brake sensor LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 6 of 1529

CONTENTS

CONTENTS 3

MAINTENANCE ........................................................................................ 10-1

PROCEDURES

V8 engine underbonnet view .......................................................................................................... 10-1

Diesel underbonnet view ................................................................................................................. 10-2

Seats and seat belts ...................................................................................................................... 10-3

Lamps, horns and warning indicators ............................................................................................. 10-5

Wipers and washers ...................................................................................................................... 10-5

Handbrake .................................................................................................................................. 10-6

Alarm handset battery ..................................................................................................................... 10-6

Road wheels ................................................................................................................................... 10-6

Tyres .............................................................................................................................................. 10-6

Brake pads, discs and calipers ....................................................................................................... 10-6

Road wheel speed sensors ............................................................................................................. 10-7

Brake fluid ....................................................................................................................................... 10-7

Fuel filter - diesel engine ................................................................................................................. 10-7

Fuel filter sedimenter ...................................................................................................................... 10-7

Road wheels ................................................................................................................................... 10-8

Radiator/Intercooler ........................................................................................................................ 10-8

Ambient air Temperature and pressure sensor .............................................................................. 10-8

Doors, bonnet and fuel filler flap ..................................................................................................... 10-8

Air suspension intake filter .............................................................................................................. 10-9

Anti-freeze....................................................................................................................................... 10-9

Cooling system ............................................................................................................................... 10-9

Spark plugs - V8 engine.................................................................................................................. 10-10

Air cleaner - V8 engine ................................................................................................................... 10-10

Air cleaner and dump valve - diesel engine .................................................................................... 10-10

Auxiliary drive belt ........................................................................................................................... 10-11

Auxiliary drive belt - V8 engine ....................................................................................................... 10-11

Auxiliary drive belt - diesel engine .................................................................................................. 10-11

Fluid reservoirs ............................................................................................................................... 10-12

Steering box .................................................................................................................................... 10-13

Battery ............................................................................................................................................. 10-13

Intercooler - diesel engine............................................................................................................... 10-14

Engine oil - V8 engine ..................................................................................................................... 10-14

Engine oil - diesel engine ................................................................................................................ 10-15

Centrifuge rotor – diesel engine ...................................................................................................... 10-15

Engine oil filter - diesel engine ........................................................................................................ 10-16

Engine oil filter – V8 engine ............................................................................................................ 10-16

Manual gearbox .............................................................................................................................. 10-17

Automatic gearbox ......................................................................................................................... 10-18

Transfer box .................................................................................................................................... 10-19

Front and rear axle .......................................................................................................................... 10-20

Propeller shafts ............................................................................................................................... 10-20

Anti-roll bar links ............................................................................................................................. 10-22

ACE actuators ................................................................................................................................. 10-23

ACE filter ......................................................................................................................................... 10-23

Page 7 of 1529

CONTENTS

4CONTENTS

Brake hose, brake, fuel, ACE, clutch pipes and unions/electrical harnesses ................................ 10-24

Engine, gearbox, transfer box and axles ........................................................................................ 10-25

Exhaust system .............................................................................................................................. 10-25

Steering box and front suspension ................................................................................................. 10-25

Steering rod ball joints ................................................................................................................... 10-27

Dampers and SLS height sensors .................................................................................................. 10-27

Front and rear axle suspension links .............................................................................................. 10-28

Towing bracket ............................................................................................................................... 10-29

Engine mountings - V8 engine........................................................................................................ 10-30

Road/roller test ............................................................................................................................... 10-31

Page 20 of 1529

CONTENTS

CONTENTS 17

BRAKES ................................................................................................... 70-1

DESCRIPTION AND OPERATION

Brake system control component layout ......................................................................................... 70-1

Brake system control diagram ........................................................................................................ 70-2

Brake system hydraulic component layout ..................................................................................... 70-4

Description ...................................................................................................................................... 70-5

Operation ........................................................................................................................................ 70-20

DESCRIPTION AND OPERATION

Handbrake component layout ......................................................................................................... 70-25

Description ...................................................................................................................................... 70-26

ADJUSTMENTS

Handbrake .................................................................................................................................... 70-29

Brake system bleeding ................................................................................................................... 70-30

REPAIRS

Brake disc - front .......................................................................................................................... 70-33

