drain bolt LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 93 of 1529

TORQUE WRENCH SETTINGS

06-2

Engine Td5

TORQUE DESCRIPTION METRIC IMPERIAL

ACE pump bolts25 Nm (18 lbf.ft)

A/C compressor bolts 25 Nm (18 lbf.ft)

Alternator support bracket to cylinder head bolts 25 Nm (18 lbf.ft)

Alternator/vacuum pump oil feed pipe union 10 Nm (7 lbf.ft)

Camshaft cover to camshaft carrier bolts 10 Nm (7 lbf.ft)

Camshaft sprocket to camshaft bolts 37 Nm (27 lbf.ft)

Centrifuge cover bolts 10 Nm (7 lbf.ft)

Centrifuge oil drain pipe to sump bolts (or nuts) 10 Nm (7 lbf.ft)

Centrifuge to oil drain pipe bolts 10 Nm (7 lbf.ft)

Centrifuge to oil cooler housing bolts 25 Nm (18 lbf.ft)

CKP sensor bolt10 Nm (7 lbf.ft)

Coolant pipe bolt50 Nm (37 lbf.ft)

Connecting rod bolts, then a further 80°20 Nm (15 lbf.ft)

Crankshaft pulley bolt 460 Nm (340 lbf.ft)

Crankshaft pulley TV damper bolts 80 Nm (59 lbf.ft)

Crankshaft rear oil seal housing bolts 10 Nm (7 lbf.ft)

Cylinder head bolts initial tighten 30 Nm (22 lbf.ft)

Cylinder head bolts final tighten, then a further 90°, then a further 180° and finally a

further 45°65 Nm (48 lbf.ft)

Dipstick tube to camshaft carrier bolt 10 Nm (7 lbf.ft)

Drive plate (automatic transmission) to crankshaft bolts 115 Nm (85 lbf.ft)

EGR pipe clamp to cylinder head bolt - if fitted 25 Nm (18 lbf.ft)

EGR pipe Allen screws 10 Nm (7 lbf.ft)

Engine mounting (front) to cylinder block bolts 48 Nm (35 lbf.ft)

Engine mounting (front) to chassis nuts 85 Nm (63 lbf.ft)

Engine mounting bracket (rear, LH & RH) to gearbox bolts 85 Nm (63 lbf.ft)

Engine mounting bracket (rear, LH & RH) nuts 45 Nm (33 lbf.ft)

Flywheel to crankshaft (manual transmission) bolts, then a further 90°40 Nm (30 lbf.ft)

Front crossmember bolts 26 Nm (20 lbf.ft)

Fuel connector block bolts 25 Nm (18 lbf.ft)

Fuel cooler to inlet manifold bolts 25 Nm (18 lbf.ft)

Gearbox housing to engine bolts 50 Nm (37 lbf.ft)

Heater pipe to cylinder head bolts 25 Nm (18 lbf.ft)

Main bearing cap bolts then a further 90°33 Nm (24 lbf.ft)

Oil cooler housing to cylinder block bolts 25 Nm (18 lbf.ft)

Oil cooler pipe clip bolts 10 Nm (7 lbf.ft)

Oil filter adaptor housing to oil cooler housing bolts 25 Nm (18 lbf.ft)

Oil pick-up strainer Torx screws + 10 Nm (7 lbf.ft)

Oil pressure switch 15 Nm (11 lbf.ft)

Oil pump drive sprocket bolt + 25 Nm (18 lbf.ft)

Oil pump pressure relief valve plug + 25 Nm (18 lbf.ft)

Oil pump and stiffener assembly to cylinder block bolts 13 Nm (10 lbf.ft)

Oil sump to cylinder block bolts 25 Nm (18 lbf.ft)

Oil sump to gearbox bell housing bolts 13 Nm (10 lbf.ft)

PAS pump bracket bolts 27 Nm (20 lbf.ft)

PAS pump pulley bolts 27 Nm (20 lbf.ft)

Rocker arm adjusting screw locknuts 16 Nm (12 lbf.ft)

