battery LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 561 of 1672

FUEL DELIVERY SYSTEM - TD5

19-1-16 REPAIRS

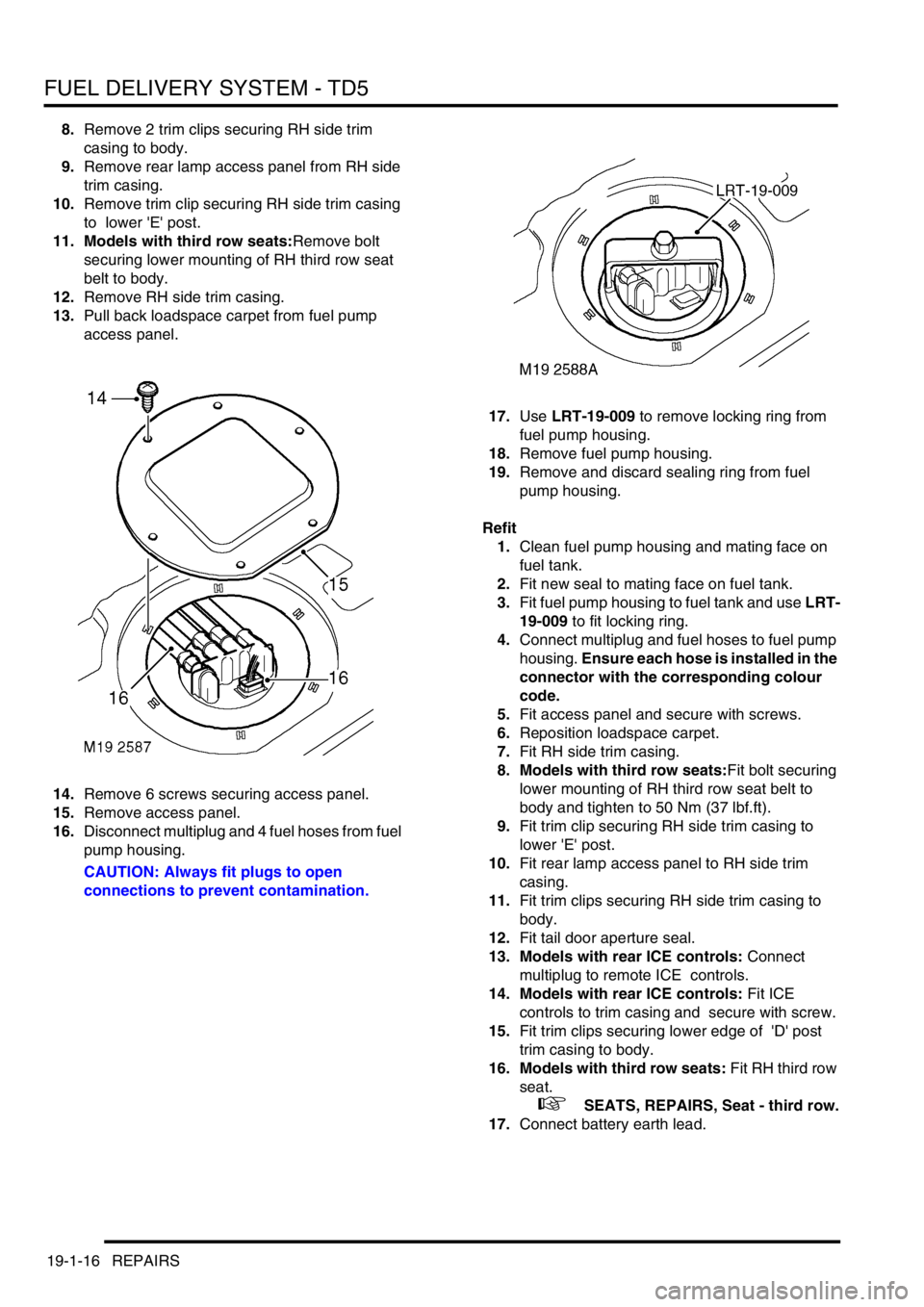

8.Remove 2 trim clips securing RH side trim

casing to body.

9.Remove rear lamp access panel from RH side

trim casing.

10.Remove trim clip securing RH side trim casing

to lower 'E' post.

11. Models with third row seats:Remove bolt

securing lower mounting of RH third row seat

belt to body.

12.Remove RH side trim casing.

13.Pull back loadspace carpet from fuel pump

access panel.

14.Remove 6 screws securing access panel.

15.Remove access panel.

16.Disconnect multiplug and 4 fuel hoses from fuel

pump housing.

