OBD port LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 242 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-9

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems are

fitted to Land Rover vehicles which are designed to maintain the emission levels within the legal limits pertaining for

the specified market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order so that it operates at its optimal condition. In particular, ignition

timing has an effect on the production of HC and NO

x emissions, with the harmful emissions rising as the ignition

timing is advanced.

CAUTION: In many countries it is against the law for a vehicle owner or an unauthorised dealer to modify or

tamper with emission control equipment. In some cases, the vehicle owner and/or the dealer may even be

liable for prosecution.

The engine management ECM is fundamental for controlling the emission control systems. In addition to controlling

normal operation, the system complies with On Board Diagnostic (OBD) system strategies. The system monitors and

reports on faults detected with ignition, fuelling and exhaust systems which cause an excessive increase in tailpipe

emissions. This includes component failures, engine misfire, catalyst damage, catalyst efficiency, fuel evaporative

loss and exhaust leaks.

When an emission relevant fault is determined, the fault condition is stored in the ECM memory. For NAS vehicles,

the MIL warning light on the instrument pack will be illuminated when the fault is confirmed. Confirmation of a fault

condition occurs if the fault is still found to be present during the driving cycle subsequent to the one when the fault

was first detected.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The following types of supplementary control system are used to reduce harmful emissions released into the

atmosphere from the vehicle:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust emission control – to limit the undesirable by-products of combustion.

3Fuel vapour evaporative loss control – to restrict the emission of fuel through evaporation from the fuel

system.

4Fuel leak detection system (NAS only) – there are two types of system which may be used to check the

evaporative emission system for the presence of leaks from the fuel tank to purge valve.

aVacuum leak detection test – checks for leaks down to 1 mm (0.04 in.) in diameter.

bPositive pressure leak detection test – utilises a leak detection pump to check for leaks down to 0.5 mm (0.02

in.) in diameter.

5Secondary air injection system (Where fitted) – to reduce emissions experienced during cold starting.

Page 305 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-6 DESCRIPTION AND OPERATION

Description - engine management

General

The V8 engine is equipped with the Bosch Motronic M5.2.1 engine management system. This system is a sequential

multiport fuel injection system controlled by an Engine Control Module (ECM).

A single ECM is used for the control of the existing 4.0 litre engine and the new 4.6 litre engine introduced with 03

model year vehicles for the NAS market only. The ECM contains the tunes for both engines variants. When the ECM

is replaced, TestBook/T4 must be used to select the correct tune to match the engine fitment.

The ECM has On Board Diagnostic (OBD) strategies as required by various market legislative bodies. To meet these

requirements the system monitors and reports on any faults that cause excessive exhaust emissions.

In markets that mandate OBD, the ECM monitors performance of the engine for misfires, catalyst efficiency, exhaust

leaks and evaporative control loss. If a fault occurs, the ECM stores the relevant fault code and warns the driver of

component failure by illuminating the Malfunction Indicator Light in the instrument pack.

In markets where OBD is not mandatory, the ECM will still monitor performance of the engine and store the fault code,

but will not illuminate the Malfunction Indicator Light.

The ECM uses input and output information from its sensors and actuators to control the following engine conditions:

lFuel quantity.

lClosed loop fuelling.

lOpen loop fuelling.

lIgnition timing.

lKnock control.

lIdle speed control.

lEmission control.

lOn-Board Diagnostic (OBD) where applicable.

lVehicle immobilisation.

lMisfire detection (where applicable).

lVehicle speed signal.

lRough road signal (where applicable).

lLow fuel level signal (where applicable).

lCoolant temperature gauge signal.

The ECM processes sensor information from the following input sources:

lIgnition switch (position II).

lCrankshaft speed and position sensor.

lCamshaft position sensor.

lEngine coolant temperature sensor.

lMass air flow sensor.

lIntake air temperature sensor.

lKnock sensor.

lThrottle position sensor.

lHeated oxygen sensors.

lHigh/ Low ratio switch.

lFuel tank pressure sensor (where fitted)

lThermostat monitoring sensor (where fitted)

Page 329 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-30 DESCRIPTION AND OPERATION

Heated Oxygen Sensors (HO2S) (C0642)

The market requirement dictates how many HO

2S are fitted to the vehicle.

l4 sensors are fitted to all NAS and EU-3 vehicles.

l2 sensors fitted to all UK, European, Australia and Japanese pre EU-3 specification vehicles.

lNo sensors fitted to ROW vehicles.

