tow LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1051 of 1529

SUNROOF

76-6-20 REPAIRS

Switch pack - sunroof

$% 76.84.44

Remove

1.Release switch pack from front stowage

pocket.

2.Disconnect multiplugs from 3 sunroof

switches.

3.Remove switches from switch pack.

Refit

1.Fit switches to switch pack.

2.Connect multiplugs to switches.

3.Fit switch pack to front stowage pocket.

ECU - sunroof

$% 76.84.46

Remove

1.Remove front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

2.Remove 2 screws securing ECU to roof.

3.Disconnect 2 multiplugs from ECU.

4.Remove sunroof ECU.

Refit

1.Position sunroof ECU and connect multiplugs.

2.Fit and tighten screws securing ECU to roof.

3.Fit front stowage pocket.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Stowage pocket - front.

Page 1139 of 1529

CORROSION PREVENTION AND SEALING

77-4-6 CORROSION PREVENTION

Corrosion prevention

Factory treatments

During production, vehicle bodies are treated with the following anti-corrosion materials:

lA PVC-based underbody sealer which is sprayed onto the underside of the main floor, rear floor, front and rear

wheelarches and the front valance assembly;

lAn application of cavity wax which is sprayed into the sill panels, 'A' post, 'B-C' post, fuel filler aperture, body rear

panel and the lower areas of the door panels;

lA coating of underbody wax which is applied to the entire underbody inboard of the sill vertical flanges, and

covers all moving and flexible components EXCEPT for wheels, tyres, brakes and exhaust;

lA coat of protective wax applied to the engine bay area.

Whenever body repairs are carried out, ensure the anti-corrosion materials in the affected area are repaired or

renewed as necessary using the approved materials.

+ BODY SEALING MATERIALS, MATERIALS AND APPLICATIONS, Approved materials.

Precautions during body repairs and handling

Take care when handling the vehicle in the workshop. Underbody sealers, seam sealers, underbody wax and body

panels may be damaged if the vehicle is carelessly lifted.

+ LIFTING AND TOWING, LIFTING.

Proprietary anti-corrosion treatments

The application of proprietary anti-corrosion treatments, in addition to the factory-applied treatment, could invalidate

the Corrosion Warranty and should be discouraged. This does not apply to Rover approved, compatible, preservative

waxes which may be applied on top of existing coatings.

Fitting approved accessories

When fitting accessories ensure that the vehicle's corrosion protection is not affected, either by breaking the protective

coating or by introducing a moisture trap.

Do not screw self-tapping screws directly into body panels. Fit suitable plastic inserts to the panel beforehand. Always

ensure that the edges of holes drilled into panels, chassis members and other body parts are protected with a suitable

zinc rich or acid etch primer, and follow with a protective wax coating brushed onto the surrounding area.

Do not attach painted metal surfaces of any accessory directly to the vehicle's bodywork unless suitably protected.

Where metal faces are bolted together always interpose a suitable interface material such as weldable zinc rich

primer, extruded strip, or zinc tape.

Steam cleaning and dewaxing

Due to the high temperatures generated by steam cleaning equipment, there is a risk that certain trim components

could be damaged and some adhesives and corrosion prevention materials softened or liquified.

Adjust the equipment so that the nozzle temperature does not exceed 90° C (194° F). Take care not to allow the steam

jet to dwell on one area, and keep the nozzle at least 300 mm (11.811 in) from panel surfaces.

DO NOT remove wax or lacquer from underbody or underbonnet areas during repairs. Should it be necessary to

steam clean these areas, apply a new coating of wax or underbody protection as soon as possible.

Inspections during maintenance servicing

It is a requirement of the Corrosion Warranty that the vehicle body is checked for corrosion by an authorised Land

Rover Dealer at least once a year, to ensure that the factory-applied protection remains effective.

Service Job Sheets include the following operations to check bodywork for corrosion:

lWith the vehicle on a lift, carry out visual check of underbody sealer for damage;

lWith the vehicle lowered, inspect exterior paintwork for damage and body panels for corrosion.

It will be necessary for the vehicle to be washed by the Dealer prior to inspection of bodywork if the customer has

offered the vehicle in a dirty condition.

Page 1166 of 1529

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-9

FBH fuel pump

The FBH fuel pump regulates the fuel supply to the FBH unit. The FBH fuel pump is installed in a rubber mounting on

the chassis crossmember immediately in front of the fuel tank. The pump is a self priming, solenoid operated plunger

pump, with a fixed displacement of 0.063 ml/Hz. The ECU in the FBH unit outputs a pulse width modulated signal to

control the operation of the pump. When the pump is de-energised, it provides a positive shut-off of the fuel supply to

the FBH unit.

