radiator LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 269 of 1672

ENGINE - V8

12-2-26 REPAIRS

Engine assembly

$% 12.41.01.99

Remove

1.Drain engine oil and remove oil filter.

2.Remove radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

3.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

4.Remove ignition coil assemblies.

5.Position absorbent material to catch spillage

and disconnect fuel pipe from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Release 2 hose clips and remove top hose.

7.Using a 15 mm spanner, release auxiliary drive

belt tension and remove drive belt. 8.Remove 3 bolts securing ACE pump, release

pump and tie aside.

9.Disconnect multiplug from A/C compressor.

10.Remove 4 bolts securing A/C compressor,

release compressor and tie aside.

Page 273 of 1672

ENGINE - V8

12-2-30 REPAIRS

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes. 27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 282 of 1672

ENGINE - V8

REPAIRS 12-2-39

Cooler - engine oil

$% 12.60.68

Remove

1.Release fixings and remove battery cover.

2.Release fixings and remove cooling fan cowl.

3.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

4.Remove 6 scrivets and remove LH and RH air

deflectors from front panel.

5.Remove nut and move LH horn aside. 6.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

7.Remove 4 screws securing air conditioning

condenser LH and RH upper mounting

brackets to condenser.

8.Remove condenser upper mounting brackets

with rubber mounts from radiator extension

brackets.

9.Remove 2 bolts securing LH and RH extension

brackets to radiator and remove brackets.

10.Position absorbent cloth under each oil cooler

hose connection to collect oil spillage.

