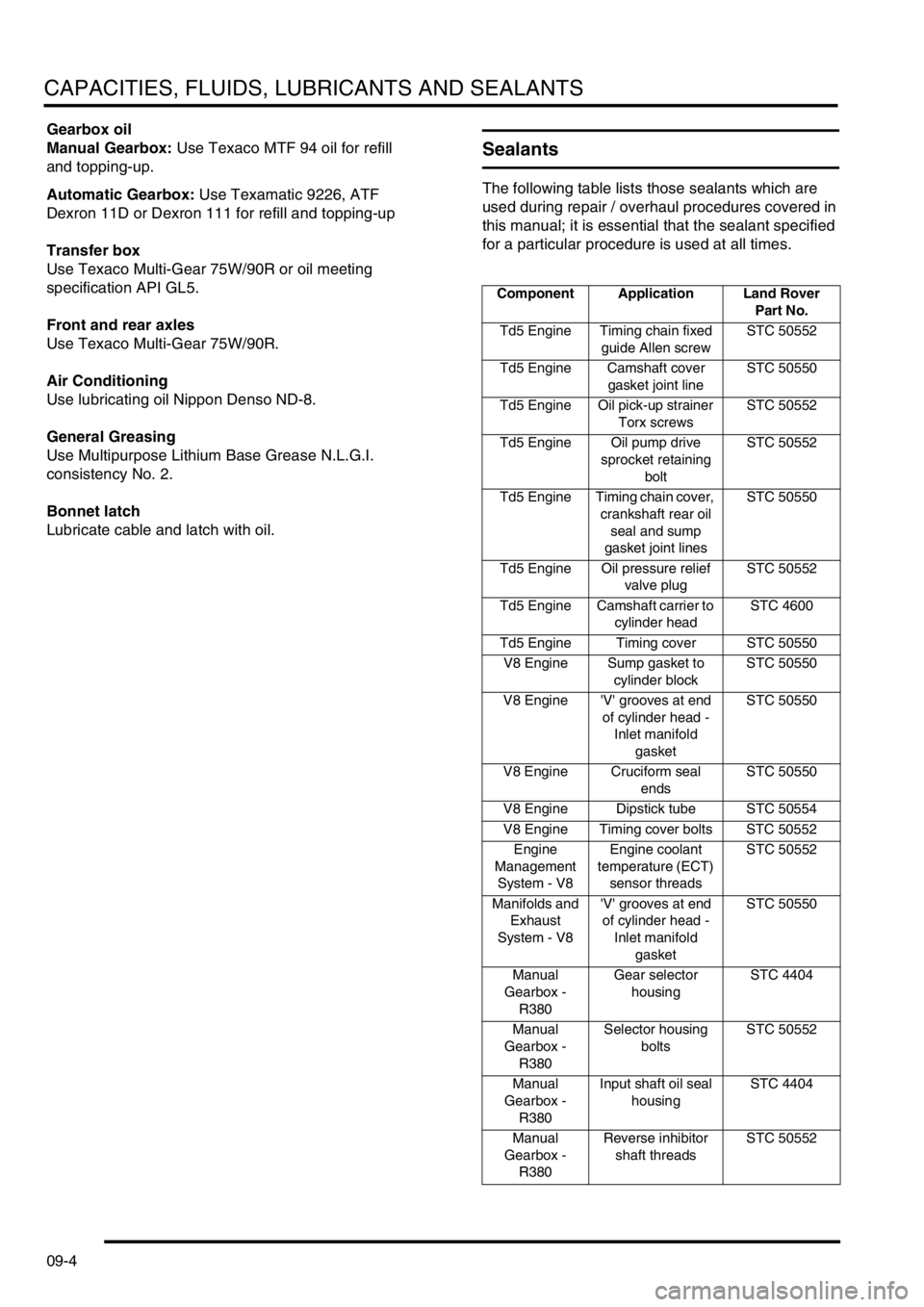

Sealants

The following table lists those sealants which are

used during repair / overhaul procedures covered in

this manual; it is essential that the sealant specified

for a particular procedure is used at all times.

