oil level LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 478 of 1529

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-7

Description

General

The R380 all synchromesh gearbox has five forward speeds and reverse and is mounted in line with the engine. The

clutch bell housing is bolted to the front of the gearbox and the transfer box is mounted at the rear.

Gearbox casings

Gearbox casings consist of a front cover, gearcase, centre plate and extension housing. All casings with the exception

of the front cover are located to each other by dowels and sealed. Gearbox filler/level and drain plugs are located in

the gearcase.

Reverse lamp switch

A reverse lamp switch is inserted into the extension housing. Selection of reverse gear will close the switch allowing

current from fuse 25 to flow through the switch to illuminate the reverse lamps. The switch also provides a feed to the

BCU and the electrochromic automatic interior mirror - if fitted; the mirror moving from the dimmed position if

applicable.

Gearchange assembly

The gearchange assembly is bolted to the top of the gearcase, the upper gear lever being attached to the lower gear

lever by means of a clamp bolt. The lower gear lever ball is housed in a Railko bush inserted in the gear change

housing, the end of the lever locating in the selector yoke which is attached to the end of the selector shaft. Bias

springs provide a positive return of the gear lever to the neutral position with selection of 1st/2nd and 5th/reverse gears

being against bias spring pressure. Spring loaded detent balls fitted in the centre plate locate in grooves in the selector

shaft to provide positive gear and neutral selection.

Lubrication

Lubrication is by an oil pump located in the extension housing and driven by the layshaft with additional lubrication

being provided by splash. The pump directs oil via a filter and internal drillings in the output shaft to lubricate the

components. On non UK and non European models, provision for oil cooling is by means of a thermostat housed in

a cover bolted to the side of the extension housing. The cover incorporates tappings for connections to an oil cooler.

On UK and European models, the thermostat and cover are replaced by an oil by-pass block.

Internal pressures produced within the gearbox are vented to atmosphere via a plastic breather pipe. The pipe is

attached to the extension housing and is routed across the top of the gearcase and secured at the open end by a clip

attached to the engine cylinder block.

Selector shaft and forks

Selector forks for 1st/2nd, 3rd/4th and 5th/reverse gears are located on a single selector shaft; the 1st/2nd and 3rd/

4th selector forks are inside the main gearcase whilst the 5th/reverse selector fork is inside the extension housing.

Each of the selector forks locates inside its corresponding synchromesh hub.

Synchromesh assemblies

Each synchromesh assembly is located on the output shaft adjacent to its corresponding gears and comprises a

synchromesh ring, hub, slippers and sleeve. The hubs and slippers are retained in the sleeves by means of spring

clips. 1st/2nd and 3rd synchromesh assemblies are fitted with double synchromesh rings whilst 4th, 5th and reverse

assemblies are fitted with single rings.

The gear train

The gear train comprises an input shaft, output shaft, layshaft and reverse idler shaft together with their appropriate

gears and synchromesh assemblies.

The gear train input shaft, output shaft and layshaft are supported by taper roller bearings with all gears on the input

and output shafts running on caged needle roller bearings. Layshaft gears are integral with the shaft with the

exception of reverse/5th gears which are splined to the shaft and retained with a nut. 1st, 2nd, 3rd and 4th gears are

shot peened to improve durability. The reverse idler shaft and gear are supported in the centre plate by a caged

needle roller bearing. End-float of the output shaft and layshaft is controlled by selective shims located in the centre

plate whilst reverse idler shaft end-float is controlled by a selective shim located behind reverse gear.

Page 494 of 1529

MANUAL GEARBOX - R380

REPAIRS 37-23

Cooler - oil - gearbox - Diesel

$% 37.24.02

Remove

1.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

2.Position absorbent cloth under each gearbox

oil cooler hose connection to collect spillage.

3.Push against coupling release ring and

disconnect both fluid hoses from oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove screw securing oil cooler to radiator.

