air condition LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 174 of 1672

ENGINE - TD5

ADJUSTMENTS 12-1-35

ADJUST ME NTS

Engine oil pressure check

$% 12.90.09.01

Check

1.Remove oil pressure switch.

+ ENGINE - Td5, REPAIRS, Switch -

oil pressure.

2.Connect pressure check kit LRT-12-052C

adaptor and gauge to oil pressure switch

position on oil cooler.

3.Check and if necessary top up engine oil.

4.Run engine at idle speed and check that oil

pressure is within limits given.

+ GENERAL DATA, Engine - Td5.

5.Switch off ignition.

6.Remove pressure check kit LRT-12-052C.

7.Clean oil spillage.

8.Fit oil pressure switch.

+ ENGINE - Td5, REPAIRS, Switch -

oil pressure.

Adjust

1.If engine oil pressure is outside of specified

limits, check condition of oil pump and/or main

and connecting rod bearings.

Page 203 of 1672

ENGINE - TD5

12-1-64 REPAIRS

Refit

1.Clean oil cooler and mating faces.

2.Fit oil pressure switch and tighten to 9 Nm (7

lbf.ft).

3.Position new gasket and fit oil cooler housing,

tighten bolts to 25 Nm (18 lbf.ft).

4.Position and fit oil filter adaptor housing,

tighten bolts to 25 Nm (18 lbf. ft).

5.Fit oil filter, tighten hand tight then a further half

turn.

6.Position coolant hose to oil cooler and secure

clip.

7.Position coolant pipe bolt and tighten to 50 Nm

(37 lbf.ft) .

8.Connect multiplug to oil pressure switch.

