brake fluid LAND ROVER DISCOVERY 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 883 of 1529

BRAKES

70-30 ADJUSTMENTS

Brake system bleeding

$% 70.25.02

Bleeding of the brake system can be carried out

using the procedures given on TestBook, or by

following the manual procedure given below.

WARNING: If any components upstream of brake

modulator, including the modulator itself are

replaced, the brake system must be bled using

the procedure on TestBook/T4, to ensure that all

air is expelled from the new component(s).

WARNING: Do not allow brake fluid to come into

contact with eyes or skin.

Bleed

NOTE: This procedure covers bleeding the

complete system, but where only the primary or

secondary circuit have been disturbed in

isolation, it should only be necessary to bleed

that circuit. Partial bleeding of the hydraulic

system is only permissible if a brake pipe or

hose has been disconnected with only minor

loss of fluid.

1.Do not allow fluid level in master cylinder to fall

below 'MIN' mark during bleeding.

2.Do not fill reservoir above 'MAX' level.

3.Raise front and rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Check all pipe and hose connections are tight

and there are no signs of leakage.

5.Top-up fluid level in brake reservoir to 'MAX'

mark.

WARNING: Do not allow dirt or foreign

liquids to enter the reservoir. Use only new

DOT 4 brake fluid from airtight containers.

Do not mix brands of brake fluid as they

may not be compatible.6.Attach bleed tube to the bleed screw on front

brake caliper on the passenger side, submerge

free end in a clear container containing brake

fluid.

7.Apply pressure to brake pedal several times,

then apply steady pressure.

8.Loosen bleed screw to release brake fluid and

air. Allow pedal to return unassisted.

9.Depress brake pedal steadily through its full

stroke and allow to return unassisted. Repeat

procedure until a flow of clean air-free fluid is

purged into container then, whilst holding

pedal at end of downward stroke, tighten brake

caliper bleed screw to 10 Nm (7 lbf.ft).

CAUTION: Ensure the fluid in the reservoir

is maintained between the minimum and

maximum levels throughout the bleed

procedure using new brake fluid.

10.Top-up brake fluid level to 'MAX' mark.

Page 888 of 1529

BRAKES

REPAIRS 70-35

Master cylinder - brake

$% 70.30.08

Remove

1.Disconnect multiplug from fluid level switch.

2.Position cloth under master cylinder to absorb

spilled fluid.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

3.Disconnect secondary system pipe union from

master cylinder.

4.Disconnect primary system pipe union from

master cylinder.

5. Manual gearbox only: Release clip and

disconnect clutch fluid supply hose from

reservoir.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 nuts and washers securing master

cylinder to servo.

7.Remove master cylinder. Refit

1.Clean master cylinder and servo mating

surfaces.

2.Align push rod and position master cylinder to

servo.

3.Fit nuts and washers securing master cylinder

to servo and tighten to 25 Nm (18 lbf.ft).

4.Connect primary and secondary brake pipes,

and tighten unions to 25 Nm (18 lbf.ft).

5. Manual gearbox only: Connect clutch fluid

hose to reservoir, secure with clip.

6.Connect fluid level switch multiplug.

7.Bleed brake system using TestBook/T4.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Page 891 of 1529

BRAKES

70-38 REPAIRS

Brake pads - front

$% 70.40.02

WARNING: Brake pads must be renewed in axle

sets only, otherwise braking efficiency may be

impaired.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove lower guide pin bolt from caliper and

pivot caliper housing upwards.

4.Remove 2 brake pads from caliper carrier.

Shims are part of the brake pads.Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc.

2.Scrape rust from pad locating surfaces on

caliper.

3.Clean dust from calipers using brake cleaning

fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

4.Using tool LRT-70-500, press caliper pistons

fully into bores. Ensure that displaced fluid

does not overflow from reservoir.

5.Fit brake pads with chamfer towards leading

edge of disc.

6.Lower caliper housing over pads.

7.Ensure flats on guide pins locate with lugs on

caliper housing. fit new pivot bolt and tighten to

30 Nm (22 lbf.ft).

8.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

9.Remove stand(s) and lower vehicle.

10.Depress brake several times to set pad to disc

clearance.

11.Check and top-up brake fluid.

Page 892 of 1529

BRAKES

REPAIRS 70-39

Brake pads - rear

$% 70.40.10

WARNING: Brake pads must be renewed in axle

sets only, otherwise braking efficiency may be

impaired.

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove lower guide pin bolt from caliper and

pivot caliper housing upwards.

4.Remove 2 brake pads from caliper carrier.

Shims are part of the brake pads.Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc.