FBH fuel pump nominal operating speeds/outputs

Sectioned view of FBH fuel pump

1Solenoid coil

2Plunger

3Filter insert

4Fuel line connector

5'O' ring seal6Spring

7Piston

8Bush

9Fuel line connector

10Non return valve

The solenoid coil of the FBH fuel pump is installed around a housing which contains a plunger and piston. The piston

locates in a bush, and a spring is installed on the piston between the bush and the plunger. A filter insert and a fuel

line connector are installed in the inlet end of the housing. A non return valve and a fuel line connector are installed

in the fuel outlet end of the housing.

While the solenoid coil is de-energised, the spring holds the piston and plunger in the 'closed' position at the inlet end

of the housing. An 'O' ring seal on the plunger provides a fuel tight seal between the plunger and the filter insert,

preventing any flow through the pump. When the solenoid coil is energised, the piston and plunger move towards the

outlet end of the housing, until the plunger contacts the bush, and draw fuel in through the inlet connection and filter.

The initial movement of the piston also closes transverse drillings in the bush and isolates the pumping chamber at

the outlet end of the housing. Subsequent movement of the piston then forces fuel from the pumping chamber through

the non return valve and into the line to the FBH unit. When the solenoid coil de-energises, the spring moves the piston

and plunger back towards the closed position. As the piston and plunger move towards the closed position, fuel flows

passed the plunger and through the annular gaps and transverse holes in the bush to replenish the pumping chamber.

Operating phase Speed, Hz Output, l/h (US galls/h)

Start sequence 0.70 0.159 (0.042)

Part load 1.35 0.306 (0.081)

Full load 2.70 0.612 (0.163)

Page 1301 of 1529

BODY CONTROL UNIT

86-3-14 DESCRIPTION AND OPERATION

Central Door Locking (CDL)

The BCU carries out the logic control operation for CDL. A CDL switch is mounted on the fascia panel and has two

inputs to the BCU, one for lock and one for unlock.

Door locking and unlocking can be performed using the remote transmitter in the keys and the receiver unit located

above the vehicle's headlining, behind the rear sunroof aperture. The receiver detects the signals sent from the

remote transmitter and sends a decoded signal to the BCU for processing.

Four methods of door locking are available:

lRemote handset locking.

lVehicle key locking.

lCDL switch locking.

lSpeed related locking.

Two security levels of door locking are available, CDL and Superlocking. The anti-theft alarm system works in

conjunction with the CDL system.

Electric windows and sunroof

The BCU controls the logical operations and the timing periods for the electric front windows. The rear windows are

hard-wired and the two electric sunroofs are controlled by a dedicated ECU which is enabled by the BCU.

The front windows are electrically operated using two rocker switches located in the centre console. Electric motors

are located in each of the front doors.

The rear windows are enabled by the IDM controlling the operation of the rear window relay located in the passenger

compartment fuse box.

Wipers and washers

The wiper and washer functions are controlled by the BCU and the IDM.

The front wipers and washers are operated from the switch stalk located on the right hand side of the steering column

and only operate when the ignition switch is in position I or II. The front wipers are operated by a motor located below

the windscreen plenum.

+ WIPERS AND WASHERS, DESCRIPTION AND OPERATION, Description.

The BCU controls the wiper motor frequency of operation via the IDM when intermittent wipe or wash is selected. The

front intermittent wipe option features five different intermittent delay periods. The shortest delay period is 3 seconds

and this is increased by 2 second increments up to a maximum delay of 11 seconds. The desired delay period for the

front wipers is set by the position of the rotary switch located on the wiper column stalk.

The rear wiper switch is located on the instrument pack cowl and is latched when pressed. The rear wiper electric

motor is located in the tail door. The rear wiper operation is controlled according to a programmed strategy via the

BCU and the IDM. The BCU also checks for a signal from either the reverse lamp switch located in the vehicle gearbox

(manual gearbox models) or the gear position switch (automatic gearbox models) for operating the rear wipers when

the vehicle is in reverse. The rear wiper and washer only operate when the ignition switch is in position II.

The front and rear washer pumps and the headlamp powerwash (where fitted) are also controlled through the BCU.

The washers are operated from electric pumps attached to the washer reservoir located in the left hand wheel arch.