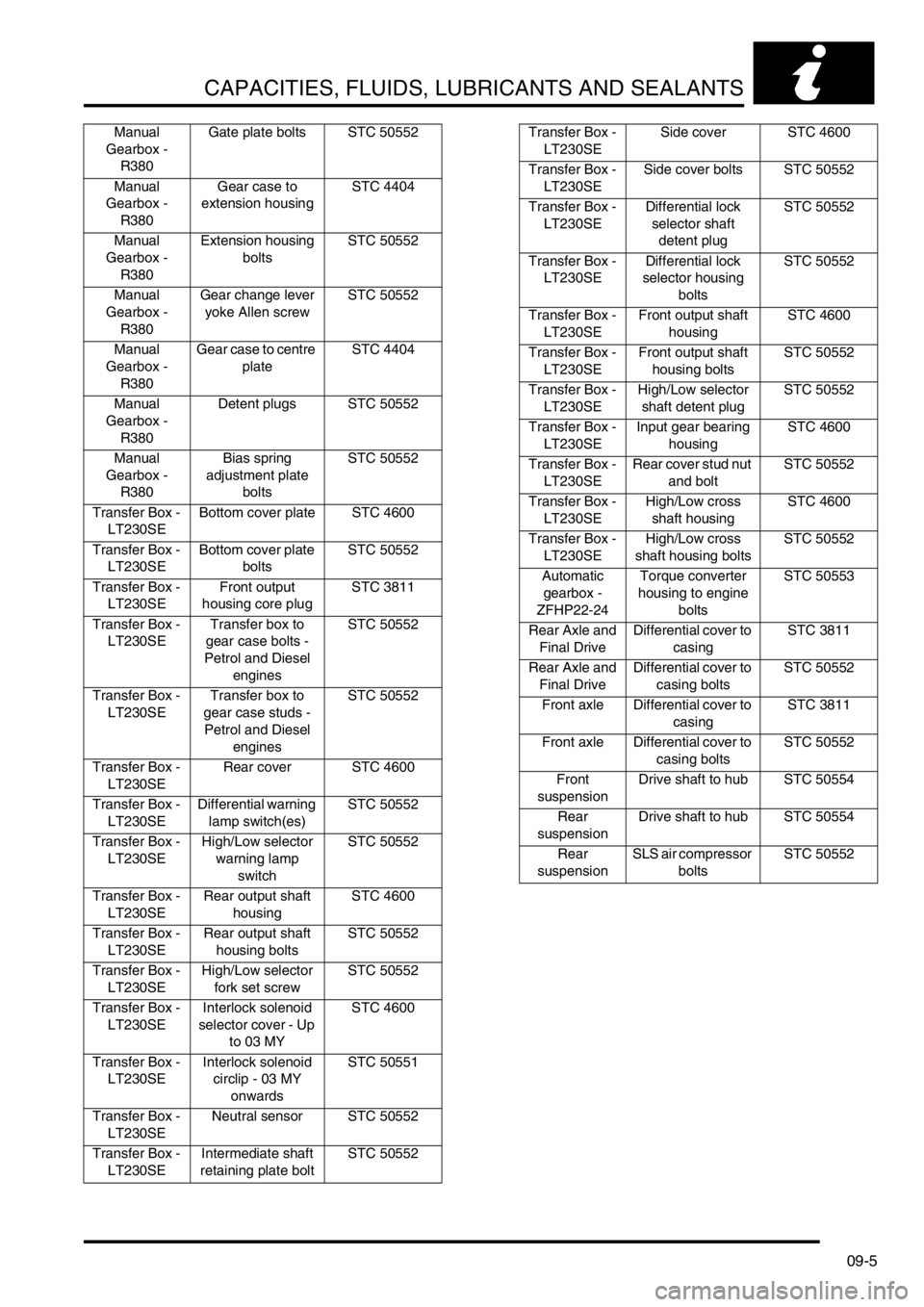

Component Application Land Rover

Part No.