Page 97 of 1529

TORQUE WRENCH SETTINGS

06-6

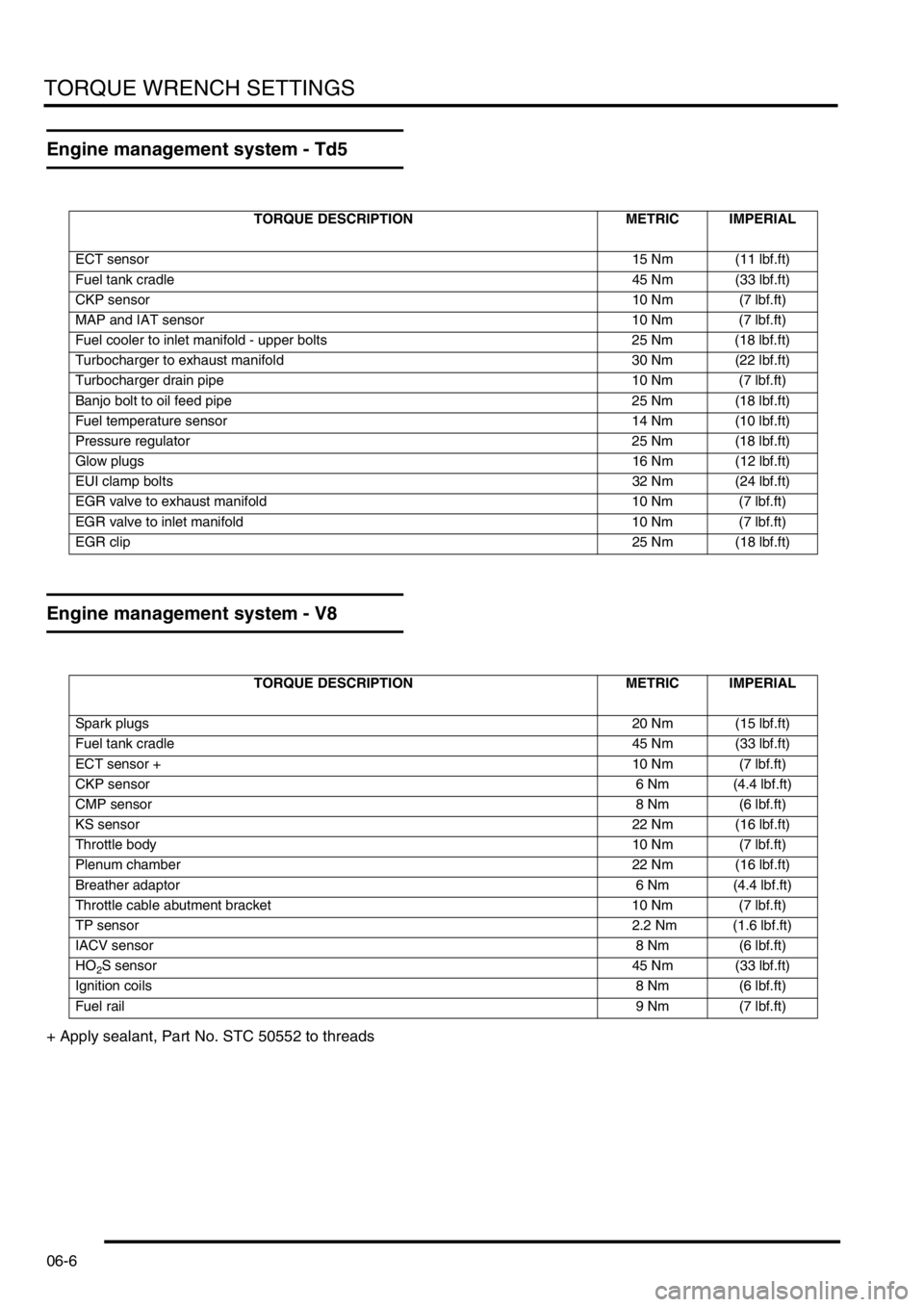

Engine management system - Td5

Engine management system - V8

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

ECT sensor15 Nm (11 lbf.ft)

Fuel tank cradle45 Nm (33 lbf.ft)

CKP sensor10 Nm (7 lbf.ft)

MAP and IAT sensor 10 Nm (7 lbf.ft)

Fuel cooler to inlet manifold - upper bolts 25 Nm (18 lbf.ft)

Turbocharger to exhaust manifold 30 Nm (22 lbf.ft)

Turbocharger drain pipe 10 Nm (7 lbf.ft)

Banjo bolt to oil feed pipe 25 Nm (18 lbf.ft)

Fuel temperature sensor 14 Nm (10 lbf.ft)

Pressure regulator 25 Nm (18 lbf.ft)

Glow plugs16 Nm (12 lbf.ft)

EUI clamp bolts32 Nm (24 lbf.ft)