The front wash switch is located on the wiper column stalk and is pulled towards the steering wheel to select the

washer function. When the front washers are operated, the wipers are also activated for three full cycles. The rear

wash switch is located on the instrument pack cowl. The BCU programme can be configured in one of two modes of

operation:

lNo wiper operation when the wash switch is pressed.

lWiper action after an initial delay of 400 ms.

Headlamp wash is activated by the BCU via the IDM and operates when the headlamps are on and the front washers

function is selected.

Page 1434 of 1529

HARNESSES

REPAIRS 86-7-29

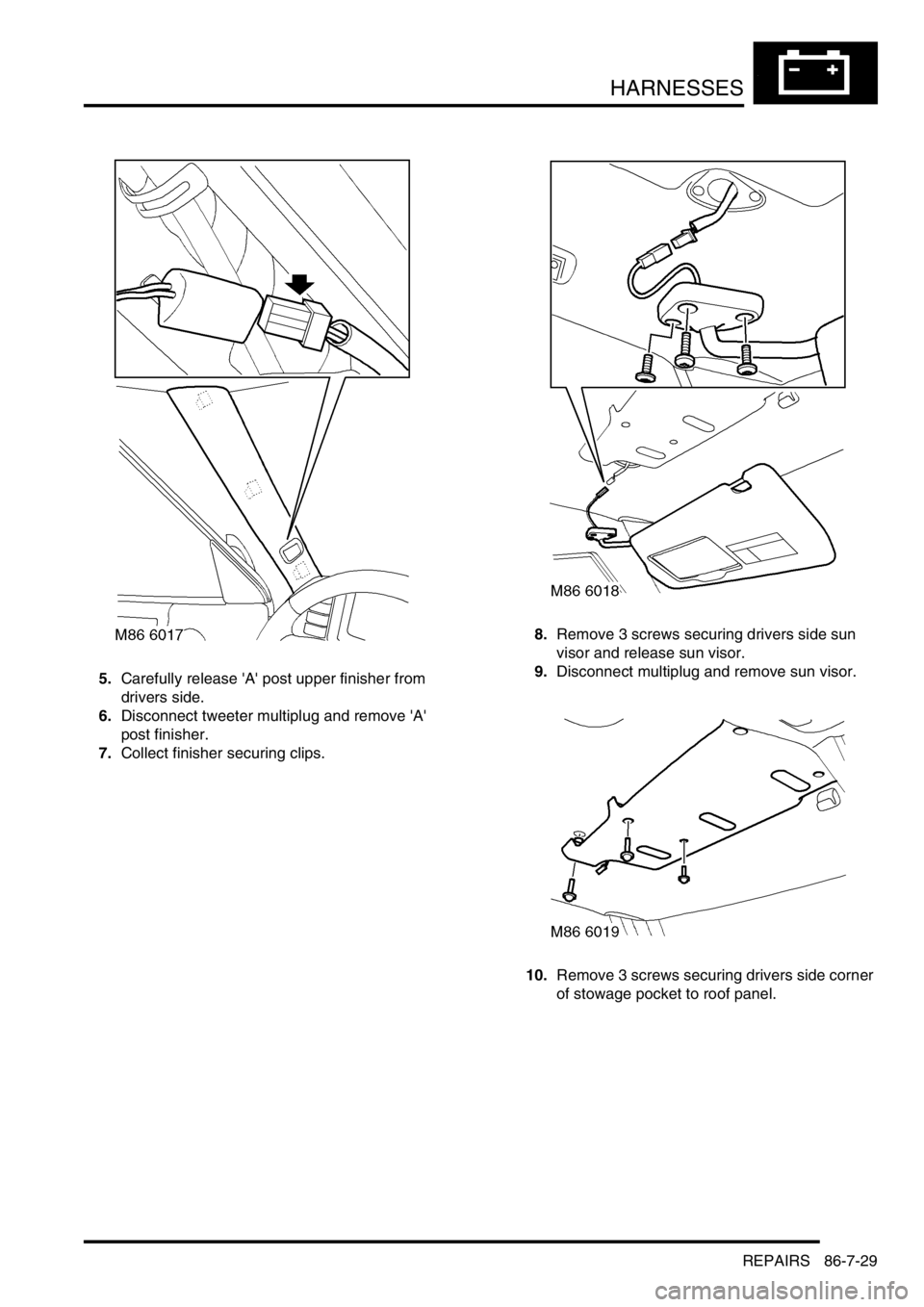

5.Carefully release 'A' post upper finisher from

drivers side.

6.Disconnect tweeter multiplug and remove 'A'

post finisher.

7.Collect finisher securing clips.8.Remove 3 screws securing drivers side sun

visor and release sun visor.

