light LAND ROVER DISCOVERY 1999 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 846 of 1529

REAR SUSPENSION

REPAIRS 64-37

Filter - intake - SLS

$% 64.50.12

Remove

1.Remove LH tail lamp.

+ LIGHTING, REPAIRS, Lamp - tail.

2.Disconnect filter from retaining peg.

3.Disconnect quick release connection and

remove filter assembly.

Refit

1.Position filter assembly and connect quick

release connection.

2.Secure filter retaining peg.

3.Fit LH tail lamp.

+ LIGHTING, REPAIRS, Lamp - tail.

Switch - ride height

$% 64.50.45

Remove

1.Carefully remove switch.

2.Disconnect multiplug from switch.

3.Remove switch.

Refit

1.Connect multiplug switch.

2.Position switch and push to secure.

Page 873 of 1529

BRAKES

70-20 DESCRIPTION AND OPERATION

Operation

Refer to illustration.

+ BRAKES, DESCRIPTION AND OPERATION, Brake system control diagram.

When the ignition is switched on, the SLABS ECU performs a check of the brake related warning lamps as part of the

power up procedure. The warning lamps are illuminated for approximately 3 seconds and then extinguished. If a fault

warning lamp remains illuminated after the lamp check, a fault has been detected and repair action is required.

ABS

The ABS function prevents the road wheels locking during brake application, thus maintaining vehicle stability even

under emergency conditions.

WARNING: ABS is an aid to retaining steering control and stability while braking:

lABS cannot defy the natural laws of physics acting on the vehicle.

lABS will not prevent accidents resulting from excessive cornering speeds, following another vehicle too

closely, aquaplaning, etc.

lThe additional control provided by ABS must never be exploited in a dangerous or reckless manner

which could jeopardise the safety of driver or other road users.

lThe fitting of ABS does not imply that the vehicle will always stop in a shorter distance.

NOTE: During normal braking the feel of the brake pedal on vehicles equipped with ABS will be the same as that on

non ABS vehicles. During anti-lock braking operation the driver will experience feedback in the form of a pulsating

brake pedal and solenoid/pump motor noise from the ABS modulator.

The anti-lock braking function is automatically enabled whenever the ABS modulator is in the normal braking mode.

While the anti-lock braking function is enabled, if the SLABS ECU detects a wheel decelerating faster than the

average and at the calibrated wheel slip limit for ABS operation, it operates the ABS modulator in the ABS braking

mode for the affected wheel.

EBD

The EBD function optimises the distribution of hydraulic pressure between the front and rear axles, under all vehicle

load configurations and road conditions, to maintain vehicle stability during braking. EBD operates in forward and

reverse and is automatically enabled whenever the ABS modulator is in the normal braking mode at vehicle

deceleration rates of 0.3 g and above (i.e. medium to high brake pedal loads). EBD operation is similar to that of ABS,

but is calibrated to intervene at lower wheel slip limits and operates the brakes in axle pairs instead of individually.

During braking, if the SLABS ECU detects the wheels of one axle going slower than those of the other axle, i.e. a

potential wheel slip situation, it signals the ABS modulator to close the inlet solenoid valve for the brakes of the slower

wheels. This prevents any further increase in hydraulic pressure to those brakes, while allowing the hydraulic pressure

to the brakes on the other axle to increase and so maximise the overall braking effort. If the wheel speeds of the axle

being subjected to EBD control return within the calibrated wheel slip limits, the SLABS ECU signals a stepped

opening of the inlet solenoid valves, which allows a progressive increase of hydraulic pressure to the related brakes.

Operation of EBD is detectable from a stiffening of brake pedal movement as the inlet solenoid valves close and a

slight pulsing of the brake pedal as the inlet solenoid valves open. EBD operation ceases immediately the brake pedal

is released.

The wheel slip limit for EBD operation varies with vehicle speed. During normal operation, the inlet solenoid valves

always operate in axle pairs, with only one axle pair closed at any one time. Since the most lightly loaded wheel during

a braking manoeuvre will usually be the first to reach the slip limit, under most vehicle load configurations and road

conditions EBD control occurs on the trailing axle. However, EBD control can occur on the leading axle or switch

between axles during the braking manoeuvre.