Td5 Engine Timing chain fixed

guide Allen screwSTC 50552

Td5 Engine Camshaft cover

gasket joint lineSTC 50550

Td5 Engine Oil pick-up strainer

Torx screwsSTC 50552

Td5 Engine Oil pump drive

sprocket retaining

boltSTC 50552

Td5 Engine Timing chain cover,

crankshaft rear oil

seal and sump

gasket joint linesSTC 50550

Td5 Engine Oil pressure relief

valve plugSTC 50552

Td5 Engine Camshaft carrier to

cylinder headSTC 4600

Td5 Engine Timing cover STC 50550

V8 Engine Sump gasket to

cylinder blockSTC 50550

V8 Engine 'V' grooves at end

of cylinder head -

Inlet manifold

gasketSTC 50550

V8 Engine Cruciform seal

endsSTC 50550

V8 Engine Dipstick tube STC 50554

V8 Engine Timing cover bolts STC 50552

Engine

Management

System - V8Engine coolant

temperature (ECT)

sensor threadsSTC 50552

Manifolds and

Exhaust

System - V8'V' grooves at end

of cylinder head -

Inlet manifold

gasketSTC 50550

Manual

Gearbox -

R380Gear selector

housingSTC 4404

Manual

Gearbox -

R380Selector housing

boltsSTC 50552

Manual

Gearbox -

R380Input shaft oil seal

housingSTC 4404

Manual

Gearbox -

R380Reverse inhibitor

shaft threadsSTC 50552

Page 122 of 1529

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-5

Manual

Gearbox -

R380Gate plate bolts STC 50552

Manual

Gearbox -

R380Gear case to

extension housingSTC 4404

Manual

Gearbox -

R380Extension housing

boltsSTC 50552

Manual

Gearbox -

R380Gear change lever

yoke Allen screwSTC 50552

Manual

Gearbox -

R380Gear case to centre

plateSTC 4404

Manual

Gearbox -

R380Detent plugs STC 50552

Manual

Gearbox -

R380Bias spring

adjustment plate

boltsSTC 50552

Transfer Box -

LT230SEBottom cover plate STC 4600

Transfer Box -

LT230SEBottom cover plate

boltsSTC 50552

Transfer Box -

LT230SEFront output

housing core plugSTC 3811

Transfer Box -

LT230SETransfer box to

gear case bolts -

Petrol and Diesel

enginesSTC 50552

Transfer Box -

LT230SETransfer box to

gear case studs -

Petrol and Diesel

enginesSTC 50552

Transfer Box -

LT230SERear cover STC 4600

Transfer Box -

LT230SEDifferential warning

lamp switch(es)STC 50552

Transfer Box -

LT230SEHigh/Low selector

warning lamp

switchSTC 50552

Transfer Box -

LT230SERear output shaft

housingSTC 4600

Transfer Box -

LT230SERear output shaft

housing boltsSTC 50552

Transfer Box -

LT230SEHigh/Low selector

fork set screwSTC 50552

Transfer Box -

LT230SEInterlock solenoid

selector cover - Up

to 03 MYSTC 4600

Transfer Box -

LT230SEInterlock solenoid

circlip - 03 MY

onwardsSTC 50551

Transfer Box -

LT230SENeutral sensor STC 50552

Transfer Box -

LT230SEIntermediate shaft

retaining plate boltSTC 50552Transfer Box -

LT230SESide cover STC 4600

Transfer Box -

LT230SESide cover bolts STC 50552

Transfer Box -

LT230SEDifferential lock

selector shaft

detent plugSTC 50552

Transfer Box -

LT230SEDifferential lock

selector housing

boltsSTC 50552

Transfer Box -

LT230SEFront output shaft

housingSTC 4600

Transfer Box -

LT230SEFront output shaft

housing boltsSTC 50552

Transfer Box -

LT230SEHigh/Low selector

shaft detent plugSTC 50552

Transfer Box -

LT230SEInput gear bearing

housingSTC 4600

Transfer Box -

LT230SERear cover stud nut

and boltSTC 50552

Transfer Box -

LT230SEHigh/Low cross

shaft housingSTC 4600

Transfer Box -

LT230SEHigh/Low cross

shaft housing boltsSTC 50552

Automatic

gearbox -

ZFHP22-24Torque converter

housing to engine

boltsSTC 50553

Rear Axle and

Final DriveDifferential cover to

casingSTC 3811

Rear Axle and

Final DriveDifferential cover to

casing boltsSTC 50552

Front axle Differential cover to

casingSTC 3811

Front axle Differential cover to

casing boltsSTC 50552

Front

suspensionDrive shaft to hub STC 50554

Rear

suspensionDrive shaft to hub STC 50554

Rear

suspensionSLS air compressor

boltsSTC 50552

Page 140 of 1529

MAINTENANCE

PROCEDURES 10-17

Manual gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Check/top-up oil level

1.Release fixings, remove rear underbelly panel.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of oil filler/level

plug hole.