The HO

2S monitor the oxygen content of the exhaust gases. By positioning the sensors one for each bank upstream

of the catalytic converter in the exhaust pipe, the ECM can control fuelling on each bank independently of the other.

This allows greater control of the air:fuel ratio and maintains optimum catalyst efficiency. On NAS vehicles the ECM

also uses two HO

2S positioned downstream of the catalytic converters in the exhaust pipe to monitor catalytic

converter efficiency. The ECM is able to achieve this by comparing the values of the upstream HO

2S and the down

stream sensor for the same bank. These comparative values form part of the ECM OBD strategy.

The HO

2S uses zirconium contained in a galvanic cell surrounded by a gas permeable ceramic, this produces an

output voltage proportional to the ratio difference between the oxygen in the exhaust gases and to the ambient

oxygen.

The HO

2S operates at approximately 350 °C (662 °F). To achieve this temperature the HO2S incorporate a heating

element which is controlled by a PWM signal from the ECM. The elements are activated immediately after engine

starts and also under low engine load conditions when the exhaust gas temperature is insufficient to maintain the

required HO

2S temperature. If the heater fails, the ECM will not allow closed loop fuelling to be implemented until the

sensor has achieved the required temperature.

This value equates to an HO

2S output of 450 to 500 mV. A richer mixture can be shown as λ = 0.97, this pushes the

HO

2S output voltage towards 1000 mV. A leaner mixture can be shown as λ = 1.10, this pushes the HO2S output

voltage towards 100 mV.

From cold start, the ECM runs an open loop fuelling strategy. The ECM keeps this strategy in place until the HO

2S is

at a working temperature of 350 °C (662 °F). At this point the ECM starts to receive HO

2S information and it can then

switch into closed loop fuelling as part of its adaptive strategy. The maximum working temperature of the tip of the

HO

2S is 930 °C (1706 °F), temperatures above this will damage the sensor.

HO

2S age with use, this increases their response time to switch from rich to lean and from lean to rich. This can lead

to increased exhaust emissions over a period of time. The switching time of the upstream sensors are monitored by

the ECM. If a pre-determined threshold is exceeded, a failure is detected and the MIL illuminated.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Exhaust Emission Control System.

Input/Output

The upstream and downstream HO

2S are colour coded to prevent incorrect fitting. The tips of the upstream sensors

are physically different to the tips of the downstream sensors.

The HO

2S are colour coded as follows:

lUpstream sensors (both banks) - orange.

lDownstream sensors (both banks) - grey.

The four HO

2S have a direct battery supply to the heater via fuse 2 located in the engine compartment fuse box.

Page 357 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-58 DESCRIPTION AND OPERATION

Conditions

The CAN system is used by the EAT ECU and the ECM for transmission of the following information:

lGearshift torque control information.

lEAT OBD information.

lMIL request.

lVehicle speed signal.

lEngine temperature.

lEngine torque and speed.

lGear selected.

lGear change information.

lAltitude adaptation factor

lAir intake temperature

lThrottle angle / pedal position

Function

The CAN system uses a twisted pair of wires to form the 'data bus' to minimise electrical interference. This method of

serial interface is very reliable and very fast. The information messages are structured so that each of the receivers

(ECM or EAT ECU) is able to interpret and react to the messages sent.

The CAN 'data bus' is directly connected between pin 36 of connector C0637 of the ECM and pin 16 of connector

C0193 at the EAT ECU, and pin 37 of connector C0637 of the ECM and pin 44 of connector C0193 at the EAT ECU.

The CAN system can fail in the following ways:

lCAN data bus wiring open circuit.

lCAN data bus wiring short circuit.

In the event of a CAN data bus failure any of the following symptoms may be observed:

lMIL illuminated after 2 drive cycles (NAS only).

lEAT defaults to 3rd gear only.

lHarsh gearshifts.

l'Sport' and 'manual' lights flash alternately.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

Drive cycles

The following are the TestBook drive cycles:

⇒ Drive cycle A:

1Switch on the ignition for 30 seconds.