9.Fit centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

10.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

11.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

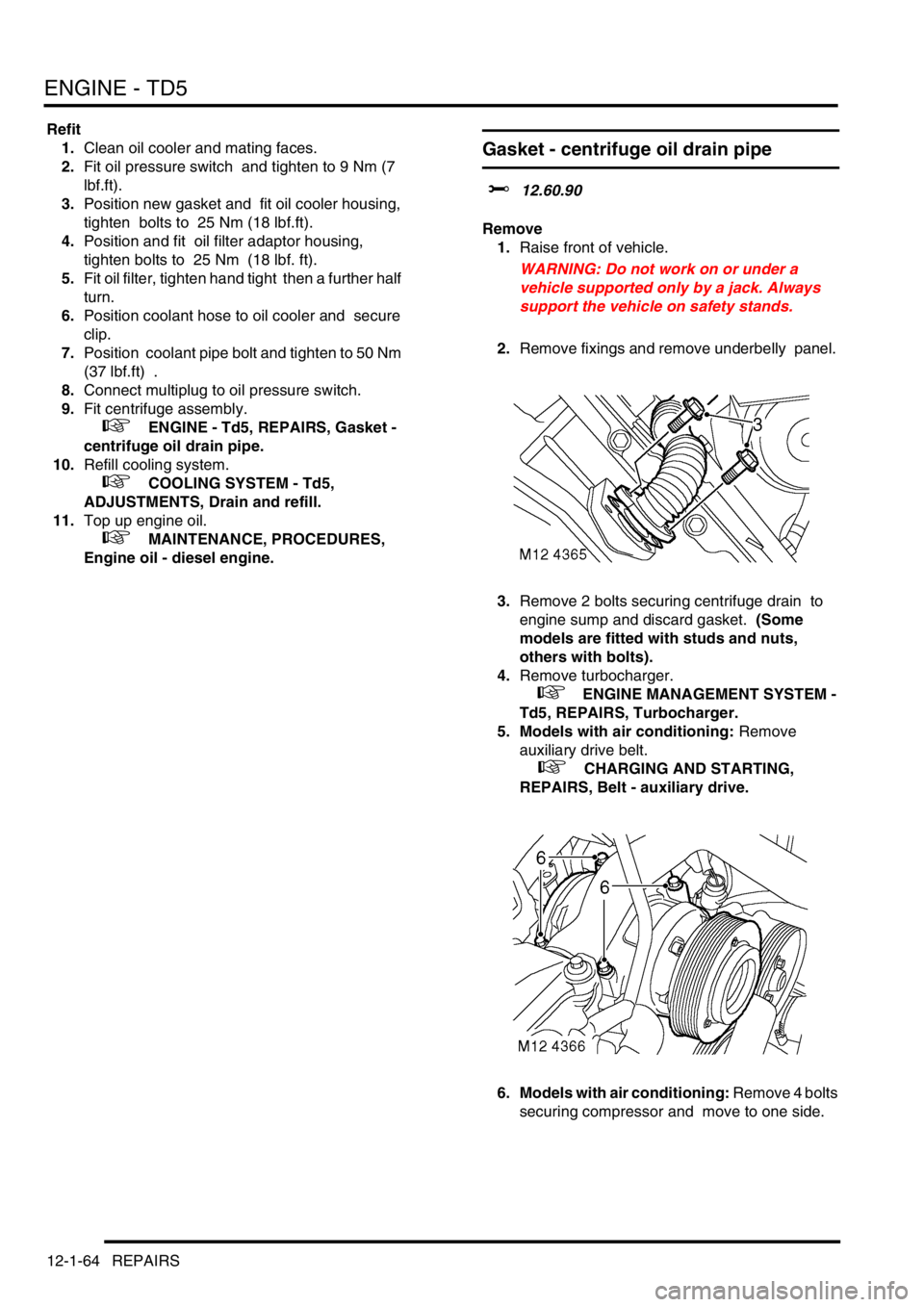

Gasket - centrifuge oil drain pipe

$% 12.60.90

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove fixings and remove underbelly panel.

3.Remove 2 bolts securing centrifuge drain to

engine sump and discard gasket. (Some

models are fitted with studs and nuts,

others with bolts).

4.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

5. Models with air conditioning: Remove

auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

6. Models with air conditioning: Remove 4 bolts

securing compressor and move to one side.

Page 204 of 1672

ENGINE - TD5

REPAIRS 12-1-65

7.Remove 3 bolts securing centrifuge to engine

oil cooler.

8.Remove centrifuge and discard 'O' ring.

9.Remove 2 bolts, remove drain pipe from

centrifuge and discard gasket. Refit

1.Clean mating faces of centrifuge, oil cooler and

sump.

2.Position new gasket and fit oil drain pipe to

centrifuge, tighten bolts to 10 Nm (7 lbf.ft).

CAUTION: Gasket must be fitted dry.

3.Position new 'O' ring to oil cooler.

4.Position centrifuge to oil cooler housing and

tighten bolts to 25 Nm (18 lbf.ft).

5.Using a new gasket, align the centrifuge oil

drain pipe to sump and tighten bolts to 10 Nm

(7 lbf.ft).

CAUTION: Gasket must be fitted dry.

6. Models with air conditioning: Position A/C

compressor and tighten bolts to 25 Nm (18

lbf.ft).

7.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

8. Models with air conditioning: Fit auxiliary

drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

9.Fit underbelly panel and secure with fixings.

10.Remove stand(s) and lower vehicle.

Page 254 of 1672

ENGINE - V8

ADJUSTMENTS 12-2-11

ADJUST ME NTS

Engine oil pressure check

$% 12.90.09.01

Check

1.Remove oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

2.Connect pressure check kit LRT-12-052C

adaptor and gauge to oil pressure switch

position on timing gear cover.

3.Check and if necessary top up engine oil.

4.Run engine at idle speed and check that oil

pressure is within limits given.

+ GENERAL DATA, Engine - V8.

5.Switch off ignition.

6.Remove pressure check kit LRT-12-052C.

7.Clean oil spillage.

8.Fit oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

Adjust

1.If engine oil pressure is below figures given,

check condition of oil pump and/or main and

big end bearings.