5.Top-up level (if required) with recommended oil

to bottom of filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Remove all traces of sealant from threads of oil

filler/level plug.

7.Apply Loctite 290 to threads of oil filler/level

plug.

8. Fit manual gearbox filler/level plug and tighten

to 30 Nm (22 lbf.ft).

9.Remove all traces of oil from gearcase.

10.Fit rear underbelly panel, secure fixings.Replace oil

1.Release fixings, remove rear underbelly panel.

2.Place a suitable container beneath gearbox

drain plug.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug, remove and discard

sealing washer.

6.Allow oil to drain.

7.Clean magnet in oil drain plug.

8.Fit new sealing washer to oil drain plug.

9.Fit manual gearbox drain plug and tighten to 50

Nm (37 lbf.ft).

10.Fill gearbox with recommended oil to bottom of

filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

11.Remove all traces of sealant from threads of oil

filler/level plug.

12.Apply Loctite 290 to threads of oil filler/level

plug.

13. Fit manual gearbox filler/level plug and tighten

to 30 Nm (22 lbf.ft).

14.Remove all traces of oil from gearcase.

15.Fit rear underbelly panel, secure fixings.

Page 141 of 1529

MAINTENANCE

10-18 PROCEDURES

Automatic gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil filter

1.Replace oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

Replace oil

1. Ensure that gearbox is cool. Apply

handbrake and securely chock front and rear

wheels.

2.Place a suitable container beneath gearbox.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil drain plug, remove and discard

sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit automatic gearbox drain plug and tighten to

15 Nm (11 lbf.ft).

8.Remove oil filler/level plug, remove and discard

sealing washer.

9.Fill gearbox with recommended oil to bottom of

oil level/filler plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Select 'P' (Park).

11.Ensure handbrake is applied.

12.Start engine and allow it to idle.

13.Apply footbrake. 14.Move selector lever through all gear positions,

while continuing to fill the gearbox. Select 'P'

(Park).

15.With engine idling, continue filling gearbox until

a 2 mm bead of oil runs from oil filler/level plug

hole.

16.Fit new sealing washer to automatic gearbox

filler/level plug, fit plug and tighten to 30 Nm (22

l b f . f t ) .

17.Stop engine.

18.Remove all traces of oil from gearbox casing.

Page 148 of 1529

MAINTENANCE

PROCEDURES 10-25

Engine, gearbox, transfer box and axles

Check

1.Check for oil leaks from engine, gearbox

(manual and automatic), transfer box and front

and rear axles; pay particular attention to areas

around oil seals.

Exhaust system

Check

1.Check for signs of exhaust system leaks,

damage and security.