Page 890 of 1529

BRAKES

REPAIRS 70-37

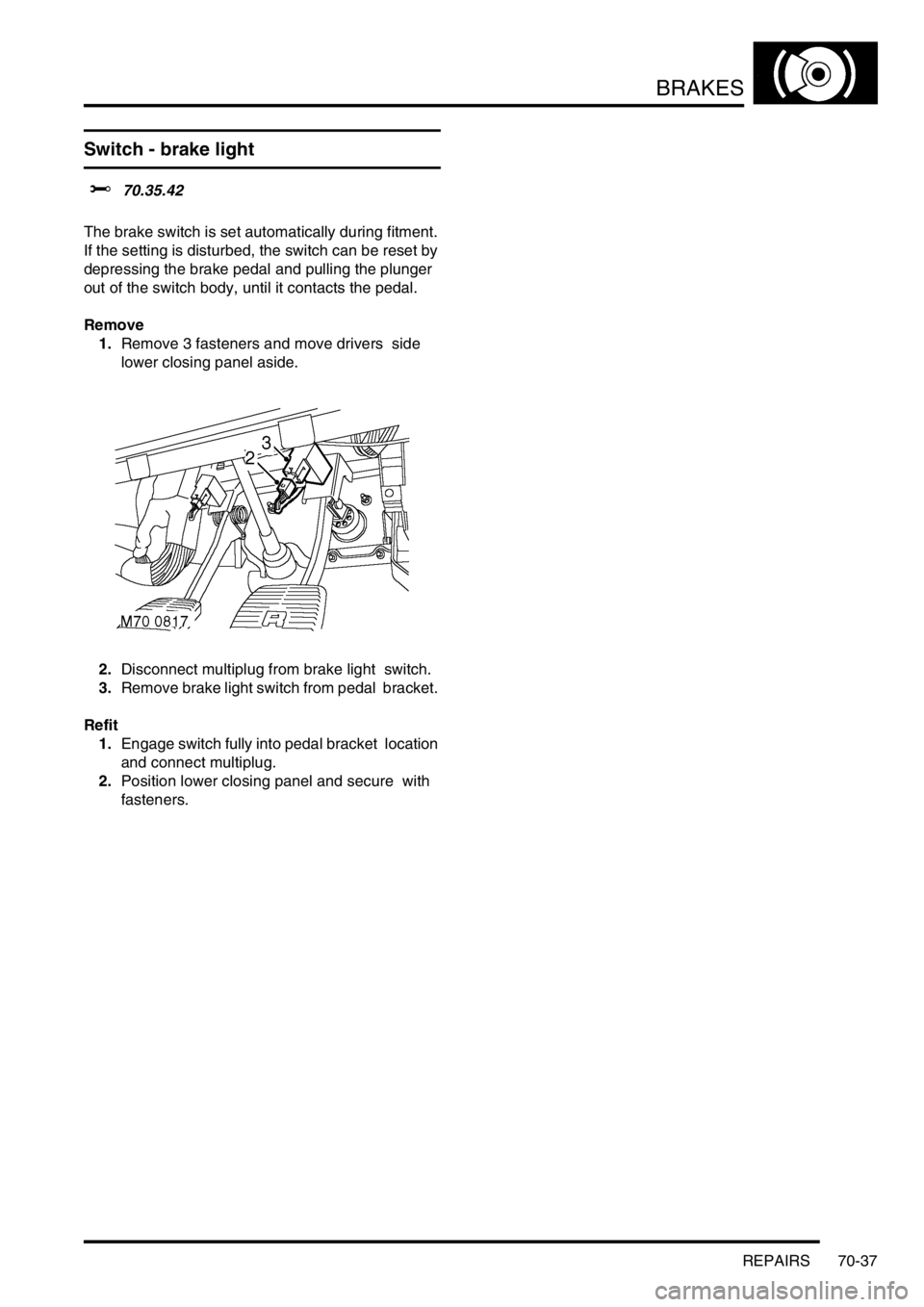

Switch - brake light

$% 70.35.42

The brake switch is set automatically during fitment.

If the setting is disturbed, the switch can be reset by

depressing the brake pedal and pulling the plunger

out of the switch body, until it contacts the pedal.

Remove

1.Remove 3 fasteners and move drivers side

lower closing panel aside.

2.Disconnect multiplug from brake light switch.

3.Remove brake light switch from pedal bracket.

Refit

1.Engage switch fully into pedal bracket location

and connect multiplug.

2.Position lower closing panel and secure with

fasteners.

