gearbox LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 418 of 1529

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-3

1Heater matrix

2Heater return hose

3Heater inlet hose

4Heater inlet pipe

5Throttle housing

6Connecting hose

7Throttle housing inlet hose

8Throttle housing return pipe

9Manifold outlet pipe

10Heater return pipe

11Coolant pump

12Radiator top hose

13Connecting hose

14Radiator bleed pipe15Viscous fan

16Radiator

17Gearbox oil cooler

18Engine oil cooler (Only applicable to vehicles

up to VIN 756821)

19Radiator bottom hose

20Thermostat housing

21Bleed screw

22Coolant pump feed hose

23Expansion tank

24Pressure cap

25Connecting hose

26Overflow pipe

Page 422 of 1529

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-7

Inlet manifold - Cooling connections

Coolant leaves the cylinder block via an outlet pipe attached to the front of the air intake manifold. The pipe is

connected to the thermostat housing and the radiator by a branch hose off the radiator top hose.

Hot coolant from the engine is also directed from the inlet manifold via pipes and hoses into the heater matrix. Coolant

is circulated through the heater matrix at all times when the engine is running.

A further tapping from the inlet manifold supplies coolant to the throttle housing via a hose. The coolant circulates

through a plate attached to the bottom of the housing and is returned through a plastic bleed pipe to an expansion

tank. The hot coolant heats the air intake of the throttle housing preventing ice from forming.

An Engine Coolant Temperature (ECT) sensor is fitted in the inlet manifold adjacent to the manifold outlet pipe. The

sensor monitors coolant temperature emerging from the engine and sends signals to the ECM for engine

management and temperature gauge operation.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Expansion tank

The expansion tank is located in the engine compartment. The tank is made from moulded plastic and attached to

brackets on the right hand inner wing. A maximum coolant when cold level is moulded onto the tank.

Excess coolant created by heat expansion is returned to the expansion tank from the radiator bleed pipe at the top of

the radiator. An outlet pipe is connected into the pump feed hose and replaces the coolant displaced by heat

expansion into the system when the engine is cool.

The expansion tank is fitted with a sealed pressure cap. The cap contains a pressure relief valve which opens to allow

excessive pressure and coolant to vent through the overflow pipe. The relief valve opens at a pressure of 1.4 bar (20

lbf.in

2) and above.

Heater matrix

The heater matrix is fitted in the heater assembly inside the passenger compartment. Two pipes pass through the

bulkhead into the engine compartment and provide coolant flow to and from the matrix. The pipes from the bulkhead

are connected to the matrix, sealed with 'O' rings and clamped with circular rings.

The matrix is constructed from aluminium with two end tanks interconnected with tubes. Aluminium fins are located

between the tubes and conduct heat away from the hot coolant flowing through the tubes. Air from the heater

assembly is warmed as it passes through the matrix fins. The warm air is then distributed into the passenger

compartment as required.

+ HEATING AND VENTILATION, DESCRIPTION AND OPERATION, Description.When the engine is

running, coolant from the engine is constantly circulated through the heater matrix.

Radiator

The 45 row radiator is located at the front of the vehicle. The cross-flow type radiator is manufactured from aluminium

with moulded plastic end tanks interconnected with tubes. Aluminium fins are located between the tubes and conduct

heat from the hot coolant flowing through the tubes, reducing the cooling temperature as it flows through the radiator.

Air intake from the front of the vehicle when moving carries heat away from the fins. When the vehicle is stationary,

the viscous fan draws air through the radiator fins to prevent the engine from overheating.

Two connections at the top of the radiator provide for the attachment of the top hose and bleed pipe. A connection at

the bottom of the radiator allows for the attachment of the bottom hose to the thermostat housing.

Two smaller radiators are located in front of the cooling radiator. The lower radiator provides cooling of the gearbox

oil and the upper radiator provides cooling for the engine oil.

+ MANUAL GEARBOX - R380, DESCRIPTION AND OPERATION, Description.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

+ ENGINE - V8, DESCRIPTION AND OPERATION, Description.

Pipes and hoses

The coolant circuit comprises flexible hoses and metal formed pipes which direct coolant into and out of the engine,

radiator and heater matrix. Plastic pipes are used for the bleed and overflow pipes to the expansion tank.