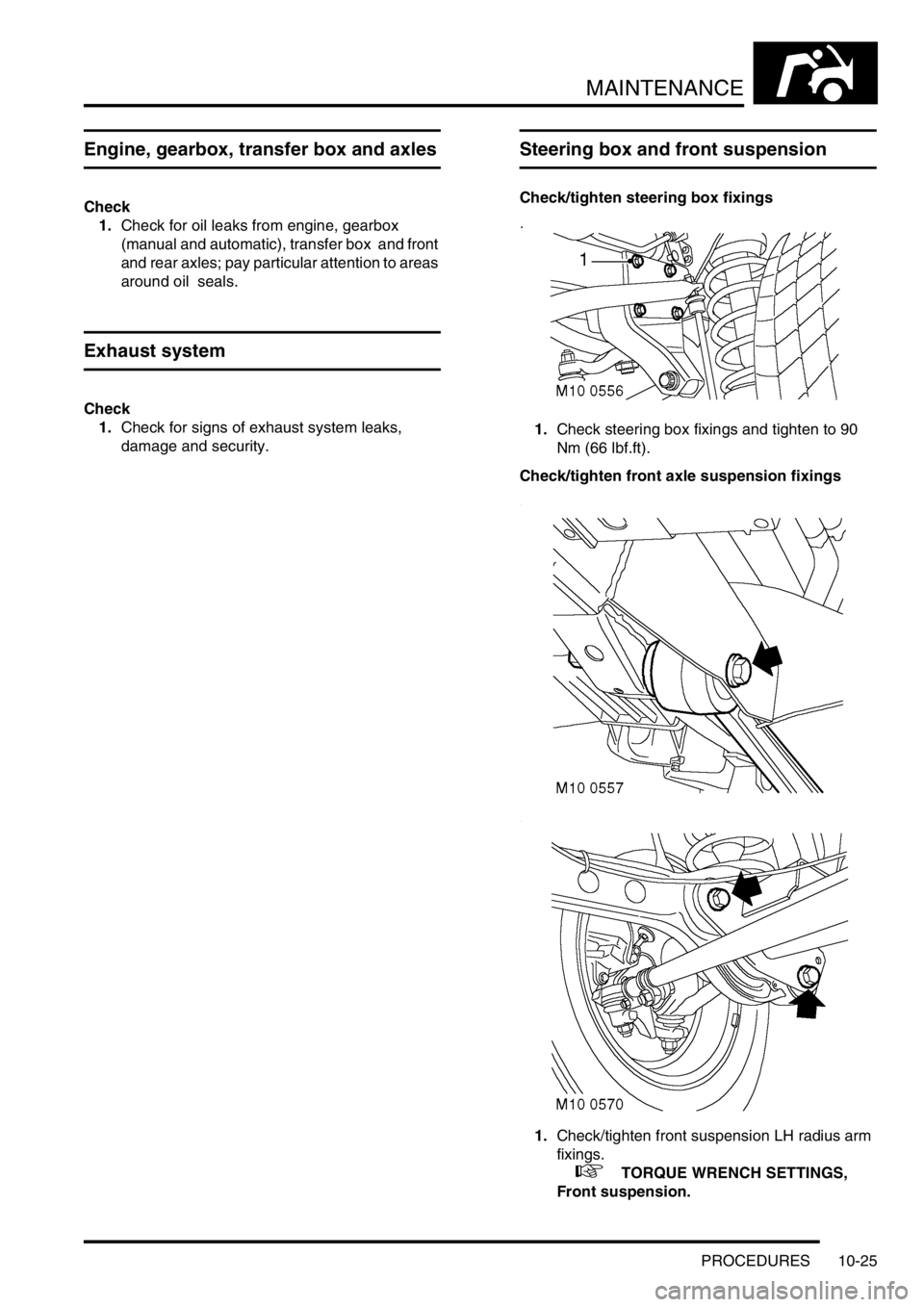

Steering box and front suspension

Check/tighten steering box fixings

1.Check steering box fixings and tighten to 90

Nm (66 lbf.ft).