CAUTION: Always fit plugs to open

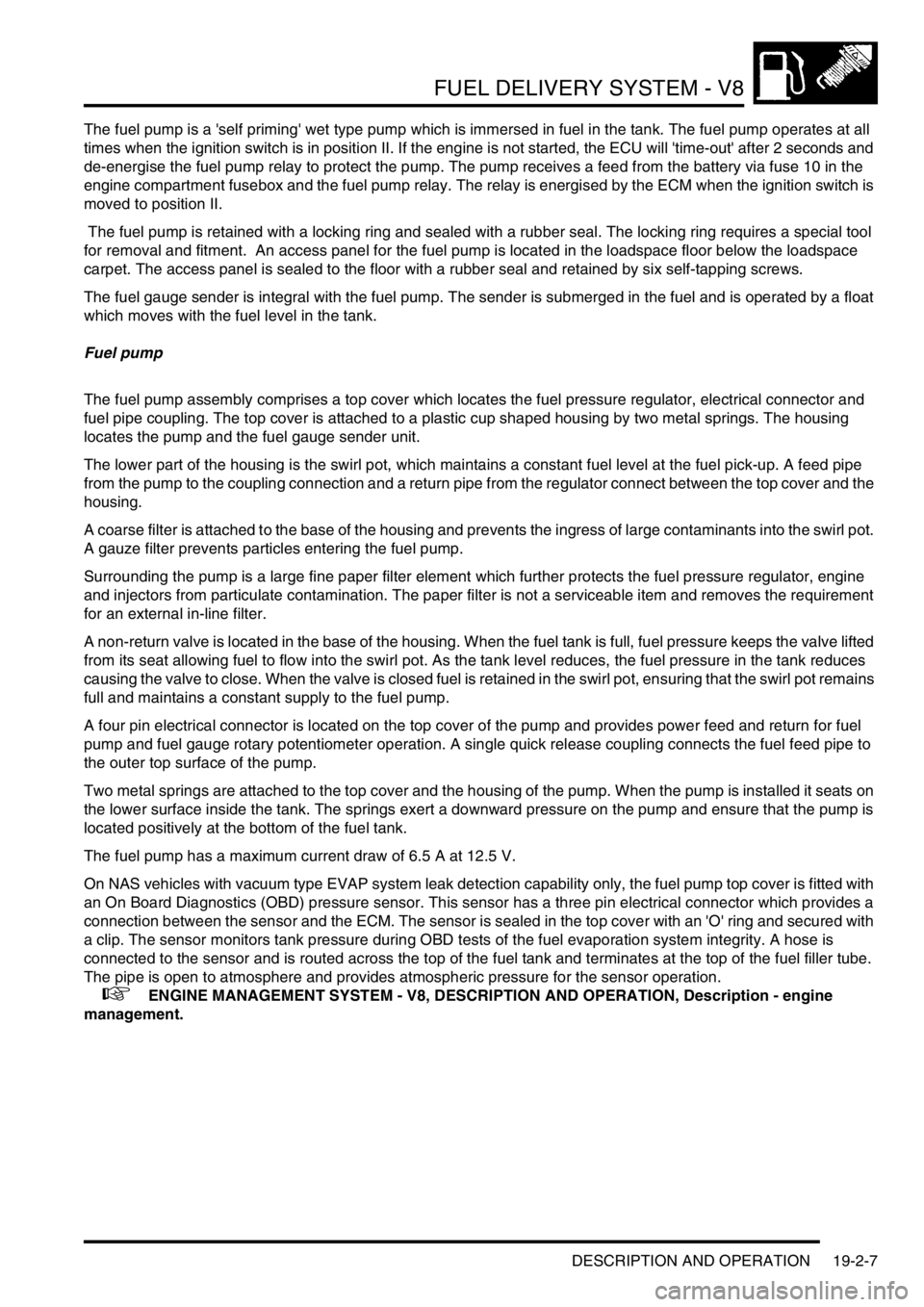

connections to prevent contamination.17.Use LRT-19-009 to remove locking ring from

fuel pump housing.

18.Remove fuel pump housing.

19.Remove and discard sealing ring from fuel

pump housing.

Refit

1.Clean fuel pump housing and mating face on

fuel tank.

2.Fit new seal to mating face on fuel tank.

3.Fit fuel pump housing to fuel tank and use LRT-

19-009 to fit locking ring.

4.Connect multiplug and fuel hoses to fuel pump

housing. Ensure each hose is installed in the

connector with the corresponding colour

code.

5.Fit access panel and secure with screws.

6.Reposition loadspace carpet.

7.Fit RH side trim casing.

8. Models with third row seats:Fit bolt securing

lower mounting of RH third row seat belt to

body and tighten to 50 Nm (37 lbf.ft).

9.Fit trim clip securing RH side trim casing to

lower 'E' post.

10.Fit rear lamp access panel to RH side trim

casing.

11.Fit trim clips securing RH side trim casing to

body.

12.Fit tail door aperture seal.

13. Models with rear ICE controls: Connect

multiplug to remote ICE controls.

14. Models with rear ICE controls: Fit ICE

controls to trim casing and secure with screw.

15.Fit trim clips securing lower edge of 'D' post

trim casing to body.

16. Models with third row seats: Fit RH third row

seat.

+ SEATS, REPAIRS, Seat - third row.

17.Connect battery earth lead.