EGR valve to exhaust manifold 10 Nm (7 lbf.ft)

EGR valve to inlet manifold 10 Nm (7 lbf.ft)

EGR clip25 Nm (18 lbf.ft)

TORQUE DESCRIPTION METRIC IMPERIAL

Spark plugs20 Nm (15 lbf.ft)

Fuel tank cradle45 Nm (33 lbf.ft)

ECT sensor +10 Nm (7 lbf.ft)

CKP sensor6 Nm (4.4 lbf.ft)

CMP sensor8 Nm (6 lbf.ft)

KS sensor22 Nm (16 lbf.ft)

Throttle body10 Nm (7 lbf.ft)

Plenum chamber22 Nm (16 lbf.ft)

Breather adaptor6 Nm (4.4 lbf.ft)

Throttle cable abutment bracket 10 Nm (7 lbf.ft)

TP sensor 2.2 Nm (1.6 lbf.ft)

IACV sensor8 Nm (6 lbf.ft)

HO

2S sensor45 Nm (33 lbf.ft)

Ignition coils8 Nm (6 lbf.ft)

Fuel rail9 Nm (7 lbf.ft)

Page 160 of 1529

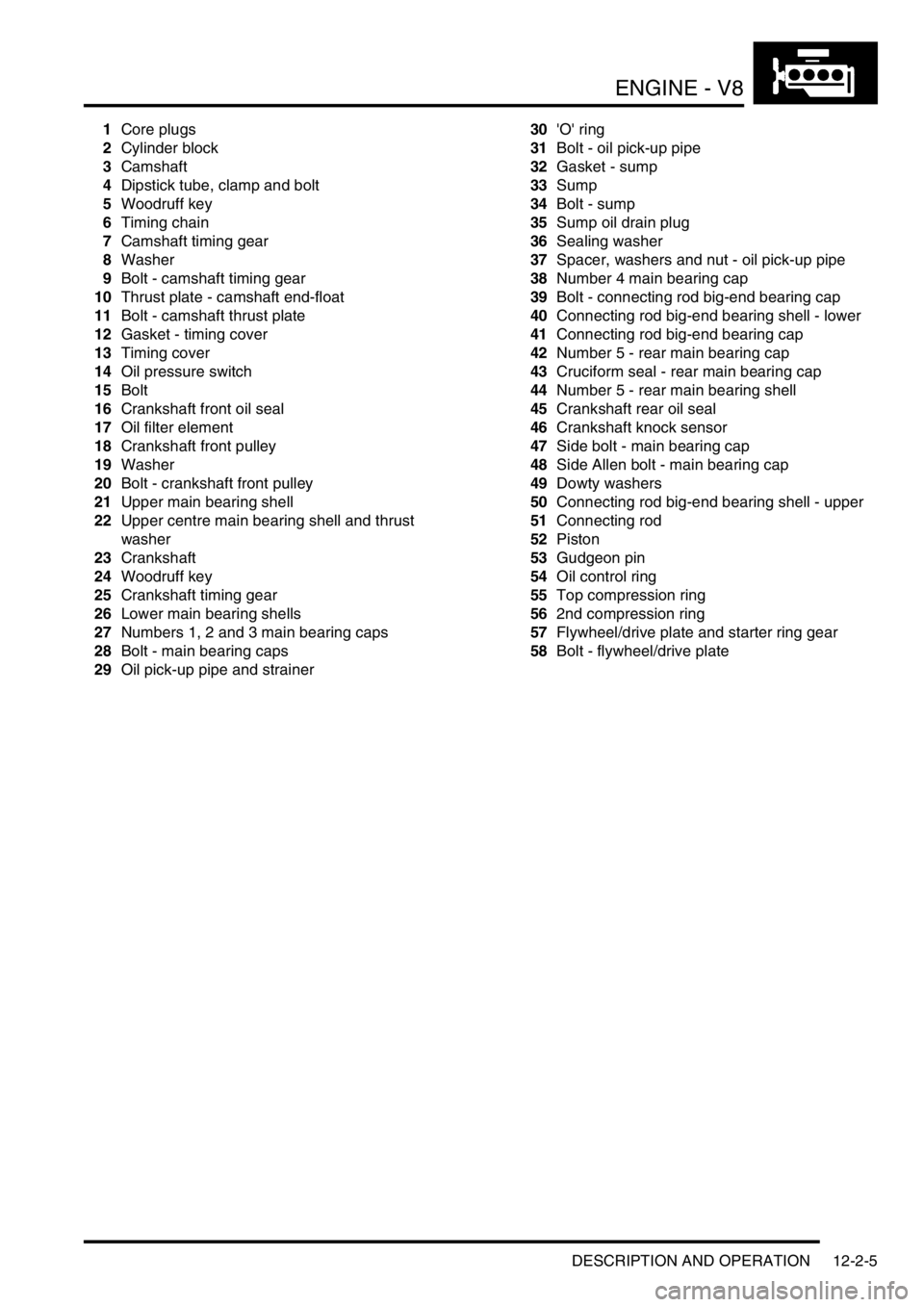

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-5

1Core plugs

2Cylinder block

3Camshaft

4Dipstick tube, clamp and bolt

5Woodruff key

6Timing chain

7Camshaft timing gear

8Washer

9Bolt - camshaft timing gear

10Thrust plate - camshaft end-float

11Bolt - camshaft thrust plate

12Gasket - timing cover

13Timing cover

14Oil pressure switch

15Bolt

16Crankshaft front oil seal

17Oil filter element

18Crankshaft front pulley

19Washer

20Bolt - crankshaft front pulley

21Upper main bearing shell

22Upper centre main bearing shell and thrust

washer

23Crankshaft

24Woodruff key

25Crankshaft timing gear

26Lower main bearing shells

27Numbers 1, 2 and 3 main bearing caps

28Bolt - main bearing caps

29Oil pick-up pipe and strainer30'O' ring

31Bolt - oil pick-up pipe

32Gasket - sump

33Sump

34Bolt - sump

35Sump oil drain plug

36Sealing washer

37Spacer, washers and nut - oil pick-up pipe

38Number 4 main bearing cap

39Bolt - connecting rod big-end bearing cap