Check/tighten front axle suspension fixings

1.Check/tighten front suspension LH radius arm

fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

Page 154 of 1529

MAINTENANCE

PROCEDURES 10-31

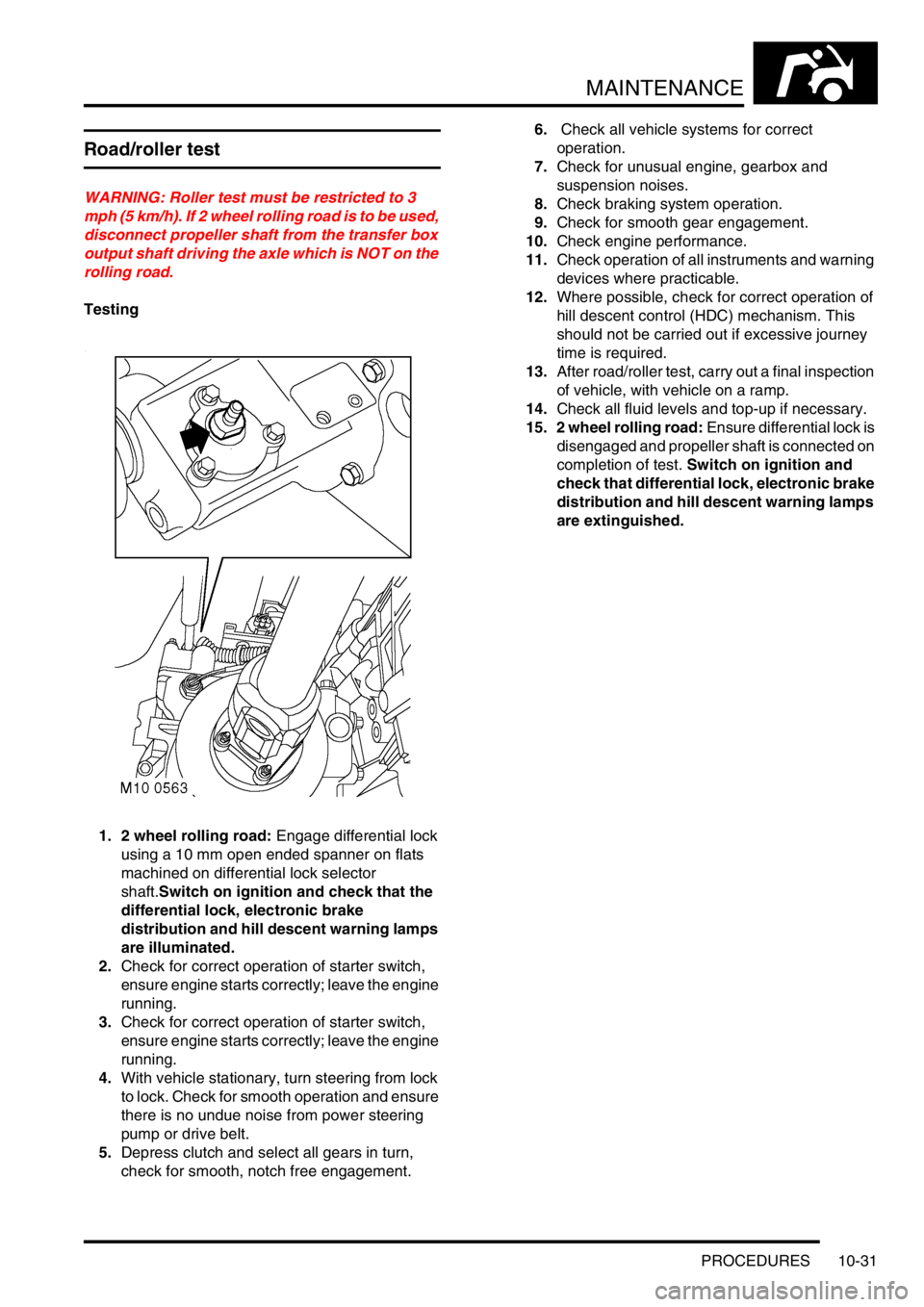

Road/roller test

WARNING: Roller test must be restricted to 3

mph (5 km/h). If 2 wheel rolling road is to be used,

disconnect propeller shaft from the transfer box

output shaft driving the axle which is NOT on the

rolling road.

Testing

1. 2 wheel rolling road: Engage differential lock

using a 10 mm open ended spanner on flats

machined on differential lock selector

shaft.Switch on ignition and check that the

differential lock, electronic brake

distribution and hill descent warning lamps

are illuminated.

2.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

3.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

4.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from power steering

pump or drive belt.

5.Depress clutch and select all gears in turn,

check for smooth, notch free engagement.6. Check all vehicle systems for correct

operation.

7.Check for unusual engine, gearbox and

suspension noises.

8.Check braking system operation.

9.Check for smooth gear engagement.

10.Check engine performance.

11.Check operation of all instruments and warning

devices where practicable.

12.Where possible, check for correct operation of

hill descent control (HDC) mechanism. This

should not be carried out if excessive journey

time is required.

13.After road/roller test, carry out a final inspection

of vehicle, with vehicle on a ramp.

14.Check all fluid levels and top-up if necessary.

15. 2 wheel rolling road: Ensure differential lock is

disengaged and propeller shaft is connected on

completion of test. Switch on ignition and

check that differential lock, electronic brake

distribution and hill descent warning lamps

are extinguished.