Page 572 of 1672

FUEL DELIVERY SYSTEM - V8

DESCRIPTION AND OPERATION 19-2-7

The fuel pump is a 'self priming' wet type pump which is immersed in fuel in the tank. The fuel pump operates at all

times when the ignition switch is in position II. If the engine is not started, the ECU will 'time-out' after 2 seconds and

de-energise the fuel pump relay to protect the pump. The pump receives a feed from the battery via fuse 10 in the

engine compartment fusebox and the fuel pump relay. The relay is energised by the ECM when the ignition switch is

moved to position II.

The fuel pump is retained with a locking ring and sealed with a rubber seal. The locking ring requires a special tool

for removal and fitment. An access panel for the fuel pump is located in the loadspace floor below the loadspace

carpet. The access panel is sealed to the floor with a rubber seal and retained by six self-tapping screws.

The fuel gauge sender is integral with the fuel pump. The sender is submerged in the fuel and is operated by a float

which moves with the fuel level in the tank.

Fuel pump

The fuel pump assembly comprises a top cover which locates the fuel pressure regulator, electrical connector and

fuel pipe coupling. The top cover is attached to a plastic cup shaped housing by two metal springs. The housing

locates the pump and the fuel gauge sender unit.

The lower part of the housing is the swirl pot, which maintains a constant fuel level at the fuel pick-up. A feed pipe

from the pump to the coupling connection and a return pipe from the regulator connect between the top cover and the

housing.

A coarse filter is attached to the base of the housing and prevents the ingress of large contaminants into the swirl pot.

A gauze filter prevents particles entering the fuel pump.

Surrounding the pump is a large fine paper filter element which further protects the fuel pressure regulator, engine

and injectors from particulate contamination. The paper filter is not a serviceable item and removes the requirement

for an external in-line filter.

A non-return valve is located in the base of the housing. When the fuel tank is full, fuel pressure keeps the valve lifted

from its seat allowing fuel to flow into the swirl pot. As the tank level reduces, the fuel pressure in the tank reduces

causing the valve to close. When the valve is closed fuel is retained in the swirl pot, ensuring that the swirl pot remains

full and maintains a constant supply to the fuel pump.

A four pin electrical connector is located on the top cover of the pump and provides power feed and return for fuel

pump and fuel gauge rotary potentiometer operation. A single quick release coupling connects the fuel feed pipe to

the outer top surface of the pump.

Two metal springs are attached to the top cover and the housing of the pump. When the pump is installed it seats on

the lower surface inside the tank. The springs exert a downward pressure on the pump and ensure that the pump is

located positively at the bottom of the fuel tank.

The fuel pump has a maximum current draw of 6.5 A at 12.5 V.

On NAS vehicles with vacuum type EVAP system leak detection capability only, the fuel pump top cover is fitted with

an On Board Diagnostics (OBD) pressure sensor. This sensor has a three pin electrical connector which provides a

connection between the sensor and the ECM. The sensor is sealed in the top cover with an 'O' ring and secured with

a clip. The sensor monitors tank pressure during OBD tests of the fuel evaporation system integrity. A hose is

connected to the sensor and is routed across the top of the fuel tank and terminates at the top of the fuel filler tube.

The pipe is open to atmosphere and provides atmospheric pressure for the sensor operation.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Page 573 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-8 DESCRIPTION AND OPERATION

Fuel pressure regulator

The fuel pressure regulator is located in the underside of the top cover. The regulator is sealed with two 'O' rings and

retained with a clip.

The regulator is connected to the fuel feed pipe at the top of the pump housing and maintains the fuel pump delivery

pressure to 3.5 bar (50 lbf.in

2). When the fuel delivery pressure exceeds 3.5 bar (50 lbf.in2), the regulator opens and

relieves excess pressure back to the swirl pot via a return pipe. The regulator ensures that the fuel rails and injectors

are supplied with a constant pressure.

The fuel pump delivery pressure and pressure regulator operating pressure can be checked using a Schraeder type

valve located at the rear of the engine on the fuel rail. The valve allows the pump delivery pressure to be measured

using a suitable gauge and an adaptor and hose which are special tools.