5.Release oil cooler from location on radiator,

and remove the oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.Refit

1.Fit oil cooler to radiator and secure with screw.

2.Ensure connections are clean and secure

hoses to cooler.

3.Fit intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

4.Top up gearbox oil level.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

Page 529 of 1529

TRANSFER BOX - LT230SE

41-4 DESCRIPTION AND OPERATION

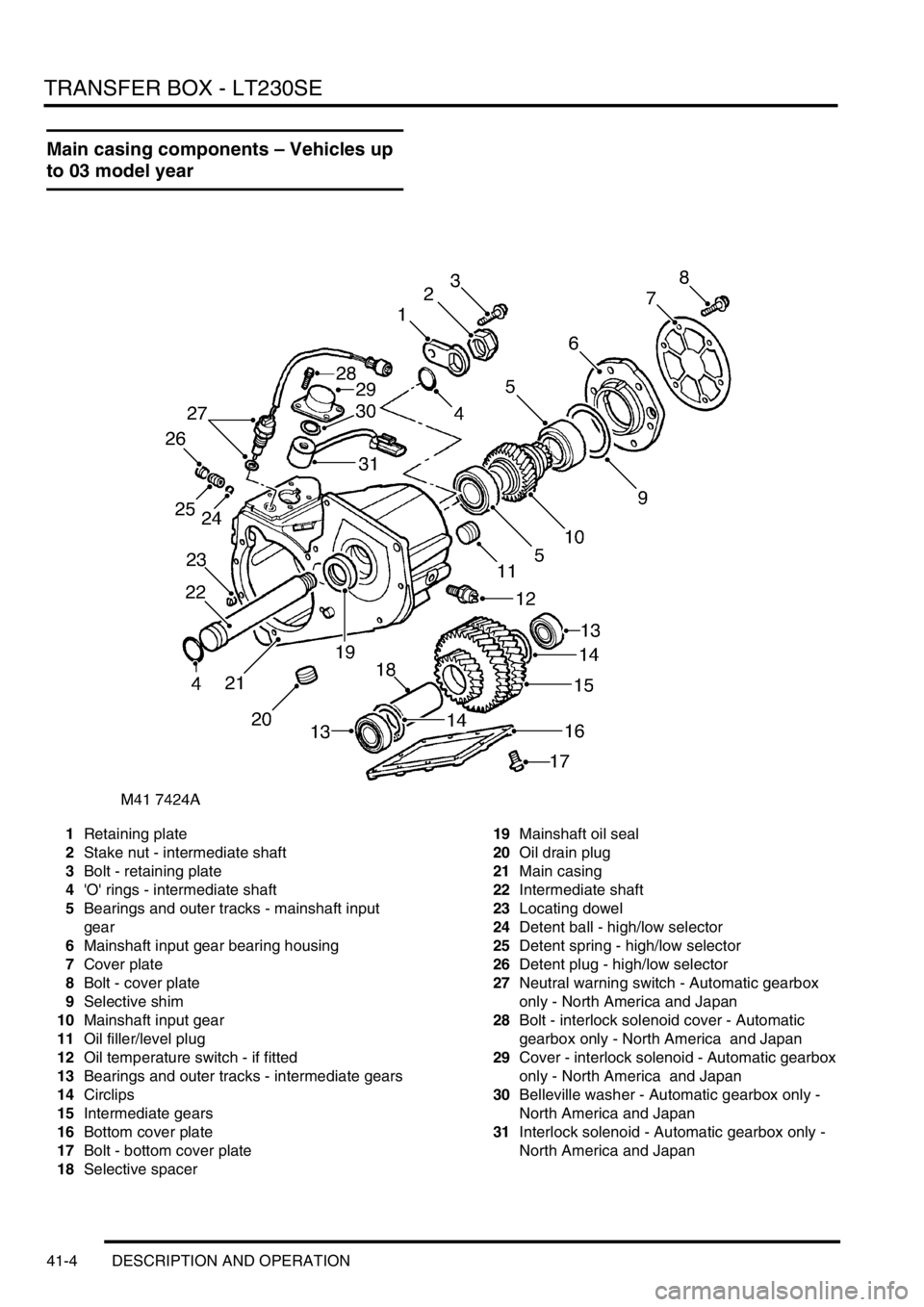

Main casing components – Vehicles up

to 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Oil temperature switch - if fitted