40Connecting rod big-end bearing shell - lower

41Connecting rod big-end bearing cap

42Number 5 - rear main bearing cap

43Cruciform seal - rear main bearing cap

44Number 5 - rear main bearing shell

45Crankshaft rear oil seal

46Crankshaft knock sensor

47Side bolt - main bearing cap

48Side Allen bolt - main bearing cap

49Dowty washers

50Connecting rod big-end bearing shell - upper

51Connecting rod

52Piston

53Gudgeon pin

54Oil control ring

55Top compression ring

562nd compression ring

57Flywheel/drive plate and starter ring gear

58Bolt - flywheel/drive plate

Page 162 of 1529

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-7

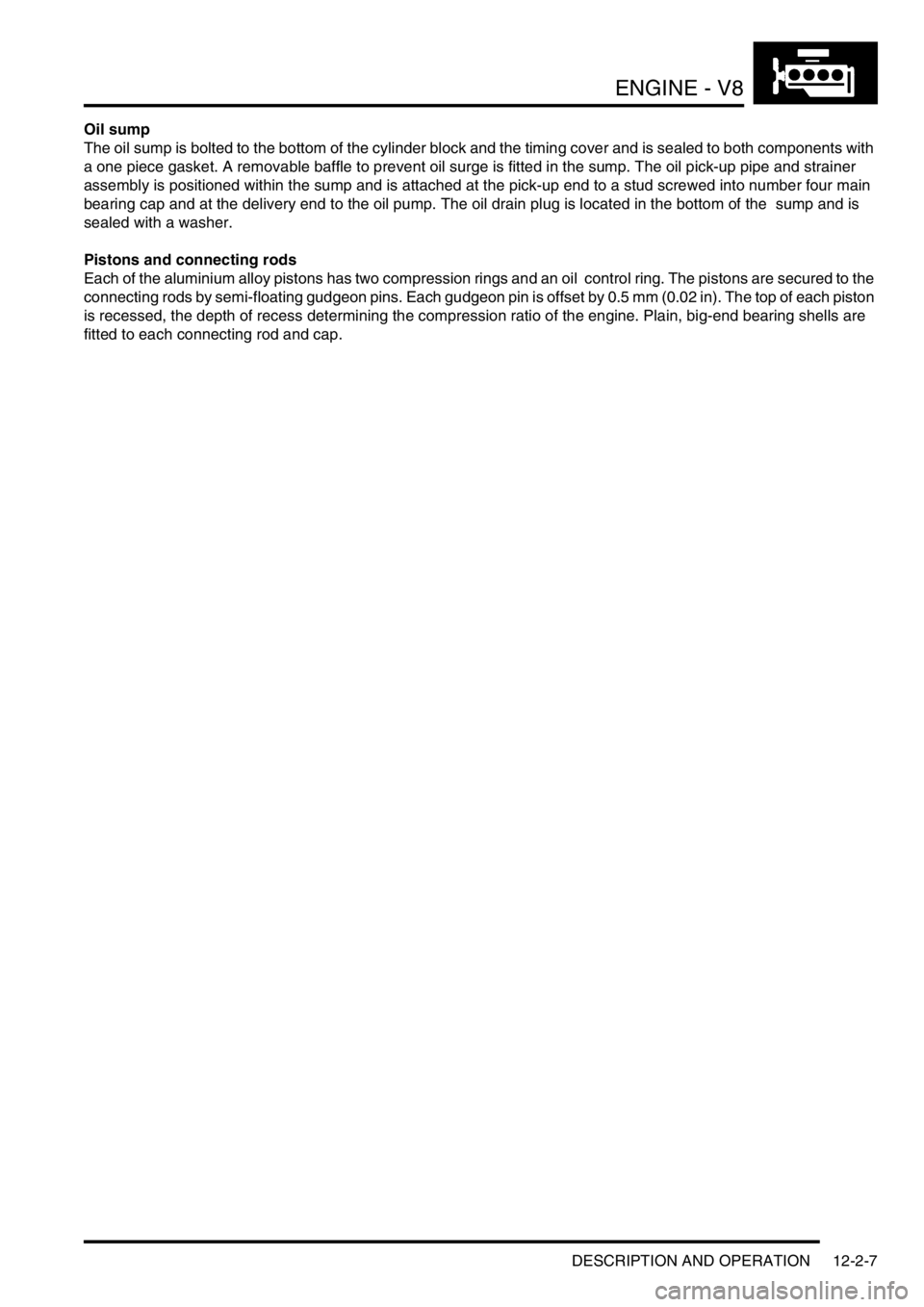

Oil sump

The oil sump is bolted to the bottom of the cylinder block and the timing cover and is sealed to both components with

a one piece gasket. A removable baffle to prevent oil surge is fitted in the sump. The oil pick-up pipe and strainer

assembly is positioned within the sump and is attached at the pick-up end to a stud screwed into number four main

bearing cap and at the delivery end to the oil pump. The oil drain plug is located in the bottom of the sump and is

sealed with a washer.

Pistons and connecting rods

Each of the aluminium alloy pistons has two compression rings and an oil control ring. The pistons are secured to the

connecting rods by semi-floating gudgeon pins. Each gudgeon pin is offset by 0.5 mm (0.02 in). The top of each piston

is recessed, the depth of recess determining the compression ratio of the engine. Plain, big-end bearing shells are

fitted to each connecting rod and cap.

Page 175 of 1529

ENGINE - V8

12-2-20 REPAIRS

Refit

1.Clean mating faces of rocker cover and