Brake disc - rear ............................................................................................................................ 70-34

Master cylinder - brake ................................................................................................................. 70-35

Cable - handbrake ........................................................................................................................ 70-36

Switch - brake light ........................................................................................................................ 70-37

Brake pads - front ......................................................................................................................... 70-38

Brake pads - rear .......................................................................................................................... 70-39

Brake shoes - handbrake ................................................................................................................ 70-40

Servo - brake .................................................................................................................................. 70-42

Vacuum pump - servo ..................................................................................................................... 70-43

Housing - caliper - front ................................................................................................................. 70-45

Housing - caliper - rear ................................................................................................................. 70-46

ECU - Self levelling and anti locking brakes (SLABS) ................................................................. 70-47

Sensor – ABS – front ..................................................................................................................... 70-48

Sensor – ABS – rear ....................................................................................................................... 70-48

Modulator unit - ABS ...................................................................................................................... 70-49

Switch - Hill descent control ............................................................................................................ 70-50

Switch - handbrake ....................................................................................................................... 70-50

Page 34 of 1529

INTRODUCTION

01-3

Abbreviations and Symbols

A Amperes

AAP Ambient Air Pressure

ABDC After Bottom Dead Centre

ABS Anti-Lock Brake System

ac Alternating current

A/C Air Conditioning

ACE Active Cornering Enhancement

ACEA Association of Constructors of

European Automobiles

AFR Air Fuel Ratio

AP Ambient Pressure

ASC Anti-shunt Control

ATC Air Temperature Control

ATDC After Top Dead Centre

BBDC Before Bottom Dead Centre

BBUS Battery Backed Up Sounder

BCU Body Control Unit

BDC Bottom Dead Centre

bhp Brake Horse Power

BP Boost Pressure

BPP Brake Pedal Position

BS British Standard

BTDC Before Top Dead Centre

C Celsius

CAN Controller Area Network

CD Compact Disc

CDC Centre Differential Control

CDL Central Door Locking

CD - ROM Compact Disc - Read Only

Memory

CFC Chlorofluorocarbon

CHMSL Centre High Mounted Stop Lamp

CKP Crankshaft Position

CLV Calculated Load Value

cm Centimetre

cm

2Square centimetre

cm3Cubic centimetre

CMP Camshaft Position

CPP Clutch Pedal Position

CO Carbon Monoxide

CO

2Carbon Dioxide

CR Common Rail

CVS Canister Vent Solenoid

deg. Degree, angle or temperature

dia. Diameter

DIN Deutsche Industrie Normen

(German Industrial Standards)

dc Direct current

DCV Directional Control Valve

DOHC Double Overhead Camshaft

DTI Dial Test Indicator

DFM Dual Mass Flywheel

DVD Digital Versatile Disc

EACV Electronic Air Control Valve EAT Electronic Automatic

Transmission

EBD Electronic Brake pressure

Distribution

ECD European Community Directive

ECM Engine Control Module

ECT Engine Coolant Temperature

ECU Electronic Control Unit

EDC Electronic Diesel Control

EEPROM Electronic Erasable

Programmable Read Only

Memory

EGR Exhaust Gas Recirculation

EKA Emergency Key Access

EN European Norm

EOBD European On Board Diagnostics

ETC Electronic Traction Control

EUI Electronic Unit Injector

EVAP Evaporative Emission

EVR Electronic Vacuum Regulator

F Fahrenheit

FBH Fuel Burning Heater

FIP Fuel Injection Pump

FTC Fast Throttle Control

g Gramme or Gravity

hHour

hc High compression

HC Hydro Carbons

HDC Hill Descent Control

HDPE High Density Polyethylene

HFS Heated Front Screen

Hg Mercury

HO2S Heated Oxygen Sensor

HMW High Molecular Weight

HRW Heated Rear Window

ht/HT High tension

IACV Idle Air Control Valve

IAT Intake Air Temperature

ICE In-Car Entertainment

i.dia. Internal diameter

IDM Intelligent Driver Module

in3Cubic inch

ILT Inlet Throttle

ISO International Organisation for

Standardisation

k Thousand

kg Kilogramme

km Kilometre

km/h Kilometres per hour

kPa KiloPascal

KS Knock Sensor

lLitre

lbf.in Pounds force inches

lbf/in

2Pounds per square inch

lbf.ft Pounds force feet

Page 35 of 1529

INTRODUCTION

01-4

λLambda

lc Low compression

LCD Liquid Crystal Display

LED Light Emitting Diode

LH Left-Hand

LHD Left-Hand Drive

LVS Liquid Vapour Separator

mMetre

µMicro

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MFU Multi-Function Unit

MFL Multi-Function Logic

max. Maximum

MEMS Modular Engine Management

System

MIL Malfunction Indicator Lamp

min. Minimum

MPa MegaPascal

- Minus (tolerance)