13Bearings and outer tracks - intermediate gears

14Circlips

15Intermediate gears

16Bottom cover plate

17Bolt - bottom cover plate

18Selective spacer19Mainshaft oil seal

20Oil drain plug

21Main casing

22Intermediate shaft

23Locating dowel

24Detent ball - high/low selector

25Detent spring - high/low selector

26Detent plug - high/low selector

27Neutral warning switch - Automatic gearbox

only - North America and Japan

28Bolt - interlock solenoid cover - Automatic

gearbox only - North America and Japan

29Cover - interlock solenoid - Automatic gearbox

only - North America and Japan

30Belleville washer - Automatic gearbox only -

North America and Japan

31Interlock solenoid - Automatic gearbox only -

North America and Japan

Page 530 of 1529

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-5

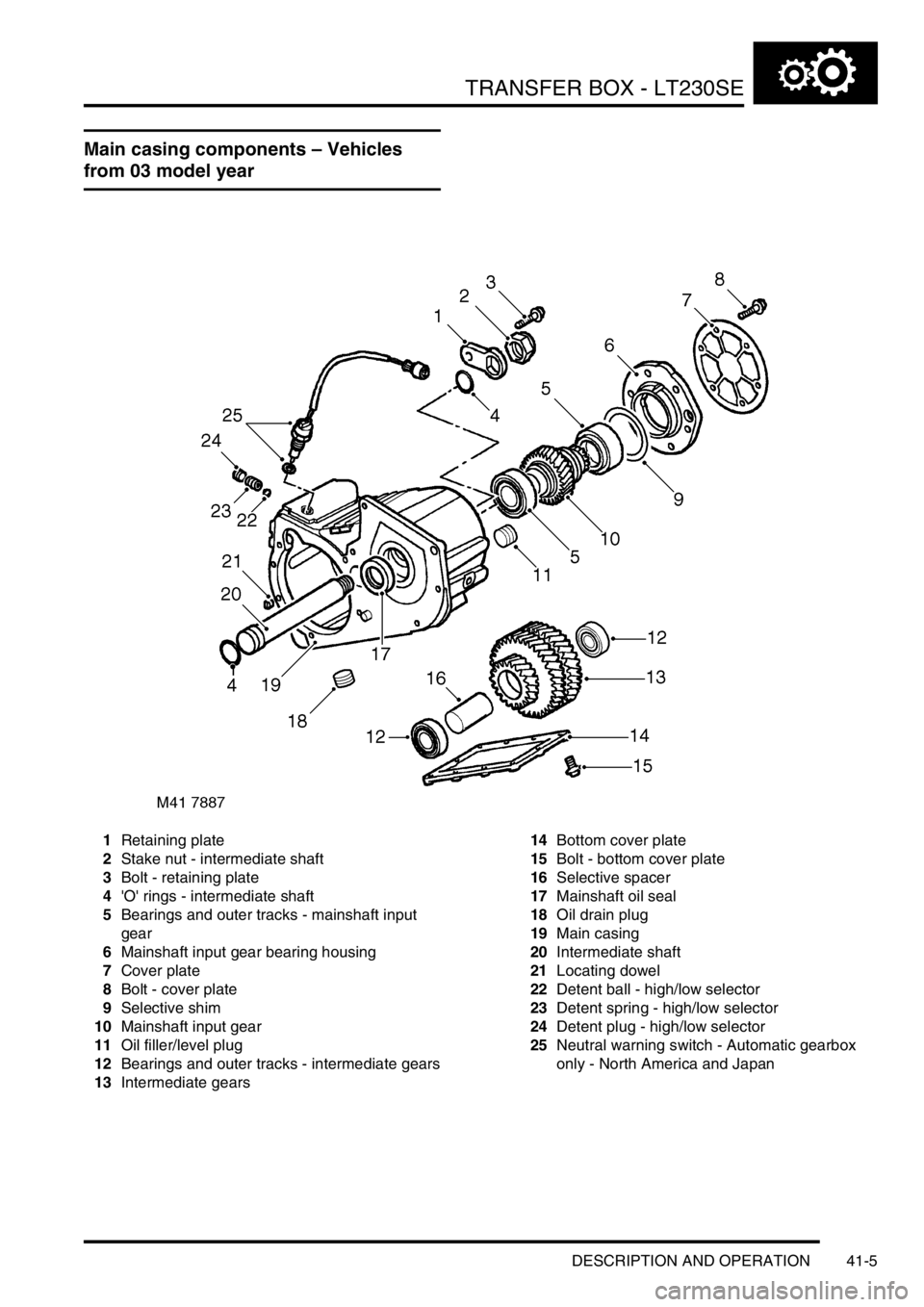

Main casing components – Vehicles

from 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Bearings and outer tracks - intermediate gears

13Intermediate gears14Bottom cover plate

15Bolt - bottom cover plate

16Selective spacer

17Mainshaft oil seal

18Oil drain plug

19Main casing

20Intermediate shaft

21Locating dowel

22Detent ball - high/low selector

23Detent spring - high/low selector

24Detent plug - high/low selector

25Neutral warning switch - Automatic gearbox

only - North America and Japan

Page 541 of 1529

TRANSFER BOX - LT230SE

41-16 DESCRIPTION AND OPERATION

Differential lock warning lamp switch - if fitted - Vehicles up to 03 model year

A differential lock warning lamp switch connected to the SLABS ECU and operated by movement of the selector fork

and shaft is screwed into the top of the output housing. The switch connects to earth when the differential lock is

engaged.

Differential lock warning lamp switches - Vehicles from 03 model year

Vehicles from 03 model year are fitted with two differential lock warning lamp switches.

Both switches are of a new design and are fitted into the top of the front output housing. The switches are connected

to the SLABS ECU and are operated by movement of the selector shaft.

