washer fluid LAND ROVER DISCOVERY 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 806 of 1529

FRONT SUSPENSION

REPAIRS 60-61

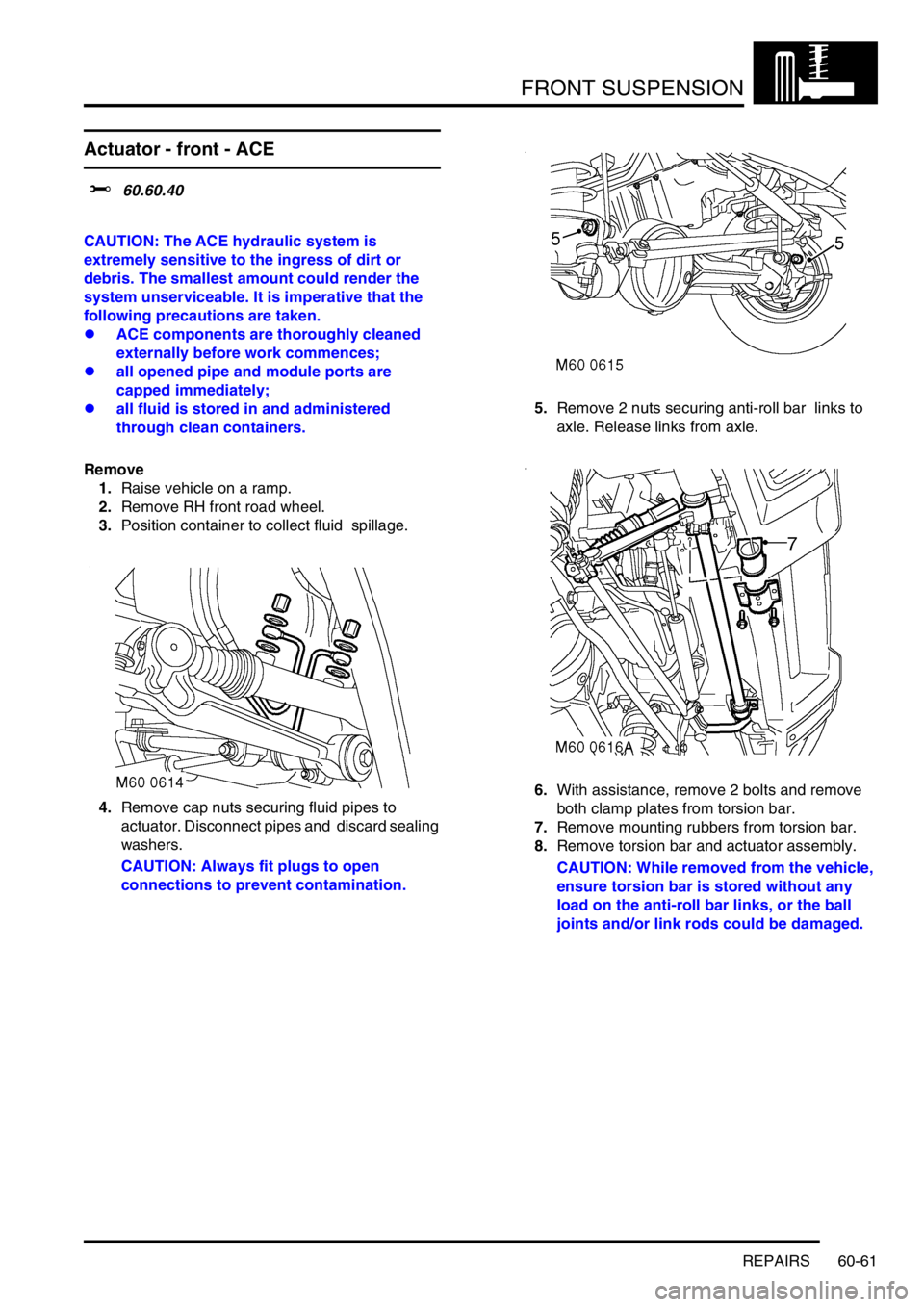

Actuator - front - ACE

$% 60.60.40

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Raise vehicle on a ramp.

2.Remove RH front road wheel.

3.Position container to collect fluid spillage.

4.Remove cap nuts securing fluid pipes to

actuator. Disconnect pipes and discard sealing

washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.5.Remove 2 nuts securing anti-roll bar links to

axle. Release links from axle.