Page 283 of 1672

ENGINE - V8

12-2-40 REPAIRS

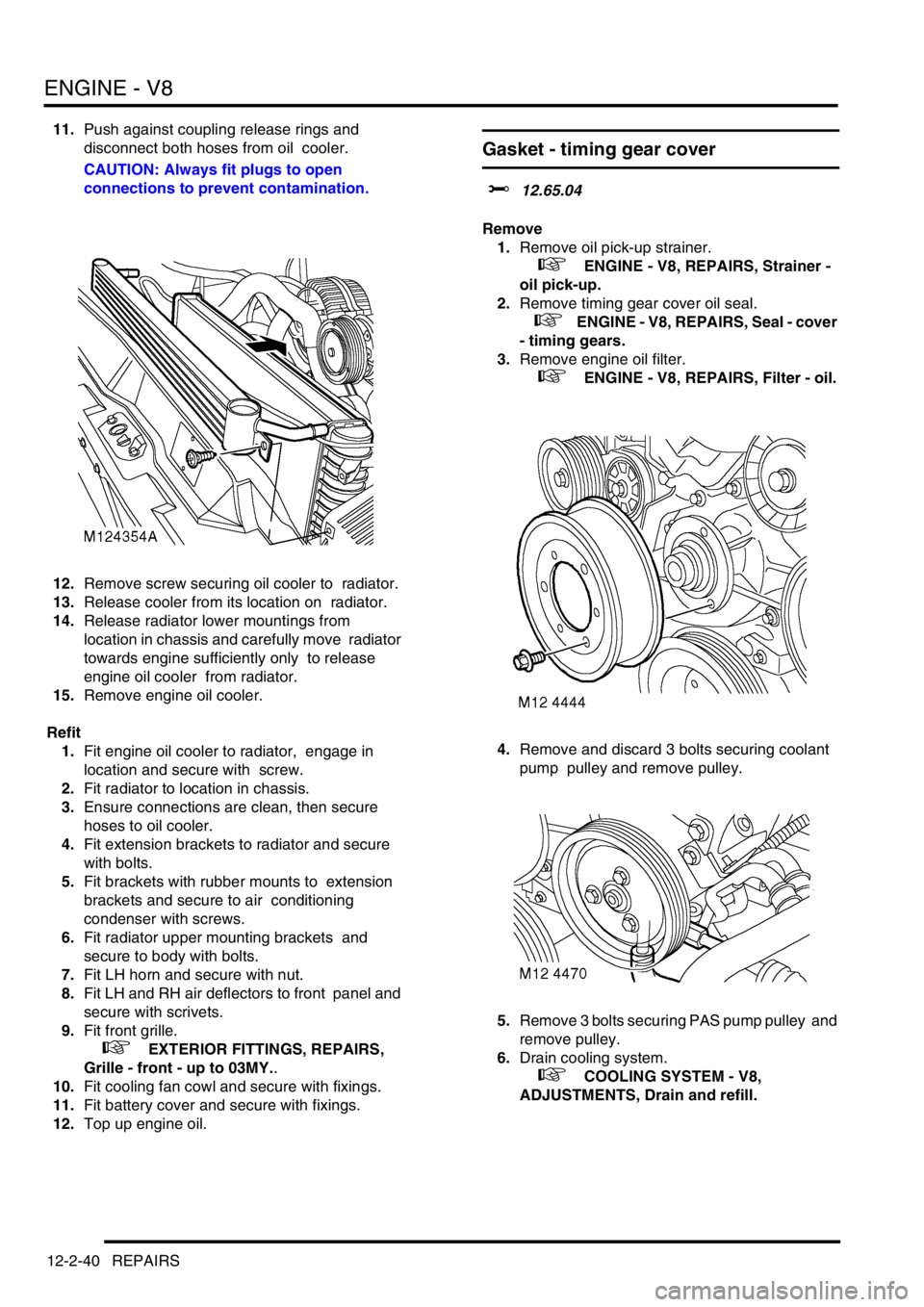

11.Push against coupling release rings and

disconnect both hoses from oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

12.Remove screw securing oil cooler to radiator.

13.Release cooler from its location on radiator.

14.Release radiator lower mountings from

location in chassis and carefully move radiator

towards engine sufficiently only to release

engine oil cooler from radiator.

15.Remove engine oil cooler.

Refit

1.Fit engine oil cooler to radiator, engage in

location and secure with screw.

2.Fit radiator to location in chassis.

3.Ensure connections are clean, then secure

hoses to oil cooler.

4.Fit extension brackets to radiator and secure

with bolts.

5.Fit brackets with rubber mounts to extension

brackets and secure to air conditioning

condenser with screws.

6.Fit radiator upper mounting brackets and

secure to body with bolts.

7.Fit LH horn and secure with nut.

8.Fit LH and RH air deflectors to front panel and

secure with scrivets.

9.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY..

10.Fit cooling fan cowl and secure with fixings.

11.Fit battery cover and secure with fixings.

12.Top up engine oil.

Gasket - timing gear cover

$% 12.65.04

Remove

1.Remove oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

2.Remove timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

3.Remove engine oil filter.

+ ENGINE - V8, REPAIRS, Filter - oil.