A bleed screw is installed in the radiator top hose and is used to bleed air during system filling. A drain plug is fitted

to each cylinder bank in the cylinder block. These are used to drain the block of coolant.

Page 431 of 1529

COOLING SYSTEM - V8

26-2-16 REPAIRS

8.Remove 6 scrivets and remove LH and RH air

deflectors from front panel. Disconnect

multiplug of gearbox oil temperature sensor

(arrowed).

9.Remove nut and move horn aside. 10.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

11.Remove 4 screws securing air conditioning

condenser LH and RH upper mounting

brackets to condenser.

12.Remove brackets with rubber mounts from

radiator extension brackets.

13.Position absorbent cloth under each cooler

hose to collect oil spillage.

14.Push against coupling release rings and

disconnect hoses from gearbox oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

15. If fitted: Push against coupling release rings

and disconnect hoses from engine oil cooler.

Page 432 of 1529

COOLING SYSTEM - V8

REPAIRS 26-2-17

16.Remove radiator assembly.

17.Release clip and remove bottom hose from

radiator.

18.Remove 2 bolts and remove extension

brackets from radiator.

19.Remove 2 captive nuts from radiator.

20.Remove 2 screws and remove gearbox oil

cooler from radiator.

21. If fitted: Remove 2 screws and remove engine

oil cooler from radiator.

22.Remove 2 rubber mountings from radiator.

23.Remove sealing strip from bottom of radiator.

24.Remove 2 cowl retaining clips from radiator. Refit

1.Fit cowl retaining clips to radiator.

2.Fit sealing strip to radiator.

3.Fit rubber mountings to radiator.

4.Fit gearbox oil cooler to radiator and secure

with screws.

5. If fitted: Fit engine oil cooler to radiator and

secure with screws.

6.Fit captive nuts to radiator.

7.Fit extension brackets to radiator and secure

with bolts.

8.Fit bottom hose to radiator and secure with clip.

9.Fit radiator and engage lower mountings in

chassis.

10.Ensure connections are clean, then secure

hoses to oil coolers.

11.Fit air conditioning condenser brackets and

secure with screws.

12.Fit radiator upper mounting brackets and

secure with bolts.

13.Fit LH horn and secure with nut.

14.Fit air deflectors and secure with scrivets.

15.Connect multiplug of gearbox oil temperature

sensor.

16.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

17.Connect bottom hose to thermostat housing

and secure with clip.

18.Connect top hose to radiator and secure with

clip.

19.Connect bleed hose to radiator and fit clip.

20.Fit lower fan cowl and secure with screws.

21.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

22.Top up gearbox oil.

23.Top up engine oil.

24.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 458 of 1529

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-3

1Brake/clutch reservoir

2Connecting hose

3Bolt 2 off

4Master cylinder

5Clutch pedal

6Gearbox housing

7Primary driveshaft

8Bolt 2 off

9Slave cylinder

10Bleed nipple

11Pressure plate

12Drive plate13Flywheel

14Metal hydraulic pipes

15Ball spigot

16Clutch release bearing sleeve

17Bolt 2 off

18Pivot washer

19Release lever

20Release bearing

21Retaining clip

22Pipe

23Pipe

Page 461 of 1529

CLUTCH - V8

33-2-6 DESCRIPTION AND OPERATION

Description

General

The clutch system is a conventional diaphragm type clutch operated by a hydraulic cylinder. The clutch requires no

adjustment to compensate for wear.

Hydraulic clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir, which is also shared with

the braking system. The master and slave cylinders are connected to each other hydraulically by plastic and metal

pipes. The plastic section of the pipe allows ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the brake/clutch fluid reservoir. A piston is fitted in the bore and has an external

rod which is attached to the clutch pedal with a pin. Two coiled springs on the clutch pedal reduce the effort required

to depress the pedal.

The master cylinder is mounted on the bulkhead in the engine compartment and secured with two bolts. The cylinder

is connected to the shared brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat shield

protects the underside of the cylinder from heat generated from the exhaust system. The slave cylinder comprises a

cylinder with a piston and a rod. A port in the cylinder body provides the attachment for the hydraulic feed pipe from

the master cylinder. A second port is fitted with a bleed nipple for removing air from the hydraulic system after

servicing. The piston rod locates on a clutch release lever located in the gearbox housing. The rod is positively

retained on the release lever with a clip.