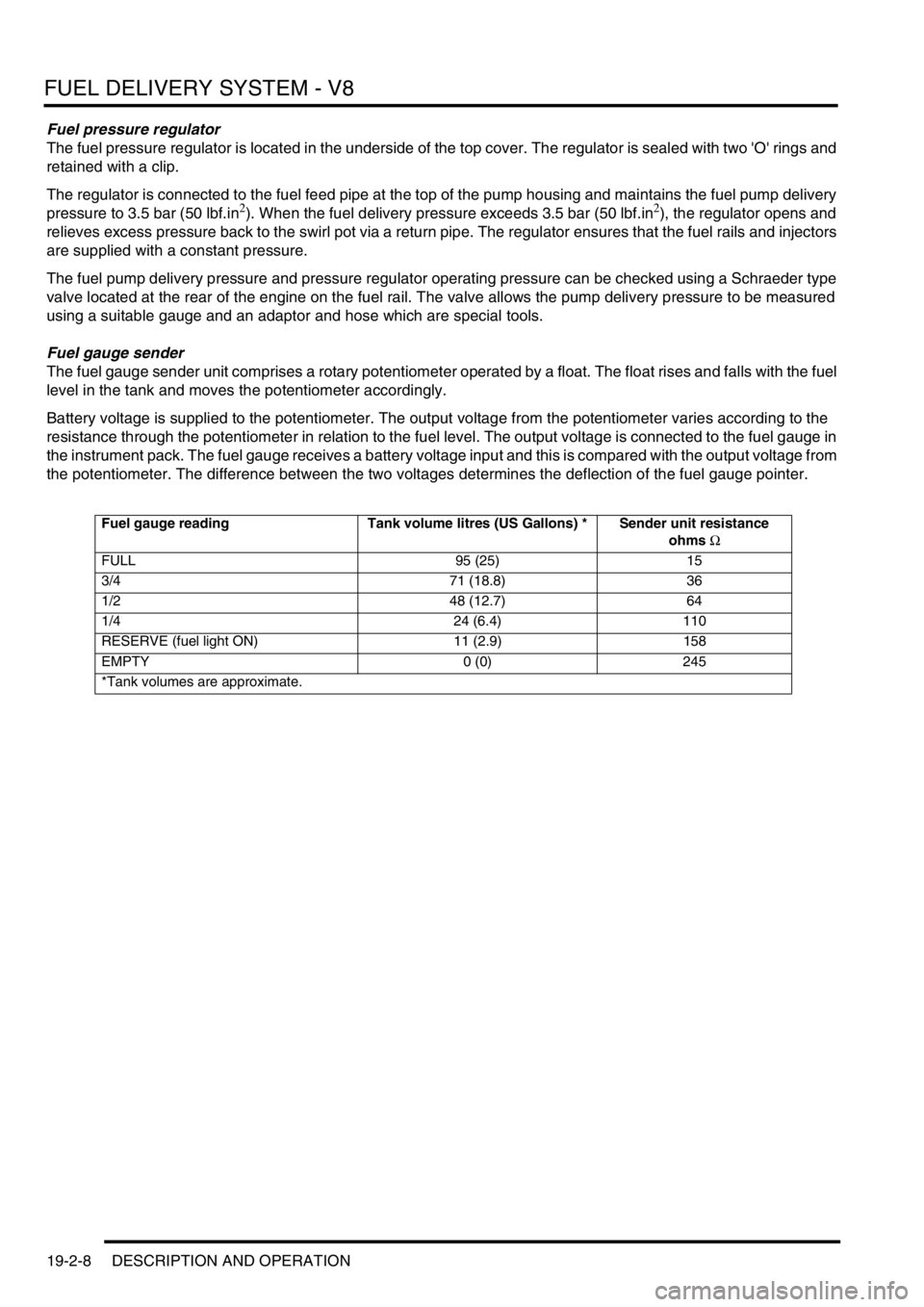

Fuel gauge sender

The fuel gauge sender unit comprises a rotary potentiometer operated by a float. The float rises and falls with the fuel

level in the tank and moves the potentiometer accordingly.

Battery voltage is supplied to the potentiometer. The output voltage from the potentiometer varies according to the

resistance through the potentiometer in relation to the fuel level. The output voltage is connected to the fuel gauge in

the instrument pack. The fuel gauge receives a battery voltage input and this is compared with the output voltage from

the potentiometer. The difference between the two voltages determines the deflection of the fuel gauge pointer.

Fuel gauge reading Tank volume litres (US Gallons) * Sender unit resistance

ohms Ω

FULL 95 (25) 15

3/4 71 (18.8) 36

1/2 48 (12.7) 64

1/4 24 (6.4) 110

RESERVE (fuel light ON) 11 (2.9) 158

EMPTY 0 (0) 245

*Tank volumes are approximate.