9.Disconnect multiplug and remove sun visor.

10.Remove 3 screws securing drivers side corner

of stowage pocket to roof panel.

Page 1436 of 1529

HARNESSES

REPAIRS 86-7-31

17.Disconnect DVD main harness multiplug from

vehicle fuse box link harness.

18.Remove DVD main harness from above

headlining and from fascia.

Refit

1.Fit DVD main harness to fascia and above

headlining.

2.Connect DVD main harness multiplug to

vehicle fuse box link harness.

3.Secure harness behind clamps at 'A' post and

multiplug to DVD unit mounting bracket.

4.Fit upper finisher to 'B' post.

5.Fit 'A' post lower finisher and secure with

fixings.

6.Fit seals to front and rear door apertures.

7.Fit screws to secure stowage pocket.

8.Position sun visor and connect multiplug.

9.Fit sun visor and secure with screws.

10.Fit finisher securing clips to 'A' post.

11.Position 'A' post upper finisher and connect

tweeter multiplug.

12.Fit 'A' post upper finisher.

13.Fit grab handles, tighten screws and fit screw

covers.

14.Fit DVD player unit.

+ IN CAR ENTERTAINMENT,

REPAIRS, DVD screen/player unit.

15.Fit CD switch box.

+ IN CAR ENTERTAINMENT,

REPAIRS, Switch box - CD/DVD player.

16.Connect battery earth lead, fit and secure

battery cover.

Page 1470 of 1529

NAVIGATION SYSTEM

DESCRIPTION AND OPERATION 87-17

GPS Antenna

The GPS antenna is installed on the rear of the roof, on the vehicle centreline. A diplexer unit on the underside of the

GPS antenna amplifies the radio signals received from the GPS satellites and transmits them through a co-axial cable

to the navigation computer for processing.

Display Unit

The display unit is integrated into the front stowage pocket, above the rear view mirror. The display unit is a colour

Liquid Crystal Display (LCD) that shows the programming menus, route guidance and traffic information. The display

illumination level automatically dims for night time viewing when the exterior lights are switched on.

Page 1480 of 1529

NAVIGATION SYSTEM

DESCRIPTION AND OPERATION 87-27

Sensor Check Menu

TestBook/T4 Diagnostics

No serial diagnostic link is provided with the CARiN III navigation system, so TestBook/T4 cannot interact with the

system.

Vehicle Position

If the vehicle’s battery has been disconnected, or if the vehicle has been transported to a new location on another

vehicle (e.g. by trailer or train), the navigation system will require up to 15 minutes to identify the new position. Entering

the vehicle’s position manually, reduces this delay. To enter the vehicle's position manually:

1Highlight and select Information.

2From the information menu, scroll down to the next screen and highlight and select Vehicle position.

NOTE: If the correct CD is in the navigation computer, the country is automatically entered. If you have travelled

to a new country, a new CD may be needed.

3From the vehicle position menu, highlight and select City, then use the typewriter menu to enter the vehicle’s

position (town, road, etc.) in the same way that you would enter a destination.

4Once the town and road names are entered, the navigation computer asks for a junction. This is the name of the

road that forms the next junction ahead of the vehicle.

5Highlight and select Junction, then enter the name using the typewriter, or select the correct road name if a list

of names is displayed. Crossing the junction will be highlighted. Drive the vehicle in the direction of the junction

and press the rotary controller when you reach the junction.

NOTE: The vehicle position menu provides a street map facility which enables you to check your vehicle’s current

position and assists in identifying the name of the next road junction.

Provided that the information entered into the computer is correct, the navigation system requires approximately 1

minute to determine the vehicle's position.

Navigation and Trafficmaster

Road navigation and off-road navigation are accessed from the main menu by highlighting and selecting the

appropriate title with the rotary controller. In both modes of navigation, this brings up a safety notice on the display

unit. Pushing the rotary controller again accepts the safety notice and replaces it with a menu screen, which is the

entry point for operation of the navigation function. The Trafficmaster function only operates in the road navigation

mode, and is activated and de-activated by pushing and holding the menu switch for more than 0.5 second. When

activating the Trafficmaster function, the system returns to the navigation mode if the menu switch is not released

within 1.5 seconds.

Refer to the Owner Handbook: Navigation, CARiN III & Traffic Master, Publication Part No. LRL 0586ENG for full

details of how to operate the road navigation, off-road navigation and Trafficmaster functions.

M86 6074

Sensor Check

Wheel Sensors

GPS Satellites

GPS Status

GYRO

Direction of Travel

< Return0

0

08

Position known

0285

Forward