2Ensure engine coolant temperature is less than 60°C (140°F).

3Start the engine and allow to idle for 2 minutes.

4Connect TestBook and check for fault codes.

⇒ Drive cycle B:

1Switch ignition on for 30 seconds.

2Ensure engine coolant temperature is less than 60°C (140°F).

3Start the engine and allow to idle for 2 minutes.

4Perform 2 light accelerations (0 to 35 mph (0 to 60 km/h) with light pedal pressure).

5Perform 2 medium accelerations (0 to 45 mph (0 to 70 km/h) with moderate pedal pressure).

6Perform 2 hard accelerations (0 to 55 mph (0 to 90 km/h) with heavy pedal pressure).

7Allow engine to idle for 2 minutes.

8Connect TestBook and with the engine still running, check for fault codes.

P Code J2012 Description Land Rover Description

P0600 Serial communication link malfunction CAN time out

P1776 Transmission control system torque interface

malfunctionEAT torque interface error

Page 402 of 1529

FUEL DELIVERY SYSTEM - V8

DESCRIPTION AND OPERATION 19-2-5

Fuel tank breather system (all markets except NAS)

The filler tube incorporates a tank vent which allows air and fuel vapour displaced from the tank when filling to vent to

atmosphere via the filler neck. A relief valve in the vent line to the EVAP canister prevents vapour escaping through

the canister during filling. This prevents the customer overfilling the tank and maintains the correct fuel cut-off level.

The filler tube also incorporates an integral Liquid Vapour Separator (LVS). During normal driving excess fuel vapour

is passed via the vent line into the EVAP canister. To prevent the canister from being overloaded with fuel vapour,

especially in hot climates, the vapour is given the opportunity to condense in the LVS. Fuel which condenses in the

LVS flows back into the tank through the ROV's.

A breather spout within the tank controls the tank 'full' height. When fuel covers the spout it prevents fuel vapour and

air from escaping from the tank. This causes the fuel to 'back-up' in the filler tube and shuts off the filler gun. The

position of the spout ensures that when the filler gun shuts off, a vapour space of approximately 10% of the tanks total

capacity remains. This vapour space ensures that Roll Over Valves (ROV's) are always above the fuel level and the

vapour can escape and allow the tank to breathe.

The pressure relief valve fitted in the vent line to the EVAP canister prevents the customer trickle filling the tank.

Trickle filling greatly reduces the vapour space in the tank which in turn affects the tank's ability to breathe properly,

reducing engine performance and safety. When filling the tank, the pressures created are too low to open the pressure

relief valve, preventing the customer from trickle filling the tank. Vapour pressures created during driving are higher

and will open the valve allowing vapour to vent to the EVAP canister.

Four ROV's are welded onto the top surface of the tank. Each ROV is connected by a tube to the main vent line to

the EVAP canister. The ROV's allow fuel vapour to pass through them during normal vehicle operation. In the event

of the vehicle being overturned the valves shut-off, sealing the tank and preventing fuel from spilling from the vent line.

Fuel tank breather system (NAS)

The filler tube incorporates a tank vent which allows air and fuel vapour displaced from the tank when filling to vent to

atmosphere via the filler neck. A filler cap operated valve within the fuel filler neck prevents vapour escaping through

the EVAP canister during filling. This prevents the customer overfilling the tank and maintains the correct fuel cut-off

level.

The filler tube also has an 'L' shaped, stainless steel Liquid Vapour Separator (LVS). During normal driving excess

fuel vapour is passed via the vent line into the EVAP canister. To prevent the canister from being overloaded with fuel

vapour, especially in hot climates, the vapour is given the opportunity to condense in the LVS. Fuel which condenses

in the LVS flows back into the tank via the LVS vent line and through the Roll Over Valves (ROV's).

For NAS vehicles with vacuum type EVAP system leak detection capability, a small tube is located alongside the filler

tube and terminates near to the filler neck. The tube is connected to the On Board Diagnostics (OBD) pressure sensor

in the fuel pump and provides the sensor with a reading of atmospheric pressure to compare against the tank

pressure.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Emission Control Systems.