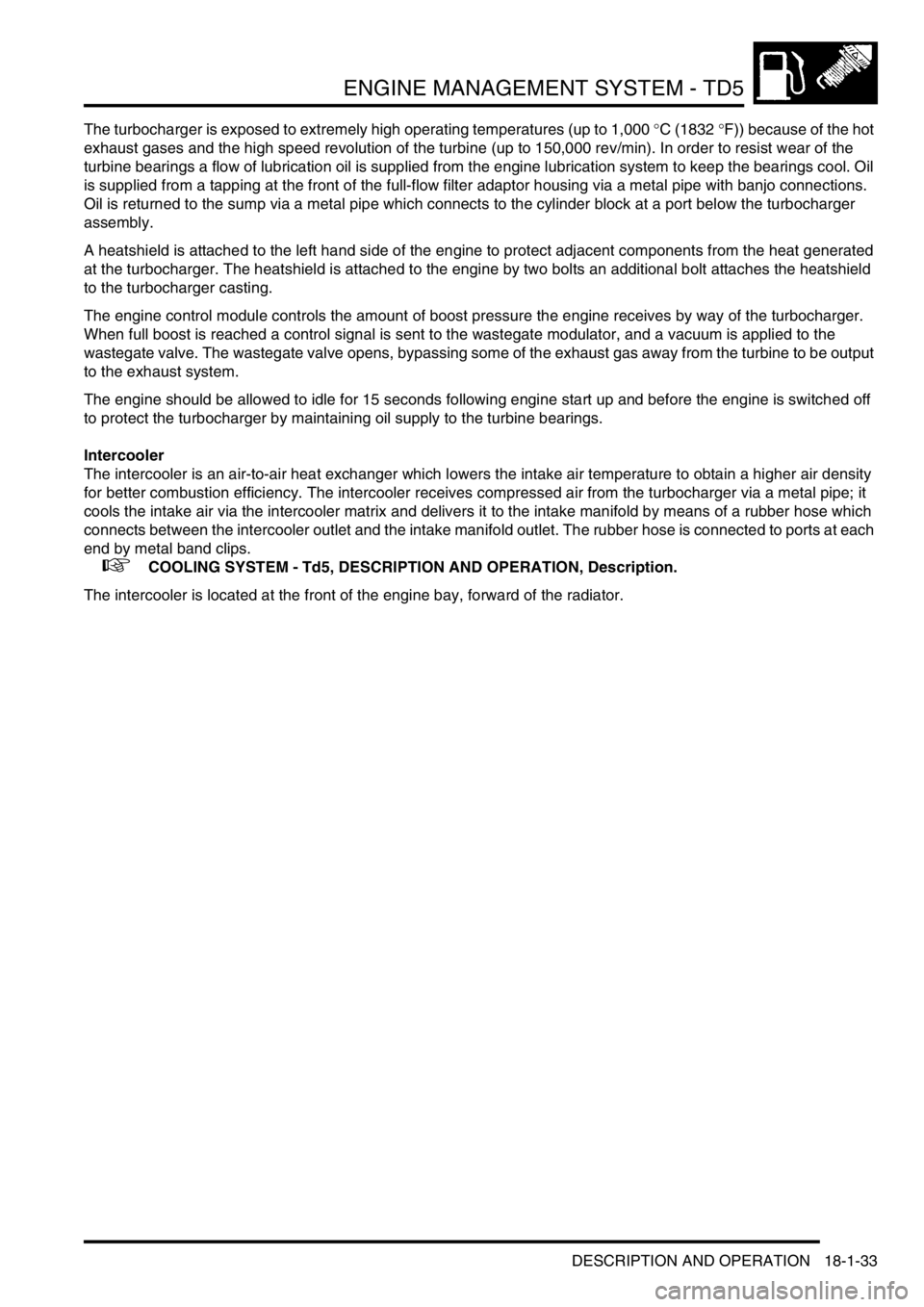

4.Remove and discard 3 bolts securing coolant

pump pulley and remove pulley.

5.Remove 3 bolts securing PAS pump pulley and

remove pulley.

6.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 426 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-33

The turbocharger is exposed to extremely high operating temperatures (up to 1,000 °C (1832 °F)) because of the hot

exhaust gases and the high speed revolution of the turbine (up to 150,000 rev/min). In order to resist wear of the

turbine bearings a flow of lubrication oil is supplied from the engine lubrication system to keep the bearings cool. Oil

is supplied from a tapping at the front of the full-flow filter adaptor housing via a metal pipe with banjo connections.

Oil is returned to the sump via a metal pipe which connects to the cylinder block at a port below the turbocharger

assembly.

A heatshield is attached to the left hand side of the engine to protect adjacent components from the heat generated

at the turbocharger. The heatshield is attached to the engine by two bolts an additional bolt attaches the heatshield

to the turbocharger casting.

The engine control module controls the amount of boost pressure the engine receives by way of the turbocharger.

When full boost is reached a control signal is sent to the wastegate modulator, and a vacuum is applied to the

wastegate valve. The wastegate valve opens, bypassing some of the exhaust gas away from the turbine to be output

to the exhaust system.

The engine should be allowed to idle for 15 seconds following engine start up and before the engine is switched off

to protect the turbocharger by maintaining oil supply to the turbine bearings.

Intercooler

The intercooler is an air-to-air heat exchanger which lowers the intake air temperature to obtain a higher air density

for better combustion efficiency. The intercooler receives compressed air from the turbocharger via a metal pipe; it

cools the intake air via the intercooler matrix and delivers it to the intake manifold by means of a rubber hose which

connects between the intercooler outlet and the intake manifold outlet. The rubber hose is connected to ports at each

end by metal band clips.

+ COOLING SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

The intercooler is located at the front of the engine bay, forward of the radiator.