Page 262 of 1672

ENGINE - V8

REPAIRS 12-2-19

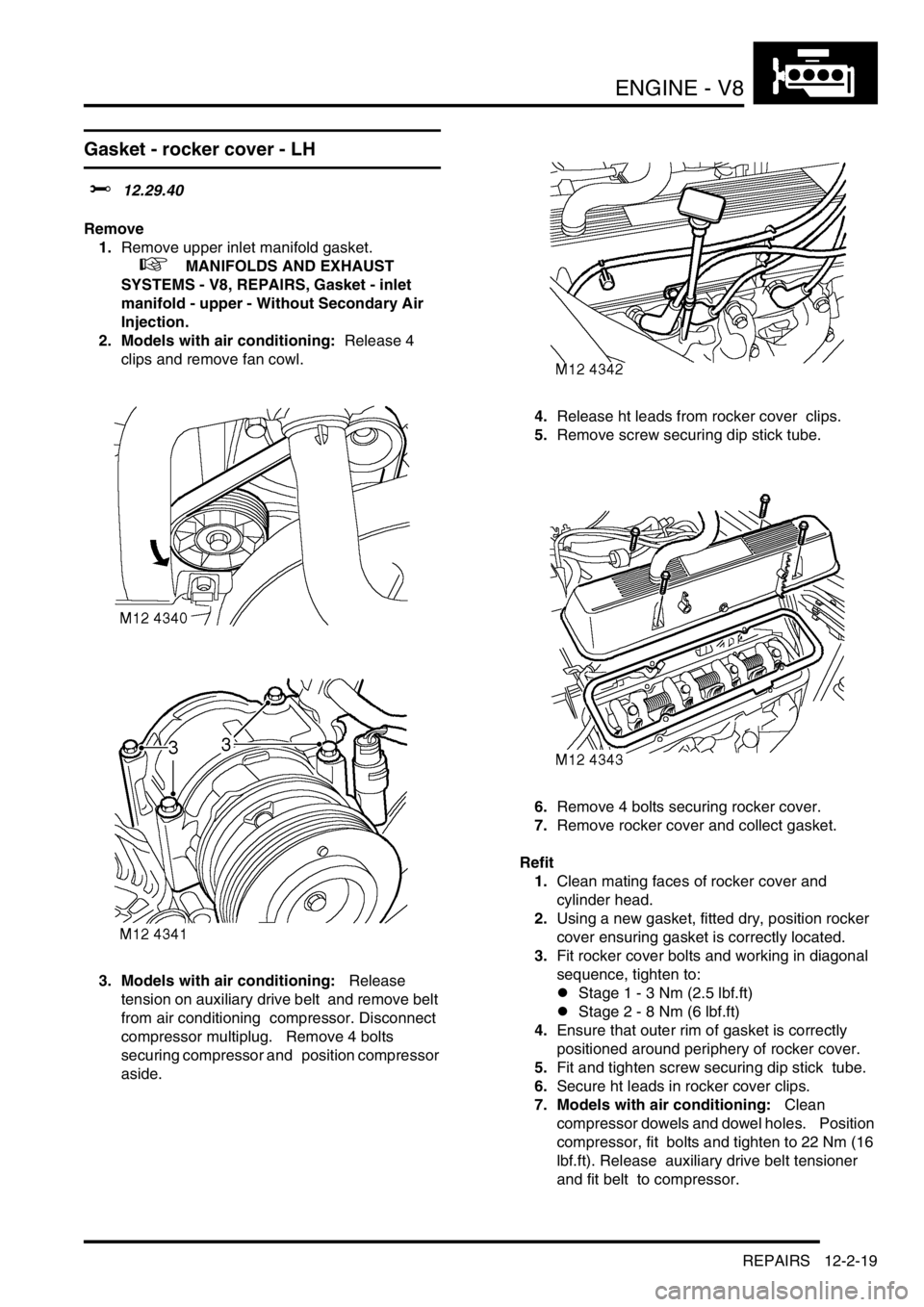

Gasket - rocker cover - LH

$% 12.29.40

Remove

1.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

2. Models with air conditioning: Release 4

clips and remove fan cowl.