cylinder head, ensure bolt holes are clean and

dry.

2.Fit a new gasket dry, position rocker cover

ensuring gasket is correctly located.

3.Fit new 'patched' multi-hex rocker cover bolts

ensuring that 2 short bolts are on side of rocker

cover nearest centre of engine.

4.Tighten bolts by diagonal selection to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

5.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

6.Fit and tighten screw securing dip stick tube.

7.Secure ht leads in rocker cover clips.

8. Models with air conditioning: Clean

compressor dowels and dowel holes. Position

compressor, fit bolts and tighten to 22 Nm (16

lbf.ft). Release auxiliary drive belt tensioner

and fit belt to compressor.

9. Models with air conditioning: Position fan

cowl and secure clips.

10.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

Gasket - rocker cover - RH

$% 12.29.41

Remove

1.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

3. Models with SAI: Disconnect 2 air manifold

unions from adapters in cylinder head and

remove manifold.

CAUTION: Take care that air manifold pipes

are not damaged during removal of union

nuts.

4.Remove 2 bolts securing coolant rails to inlet

manifold.

Page 176 of 1529

ENGINE - V8

REPAIRS 12-2-21

5.Release coolant rail from inlet manifold and

discard 'O' ring.

6.Remove nuts securing alternator cables and

release cables from alternator.

7.Disconnect multiplugs from RH bank of

injectors and release harness from fuel rail.

8.Release ht leads from clips on rocker cover.

9.Noting fitted position of 2 long screws or multi-

hex bolts, remove and discard screws/bolts

securing rocker cover; remove rocker cover.