Page 450 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-57

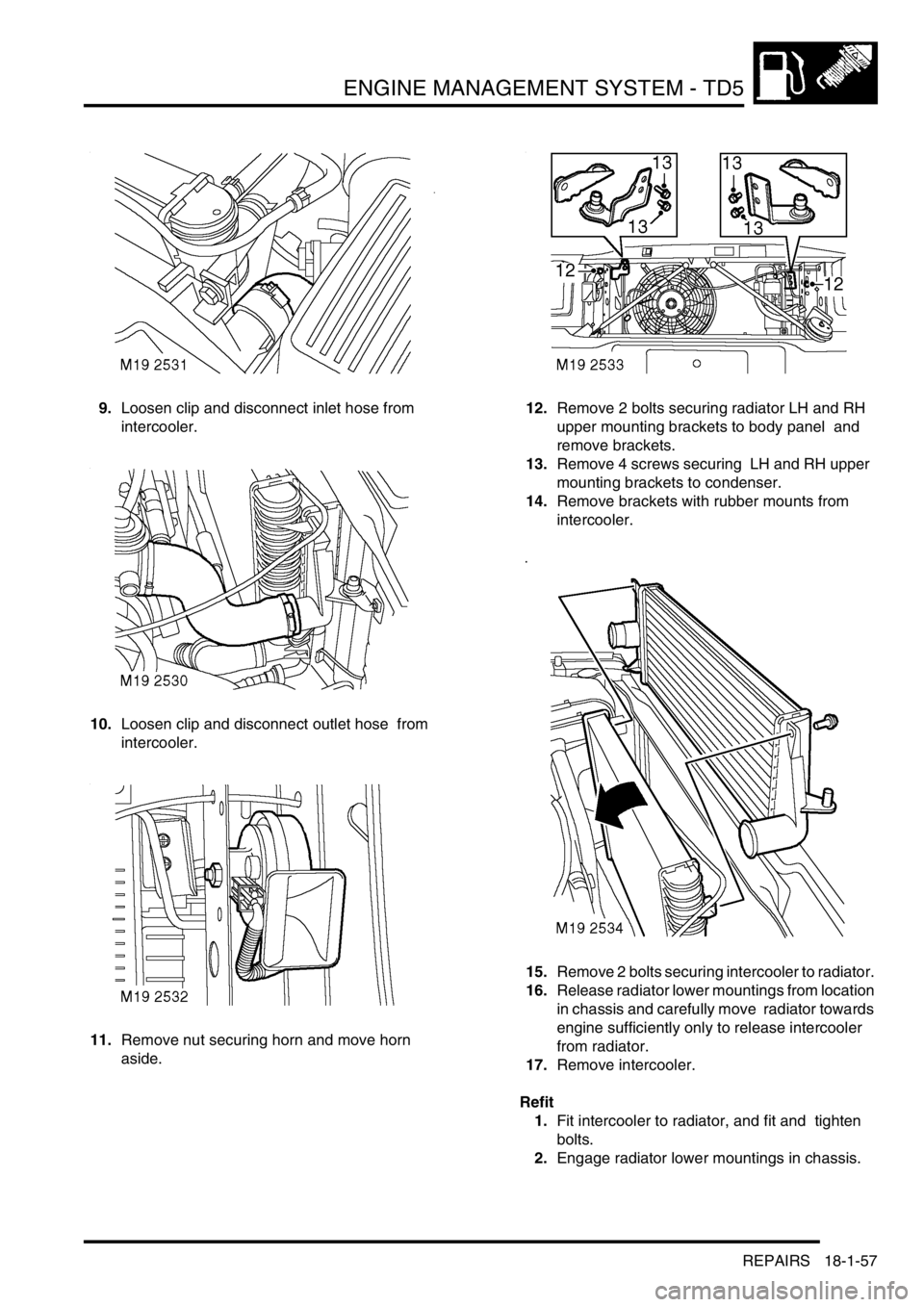

9.Loosen clip and disconnect inlet hose from

intercooler.

10.Loosen clip and disconnect outlet hose from

intercooler.

11.Remove nut securing horn and move horn

aside. 12.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

13.Remove 4 screws securing LH and RH upper

mounting brackets to condenser.

14.Remove brackets with rubber mounts from

intercooler.

15.Remove 2 bolts securing intercooler to radiator.

16.Release radiator lower mountings from location

in chassis and carefully move radiator towards

engine sufficiently only to release intercooler

from radiator.

17.Remove intercooler.

Refit

1.Fit intercooler to radiator, and fit and tighten

bolts.

2.Engage radiator lower mountings in chassis.

Page 451 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-58 REPAIRS

3.Fit brackets with rubber mountings to

intercooler and fit and tighten screws securing

brackets to condenser.

4.Fit radiator upper mounting brackets and

tighten bolts.

5.Fit LH horn and secure with nut.

6.Connect inlet and outlet hoses to intercooler

and tighten clips.

7.Fit lower half of fan cowl and secure with

screws.

8.Fit LH and RH air deflectors to front panel and

secure with scrivets.

9.Fit front grille.

10.Fit battery carrier and secure with bolts.