3. Models with air conditioning: Release

tension on auxiliary drive belt and remove belt

from air conditioning compressor. Disconnect

compressor multiplug. Remove 4 bolts

securing compressor and position compressor

aside. 4.Release ht leads from rocker cover clips.

5.Remove screw securing dip stick tube.

6.Remove 4 bolts securing rocker cover.

7.Remove rocker cover and collect gasket.

Refit

1.Clean mating faces of rocker cover and

cylinder head.

2.Using a new gasket, fitted dry, position rocker

cover ensuring gasket is correctly located.

3.Fit rocker cover bolts and working in diagonal

sequence, tighten to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

4.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

5.Fit and tighten screw securing dip stick tube.

6.Secure ht leads in rocker cover clips.

7. Models with air conditioning: Clean

compressor dowels and dowel holes. Position

compressor, fit bolts and tighten to 22 Nm (16

lbf.ft). Release auxiliary drive belt tensioner

and fit belt to compressor.

Page 263 of 1672

ENGINE - V8

12-2-20 REPAIRS

8. Models with air conditioning: Position fan

cowl and secure clips.

9.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

Gasket - rocker cover - RH

$% 12.29.41

Remove

1.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

3. Models with SAI: Disconnect 2 air manifold

unions from adapters in cylinder head and

remove manifold.

4.Remove 2 bolts securing coolant rails to inlet

manifold.

Page 282 of 1672

ENGINE - V8

REPAIRS 12-2-39

Cooler - engine oil

$% 12.60.68

Remove

1.Release fixings and remove battery cover.

2.Release fixings and remove cooling fan cowl.

3.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

4.Remove 6 scrivets and remove LH and RH air

deflectors from front panel.

5.Remove nut and move LH horn aside. 6.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

7.Remove 4 screws securing air conditioning

condenser LH and RH upper mounting

brackets to condenser.

8.Remove condenser upper mounting brackets

with rubber mounts from radiator extension

brackets.

9.Remove 2 bolts securing LH and RH extension

brackets to radiator and remove brackets.

10.Position absorbent cloth under each oil cooler

hose connection to collect oil spillage.