Clutch mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A spigot

with a ball end is formed on the release bearing sleeve and provides a mounting and pivot point for the clutch release

lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located on the ball, the pivot

washer seats against the rear face of the release lever. A spring clip is located on the lever and the pivot washer and

secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned centrally

on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever to pivot freely

around the ball.

The clutch release bearing locates on the clutch release lever and the release bearing sleeve. The bearing is retained

on a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever on

the carrier. The bearing and carrier are not serviceable individually.

Flywheel

The flywheel is bolted to a flange on the rear of the crankshaft with six bolts. A dowel on the crankshaft flange ensures

that the flywheel is correctly located. A ring gear is fitted on the outside diameter of the flywheel and seats against a

flange. The ring gear is an interference fit on the flywheel and is installed by heating the ring and cooling the flywheel.

The ring gear is a serviceable item and can be replaced if damaged or worn.

The operating face of the flywheel is machined to provide a smooth surface for the drive plate to engage on. Three

dowels and six threaded holes provide for the location and attachment of the pressure plate. The flywheel is balanced

to ensure that it does not produce vibration when rotating. A machined slot, with a series of holes within the slot, is

located on the engine side of the flywheel. The slot accommodates the tip of the crankshaft position sensor which is

used by the Engine Control Module (ECM) for engine management.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Page 463 of 1529