Page 574 of 1672

FUEL DELIVERY SYSTEM - V8

DESCRIPTION AND OPERATION 19-2-9

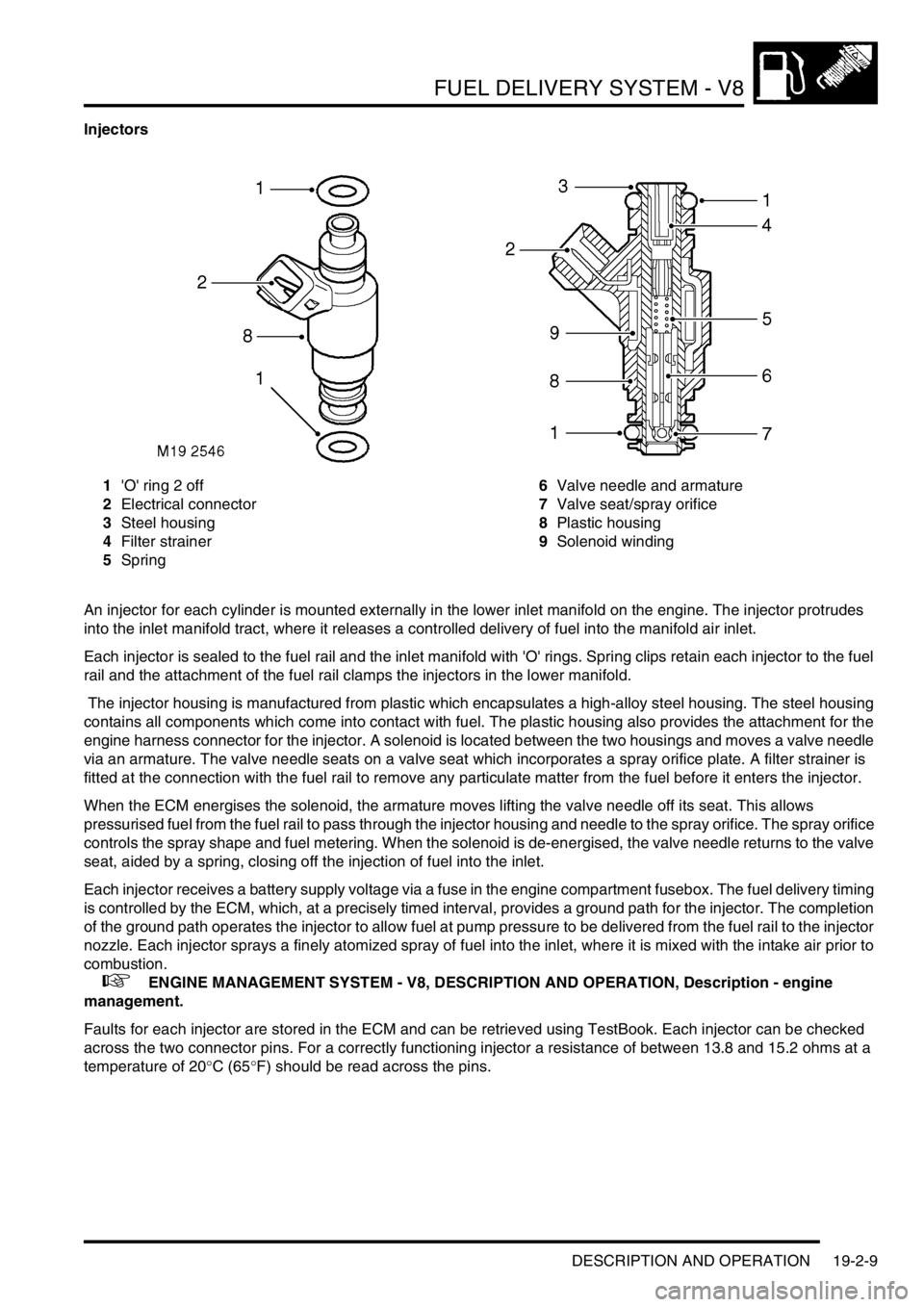

Injectors

1'O' ring 2 off

2Electrical connector

3Steel housing

4Filter strainer

5Spring6Valve needle and armature

7Valve seat/spray orifice

8Plastic housing

9Solenoid winding

An injector for each cylinder is mounted externally in the lower inlet manifold on the engine. The injector protrudes

into the inlet manifold tract, where it releases a controlled delivery of fuel into the manifold air inlet.

Each injector is sealed to the fuel rail and the inlet manifold with 'O' rings. Spring clips retain each injector to the fuel

rail and the attachment of the fuel rail clamps the injectors in the lower manifold.

The injector housing is manufactured from plastic which encapsulates a high-alloy steel housing. The steel housing

contains all components which come into contact with fuel. The plastic housing also provides the attachment for the

engine harness connector for the injector. A solenoid is located between the two housings and moves a valve needle

via an armature. The valve needle seats on a valve seat which incorporates a spray orifice plate. A filter strainer is

fitted at the connection with the fuel rail to remove any particulate matter from the fuel before it enters the injector.

When the ECM energises the solenoid, the armature moves lifting the valve needle off its seat. This allows

pressurised fuel from the fuel rail to pass through the injector housing and needle to the spray orifice. The spray orifice

controls the spray shape and fuel metering. When the solenoid is de-energised, the valve needle returns to the valve

seat, aided by a spring, closing off the injection of fuel into the inlet.

Each injector receives a battery supply voltage via a fuse in the engine compartment fusebox. The fuel delivery timing

is controlled by the ECM, which, at a precisely timed interval, provides a ground path for the injector. The completion

of the ground path operates the injector to allow fuel at pump pressure to be delivered from the fuel rail to the injector

nozzle. Each injector sprays a finely atomized spray of fuel into the inlet, where it is mixed with the intake air prior to

combustion.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Faults for each injector are stored in the ECM and can be retrieved using TestBook. Each injector can be checked

across the two connector pins. For a correctly functioning injector a resistance of between 13.8 and 15.2 ohms at a

temperature of 20

°C (65°F) should be read across the pins.

Page 575 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-10 DESCRIPTION AND OPERATION

Operation

When the ignition switch is moved to position II, the fuel pump relay in the engine compartment fusebox is energised

by the ECM. Battery voltage is supplied from the fuel pump relay to the fuel pump which operates. If engine cranking

is not detected by the ECU within a thirty second period, the ECU will 'time-out', de-energising the fuel pump relay.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The fuel pump draws fuel from the swirl pot and pumps it along the fuel feed pipe to the injector fuel rail on the engine.