Page 283 of 1672

ENGINE - V8

12-2-40 REPAIRS

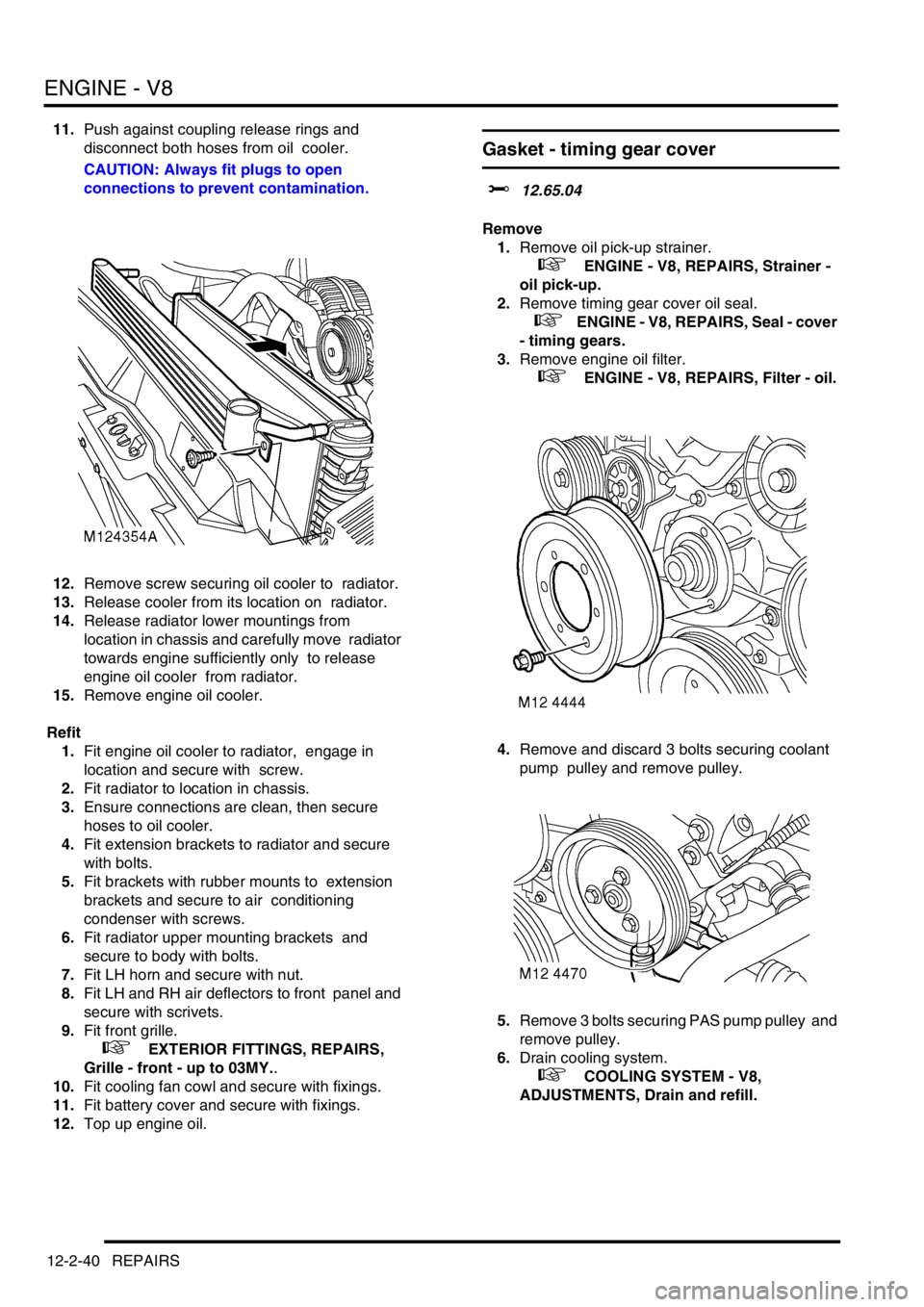

11.Push against coupling release rings and

disconnect both hoses from oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

12.Remove screw securing oil cooler to radiator.

13.Release cooler from its location on radiator.

14.Release radiator lower mountings from

location in chassis and carefully move radiator

towards engine sufficiently only to release

engine oil cooler from radiator.

15.Remove engine oil cooler.

Refit

1.Fit engine oil cooler to radiator, engage in

location and secure with screw.

2.Fit radiator to location in chassis.

3.Ensure connections are clean, then secure

hoses to oil cooler.

4.Fit extension brackets to radiator and secure

with bolts.

5.Fit brackets with rubber mounts to extension

brackets and secure to air conditioning

condenser with screws.

6.Fit radiator upper mounting brackets and

secure to body with bolts.

7.Fit LH horn and secure with nut.

8.Fit LH and RH air deflectors to front panel and

secure with scrivets.

9.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY..

10.Fit cooling fan cowl and secure with fixings.

11.Fit battery cover and secure with fixings.

12.Top up engine oil.

Gasket - timing gear cover

$% 12.65.04

Remove

1.Remove oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

2.Remove timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

3.Remove engine oil filter.

+ ENGINE - V8, REPAIRS, Filter - oil.

4.Remove and discard 3 bolts securing coolant

pump pulley and remove pulley.

5.Remove 3 bolts securing PAS pump pulley and

remove pulley.

6.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 325 of 1672

EMISSION CONTROL - TD5

17-1-4 DESCRIPTION AND OPERATION

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems fitted

to Land Rover vehicles are designed to maintain the emission levels within the legal limits pertaining for the specified

market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order, so that it operates at its optimum condition.

