charging LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 641 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

30-2-12 REPAIRS

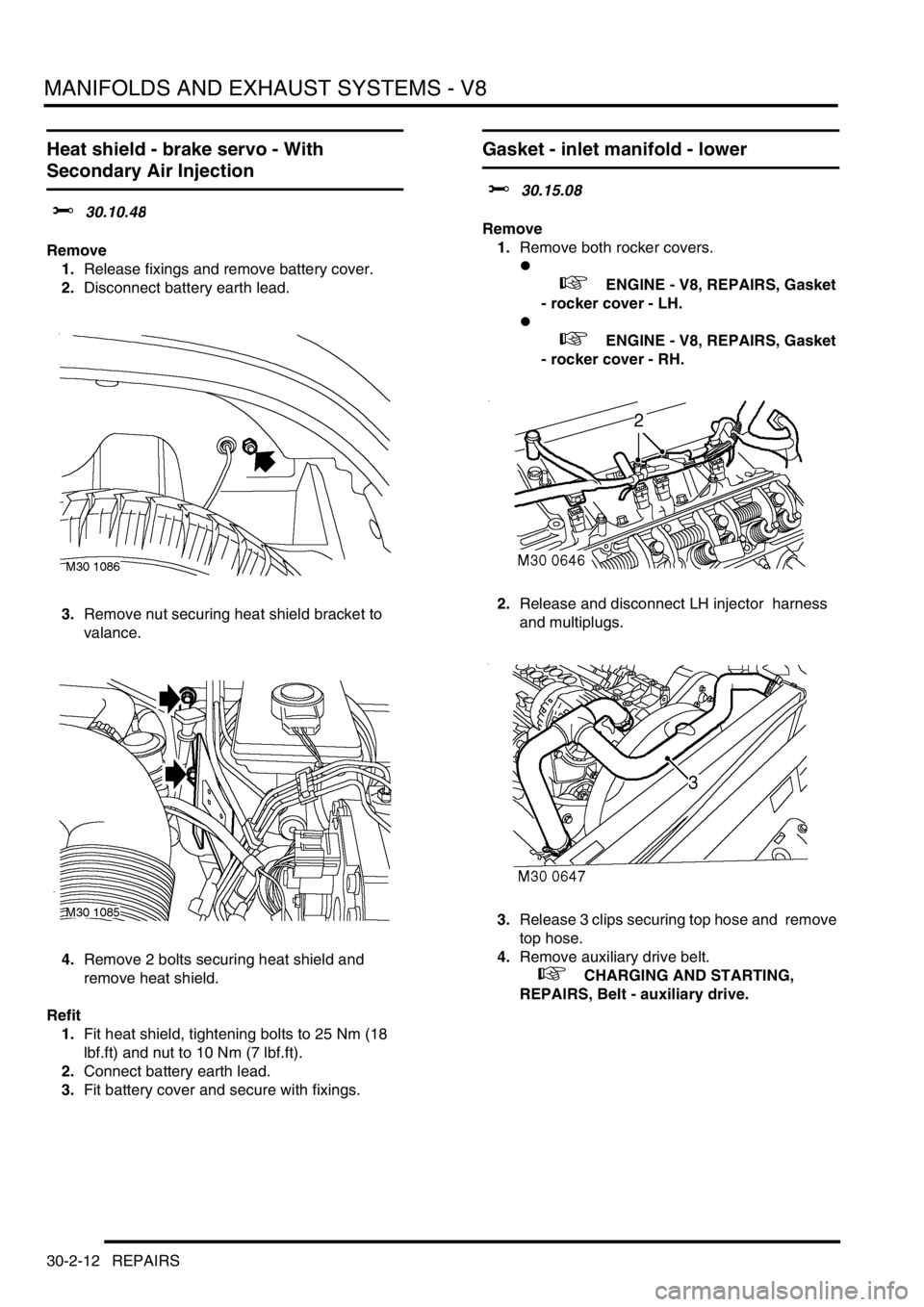

Heat shield - brake servo - With

Secondary Air Injection

$% 30.10.48

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove nut securing heat shield bracket to

valance.

4.Remove 2 bolts securing heat shield and

remove heat shield.

Refit

1.Fit heat shield, tightening bolts to 25 Nm (18

lbf.ft) and nut to 10 Nm (7 lbf.ft).

2.Connect battery earth lead.

3.Fit battery cover and secure with fixings.