Page 939 of 1529

DOORS

76-1-6 REPAIRS

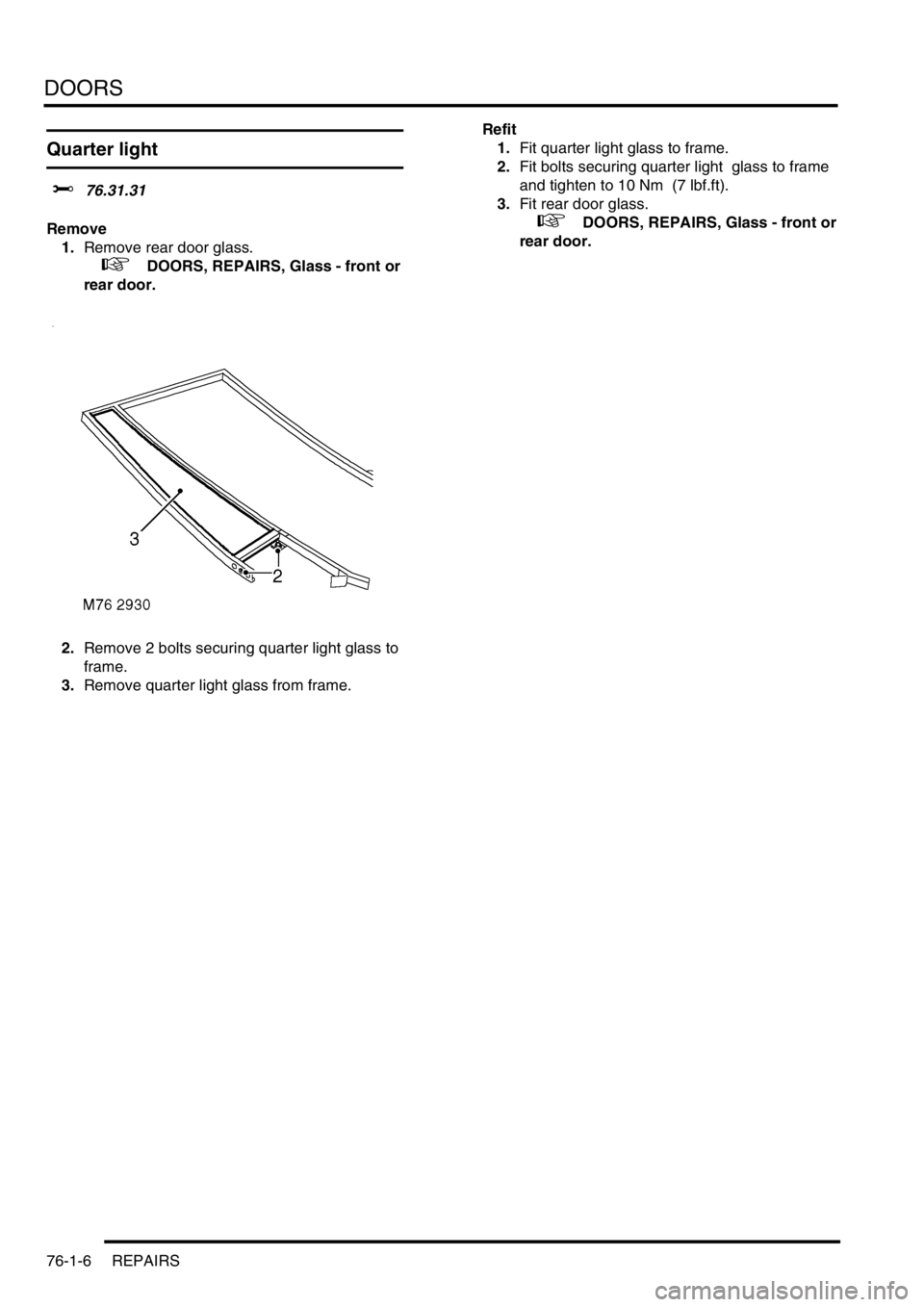

Quarter light

$% 76.31.31

Remove

1.Remove rear door glass.

+ DOORS, REPAIRS, Glass - front or

rear door.

2.Remove 2 bolts securing quarter light glass to

frame.

3.Remove quarter light glass from frame. Refit

1.Fit quarter light glass to frame.

2.Fit bolts securing quarter light glass to frame

and tighten to 10 Nm (7 lbf.ft).

3.Fit rear door glass.

+ DOORS, REPAIRS, Glass - front or

rear door.