In addition to emissions improvements through engine design and the application of electronic engine management

systems, special emission control systems are used to limit the pollutant levels developed under certain conditions.

Two main types of additional emission control system are utilised with the Td5 engine to reduce the levels of harmful

emissions released into the atmosphere. These are as follows:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust gas recirculation – to reduce NO

2 emissions.

Crankcase emission control

All internal combustion engines generate oil vapour and smoke in the crankcase as a result of high crankcase

temperatures and piston ring and valve stem blow-by, a closed crankcase ventilation system is used to vent

crankcase gases back to the air induction system and so reduce the emission of hydrocarbons.

Gases from the crankcase are drawn into the inlet manifold to be burnt in the combustion chambers with the fresh air/

fuel mixture. The system provides effective emission control under all engine operating conditions.

Crankcase gases are drawn through the breather port in the top of the camshaft cover and routed through the breather

hose and breather valve on the flexible air intake duct to be drawn into the turbocharger intake for delivery to the air

inlet manifold via an intercooler.

An oil separator plate is included in the camshaft cover which removes the heavy particles of oil before the crankcase

gas leaves via the camshaft cover port. The rocker cover features circular chambers which promote swirl in the oil

mist emanating from the cylinder head and camshaft carrier. As the mist passes through the series of chambers

between the rocker cover and oil separator plate, oil particles are thrown against the separator walls where they

condense and fall back into the cylinder head via two air inlet holes located at each end of the rocker cover.

The breather valve is a depression limiting valve which progressively closes as engine speed increases, thereby

limiting the depression in the crankcase. The valve is of moulded plastic construction and has a port on the underside

which plugs into a port in the flexible air intake duct. A port on the side of the breather valve connects to the camshaft

cover port by means of a breather hose which is constructed from a heavy-duty braided rubber hose which is held in

place by hose clips. A corrugated plastic sleeve is used to give further protection to the breather hose. The breather

valve is orientation sensitive, and “TOP” is marked on the upper surface to ensure it is mounted correctly.

It is important that the system is airtight so hose connections to ports should be checked and the condition of the

breather hose should be periodically inspected to ensure it is in good condition.

Page 326 of 1672

EMISSION CONTROL - TD5

DESCRIPTION AND OPERATION 17-1-5

Exhaust gas recirculation

The exhaust gas recirculation (EGR) valve permits a controlled amount of exhaust gas to combine with the fresh air

entering the engine. The exhaust gas reduces the combustion temperature by delaying the fuel burning rate, which

assists in reducing the quantity of oxides of nitrogen.

On EU3 models, an EGR cooler is employed to further reduce the combustion temperature. By passing the exhaust

gas through a bundle of pipes flooded by coolant, the density of the exhaust gas going into the engine is increased.

This process further reduces the amount of oxygen, which in turn, further reduces the amount of NO

2 in the exhaust.

Recirculating too much exhaust gas can result in higher emissions of soot, HC and CO due to insufficient air. The

recirculated exhaust gas must be limited so that there is sufficient oxygen available for combustion of the injected fuel

in the combustion chamber, to do this the Engine Control Module (ECM) is used to control the precise quantity of

exhaust gas to be recirculated in accordance with the prevailing operating conditions. Influencing factors include:

lthe mass of air flow detected by the mass air flow sensor.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

lthe ambient air pressure, determined by the ambient air pressure sensor which is used to initiate adjustments

to reduce the amount of smoke produced at high altitudes.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

Other factors which are taken into consideration by the engine management system for determining the optimum

operating condition include:

lManifold inlet air temperature

lCoolant temperature

lEngine speed

lFuel delivered

The main components of the EGR system are as follows.