2.Scrape rust from pad locating surfaces on

caliper.

3.Clean dust from calipers using brake cleaning

fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

4.Using tool LRT-70-500, press caliper pistons

fully into bores. Ensure that displaced fluid

does not overflow from reservoir.

5.Fit pads to caliper carrier.

6.Lower caliper housing over pads.

7.Ensure flats on guide pins locate with lugs on

caliper housing. fit new pivot bolt and tighten to

30 Nm (22 lbf.ft).

8.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

9.Remove stand(s) and lower vehicle.

10.Depress brake several times to set pad to disc

clearance.

11.Check and top-up brake fluid.

Page 894 of 1529

BRAKES

REPAIRS 70-41

Refit

1.Clean components with brake cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

2.Lubricate cable lever pivot pin.

3.Fit pivot pin to shoe, fit cable lever washers and

secure with 'C' clip.

4.Fit adjuster plungers.

5.Fit shoe to brake cable, align to back plate and

adjuster. Secure shoe to back plate with pin,

spring and washer.

6.Fit abutment plate to brake shoe.

7.Fit return springs with remaining shoe. Secure

shoe to back plate with pin, spring and washer.

8.Fit abutment plate retaining spring.

9.Clean brake drum and mating face.

10.Position brake drum and tighten retaining

screw.

11.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

12.Adjust handbrake.

+ BRAKES, ADJUSTMENTS,

Handbrake.

Page 898 of 1529

BRAKES

REPAIRS 70-45

Housing - caliper - front

$% 70.55.24

Remove

1.Raise front of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Clamp brake hose to prevent fluid loss.

4.Remove brake hose banjo bolt and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 guide pin bolts and remove caliper

housing from carrier.

6.Remove 2 brake pads from caliper carrier. Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on caliper bracket.

2.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

3.Fit brake pads to caliper carrier.

4.Position caliper housing to carrier, align flats on

guide pins with caliper housing.

5.Fit guide pin bolts and tighten to 30 Nm (22

lbf.ft).

6.Clean banjo bolt and fit new sealing washers.

7.Position hose to caliper and tighten banjo bolt

to 32 Nm (24 lbf.ft).

8.Remove clamp from brake hose.

9.Bleed brake system.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

10.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

11.Remove stand(s) and lower vehicle.

Page 899 of 1529

BRAKES

70-46 REPAIRS

Housing - caliper - rear

$% 70.55.25

Remove

1.Raise rear of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Clamp brake hose to prevent fluid loss.

4.Remove brake hose banjo bolt and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 guide pin bolts and remove caliper

housing from carrier.

6.Remove 2 brake pads from caliper carrier. Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on caliper bracket.

2.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

3.Fit brake pads to caliper carrier.

4.Position caliper housing to carrier, align flats on

guide pins with caliper housing.

5.Fit guide pin bolts and tighten to 30 Nm (22

lbf.ft).

6.Clean banjo bolt and fit new sealing washers.

7.Position hose to caliper and tighten banjo bolt

to 32 Nm (24 lbf.ft).

8.Remove clamp from brake hose.

9.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

10.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

11.Remove stand(s) and lower vehicle.