A breather spout within the tank controls the tank 'full' height. When fuel covers the spout it prevents fuel vapour and

air from escaping from the tank. This causes the fuel to 'back-up' in the filler tube and shuts off the filler gun. The

position of the spout ensures that when the filler gun shuts off, a vapour space of approximately 10% of the tanks total

capacity remains. This vapour space ensures that the ROV's are always above the fuel level and the vapour can

escape to the LVS and allow the tank to breathe.

The filler cap operated valve closes the vent line to the EVAP canister to prevent the customer trickle filling the tank.

Trickle filling greatly reduces the vapour space in the tank which in turn affects the tank's ability to breathe properly,

reducing engine performance and safety. When filling the tank, the removal of the filler cap closes the valve and the

vent line preventing the customer from trickle filling the tank. When the cap is installed the valve is opened by the cap

allowing vapour to vent to the EVAP canister.

The four ROV's are welded inside the top surface of the tank. Each ROV is connected internally in the tank by a tube

to the LVS. The ROV's allow fuel vapour to pass through them during normal vehicle operation. In the event of the

vehicle being overturned the valves shut-off, sealing the tank and preventing fuel from spilling from the vent line into

the LVS.

Page 616 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-19

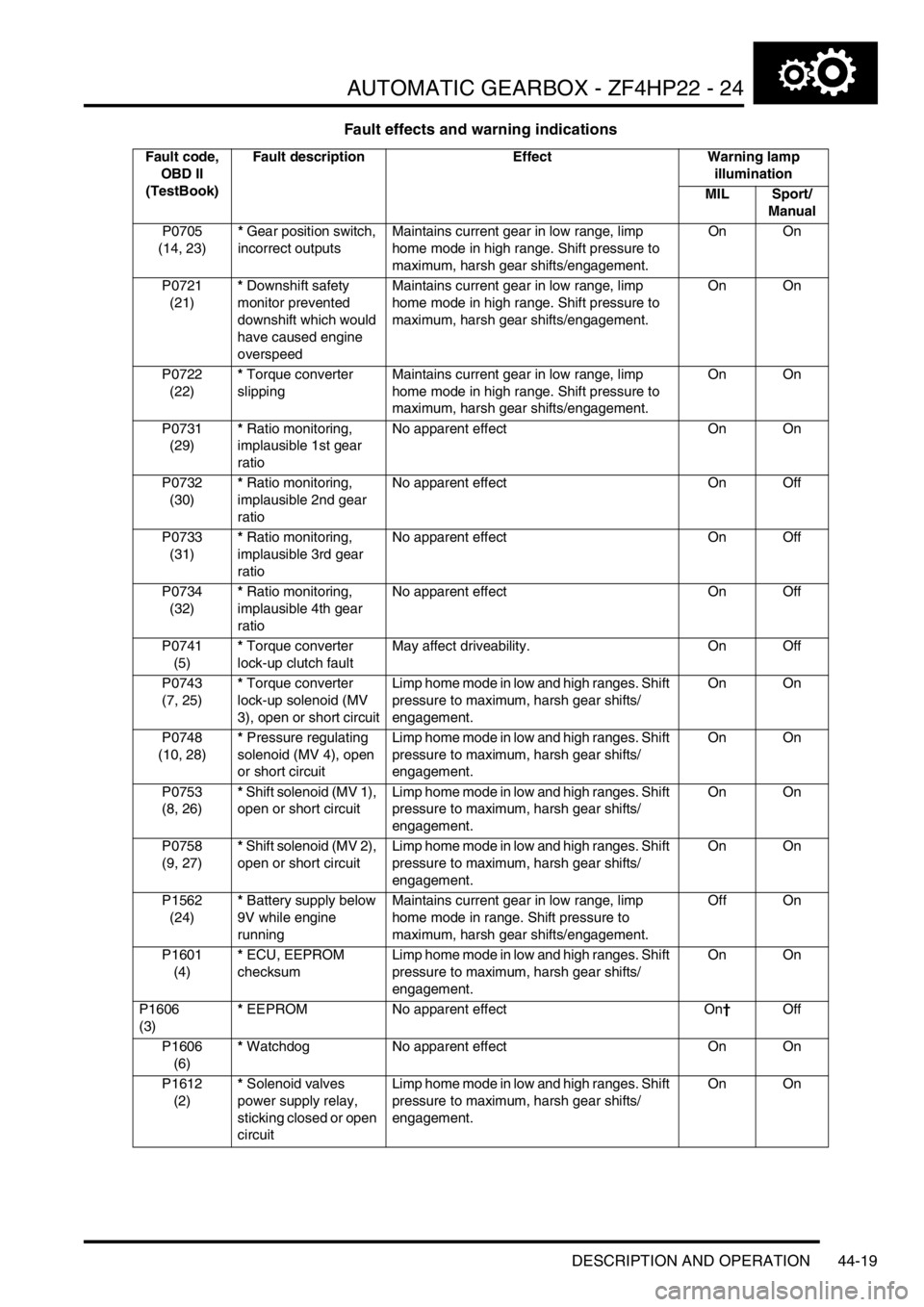

Fault effects and warning indications

Fault code,

OBD II

(TestBook)Fault description Effect Warning lamp

illumination

MIL Sport/

Manual

P0705

(14, 23)* Gear position switch,

incorrect outputsMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P0721