' Minute (angle)

mm Millimetre

mph Miles per hour

MPi Multi-Point injection

MY Model Year

NAS North American Specification

(-) Negative (electrical)

Nm Newton metre

No. Number

NO

2Nitrogen Dioxide

NO

xOxides of Nitrogen

NTC Negative Temperature

Coefficient

OBD On Board Diagnostics

o.dia. Outside diameter

ORM Off-road Mode

ΩOhm

PAS Power Assisted Steering

PCV Positive Crankcase Ventilation

PDC Parking Distance Control

% Percentage

+ Plus (tolerance) or Positive

(electrical)

±Plus or minus (tolerance)

PTC Positive Temperature Coefficient

PTFE Polytetrafluorethylene

PWM Pulse Width Modulation

rRadius

:Ratio

ref Reference

RES Rover Engineering Standards

rev/min Revolutions per minute

RF Radio Frequency

RH Right-Hand

RHD Right-Hand Drive

ROM Read Only Memory

RON Research Octane Number

ROV Roll Over ValveROW Rest Of World

SAE Society of Automotive Engineers

" Second (angle)

SLABS Self Levelling and Anti-Lock

Brake System

SLS Self Levelling Suspension

SOHC Single Overhead Camshaft

sp.gr Specific gravity

SRS Supplementary Restraint System

std. Standard

synchro Synchronizer or synchromesh

TDC Top Dead Centre

TMAP Temperature, Manifold Absolute

Pressure

TP Throttle Position

TPS Throttle Position Sensor

TV Torsional Vibration

TXV Thermostatic Expansion Valve

UK United Kingdom

US United States

V Volt

Var. Variable

VIN Vehicle Identification Number

VIS Variable Intake System

VRS Variable Reluctance Sensor

VSS Vehicle Speed Signal

WWatt

Page 130 of 1529

MAINTENANCE

PROCEDURES 10-7

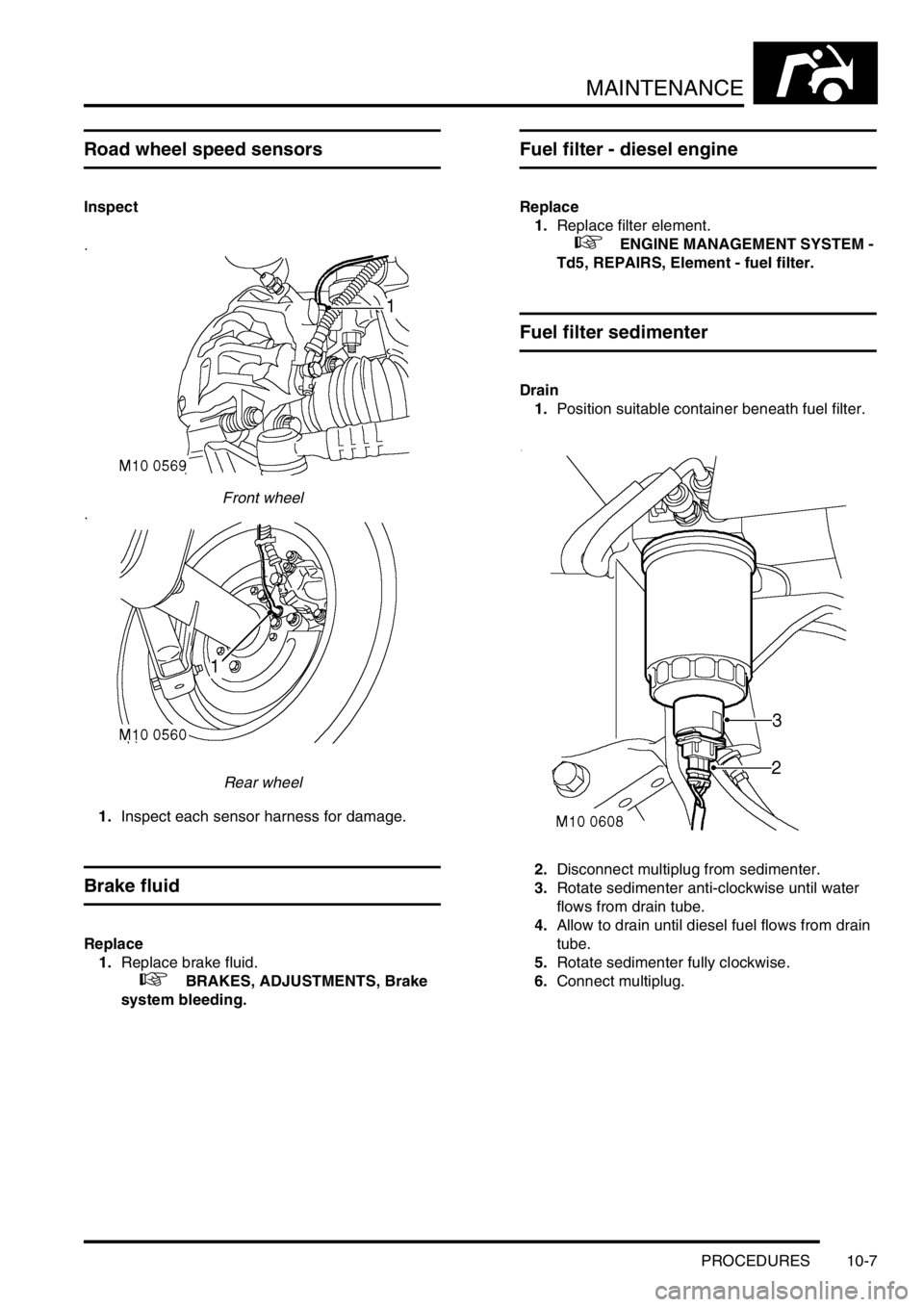

Road wheel speed sensors

Inspect

Front wheel

Rear wheel

1.Inspect each sensor harness for damage.

Brake fluid

Replace

1.Replace brake fluid.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Fuel filter - diesel engine

Replace

1.Replace filter element.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Element - fuel filter.

Fuel filter sedimenter

Drain