Page 948 of 1529

EXTERIOR FITTINGS

REPAIRS 76-2-1

EXTERIOR FITTINGS REPAIRS

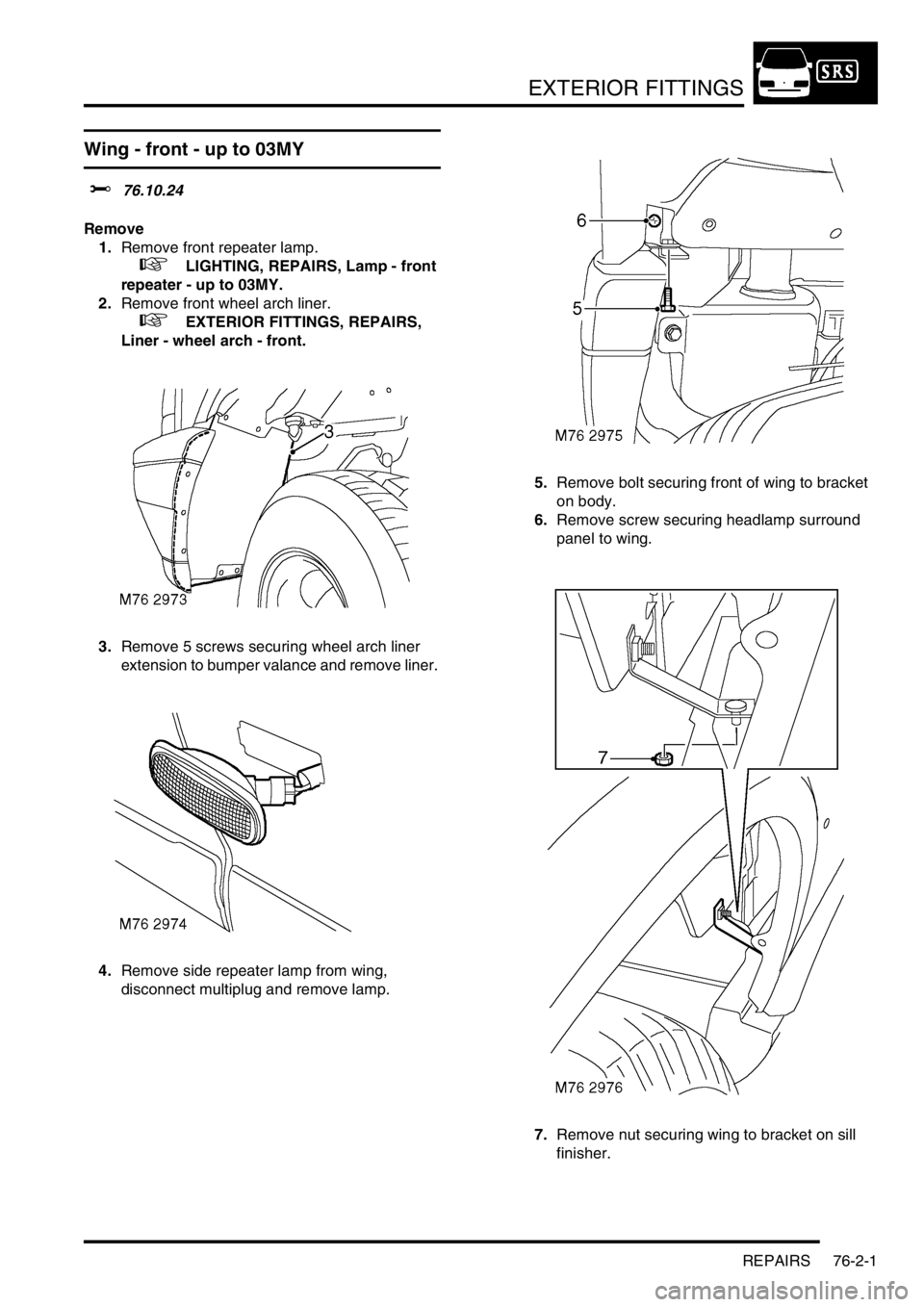

Wing - front - up to 03MY

$% 76.10.24

Remove

1.Remove front repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater - up to 03MY.

2.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - front.

3.Remove 5 screws securing wheel arch liner

extension to bumper valance and remove liner.

4.Remove side repeater lamp from wing,

disconnect multiplug and remove lamp.5.Remove bolt securing front of wing to bracket

on body.

6.Remove screw securing headlamp surround

panel to wing.

7.Remove nut securing wing to bracket on sill

finisher.