Gasket - inlet manifold - lower

$% 30.15.08

Remove

1.Remove both rocker covers.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - LH.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - RH.

2.Release and disconnect LH injector harness

and multiplugs.

3.Release 3 clips securing top hose and remove

top hose.

4.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 644 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

REPAIRS 30-2-15

Refit

1.Clean old RTV sealant from cylinder head and

cylinder block notches.

2.Clean mating faces of cylinder block, cylinder

head and inlet manifold.

3.Apply RTV sealant to cylinder head and

cylinder block notches.

4.Fit new gasket seals, ensuring ends engage

correctly in notches.

5.Fit new inlet manifold gasket.

6.Position gasket clamps and fit bolts, but do not

tighten at this stage.

7.Position inlet manifold to engine. Fit manifold

bolts and, working in the sequence shown,

tighten bolts initially to 10 Nm (7 lbf.ft) then to

51 Nm (38 lbf.ft).

8.Tighten gasket clamp bolts to 18 Nm (13 lbf.ft).

9.Connect fuel pipe.

10.Clean top hose outlet pipe mating faces.

11.Fit new 'O' ring to outlet pipe.

12.Position outlet pipe, fit bolts and tighten to 22

Nm (16 lbf.ft).

13.Position alternator, fit bolts and tighten to 45

Nm (33 lbf.ft).

14.Position PAS pump to auxiliary housing and

locate housing on engine. Fit bolts and tighten

to 40 Nm (30 lbf.ft).

15.Fit and tighten auxiliary housing nut to 10 Nm (7

lbf.ft).

16.Fit bolts securing PAS pump and tighten to 22

Nm (16 lbf.ft). 17.Position oil cooling pipe bracket fit bolt and

tighten to 22 Nm (16 lbf.ft).

18.Fit and tighten PAS pump high pressure pipe.

19.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

20.Clean PAS pump pulley mating faces.

21.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (16 lbf.ft).

22.Clean ACE pump dowels and dowel holes.

23.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

24.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

25.Secure injector harness and connect injector

multiplugs.

26.Position top hose and secure clips.

27.Fit rocker covers.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - LH.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - RH.

28.Check and top up PAS fluid

Page 699 of 1672

MANUAL GEARBOX - R380

37-16 REPAIRS

Gearbox - Diesel

$% 37.20.02.99

Remove

1.Release turn buckles and remove battery cover

and cooling fan cowl.

2.Disconnect battery earth lead.

3.Remove gear lever knob and gear lever trim.

4.Remove clamp bolt and remove gear lever

extension.

5.Apply a little lubricant to gear lever to aid

removal through grommet.

6.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.7.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

8.Drain gearbox oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

9.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

10.Remove 3 nuts securing intermediate silencer

to tail pipe.

11.Release silencer from mounting rubbers,

remove silencer and discard gasket.