(21)* Downshift safety

monitor prevented

downshift which would

have caused engine

overspeedMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P0722

(22)* Torque converter

slippingMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P0731

(29)* Ratio monitoring,

implausible 1st gear

ratioNo apparent effect On On

P0732

(30)* Ratio monitoring,

implausible 2nd gear

ratioNo apparent effect On Off

P0733

(31)* Ratio monitoring,

implausible 3rd gear

ratioNo apparent effect On Off

P0734

(32)* Ratio monitoring,

implausible 4th gear

ratioNo apparent effect On Off

P0741

(5)* Torque converter

lock-up clutch faultMay affect driveability. On Off

P0743

(7, 25)* Torque converter

lock-up solenoid (MV

3), open or short circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P0748

(10, 28)* Pressure regulating

solenoid (MV 4), open

or short circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P0753

(8, 26)* Shift solenoid (MV 1),

open or short circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P0758

(9, 27)* Shift solenoid (MV 2),

open or short circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1562

(24)* Battery supply below

9V while engine

runningMaintains current gear in low range, limp

home mode in range. Shift pressure to

maximum, harsh gear shifts/engagement.Off On

P1601

(4)* ECU, EEPROM

checksumLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1606

(3)* EEPROM No apparent effect On†Off

P1606

(6)* Watchdog No apparent effect On On

P1612

(2)* Solenoid valves

power supply relay,

sticking closed or open

circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

Page 617 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-20 DESCRIPTION AND OPERATION