Page 949 of 1529

EXTERIOR FITTINGS

76-2-2 REPAIRS

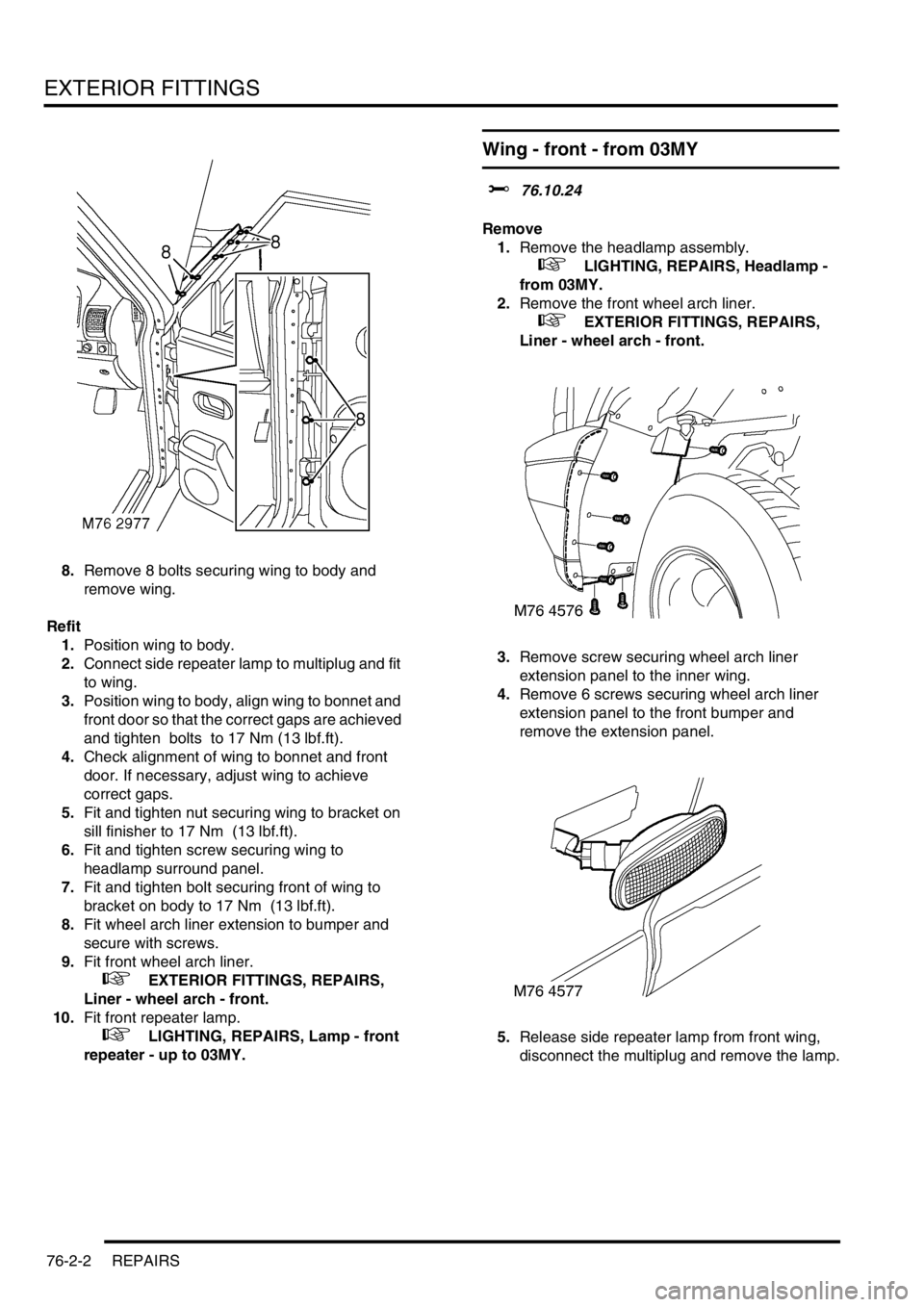

8.Remove 8 bolts securing wing to body and

remove wing.

Refit

1.Position wing to body.

2.Connect side repeater lamp to multiplug and fit

to wing.

3.Position wing to body, align wing to bonnet and

front door so that the correct gaps are achieved

and tighten bolts to 17 Nm (13 lbf.ft).

4.Check alignment of wing to bonnet and front

door. If necessary, adjust wing to achieve

correct gaps.

5.Fit and tighten nut securing wing to bracket on

sill finisher to 17 Nm (13 lbf.ft).

6.Fit and tighten screw securing wing to

headlamp surround panel.

7.Fit and tighten bolt securing front of wing to

bracket on body to 17 Nm (13 lbf.ft).

8.Fit wheel arch liner extension to bumper and

secure with screws.

9.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - front.

10.Fit front repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater - up to 03MY.