1.Position suitable container beneath fuel filter.

2.Disconnect multiplug from sedimenter.

3.Rotate sedimenter anti-clockwise until water

flows from drain tube.

4.Allow to drain until diesel fuel flows from drain

tube.

5.Rotate sedimenter fully clockwise.

6.Connect multiplug.

Page 440 of 1529

MANIFOLDS AND EXHAUST SYSTEMS - V8

DESCRIPTION AND OPERATION 30-2-5

Description

General

The inlet manifold on the V8 engine is located on the top of the engine, between the cylinders. The manifold directs

intake air into the cylinders. The intake air is mixed with fuel delivered by the injectors prior to ignition in the cylinders.

The inlet manifold comprises three separate aluminium castings.

Two exhaust manifolds are used, one for each bank of four cylinders. Each exhaust manifold allows combustion

gases from the cylinders to leave the engine and directs them into the exhaust system.

The exhaust system is connected to each exhaust manifold and merges into one pipe midway along the underside of

the vehicle. A catalytic converter (where fitted) is located in the front pipe from each manifold. A silencer is installed

midway along the system and a second tail silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold comprises three aluminium castings; a lower manifold, an upper manifold and a plenum. The inlet

manifold is located on the top of the engine and feeds air into the cylinders.

Lower manifold

The lower manifold is a one piece machined aluminium casting which locates in the vee on the top of the engine and

is secured to each cylinder head with six bolts per head. A one piece coated metal gasket seals the lower manifold to

each cylinder head and also serves as a cover for the cylinder block.

Eight injectors are fitted into the lower manifold, four on each side. Each injector is sealed in the manifold with O-ring

seals and retained in position by the fuel rails. A fuel rail is attached to each side of the manifold and secured with two

bolts.