Both switches have an aluminium washer which seals the switch to the casing and also sets the switch position,

removing the requirement for a setting procedure.

Both switches are connected in parallel to earth when the differential lock is engaged. This earth is sensed by the

SLABS ECU which illuminates the differential lock warning lamp in the instrument pack.

Differential lock warning lamp - Vehicles up to 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a warning to the driver when the

ignition is switched on that the differential lock is engaged. The warning lamp illuminates in a Red colour.

With the lock engaged, the traction control and electronic brake distribution warning lamps will also be illuminated.

Disengagement of the differential lock should be carried out with the ignition switched off. The warning lamps must

be extinguished when the ignition is switched on again.

Differential lock warning lamp – vehicles from 03 model year

The differential lock warning lamp is amber coloured and is located in the instrument pack.

When the lock is engaged, the warning lamp is illuminated and the instrument pack sounder emits three audible

chimes. When the lock is disengaged, the warning lamp is extinguished and the instrument pack sounder emits three

audible chimes.

Rear output housing

The rear output housing carries the output shaft and flange. A cable operated transmission brake is attached to the

housing, the brake drum being attached to the output flange.

The rear output shaft is supported in the housing by a single bearing and is splined into the differential rear sun gear.

Lubrication

Lubrication is by splash, oil filler/level and drain plugs being located in the main casing.

Internal pressures caused by thermal expansion and contraction are avoided by the use of a plastic breather pipe

venting the interior of the box to atmosphere. The pipe is attached to the top of the high/low selector housing by a

banjo bolt and is then routed in a continuously rising path into the engine compartment where the open end is secured

by a clip attached to the engine cylinder block.