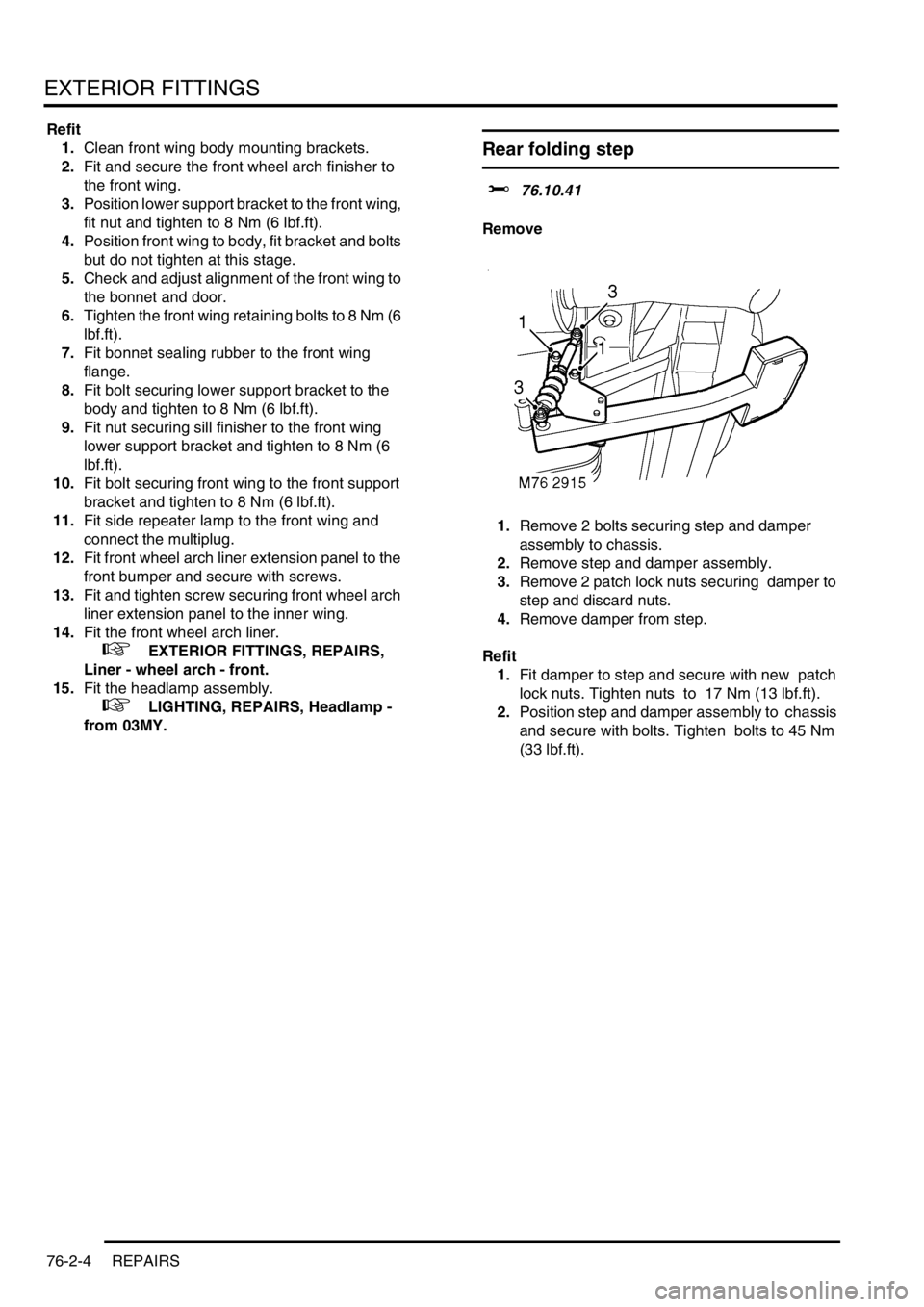

Wing - front - from 03MY

$% 76.10.24

Remove

1.Remove the headlamp assembly.

+ LIGHTING, REPAIRS, Headlamp -

from 03MY.

2.Remove the front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - front.

3.Remove screw securing wheel arch liner

extension panel to the inner wing.

4.Remove 6 screws securing wheel arch liner

extension panel to the front bumper and

remove the extension panel.

5.Release side repeater lamp from front wing,

disconnect the multiplug and remove the lamp.

Page 951 of 1529

EXTERIOR FITTINGS

76-2-4 REPAIRS

Refit

1.Clean front wing body mounting brackets.

2.Fit and secure the front wheel arch finisher to

the front wing.

3.Position lower support bracket to the front wing,

fit nut and tighten to 8 Nm (6 lbf.ft).

4.Position front wing to body, fit bracket and bolts

but do not tighten at this stage.

5.Check and adjust alignment of the front wing to

the bonnet and door.

6.Tighten the front wing retaining bolts to 8 Nm (6

lbf.ft).

7.Fit bonnet sealing rubber to the front wing

flange.

8.Fit bolt securing lower support bracket to the

body and tighten to 8 Nm (6 lbf.ft).

9.Fit nut securing sill finisher to the front wing

lower support bracket and tighten to 8 Nm (6

lbf.ft).

10.Fit bolt securing front wing to the front support

bracket and tighten to 8 Nm (6 lbf.ft).

11.Fit side repeater lamp to the front wing and

connect the multiplug.

12.Fit front wheel arch liner extension panel to the

front bumper and secure with screws.

13.Fit and tighten screw securing front wheel arch

liner extension panel to the inner wing.

14.Fit the front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - wheel arch - front.

15.Fit the headlamp assembly.

+ LIGHTING, REPAIRS, Headlamp -

from 03MY.

Rear folding step

$% 76.10.41

Remove

1.Remove 2 bolts securing step and damper

assembly to chassis.

2.Remove step and damper assembly.

3.Remove 2 patch lock nuts securing damper to

step and discard nuts.

4.Remove damper from step.

Refit

1.Fit damper to step and secure with new patch

lock nuts. Tighten nuts to 17 Nm (13 lbf.ft).

2.Position step and damper assembly to chassis

and secure with bolts. Tighten bolts to 45 Nm

(33 lbf.ft).