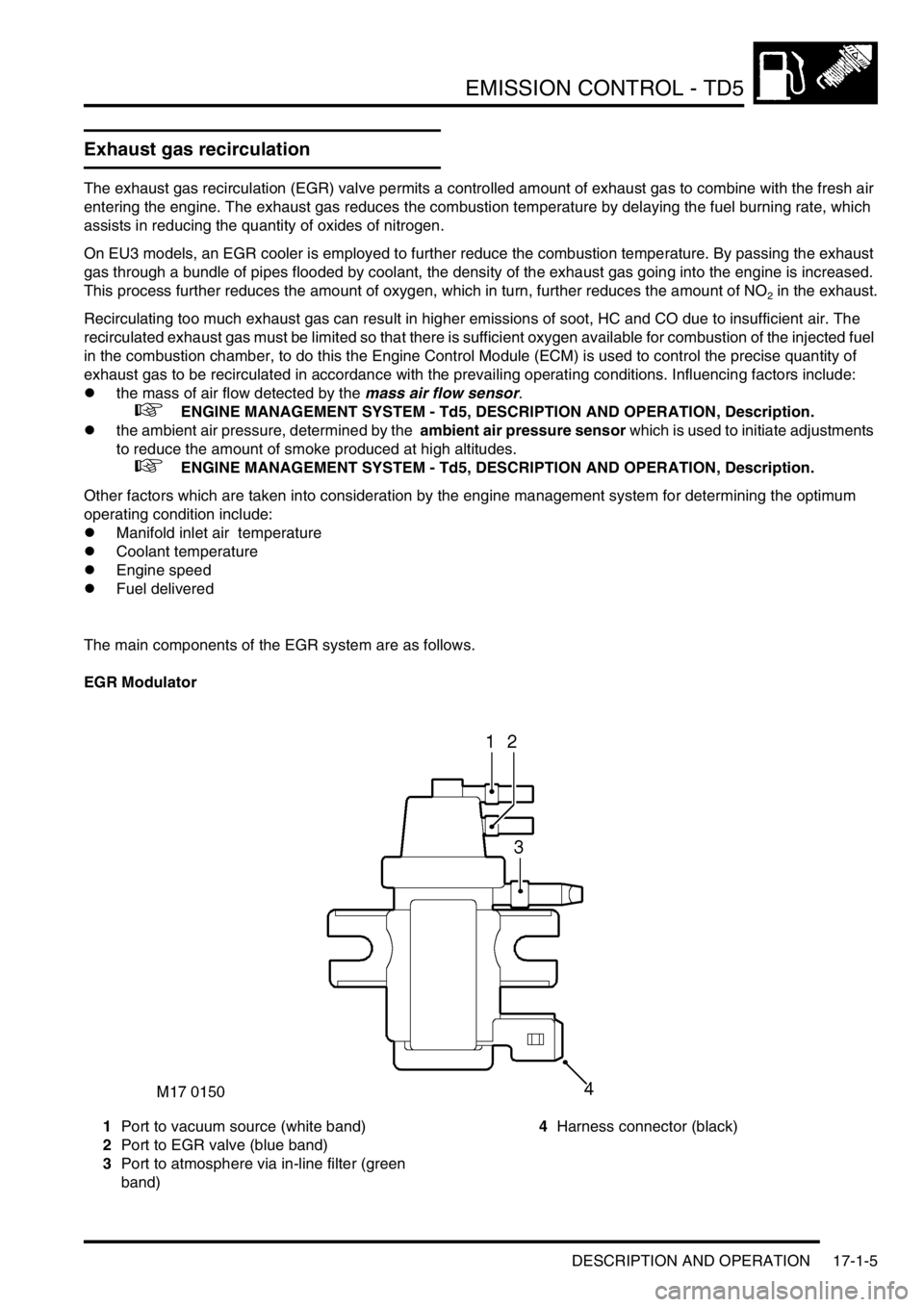

EGR Modulator

1Port to vacuum source (white band)

2Port to EGR valve (blue band)

3Port to atmosphere via in-line filter (green

band)4Harness connector (black)