12.Remove front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

13.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

Page 702 of 1672

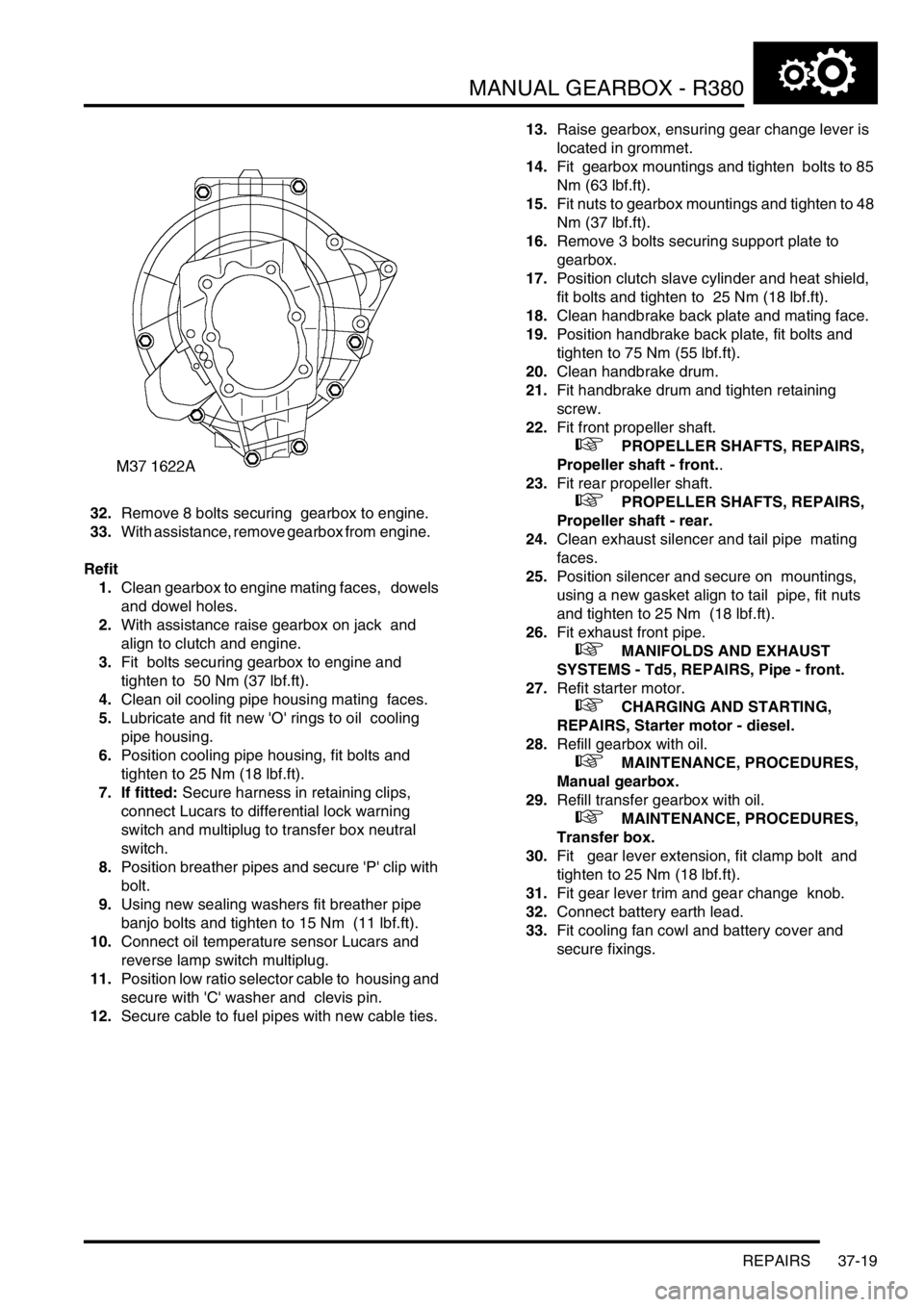

MANUAL GEARBOX - R380

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 823 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-26 REPAIRS

Refit

1.Clean shaft and seal housing.

2.Using a suitable adapter, fit new seal.

3.Position selector quadrant and connecting rod.

4.Position selector shaft and secure to quadrant

using new roll pin.

5.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

Gearbox - convertor and transfer

gearbox - Diesel

$% 44.20.04.99

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise vehicle on a ramp.

4.Remove starter motor

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

5.Remove 2 upper bolts securing gearbox

housing to engine.

6.Remove bolt securing closing plate to gearbox

housing.

7.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

8.Remove 3 nuts securing intermediate silencer

to tail pipe.

9.Release and remove silencer from rubber

mountings.

10.Drain automatic gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 827 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-30 REPAIRS

14.Secure gearbox breather pipes to bulkhead

clip.

15.Connect multiplugs to high/low ratio switch and

neutral sensor. Connect Lucars to differential

lock switch.

16.Position cable tie and multi plug to transfer box

bracket.

17.Connect high/low ratio cable to transfer box

and secure with retaining clips.

18.Position hand brake back plate and tighten

bolts to 75 Nm (55 lbf.ft).

19.Fit hand brake drum and tighten screw.

20.Remove bolts securing tool LRT-99-008A to

gearbox.

21.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

22.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

23.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

24.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

25.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

26.Position intermediate silencer and secure to

mounting rubbers.

27.Clean silencer and tail pipe mating faces.

28.Position new gasket to tail pipe and tighten

nuts to 25 Nm (18 lbf.ft).

29.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

30.Fit bolt securing closing plate to gearbox

housing and tighten to 7 Nm (5.2 lbf.ft).

31.Fit upper bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

32.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

33.Tighten remaining gearbox housing to engine

bolts to 50 Nm (37 lbf.ft).

34.Connect battery earth lead.

35.Fit battery cover and secure with fixings.

36.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.