When the pressure in the fuel feed line reaches 3.5 bar (50 lbf.in

2) the fuel pressure regulator opens and relieves

pressure by directing fuel back into the swirl pot. The pressure regulator is constantly opening and closing to maintain

the pressure in the fuel feed pipe and the fuel rail at 3.5 bar (50 lbf.in

2).

The pressure is felt at each of the eight injectors connected to the fuel rail. The ECM controls the injection timing and

energises each injector to allow a metered amount of fuel at pump pressure to be injected into the inlet tract of the

inlet manifold. The atomised fuel from the injector is mixed with air from the inlet manifold before passing into the

cylinder.

Page 576 of 1672

FUEL DELIVERY SYSTEM - V8

ADJUSTMENTS 19-2-11

ADJUST ME NTS

Fuel tank - drain

$% 19.55.02

Drain

1.Disconnect both leads from battery.

WARNING: Always disconnect the negative

lead first. Disconnection of the positive lead

while the negative lead is connected could

result in a short circuit through accidental

grounding and cause personal injury.

2.Connect TestBook to vehicle and depressurise

fuel system.

3.Remove fuel pump.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Pump - fuel.

4.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturers instructions for the

connection and safe use of the appliance.

Refill

1.Fit fuel pump unit.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Pump - fuel.

2.Refill fuel tank with extracted fuel.

3.Connect battery leads, positive lead first.

Page 578 of 1672

FUEL DELIVERY SYSTEM - V8

REPAIRS 19-2-13

REPAIRS

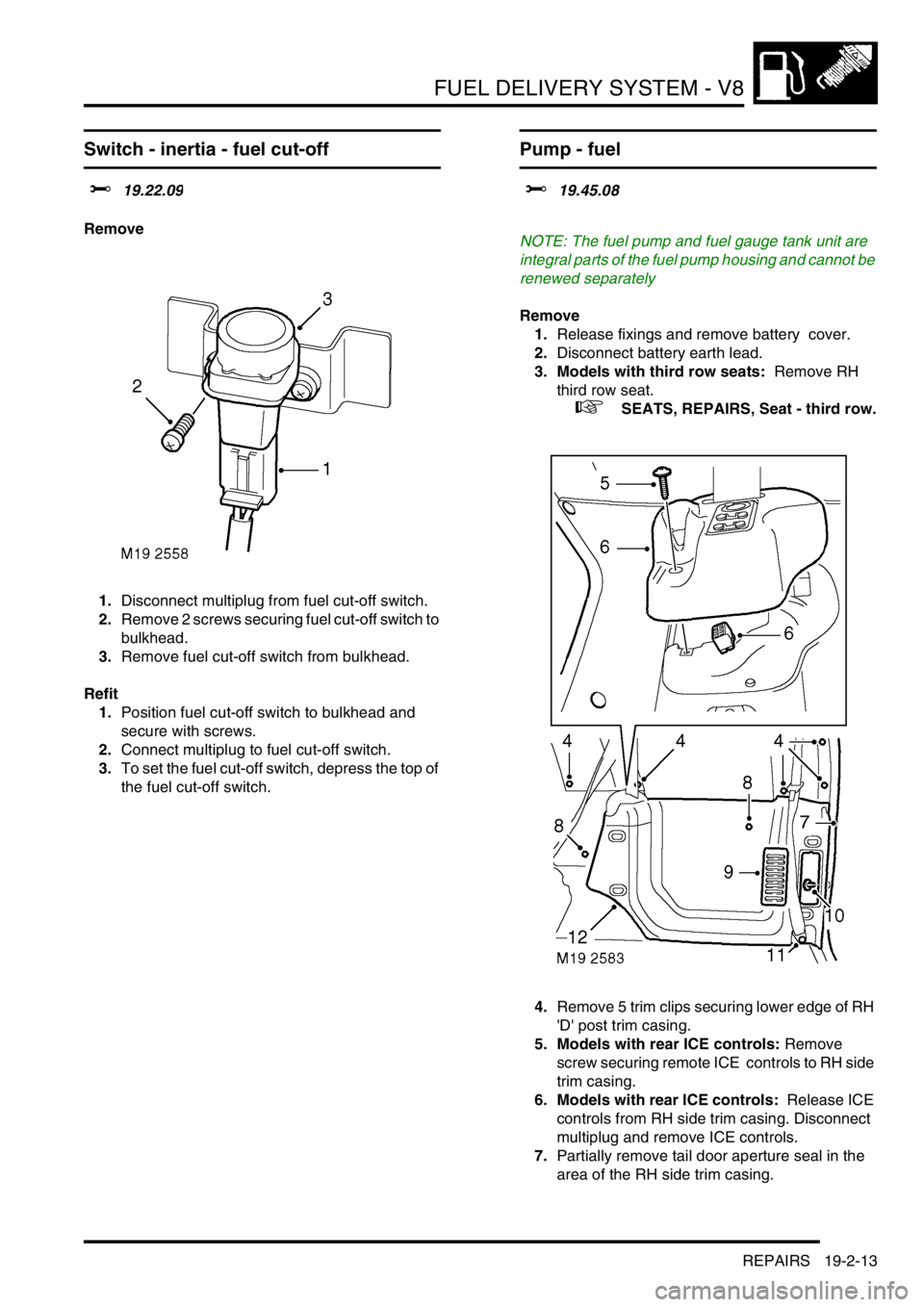

Switch - inertia - fuel cut-off

$% 19.22.09

Remove

1.Disconnect multiplug from fuel cut-off switch.