11.Fit ECM and secure with screw.

12.Fit jack to battery carrier.

13.Fit battery.

14.Fit cooling fan and coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

Valve - solenoid boost control

$% 19.42.30

Remove

1.Loosen clip and release air intake hose from

MAF sensor.

2.Release clips and disconnect vacuum hoses

from solenoid valve.

3.Disconnect multiplug from solenoid valve.

4.Remove 2 bolts and remove solenoid valve.

Refit

1.Position solenoid valve and tighten bolts.

2.Connect multiplug to solenoid valve.

3.Connect vacuum hoses and secure with clips.

4.Position air intake hose to MAF sensor and

secure clip.

Page 475 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-18 DESCRIPTION AND OPERATION

Thermostat Monitoring sensor

The thermostat monitoring sensor is located in the radiator, adjacent the bottom hose. The ECM compares the

temperature measured by the thermostat monitoring sensor to the temperature measured by the ECT sensor. If the

difference between the two readings is too great, the ECM determines the thermostat is stuck. In this case, the ECM

registers a fault code in its memory.

The thermostat monitoring sensor works as a Negative Temperature Coefficient (NTC) sensor. As temperature rises,

the resistance in the sensor decreases, as temperature decreases, the resistance in the sensor increases. With this

information, the ECM is able to monitor the performance of the thermostat. The normal operating parameters of the

thermostat monitoring sensor are as follows:

Page 477 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-20 DESCRIPTION AND OPERATION

Should a malfunction occur, the following fault codes may be evident and can be retrieved by TestBook:

Mass Air Flow (MAF)/ Inlet Air Temperature (IAT) sensor (C0149)

The MAF/ IAT sensors are combined into a single unit and located between the air filter housing and the inlet manifold.

The ECM receives input signals from the MAF/ IAT sensor to calculate the mass of air flowing into the engine inlet

manifold.

Input/Output

The MAF sensor has both electrical input and output. Input to the MAF sensor comes from two different sources.

Battery voltage is supplied to the MAF sensor via fuse 2 of the engine compartment fuse box. The MAF sensor also

utilises a 5 volt reference input via pin 7 of connector C0636 of the ECM. The MAF sensor output voltage is measured

via pin 23 of connector C0636 of the ECM.

The IAT sensor has only electrical output. Output from the IAT sensor is measured at pin 34 of connector C0636 of

the ECM, this is a variable voltage/ resistance measured by the sensor to provide air temperature information to the

ECM.

The MAF/ IAT sensor share the same sensor earth. Sensor earth is via pin 9 of connector C0636 of the ECM.

The MAF/ IAT sensor and its connector has silver plated terminals for its low current signals to protect against

corrosion. DO NOT apply 12V to the 5V supply, as this will destroy the internal circuitry. The MAF/IAT sensor should

not be dropped or roughly handled and should be kept free from contamination.

P code J2012 description Land Rover description

P1117 Radiator outlet temperature

thermister lowThermostat reading below -33 °C (-

27 °F)

P1118 Radiator outlet temperature

thermister highThermostat reading above 140 °C

(284 °F)

P0126 Engine thermostat defective Difference in radiator and engine

coolant temperatures too small

Page 499 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-42 DESCRIPTION AND OPERATION

Cooling fan relay

The cooling fan relay is located in the engine compartment fuse box. It is a four pin normally open relay. The relay

must be energised to drive the cooling fan.

The cooling fan is used to cool both the condenser in which the ATC refrigerant is held and the radiator. This fan is

used especially when the engine is operating at excessively high temperatures. It is also used as a part of the ECM

backup strategy if the ECT fails.

Input/Output

The ECM provides the earth for the relay coils to allow the relay contacts to close and the cooling fan motor to receive

battery voltage. The ECM uses a transistor as a switch to generate an open circuit in the earth path of the relay

windings. When the ECM opens the earth path, the return spring in the relay will pull the contacts apart to shut down

the cooling fan motor drive.

Input to the cooling fan relay switching contacts is via fuse 5 located in the engine compartment fuse box. The relay

coils are supplied with battery voltage from the main relay, also located in the engine compartment fuse box. The earth

path for the relay coils is via pin 31 of the ECM connector C0636. When the relay is energised the output from the

switching contacts is directly to the cooling fan motor.

The cooling fan relay can fail in the following ways:

lRelay open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lBroken return spring.

In the event of a cooling fan relay failure, the cooling fan does not work.