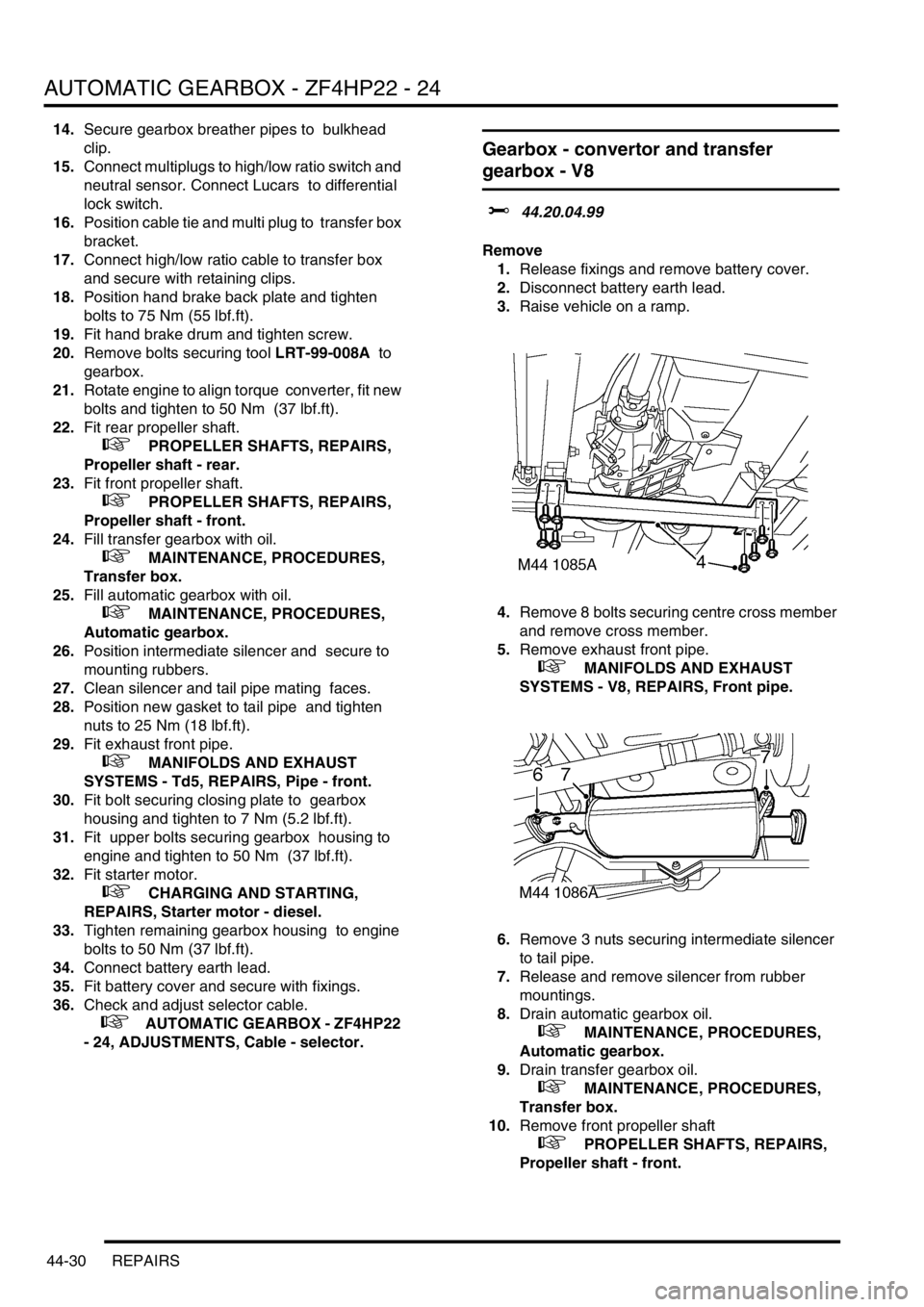

Gearbox - convertor and transfer

gearbox - V8

$% 44.20.04.99

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Raise vehicle on a ramp.

4.Remove 8 bolts securing centre cross member

and remove cross member.

5.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

6.Remove 3 nuts securing intermediate silencer

to tail pipe.

7.Release and remove silencer from rubber

mountings.

8.Drain automatic gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

9.Drain transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

10.Remove front propeller shaft

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

Page 926 of 1672

STEERING

REPAIRS 57-39

Refit

1.Clean seal recess, output shaft, end cover and

mating face.

2.Lubricate new end cover 'O' ring with clean

PAS fluid. Fit 'O' ring to end cover.