2.Remove 2 screws securing fuel cut-off switch to

bulkhead.

3.Remove fuel cut-off switch from bulkhead.

Refit

1.Position fuel cut-off switch to bulkhead and

secure with screws.

2.Connect multiplug to fuel cut-off switch.

3.To set the fuel cut-off switch, depress the top of

the fuel cut-off switch.

Pump - fuel

$% 19.45.08

NOTE: The fuel pump and fuel gauge tank unit are

integral parts of the fuel pump housing and cannot be

renewed separately

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3. Models with third row seats: Remove RH

third row seat.

+ SEATS, REPAIRS, Seat - third row.

4.Remove 5 trim clips securing lower edge of RH

'D' post trim casing.

5. Models with rear ICE controls: Remove

screw securing remote ICE controls to RH side

trim casing.

6. Models with rear ICE controls: Release ICE

controls from RH side trim casing. Disconnect

multiplug and remove ICE controls.

7.Partially remove tail door aperture seal in the

area of the RH side trim casing.

Page 579 of 1672

FUEL DELIVERY SYSTEM - V8

19-2-14 REPAIRS

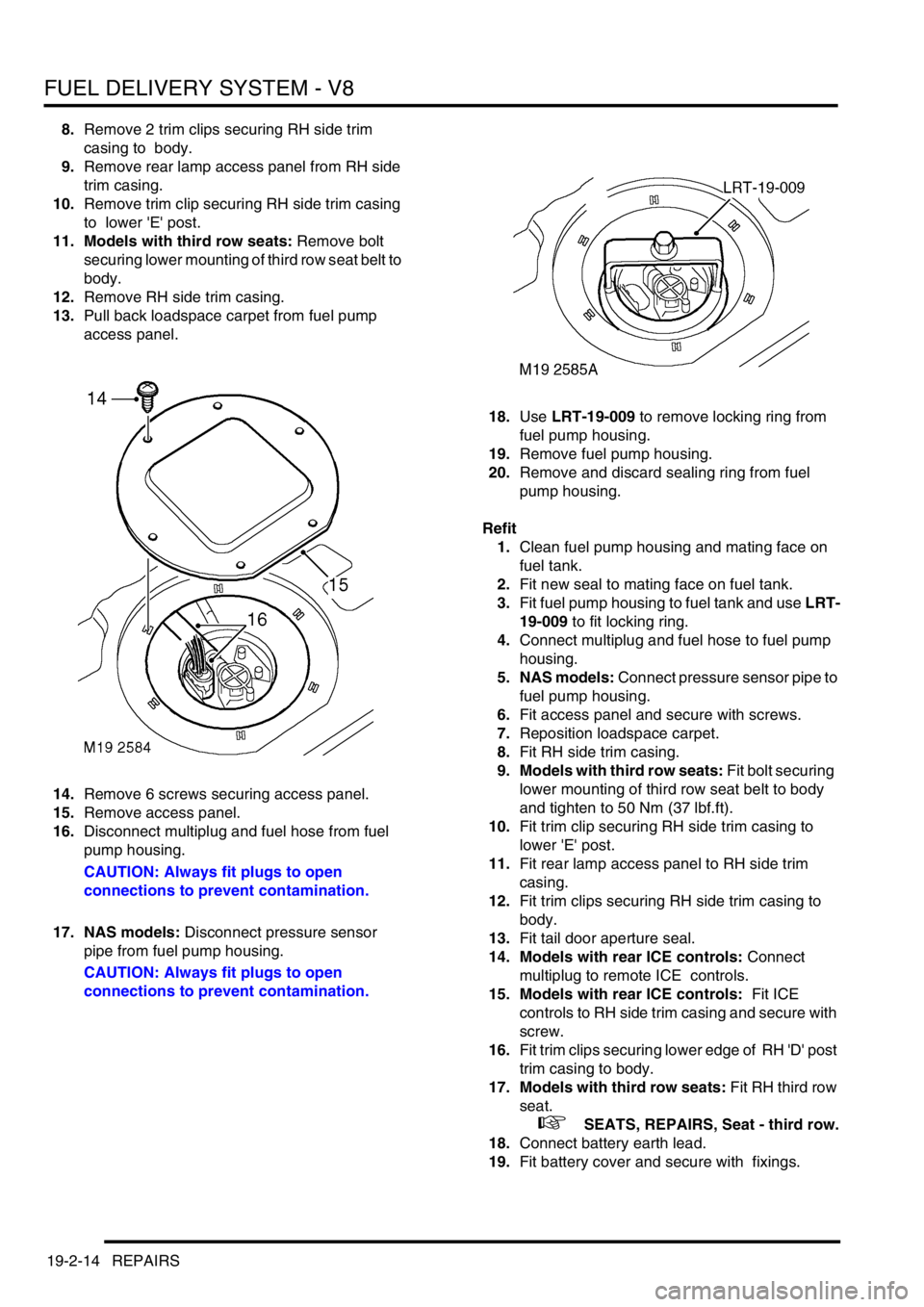

8.Remove 2 trim clips securing RH side trim

casing to body.