10.Remove and discard rocker cover gasket. Refit

1.Clean mating faces of rocker cover and

cylinder head, ensure bolt holes are clean and

dry.

2.Fit a new gasket dry, position rocker cover

ensuring gasket is correctly located.

3.Fit new 'patched' multi-hex rocker cover bolts

ensuring that 2 short bolts are on side of rocker

cover nearest centre of engine.

4.Tighten bolts by diagonal selection to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

5.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

6.Secure ht leads in rocker cover clips.

7.Secure injector harness to fuel rail and connect

multiplugs to injectors.

8.Position alternator cables, and tighten terminal

B+ nut to 18 Nm (13 lbf.ft) and terminal D+ nut

to 5 Nm (3 lbf.ft).

9.Clean coolant rail 'O' ring recess.

10.Lubricate and fit new 'O' ring to coolant rail,

position coolant rails, fit bolts and tighten to 22

Nm (16 lbf.ft).

11. Models with SAI: Apply a small amount of

engine oil to top of air manifold union nuts and

around air manifold pipes.

12. Models with SAI:Position air manifold and

finger tighten both air manifold union nuts.

CAUTION: Finger tighten union nuts as far

as possible, damage to air manifold pipes or

adapters may result if this is not done.

13. Models with SAI: Tighten both union nuts to

25 Nm (18 lbf.ft).

CAUTION: Ensure that air manifold pipes

are not distorted during tightening

operation.