3.Position output shaft, fit bolts and tighten to 88

Nm (65 lbf.ft).

4.Tighten rack adjuster one turn, align marks and

secure with Allen screw.

5.Lubricate new output shaft seal with clean PAS

fluid.

6.Fit seal using LRT-57-504.

7.Fit spacer, circlip and seal shield.

8.Clean drop arm and steering box splines.

9.Ensure steering box is in the central position.

Align and fit drop arm to output shaft and

secure with new lock washer and nut. Tighten

nut to 240 Nm (177 lbf.ft).

10.Secure lock washer to drop arm nut.

11.Fit steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

Pump - power steering - V8

$% 57.20.14

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove cable tie securing harness to air intake

hose.

3.Loosen 3 clips securing air intake hose, release

and remove hose.

Note: Pre 03 MY air intake hose illustrated.

4. Models with ACE: Remove 3 bolts securing

ACE pump, release pump and position aside.

Page 928 of 1672

STEERING

REPAIRS 57-41

Refit

1.Position PAS pump to auxiliary housing and

locate housing to engine. Fit and tighten

auxiliary housing bolts to 40 Nm (30 lbf.ft).

2.Tighten auxiliary housing nut to 10 Nm (7 lbf.ft).

3.Fit bolts securing PAS pump and tighten to 22

Nm (16 lbf.ft).

4.Position PAS pump pipe bracket, fit and tighten

bolt to 22 Nm (16 lbf.ft).

5.Fit and tighten PAS pump pressure pipe.

6.Fit PAS pump inlet hose and secure with clip.

7.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

8.Clean PAS pump pulley mating faces.

9.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (16 lbf.ft).

10. Models with ACE: Clean ACE pump dowels

and dowel holes. Position ACE pump, fit bolts

and tighten to 25 Nm (18 lbf.ft).

11. Models with A/C: Clean A/C compressor

dowels and dowel holes. Position A/C

compressor, fit bolts and tighten to 22 Nm (16

lbf.ft).

12.Position air intake hose and secure with clips.

13.Secure harness to air intake hose with new

cable tie.

14.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive..

15.Bleed PAS system.

+ STEERING, ADJUSTMENTS,

Hydraulic system - bleed.