CLUTCH - V8

33-2-8 DESCRIPTION AND OPERATION

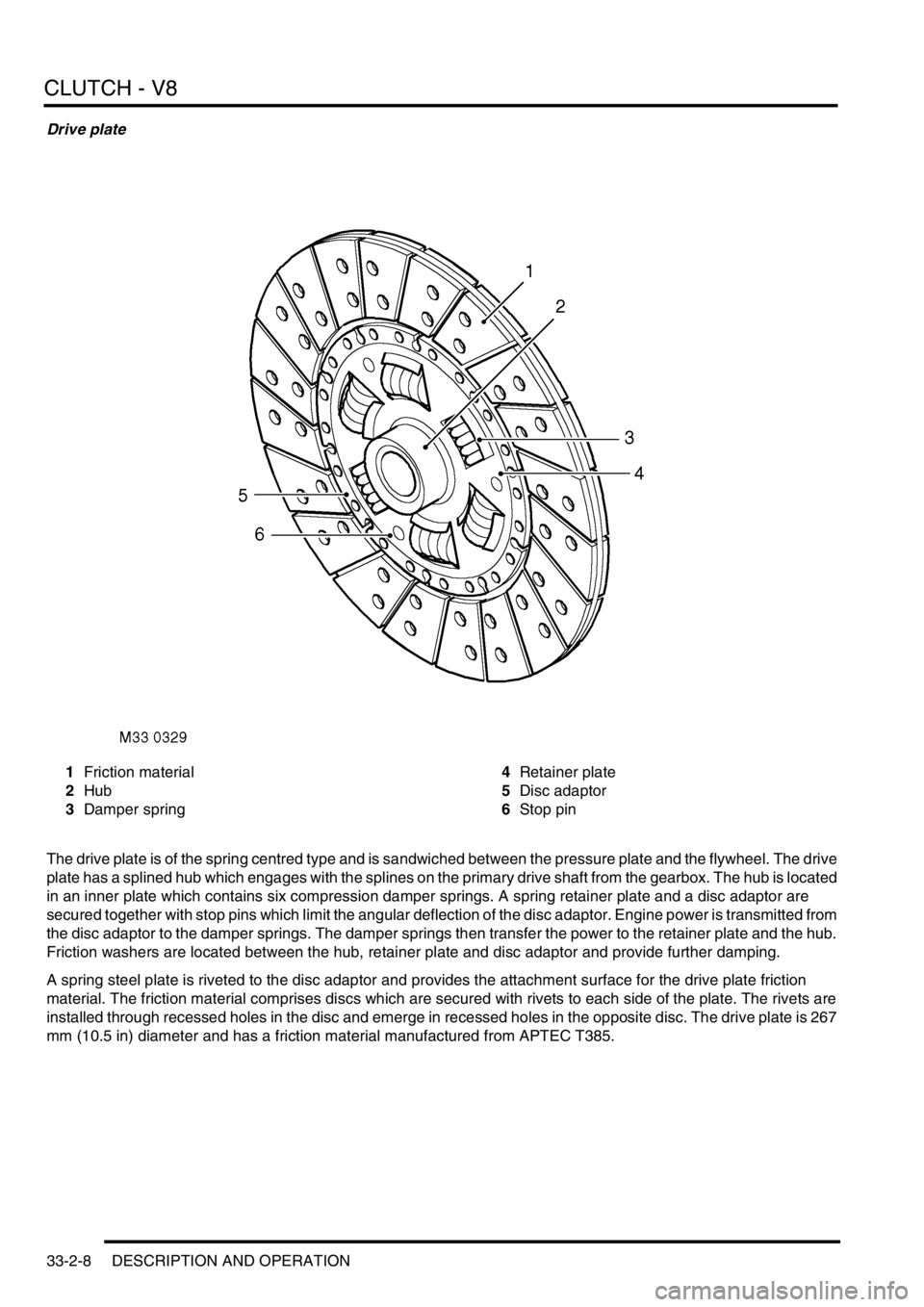

Drive plate

1Friction material

2Hub

3Damper spring4Retainer plate

5Disc adaptor

6Stop pin

The drive plate is of the spring centred type and is sandwiched between the pressure plate and the flywheel. The drive

plate has a splined hub which engages with the splines on the primary drive shaft from the gearbox. The hub is located

in an inner plate which contains six compression damper springs. A spring retainer plate and a disc adaptor are

secured together with stop pins which limit the angular deflection of the disc adaptor. Engine power is transmitted from

the disc adaptor to the damper springs. The damper springs then transfer the power to the retainer plate and the hub.

Friction washers are located between the hub, retainer plate and disc adaptor and provide further damping.

A spring steel plate is riveted to the disc adaptor and provides the attachment surface for the drive plate friction

material. The friction material comprises discs which are secured with rivets to each side of the plate. The rivets are

installed through recessed holes in the disc and emerge in recessed holes in the opposite disc. The drive plate is 267

mm (10.5 in) diameter and has a friction material manufactured from APTEC T385.

Page 468 of 1529

CLUTCH - V8

REPAIRS 33-2-13

REPAIRS

Clutch assembly

$% 33.10.01

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Restrain flywheel.

3.Working in diagonal sequence, progressively

loosen 6 bolts securing clutch cover to flywheel.

Remove bolts.

4.Remove clutch cover.

5.Remove clutch plate.

6.Renew all worn or damaged components.Refit

1.Clean clutch cover and flywheel mating faces

and spigot bush in end of crankshaft.

2.Fit LRT-12-001 to spigot bearing in crankshaft.

3.Fit clutch plate onto LRT-12-001, ensure side

marked 'flywheel side' is against flywheel.

4.Fit clutch cover and locate on dowels.

5.Fit clutch cover bolts and progressively tighten,

in diagonal sequence shown, to 40 Nm. (30

lbf.ft).

6.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Page 470 of 1529

CLUTCH - V8

REPAIRS 33-2-15

Bearing and lever - clutch release

$% 33.25.12

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release lever.

Remove retaining clip and remove clutch

release lever.

Refit

1.Clean clutch release lever.

2.Examine clutch release lever pivot points for

wear.

3.Apply a smear of Molybdenum disulphide

grease to clutch release lever pivot points.

4.Fit retaining clip, ensuring it locates over clutch

release lever pivot point washer. Fit bolt and

tighten to 8 Nm (6 lbf.ft).

5.Clean release bearing and bearing sleeve

mating faces.

6.Apply a smear of Molybdenum disulphide

grease to release bearing sleeve.

7.Fit release bearing and secure with retaining

peg.

8.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Slave cylinder

$% 33.35.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch spillage.

3.Disconnect hydraulic pipe from slave cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing slave cylinder to

gearbox housing and collect heat shield.

5.Withdraw slave cylinder from gearbox housing

and push rod.

Refit

1.Clean ends of pipes, gearbox housing and

slave cylinder mating faces.

2.Lubricate end of push rod with Molybdenum

disulphide grease.

3.Locate slave cylinder to push rod and gearbox

housing.

4.Position heatshield. Fit bolts securing slave

cylinder and tighten to 25 Nm (18 lbf.ft).

5.Connect hydraulic pipe to slave cylinder.

6.Bleed clutch system.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 472 of 1529

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-1

MANUAL GEARBOX - R380 DESCRIPTION AND OPERAT ION

R380 gearbox