Eight air intake ports are cast and machined on the top of the manifold, each port directing intake air into one cylinder.

These ports mate with matching ports in the upper manifold and are sealed with a coated metal gasket between the

two manifolds.

A cavity at the front of the manifold collects coolant flow from the engine. A coolant outlet pipe is sealed and attached

to the front of the manifold and provides for coolant to flow through the cavity in the casting to the radiator top hose.

A smaller port in the manifold also allows coolant to flow from the cavity to the heater matrix. The lower manifold also

locates the Engine Coolant Temperature (ECT) sensor in a port in the front of the manifold.

Upper manifold

The upper manifold is a one piece machined aluminium casting. The manifold has eight ports on its lower face which

mate with the eight ports on the lower manifold. The joint between the upper and lower manifolds is sealed with a

coated metal gasket and secured with six bolts.

The manifold divides from the eight ports into eight branches, four on each side. Each set of four branches merge into

one gallery on each side of the manifold. Each gallery has an opening at its forward end which mates with the intake

plenum.

The upper manifold provides attachment for the Idle Air Control (IAC) valve and for brackets which retain pipes, plug

leads and throttle cables.

Inlet plenum

The plenum is mounted transversely on the front of the upper manifold. The plenum divides into two galleries which

connect with the galleries on the upper manifold. The plenum is secured to the upper manifold with four bolts and

sealed with a coated metal gasket.

The plenum provides attachment for the throttle housing, which is secured with four bolts and sealed with a coated

metal gasket. The plenum also has vacuum connections for brake servo, rocker cover breather and fuel vapour from

the charcoal canister. A port on the top of the plenum connects via a hose to the IAC valve.