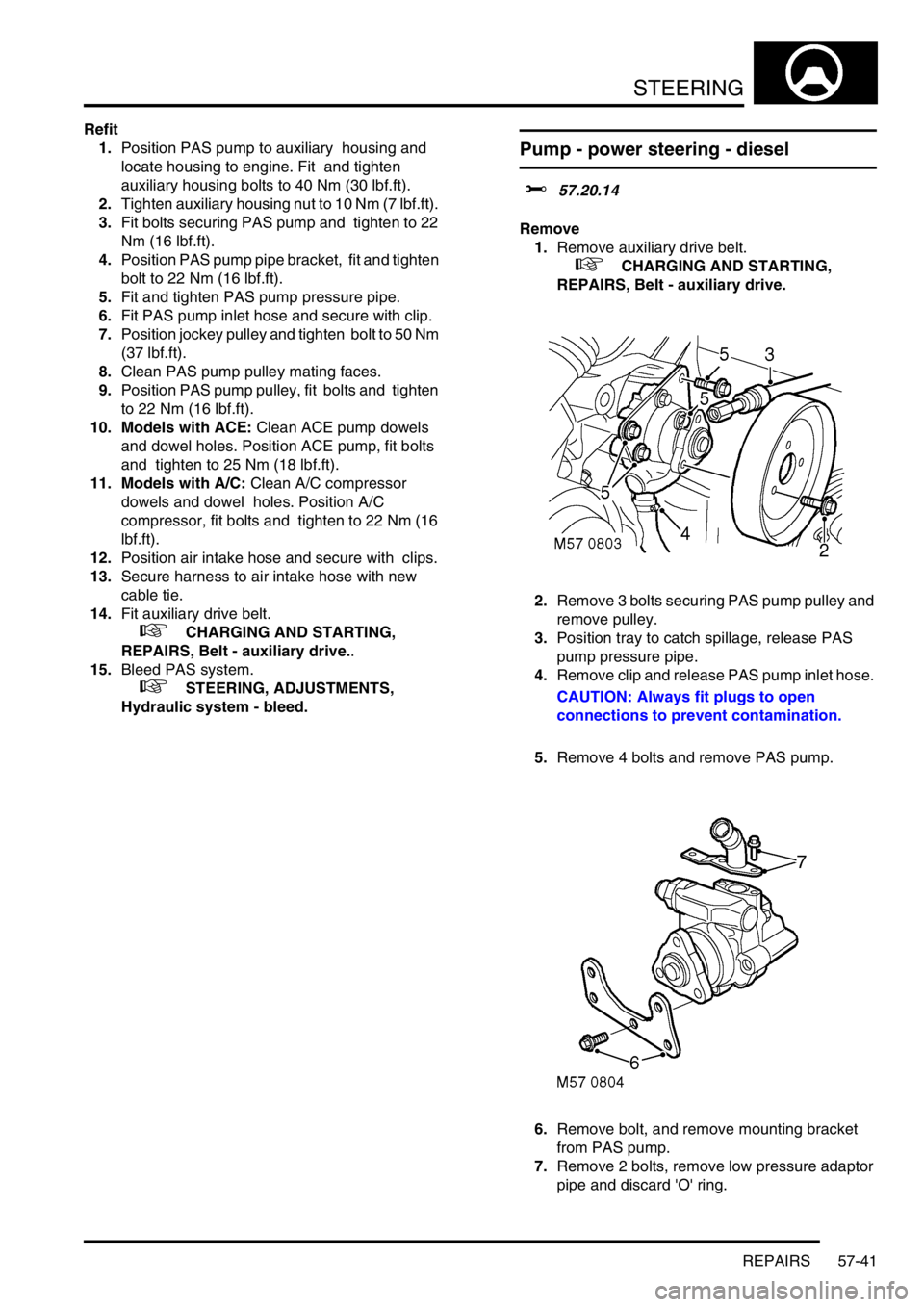

Pump - power steering - diesel

$% 57.20.14

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove 3 bolts securing PAS pump pulley and

remove pulley.

3.Position tray to catch spillage, release PAS

pump pressure pipe.

4.Remove clip and release PAS pump inlet hose.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove 4 bolts and remove PAS pump.

6.Remove bolt, and remove mounting bracket

from PAS pump.

7.Remove 2 bolts, remove low pressure adaptor

pipe and discard 'O' ring.

Page 929 of 1672

STEERING

57-42 REPAIRS

Refit

1.Clean PAS pump and adaptor pipe.

2.Fit new 'O' ring to adaptor pipe, fit pipe and

tighten bolts to 10 Nm (7 lbf.ft).

3.Position mounting bracket to PAS pump, fit but

do not tighten bolt.

4.Position PAS pump and align pump drive to

coolant pump. Fit and tighten bolts to 25 Nm

(18 lbf.ft).

5.Tighten mounting plate bolt to 25 Nm (18 lbf.ft).

6.Clean PAS pump and pipe union.

7.Fit and tighten PAS pump pressure pipe to 20

Nm (15 lbf.ft).

8.Fit PAS pump inlet hose and secure with clip.

9.Clean PAS pump and pulley mating faces.

10.Position PAS pump pulley, fit and tighten bolts

to 10 Nm (7 lbf.ft).

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

12.Bleed power steering system.

+ STEERING, ADJUSTMENTS,

Hydraulic system - bleed.

Steering column assembly and lock

$% 57.40.01

Remove

1.Remove steering column intermediate shaft.

+ STEERING, REPAIRS, Shaft -

intermediate and universal joint - steering

column.

2.Remove rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler.

3.Open fascia lower access panel.

4.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

5.Disconnect multiplug and illumination bulb

from passive coil and remove passive coil.

Page 981 of 1672

FRONT SUSPENSION

60-42 REPAIRS

Accelerometer - ACE - lower

$% 60.60.03

CAUTION: The accelerometer is an extremely

delicate component and can easily be rendered

unserviceable. Never use an accelerometer

which has been dropped or subjected to

mistreatment of any type.

Remove

1.Raise vehicle on a ramp.

2.Disconnect multiplug from accelerometer.

3.Use LRT-60-014A to release clip and remove

accelerometer.

Refit

1.Use LRT-60-014A, fit accelerometer fully into

clip.

2.Connect accelerometer multiplug.

3.Lower vehicle.

4.If a replacement accelerometer has been fitted,

use TestBook to calibrate ACE system.

Pump - ACE - V8

$% 60.60.10

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Loosen 3 clips securing air intake hose.

Release air intake hose and position aside.

Note: Pre 03 MY air intake hose illustrated.