9.Remove rear lamp access panel from RH side

trim casing.

10.Remove trim clip securing RH side trim casing

to lower 'E' post.

11. Models with third row seats: Remove bolt

securing lower mounting of third row seat belt to

body.

12.Remove RH side trim casing.

13.Pull back loadspace carpet from fuel pump

access panel.

14.Remove 6 screws securing access panel.

15.Remove access panel.

16.Disconnect multiplug and fuel hose from fuel

pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.

17. NAS models: Disconnect pressure sensor

pipe from fuel pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.18.Use LRT-19-009 to remove locking ring from

fuel pump housing.

19.Remove fuel pump housing.

20.Remove and discard sealing ring from fuel

pump housing.

Refit

1.Clean fuel pump housing and mating face on

fuel tank.

2.Fit new seal to mating face on fuel tank.

3.Fit fuel pump housing to fuel tank and use LRT-

19-009 to fit locking ring.

4.Connect multiplug and fuel hose to fuel pump

housing.

5. NAS models: Connect pressure sensor pipe to

fuel pump housing.

6.Fit access panel and secure with screws.

7.Reposition loadspace carpet.

8.Fit RH side trim casing.

9. Models with third row seats: Fit bolt securing

lower mounting of third row seat belt to body

and tighten to 50 Nm (37 lbf.ft).

10.Fit trim clip securing RH side trim casing to

lower 'E' post.

11.Fit rear lamp access panel to RH side trim

casing.

12.Fit trim clips securing RH side trim casing to

body.

13.Fit tail door aperture seal.

14. Models with rear ICE controls: Connect

multiplug to remote ICE controls.

15. Models with rear ICE controls: Fit ICE

controls to RH side trim casing and secure with

screw.

16.Fit trim clips securing lower edge of RH 'D' post

trim casing to body.

17. Models with third row seats: Fit RH third row

seat.

+ SEATS, REPAIRS, Seat - third row.

18.Connect battery earth lead.

19.Fit battery cover and secure with fixings.

Page 596 of 1672

COOLING SYSTEM - TD5

ADJUSTMENTS 26-1-13

ADJUST ME NTS

Drain and refill

$% 26.10.01

WARNING: Since injury such as scalding could

be caused by escaping steam or coolant, do not

remove the filler cap from the coolant expansion

tank while the system is hot.

Drain

1.Visually check engine and cooling system for

signs of coolant leaks.

2.Examine hoses for signs of cracking, distortion

and security of connections.

3.Position drain tray to collect coolant.

4.Remove expansion tank filler cap.

5.Remove drain plug access cover from

underbelly panel.

6.Remove drain plug from coolant pump feed

pipe and allow cooling system to drain. Discard

drain plug sealing washer.

Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Fit new sealing washer to drain plug. Fit and

tighten drain plug in coolant pump feed pipe.

3.Fit access cover to underbelly panel.

4.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Anti-Freeze Concentration.5.Remove bleed screw from top hose.

6.Unclip the bleed hose from the battery box.

7.Unclip the expansion tank from its mounting

bracket, remove the expansion tank cap and

raise the expansion tank vertically 10 cm (4 in).

Retain the tank in this position.

8.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

9.Fit the bleed screw, then, with the expansion

tank still raised, continue filling the system until

coolant level reaches the cold level mark on

expansion tank.

10.Fit expansion tank filler cap, fit the expansion

tank to its mounting bracket and clip the bleed

hose to the battery box.

11.Start and run engine until normal operating

temperature is reached, and check for leaks.

12.Switch off engine and allow to cool.

13.Check for leaks and top-up coolant to the cold

level mark on expansion tank

Page 598 of 1672

COOLING SYSTEM - TD5

REPAIRS 26-1-15

REPAIRS

Fan - viscous

$% 26.25.19

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Remove upper fan cowl.

5.Remove viscous fan using tool LRT-12-093

and tool LRT-12-094.

RH thread.

Refit

1.Position viscous fan and tighten using tool

LRT-12-093 and tool LRT-12-094.

2.Fit upper fan cowl.

3. Fit engine acoustic cover and tighten bolts.

4.Connect battery earth lead.

5.Fit battery cover and secure with fixings.

Radiator

$% 26.40.01

Remove

1.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

2.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

3.Remove clip and disconnect bleed hose from

radiator.

4.Release clip and disconnect top hose from

radiator.

5.Release clip and disconnect bottom hose from

radiator.

6.Release clip and disconnect engine oil cooler

hose from radiator.

7.Release clip and disconnect fuel cooler hose

from radiator.