Page 452 of 1529

MANIFOLDS AND EXHAUST SYSTEMS - V8

REPAIRS 30-2-17

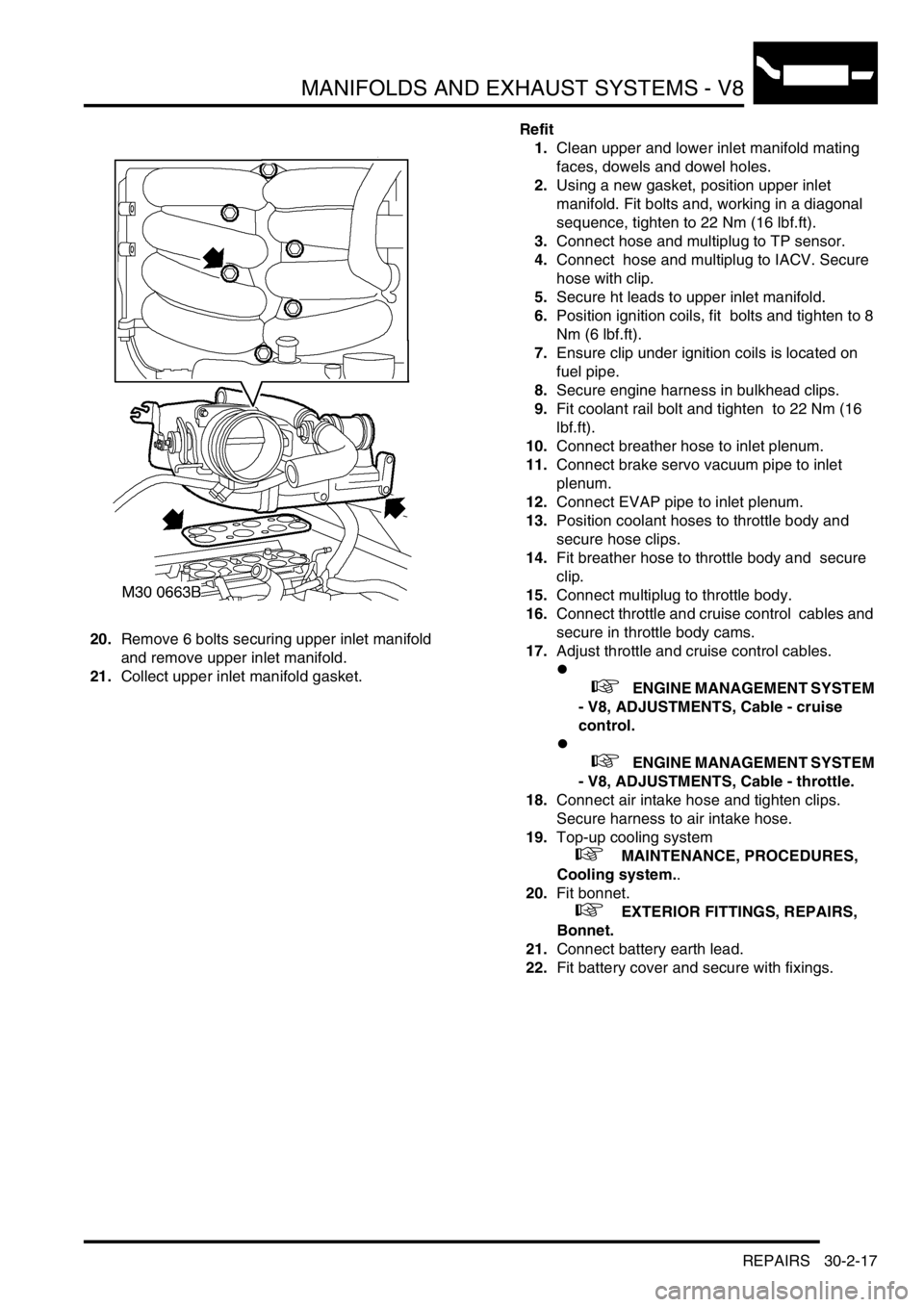

20.Remove 6 bolts securing upper inlet manifold

and remove upper inlet manifold.

21.Collect upper inlet manifold gasket. Refit

1.Clean upper and lower inlet manifold mating

faces, dowels and dowel holes.

2.Using a new gasket, position upper inlet

manifold. Fit bolts and, working in a diagonal

sequence, tighten to 22 Nm (16 lbf.ft).

3.Connect hose and multiplug to TP sensor.

4.Connect hose and multiplug to IACV. Secure

hose with clip.

5.Secure ht leads to upper inlet manifold.

6.Position ignition coils, fit bolts and tighten to 8

Nm (6 lbf.ft).

7.Ensure clip under ignition coils is located on

fuel pipe.

8.Secure engine harness in bulkhead clips.

9.Fit coolant rail bolt and tighten to 22 Nm (16

lbf.ft).

10.Connect breather hose to inlet plenum.

11.Connect brake servo vacuum pipe to inlet

plenum.

12.Connect EVAP pipe to inlet plenum.

13.Position coolant hoses to throttle body and

secure hose clips.

14.Fit breather hose to throttle body and secure

clip.

15.Connect multiplug to throttle body.

16.Connect throttle and cruise control cables and

secure in throttle body cams.

17.Adjust throttle and cruise control cables.

l

+ ENGINE MANAGEMENT SYSTEM

- V8, ADJUSTMENTS, Cable - cruise

control.

l

+ ENGINE MANAGEMENT SYSTEM

- V8, ADJUSTMENTS, Cable - throttle.

18.Connect air intake hose and tighten clips.

Secure harness to air intake hose.

19.Top-up cooling system

+ MAINTENANCE, PROCEDURES,

Cooling system..

20.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

21.Connect battery earth lead.

22.Fit battery cover and secure with fixings.

Page 455 of 1529

MANIFOLDS AND EXHAUST SYSTEMS - V8

30-2-20 REPAIRS

34.Release clip and disconnect IACV hose.

35.Remove 6 bolts securing upper manifold and

remove manifold.

36.Collect upper manifold gasket.

Refit

1.Clean upper and lower inlet manifold mating

faces, dowels and dowel holes.

2.Using a new gasket, position upper inlet

manifold. Fit bolts and, working in a diagonal

sequence, tighten to 22 Nm (16 lbf.ft).

3.Connect IACV hose and secure clip.

4.Connect hose to air valve and tighten clip.

5.Secure plug leads to clips.

6.Fit and tighten nuts securing RH air manifold

support bracket.

7.Align air pipe and coil bracket, fit bolts and

tighten to 8 Nm (6 lbf.ft).

8.Tighten 2 lower bolts securing coil bracket to 8

Nm (6 lbf.ft).

9.Fit bonnet seal.

10.Secure engine harness in bulkhead clips.