14.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

15.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 181 of 1529

ENGINE - V8

12-2-26 REPAIRS

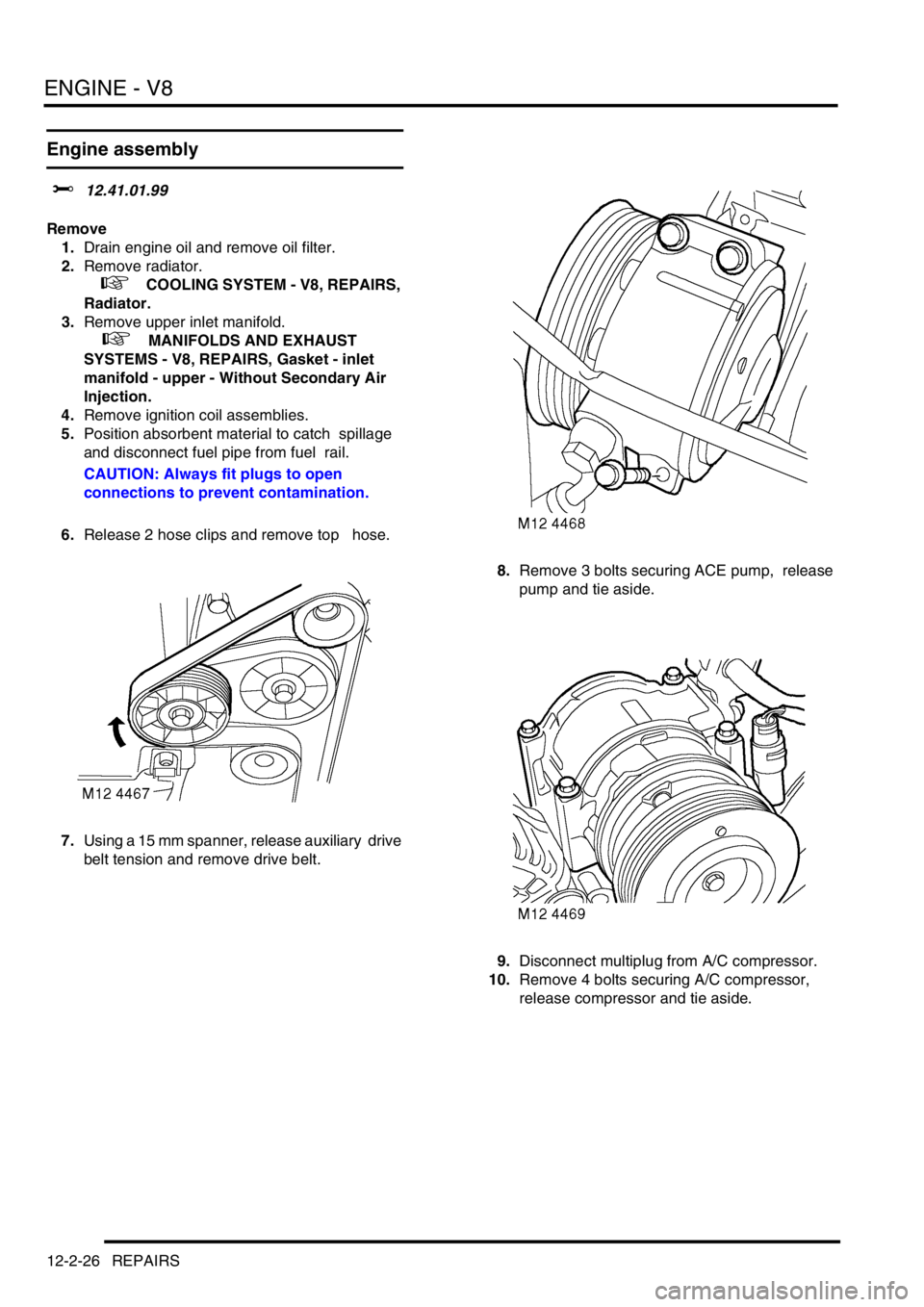

Engine assembly

$% 12.41.01.99

Remove

1.Drain engine oil and remove oil filter.

2.Remove radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

3.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

4.Remove ignition coil assemblies.

5.Position absorbent material to catch spillage

and disconnect fuel pipe from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Release 2 hose clips and remove top hose.

7.Using a 15 mm spanner, release auxiliary drive

belt tension and remove drive belt. 8.Remove 3 bolts securing ACE pump, release

pump and tie aside.

9.Disconnect multiplug from A/C compressor.

10.Remove 4 bolts securing A/C compressor,

release compressor and tie aside.

Page 192 of 1529

ENGINE - V8

REPAIRS 12-2-37

Gasket - sump

$% 12.60.38

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove dipstick.

4.Raise the vehicle on a ramp.

5.Drain engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

6.Remove 8 bolts securing cross member and

remove cross member.

7.Raise front of vehicle under body to increase

clearance between engine and front axle.

8.Disconnect and release gearbox oil cooler pipe

and discard 'O' ring. 9.Remove 2 clips securing oil cooler pipes at

front of sump.

10.Remove clip securing oil cooler pipes to side of

sump.

11.Remove clip bracket.

12.Remove 2 forward facing bolts securing sump

to bell housing.

13.Remove 4 rear facing bolts securing sump to

bell housing.

14.Remove 2 bolts in sump recess.

15.Remove 3 nuts securing front of sump.

Page 196 of 1529

ENGINE - V8

REPAIRS 12-2-41

Gasket - timing gear cover

$% 12.65.04

Remove

1.Remove oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

2.Remove timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

3.Remove engine oil filter.

+ ENGINE - V8, REPAIRS, Filter - oil.

4.Remove and discard 3 bolts securing coolant

pump pulley and remove pulley.

5.Remove 3 bolts securing PAS pump pulley and

remove pulley.

6.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.7.Release clip and disconnect coolant hose from

coolant pump.

8.Disconnect multiplug from oil pressure switch.

9.Disconnect multiplug from CMP sensor.

10. If fitted: Loosen union and disconnect oil

cooler pipe from timing gear cover. Remove

and discard 'O' ring.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11.Remove 9 bolts securing timing gear cover and

remove cover. Remove and discard gasket.