Oil temperature warning lamp switch

An oil temperature switch is fitted to V8 engine models up to 03 Model Year. In the event of the transfer box oil

approaching maximum recommended working temperature of 145°C (293°F), the switch will close and a warning

lamp in the instrument pack will be illuminated.

Page 666 of 1529

REAR AXLE

DESCRIPTION AND OPERATION 51-1

REAR AXLE DESCRIPTION AND OPERAT ION

Rear axle component layout

1Drive shaft

2'O' ring

3Hub bearing

4Stake nut

5Hub flange

6Breather tube

7Bolt

8Bolt

9Oil seal10Pinion flange

11Centralising peg

12Bolt

13Washer

14Differential unit

15Drain plug

16Axle casing

17Oil level plug

18'O' ring

Page 667 of 1529

REAR AXLE

51-2 DESCRIPTION AND OPERATION

Description

General

The rear axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in each end of the axle casing and connected to the differential unit by a drive shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the rear suspension.

A differential cover on the rear of the axle casing contains an oil level plug for checking and replenishment of the

differential unit lubricating oil. A magnetic drain plug is installed on the underside of the axle casing.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located between the chassis and the left rear wheelarch.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a pinion flange which is secured with a bolt

and washer. An oil seal prevents leakage past the pinion flange.

Centralising peg

The centralising peg is a press fit in the centre of the pinion flange and provides a positive location for the rear

propellor shaft to ensure it is centralised with the flange.

Page 673 of 1529

REAR AXLE

51-8 REPAIRS

Refit

1.Clean pinion oil seal recess and pinion flange.

2.Lubricate oil seal lip with clean differential oil.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Using tool LRT-51-010, fit pinion oil seal.

4.Fit pinion flange and securing bolt and washer.

Using tool LRT-51-003 to restrain pinion

flange, tighten pinion flange securing bolt to

100 Nm (74 lbf.ft).

5.Using a tubular drift, fit centralising peg to

pinion flange. Ensure that large diameter part of

centralising peg is below pinion flange

mounting surface.

6.Position propeller shaft and align reference

marks.

7.Fit nuts and bolts securing flexible coupling to

pinion flange and tighten to 76 Nm (55 lbf.ft).

8.Remove stand(s) and lower vehicle.

9.Check differential oil level.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

M51 0047A

LRT-51-003

Page 680 of 1529

FRONT AXLE

DESCRIPTION AND OPERATION 54-1

FRONT AXLE DESCRIPTION AND OPERAT ION

Front axle component layout

1Stake nut

2Hub flange

3Hub bearing

4Steering knuckle

5Drive shaft

6Oil seal

7Bolt

8Bolt

9Washer10Drive flange

11Oil seal

12Differential unit

13Drain plug

14Axle casing

15Breather tube

16Oil level plug

17'O' ring

Page 681 of 1529

FRONT AXLE

54-2 DESCRIPTION AND OPERATION

Description

General

The front axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in a steering knuckle at each end of the axle casing and connected to the differential unit by a drive

shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the front suspension.

Yokes at each end of the casing incorporate upper and lower ball joints for attachment of the steering knuckles.

A differential cover on the front of the axle casing contains an oil level plug for checking and replenishment of the

differential lubricating oil. A magnetic drain plug is installed on the underside of the casing. An oil seal is installed in

each end of the axle casing to prevent leakage past the drive shafts.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located in the left rear corner of the engine compartment.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a drive flange which is secured with a bolt

and washer. An oil seal prevents leakage past the drive flange.

Steering knuckle

The steering knuckles are mounted on upper and lower ball joints in the yokes at the end of the axle casing. A tension

collet, in the lower mounting point of each steering knuckle, accommodates manufacturing tolerances to enable the

correct tightening of both ball joints. Lugs are incorporated on the steering knuckles for attachment of the steering

system drag link and track rod.