6.With assistance, remove 2 bolts and remove

both clamp plates from torsion bar.

7.Remove mounting rubbers from torsion bar.

8.Remove torsion bar and actuator assembly.

CAUTION: While removed from the vehicle,

ensure torsion bar is stored without any

load on the anti-roll bar links, or the ball

joints and/or link rods could be damaged.

Page 848 of 1529

REAR SUSPENSION

REPAIRS 64-39

Actuator - rear - ACE

$% 64.60.40

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Models with SLS:

WARNING: Ensure the air suspension system is

made safe before commencing work. Otherwise

the chassis may lower onto the bump stops

during repair.

Remove

1.Raise vehicle on ramp.

2.Remove nuts securing anti-roll bar links to

axle. Release links from axle.

3.Pull torsion bar down for access to actuator. 4.Remove nut securing anti-roll bar link to long

arm and remove link.

5.Position container to collect fluid spillage.

6.Remove cap nuts securing fluid pipes to

actuator. Disconnect pipes and remove and

discard sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 850 of 1529

REAR SUSPENSION

REPAIRS 64-41

Bushes - rear long arm - ACE

$% 64.60.46

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Models with SLS:

WARNING: Ensure the air suspension system is

made safe before commencing work. Otherwise

the chassis may lower onto the bump stops

during repair.

Remove

1.Raise vehicle on ramp.

2.Remove nuts securing anti-roll bar links to axle.

Release links from axle.

3.Pull torsion bar down for access to actuator.4.Remove securing nuts and remove anti-roll bar

links from torsion bar.

5.Position container to collect fluid spillage.

6.Remove cap nuts securing fluid pipes to

actuator. Disconnect pipes and remove and

discard sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

7.With assistance, remove bolts securing torsion

bar clamps. Remove clamps and remove

torsion bar and actuator.

Page 888 of 1529

BRAKES

REPAIRS 70-35

Master cylinder - brake

$% 70.30.08

Remove

1.Disconnect multiplug from fluid level switch.

2.Position cloth under master cylinder to absorb

spilled fluid.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

3.Disconnect secondary system pipe union from

master cylinder.

4.Disconnect primary system pipe union from

master cylinder.

5. Manual gearbox only: Release clip and

disconnect clutch fluid supply hose from

reservoir.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 nuts and washers securing master

cylinder to servo.

7.Remove master cylinder. Refit

1.Clean master cylinder and servo mating

surfaces.

2.Align push rod and position master cylinder to

servo.

3.Fit nuts and washers securing master cylinder

to servo and tighten to 25 Nm (18 lbf.ft).

4.Connect primary and secondary brake pipes,

and tighten unions to 25 Nm (18 lbf.ft).

5. Manual gearbox only: Connect clutch fluid

hose to reservoir, secure with clip.

6.Connect fluid level switch multiplug.

7.Bleed brake system using TestBook/T4.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Page 894 of 1529

BRAKES

REPAIRS 70-41

Refit

1.Clean components with brake cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

2.Lubricate cable lever pivot pin.

3.Fit pivot pin to shoe, fit cable lever washers and

secure with 'C' clip.

4.Fit adjuster plungers.

5.Fit shoe to brake cable, align to back plate and

adjuster. Secure shoe to back plate with pin,

spring and washer.

6.Fit abutment plate to brake shoe.

7.Fit return springs with remaining shoe. Secure

shoe to back plate with pin, spring and washer.

8.Fit abutment plate retaining spring.

9.Clean brake drum and mating face.

10.Position brake drum and tighten retaining

screw.

11.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

12.Adjust handbrake.

+ BRAKES, ADJUSTMENTS,

Handbrake.

Page 898 of 1529

BRAKES

REPAIRS 70-45

Housing - caliper - front

$% 70.55.24

Remove

1.Raise front of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Clamp brake hose to prevent fluid loss.

4.Remove brake hose banjo bolt and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 guide pin bolts and remove caliper

housing from carrier.

6.Remove 2 brake pads from caliper carrier. Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on caliper bracket.

2.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

3.Fit brake pads to caliper carrier.

4.Position caliper housing to carrier, align flats on

guide pins with caliper housing.

5.Fit guide pin bolts and tighten to 30 Nm (22

lbf.ft).