11.Connect breather hose to manifold and secure

clip.

12.Connect vacuum hose to inlet manifold.

13.Connect brake servo hose to inlet manifold.

14.Connect throttle and cruise control cables.

15.Adjust throttle cable.

+ ENGINE MANAGEMENT SYSTEM -

V8, ADJUSTMENTS, Cable - throttle.16.Adjust cruise control cable.

+ ENGINE MANAGEMENT SYSTEM -

V8, ADJUSTMENTS, Cable - cruise control.

17.Connect coolant hoses to throttle housing and

secure clips.

18.Connect multiplug to TP sensor.

19.Connect breather hose to throttle housing and

secure with clip.

20.Connect multiplug to IACV.

21.Secure purge valve and air control valve to clips

and bracket.

22.Connect purge hose to manifold.

23.Clean air manifold unions.

24.Apply a small amount of engine oil to top of air

manifold union nuts and around air manifold

pipes.

25.Position air manifold and finger tighten both air

manifold union nuts.

CAUTION: Finger tighten union nuts as far

as possible, damage to air manifold pipes or

adaptors may result if this is not done.

26.Tighten both air manifold union nuts to 25 Nm

(18 lbf.ft).

CAUTION: Ensure that air manifold pipes

are not distorted during tightening

operation.

27.Fit nuts securing air manifold support bracket

and tighten to 25 Nm (18 lbf.ft).

28.Connect hose to air valve and tighten clip.

29.Connect vacuum hose to air valve.

30.Fit air intake hose.

31.Connect multiplug to MAF sensor.

32.Secure harness to clip.

33.Connect battery earth lead.

34.Fit battery cover and secure with fixings.

35.Top up cooling system.

+ MAINTENANCE, PROCEDURES,

Cooling system.

36.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 461 of 1529

CLUTCH - V8

33-2-6 DESCRIPTION AND OPERATION

Description

General

The clutch system is a conventional diaphragm type clutch operated by a hydraulic cylinder. The clutch requires no

adjustment to compensate for wear.

Hydraulic clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir, which is also shared with

the braking system. The master and slave cylinders are connected to each other hydraulically by plastic and metal

pipes. The plastic section of the pipe allows ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the brake/clutch fluid reservoir. A piston is fitted in the bore and has an external

rod which is attached to the clutch pedal with a pin. Two coiled springs on the clutch pedal reduce the effort required

to depress the pedal.

The master cylinder is mounted on the bulkhead in the engine compartment and secured with two bolts. The cylinder

is connected to the shared brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat shield

protects the underside of the cylinder from heat generated from the exhaust system. The slave cylinder comprises a

cylinder with a piston and a rod. A port in the cylinder body provides the attachment for the hydraulic feed pipe from

the master cylinder. A second port is fitted with a bleed nipple for removing air from the hydraulic system after

servicing. The piston rod locates on a clutch release lever located in the gearbox housing. The rod is positively

retained on the release lever with a clip.

Clutch mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A spigot

with a ball end is formed on the release bearing sleeve and provides a mounting and pivot point for the clutch release

lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located on the ball, the pivot

washer seats against the rear face of the release lever. A spring clip is located on the lever and the pivot washer and

secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned centrally

on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever to pivot freely

around the ball.

The clutch release bearing locates on the clutch release lever and the release bearing sleeve. The bearing is retained

on a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever on

the carrier. The bearing and carrier are not serviceable individually.

Flywheel

The flywheel is bolted to a flange on the rear of the crankshaft with six bolts. A dowel on the crankshaft flange ensures

that the flywheel is correctly located. A ring gear is fitted on the outside diameter of the flywheel and seats against a

flange. The ring gear is an interference fit on the flywheel and is installed by heating the ring and cooling the flywheel.

The ring gear is a serviceable item and can be replaced if damaged or worn.

The operating face of the flywheel is machined to provide a smooth surface for the drive plate to engage on. Three

dowels and six threaded holes provide for the location and attachment of the pressure plate. The flywheel is balanced

to ensure that it does not produce vibration when rotating. A machined slot, with a series of holes within the slot, is

located on the engine side of the flywheel. The slot accommodates the tip of the crankshaft position sensor which is

used by the Engine Control Module (ECM) for engine management.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.