Page 956 of 1529

EXTERIOR FITTINGS

REPAIRS 76-2-9

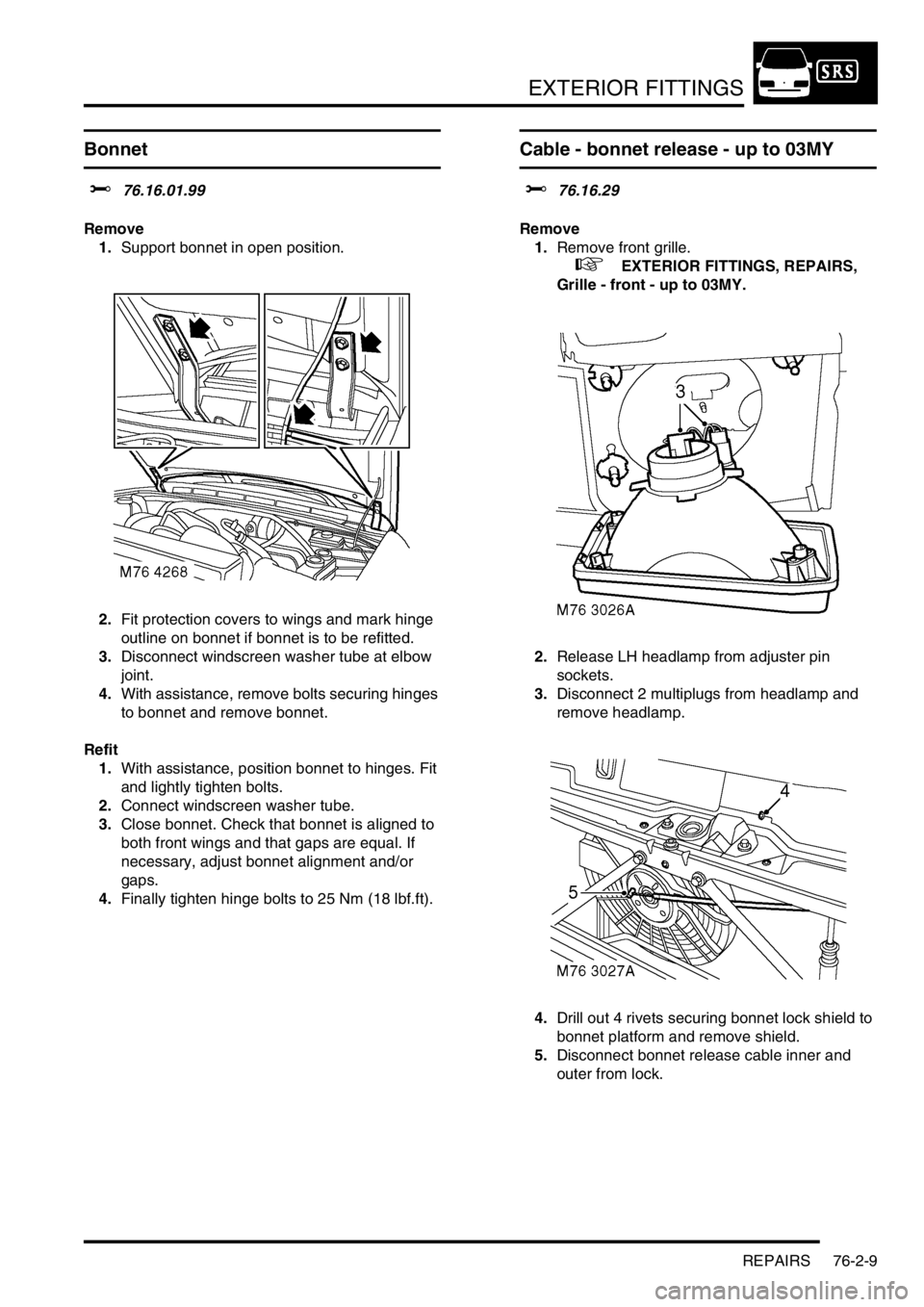

Bonnet

$% 76.16.01.99

Remove

1.Support bonnet in open position.

2.Fit protection covers to wings and mark hinge

outline on bonnet if bonnet is to be refitted.

3.Disconnect windscreen washer tube at elbow

joint.

4.With assistance, remove bolts securing hinges

to bonnet and remove bonnet.

Refit

1.With assistance, position bonnet to hinges. Fit

and lightly tighten bolts.

2.Connect windscreen washer tube.

3.Close bonnet. Check that bonnet is aligned to

both front wings and that gaps are equal. If

necessary, adjust bonnet alignment and/or

gaps.

4.Finally tighten hinge bolts to 25 Nm (18 lbf.ft).

Cable - bonnet release - up to 03MY

$% 76.16.29

Remove

1.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

2.Release LH headlamp from adjuster pin

sockets.

3.Disconnect 2 multiplugs from headlamp and

remove headlamp.

4.Drill out 4 rivets securing bonnet lock shield to

bonnet platform and remove shield.

5.Disconnect bonnet release cable inner and

outer from lock.

Page 960 of 1529

EXTERIOR FITTINGS

REPAIRS 76-2-13

Bumper assembly - rear - from 03MY

$% 76.22.15

Remove

1.Remove both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp - tail/

flasher - bumper.

2.Disconnect park distance control harness

multiplug.

3.Release rear lamp harness clips.4.Remove 2 bolts securing bumper.

5.With assistance remove bumper.

NOTE: Do not carry out further dismantling if

component is removed for access only.

6.Remove 7 bolts and 5 screws securing closing

panel and remove panel.