6.Clean banjo bolt and fit new sealing washers.

7.Position hose to caliper and tighten banjo bolt

to 32 Nm (24 lbf.ft).

8.Remove clamp from brake hose.

9.Bleed brake system.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

10.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

11.Remove stand(s) and lower vehicle.

Page 899 of 1529

BRAKES

70-46 REPAIRS

Housing - caliper - rear

$% 70.55.25

Remove

1.Raise rear of vehicle, one side.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Clamp brake hose to prevent fluid loss.

4.Remove brake hose banjo bolt and discard

sealing washers.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 2 guide pin bolts and remove caliper

housing from carrier.

6.Remove 2 brake pads from caliper carrier. Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on caliper bracket.

2.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

3.Fit brake pads to caliper carrier.

4.Position caliper housing to carrier, align flats on

guide pins with caliper housing.

5.Fit guide pin bolts and tighten to 30 Nm (22

lbf.ft).

6.Clean banjo bolt and fit new sealing washers.

7.Position hose to caliper and tighten banjo bolt

to 32 Nm (24 lbf.ft).

8.Remove clamp from brake hose.

9.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

10.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

11.Remove stand(s) and lower vehicle.

Page 959 of 1529

EXTERIOR FITTINGS

76-2-12 REPAIRS

Bumper assembly - front

$% 76.22.08

Remove

1.Remove 14 screws securing LH and RH wheel

arch liner extensions to wheel arch liners and

bumper valance and remove extensions.

Note: 18 screws are used on 03 MY onwards.

2.Disconnect multiplugs from fog lamps. 3.Remove 2 nuts securing bumper valance side

mountings to body.

4.Remove 4 nuts securing bumper to crush cans

and remove bumper from body.

5.Remove 3 screws securing bumper to front

cross bar.

6. Models with headlamp wash: Position

container to collect screen washer fluid and

disconnect hose from headlamp washer pump.

Refit

1. Models with headlamp wash: Connect hose

to headlamp washer pump. Refill washer

reservoir with fluid.

2.With assistance position bumper to body.

3.Fit and tighten 3 screws securing bumper to

front cross bar.

4.Tighten nuts securing bumper to crush cans to

13 Nm (10 lbf.ft).

5.Tighten nuts securing bumper to side

mountings to 13 Nm (10 lbf.ft).

6.Connect multiplugs to fog lamps.

7.Fit wheel arch liner extensions and secure with

screws.

Page 1088 of 1529

PANEL REPAIRS

REPAIRS 77-2-21

REPAIRS

Front bulkhead assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

5. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

6. Diesel models: Remove gearbox fluid cooler.

7.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8.Release headlamp levelling motors and

position aside.

9.Release headlamp wiring and position aside.

10.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove battery tray.

12.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

13.Remove 2 earth leads from LH of front

bulkhead.

14.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

15. Models with A/C: Release and remove A/C

pipes.

16.Remove RH and LH crush cans.

17.Remove bonnet release cable.

18.Support bonnet in open position

19.Remove bonnet locking mechanism.

20.Remove VIN plate.

21.Remove 2 bolts securing front bulkhead

assembly to chassis.

22.Remove centre braces.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten to 45 Nm (33 lbf.ft).

3.Fit VIN plate.

4.Fit bonnet locking mechanism.

5.Fit bonnet release cable.

6.Fit crush cans.

7. Models with A/C: Fit A/C pipes.

8.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

9.Fit 2 earth leads to LH of front bulkhead.

10.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Fit battery tray.

12.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Fit headlamp wiring and headlamp levelling

motors.

14.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

15. Diesel models: Fit gearbox fluid cooler.

16. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

17.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

Page 1091 of 1529

PANEL REPAIRS

77-2-24 REPAIRS

Front cross member

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Release headlamp levelling motors and

position aside.

8.Release headlamp wiring and position aside.

9.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

10. Models with A/C: Release and remove A/C

pipes.

11.Remove RH and LH crush cans.

12.Remove 2 bolts securing front bulkhead

assembly to chassis.

13.Remove centre braces.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit crush cans.

4. Models with A/C: Fit A/C pipes.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit headlamp wiring and headlamp levelling

motors.

7.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8. Diesel models: Fit gearbox fluid cooler.

9. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

10.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

11.Connect leads/multiplug to alternator.

12.Connect battery leads, negative lead last.