Page 197 of 1529

ENGINE - V8

12-2-42 REPAIRS

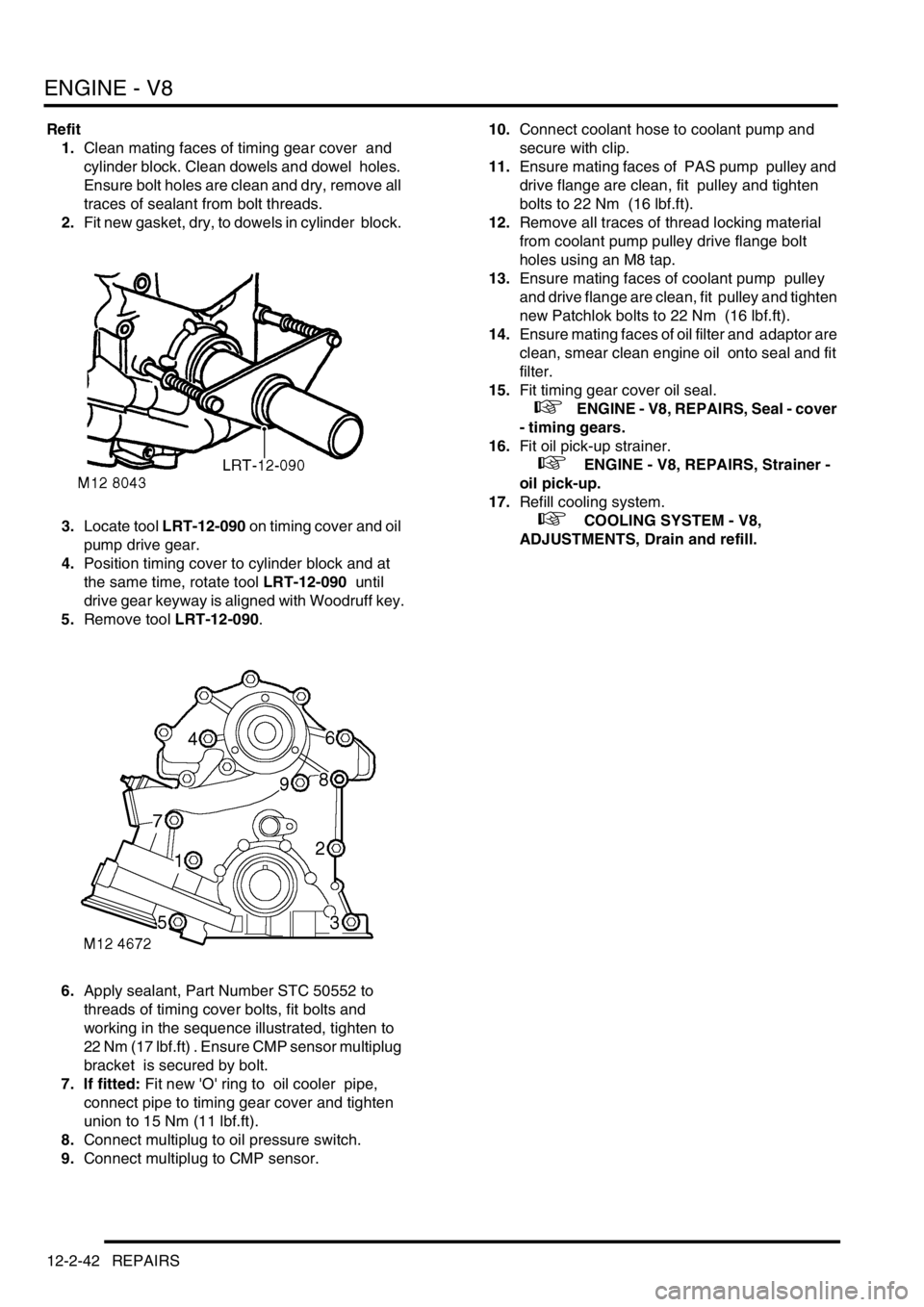

Refit

1.Clean mating faces of timing gear cover and

cylinder block. Clean dowels and dowel holes.

Ensure bolt holes are clean and dry, remove all

traces of sealant from bolt threads.

2.Fit new gasket, dry, to dowels in cylinder block.

3.Locate tool LRT-12-090 on timing cover and oil

pump drive gear.

4.Position timing cover to cylinder block and at

the same time, rotate tool LRT-12-090 until

drive gear keyway is aligned with Woodruff key.

5.Remove tool LRT-12-090.

6.Apply sealant, Part Number STC 50552 to

threads of timing cover bolts, fit bolts and

working in the sequence illustrated, tighten to

22 Nm (17 lbf.ft) . Ensure CMP sensor multiplug

bracket is secured by bolt.

7. If fitted: Fit new 'O' ring to oil cooler pipe,

connect pipe to timing gear cover and tighten

union to 15 Nm (11 lbf.ft).

8.Connect multiplug to oil pressure switch.

9.Connect multiplug to CMP sensor. 10.Connect coolant hose to coolant pump and

secure with clip.

11.Ensure mating faces of PAS pump pulley and

drive flange are clean, fit pulley and tighten

bolts to 22 Nm (16 lbf.ft).

12.Remove all traces of thread locking material

from coolant pump pulley drive flange bolt

holes using an M8 tap.

13.Ensure mating faces of coolant pump pulley

and drive flange are clean, fit pulley and tighten

new Patchlok bolts to 22 Nm (16 lbf.ft).

14.Ensure mating faces of oil filter and adaptor are

clean, smear clean engine oil onto seal and fit

filter.

15.Fit timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

16.Fit oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

17.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.