M76 4566

Page 961 of 1529

EXTERIOR FITTINGS

76-2-14 REPAIRS

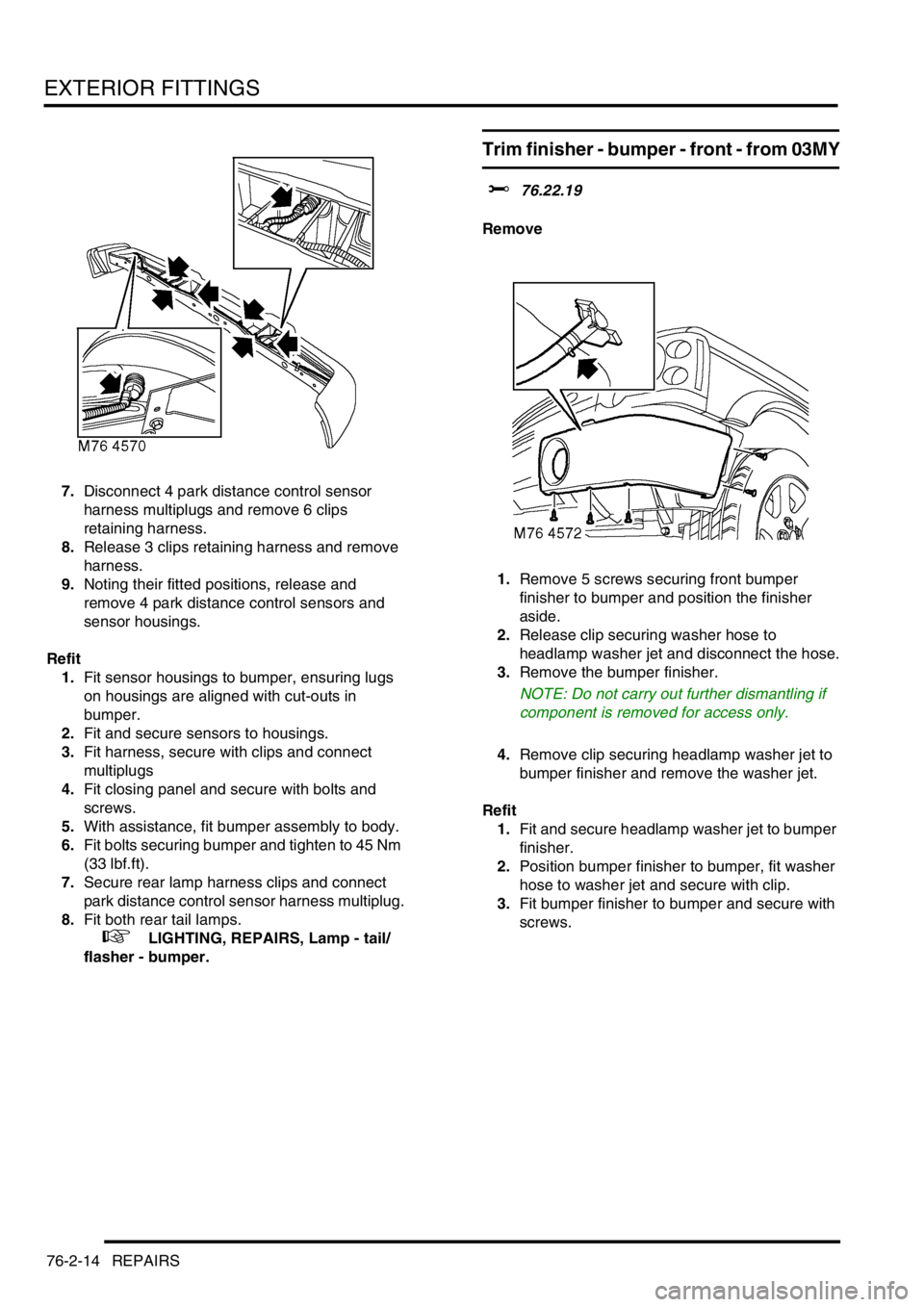

7.Disconnect 4 park distance control sensor

harness multiplugs and remove 6 clips

retaining harness.

8.Release 3 clips retaining harness and remove

harness.

9.Noting their fitted positions, release and

remove 4 park distance control sensors and

sensor housings.

Refit

1.Fit sensor housings to bumper, ensuring lugs

on housings are aligned with cut-outs in

bumper.

2.Fit and secure sensors to housings.

3.Fit harness, secure with clips and connect

multiplugs

4.Fit closing panel and secure with bolts and

screws.

5.With assistance, fit bumper assembly to body.

6.Fit bolts securing bumper and tighten to 45 Nm

(33 lbf.ft).

7.Secure rear lamp harness clips and connect

park distance control sensor harness multiplug.

8.Fit both rear tail lamps.

+ LIGHTING, REPAIRS, Lamp - tail/

flasher - bumper.

Trim finisher - bumper - front - from 03MY

$% 76.22.19

Remove

1.Remove 5 screws securing front bumper

finisher to bumper and position the finisher

aside.

2.Release clip securing washer hose to

headlamp washer jet and disconnect the hose.

3.Remove the bumper finisher.

NOTE: Do not carry out further dismantling if

component is removed for access only.

4.Remove clip securing headlamp washer jet to

bumper finisher and remove the washer jet.

Refit

1.Fit and secure headlamp washer jet to bumper

finisher.

2.Position bumper finisher to bumper, fit washer

hose to washer jet and secure with clip.

3.Fit bumper finisher to bumper and secure with

screws.