Page 902 of 1529

BRAKES

REPAIRS 70-49

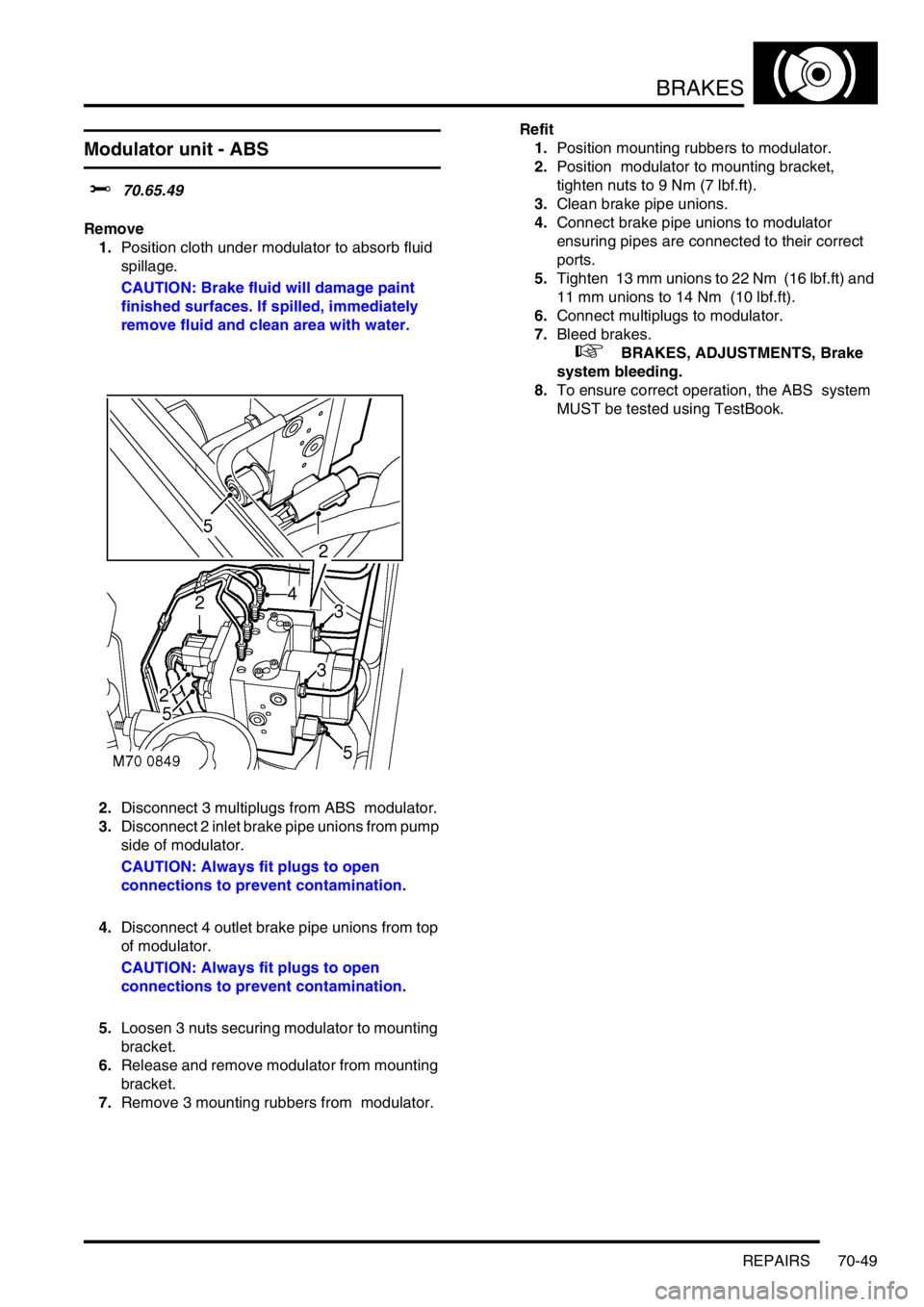

Modulator unit - ABS

$% 70.65.49

Remove

1.Position cloth under modulator to absorb fluid

spillage.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

2.Disconnect 3 multiplugs from ABS modulator.

3.Disconnect 2 inlet brake pipe unions from pump

side of modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Disconnect 4 outlet brake pipe unions from top

of modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Loosen 3 nuts securing modulator to mounting

bracket.

6.Release and remove modulator from mounting

bracket.

7.Remove 3 mounting rubbers from modulator. Refit

1.Position mounting rubbers to modulator.

2.Position modulator to mounting bracket,

tighten nuts to 9 Nm (7 lbf.ft).

3.Clean brake pipe unions.

4.Connect brake pipe unions to modulator

ensuring pipes are connected to their correct

ports.

5.Tighten 13 mm unions to 22 Nm (16 lbf.ft) and

11 mm unions to 14 Nm (10 lbf.ft).

6.Connect multiplugs to modulator.

7.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

8.To ensure correct operation, the ABS system

MUST be tested using TestBook.

Page 1096 of 1529

PANEL REPAIRS

REPAIRS 77-2-29

Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit brake pipes to valance.

4.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

5.Fit PAS/ACE reservoir, refill fluids to correct

levelsand bleed ACE system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

7.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - from 03MY.

8.Connect leads/multiplug to alternator.

9.Connect battery leads, negative lead last.

Valance upper assembly - RH

In this procedure, the front wing and the valance

outer reinforcement are replaced in conjunction with

the RH valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - from 03MY.

4.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

5.Remove battery tray.

6.Remove fuse box.

7.Release expansion tank from fixings and

position aside.

8.Release harness from valance and position

aside.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

M77 1692A

M77 1750

Page 1098 of 1529

PANEL REPAIRS

REPAIRS 77-2-31

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

4.Fit PAS/ACE reservoir and refill fluids to correct

levels.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

5.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

6.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - from 03MY.

7.Connect leads/multiplug to alternator.

8.Connect battery leads, negative lead last.

M77 1744

M77 1689A