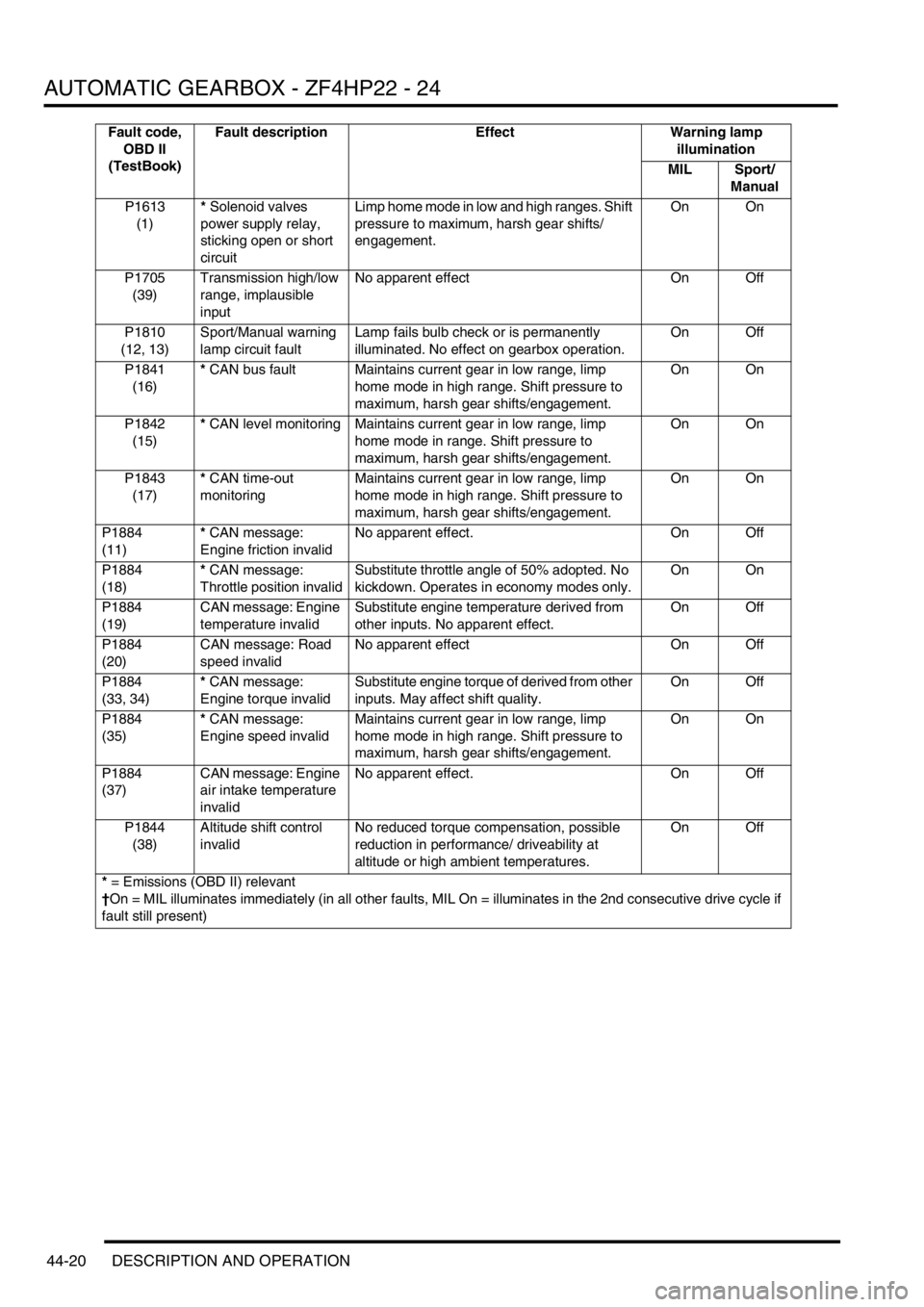

P1613

(1)* Solenoid valves

power supply relay,

sticking open or short

circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1705

(39)Transmission high/low

range, implausible

inputNo apparent effect On Off

P1810

(12, 13)Sport/Manual warning

lamp circuit faultLamp fails bulb check or is permanently

illuminated. No effect on gearbox operation.On Off

P1841

(16)* CAN bus fault Maintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1842

(15)* CAN level monitoring Maintains current gear in low range, limp

home mode in range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1843

(17)* CAN time-out

monitoringMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(11)* CAN message:

Engine friction invalidNo apparent effect. On Off

P1884

(18)* CAN message:

Throttle position invalidSubstitute throttle angle of 50% adopted. No

kickdown. Operates in economy modes only.On On

P1884

(19)CAN message: Engine

temperature invalidSubstitute engine temperature derived from

other inputs. No apparent effect.On Off

P1884

(20)CAN message: Road

speed invalidNo apparent effect On Off

P1884

(33, 34)* CAN message:

Engine torque invalidSubstitute engine torque of derived from other

inputs. May affect shift quality.On Off

P1884

(35)* CAN message:

Engine speed invalidMaintains current gear in low range, limp

home mode in high range. Shift pressure to

maximum, harsh gear shifts/engagement.On On

P1884

(37)CAN message: Engine

air intake temperature

invalidNo apparent effect. On Off

P1844

(38)Altitude shift control

invalidNo reduced torque compensation, possible

reduction in performance/ driveability at

altitude or high ambient temperatures.On Off

* = Emissions (OBD II) relevant

†On = MIL illuminates immediately (in all other faults, MIL On = illuminates in the 2nd consecutive drive cycle if

fault still present)Fault code,

OBD II

(TestBook)Fault description Effect Warning lamp

illumination

MIL Sport/

Manual