key LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 544 of 1672

ENGINE MANAGEMENT SYSTEM - V8

REPAIRS 18-2-87

Switch - cruise control (on/off)

$% 19.75.30

Remove

1.Carefully remove switch from instrument cowl.

2.Disconnect multiplug and remove switch.

Refit

1.Position new switch and connect multiplug.

2.Carefully push switch into instrument cowl.

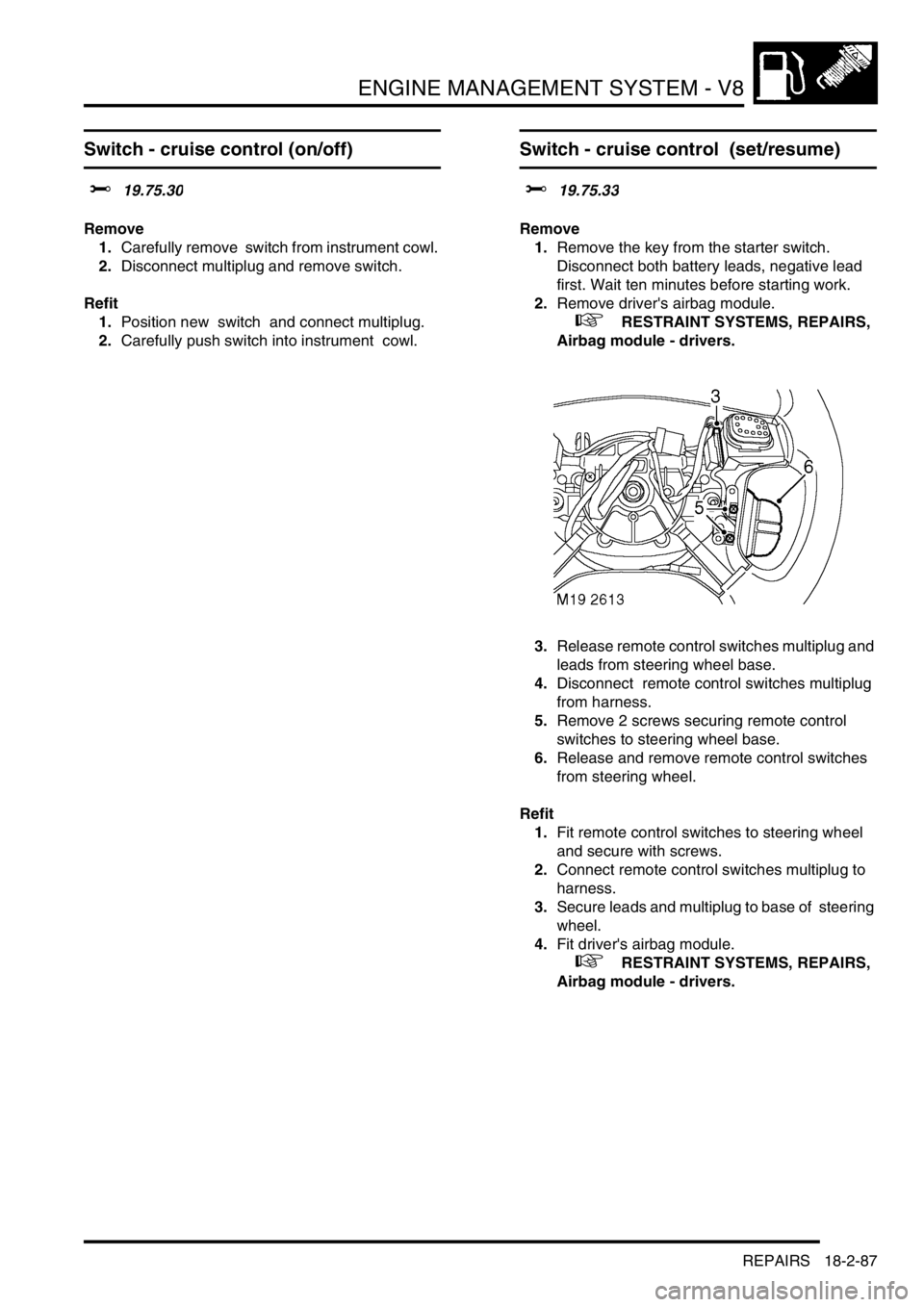

Switch - cruise control (set/resume)

$% 19.75.33

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release remote control switches multiplug and

leads from steering wheel base.

4.Disconnect remote control switches multiplug

from harness.

5.Remove 2 screws securing remote control

switches to steering wheel base.

6.Release and remove remote control switches

from steering wheel.

Refit

1.Fit remote control switches to steering wheel

and secure with screws.

2.Connect remote control switches multiplug to

harness.

3.Secure leads and multiplug to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Page 642 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

REPAIRS 30-2-13

5.Remove 3 bolts securing ACE pump, release

pump and position aside.

6.Remove 2 bolts securing alternator and

remove alternator. 7.Remove 3 bolts securing PAS pump pulley and

remove pulley.

8.Remove jockey pulley.

9.Position tray to catch spillage, release PAS

pump high pressure pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

10.Remove bolt securing oil cooling pipe and

release bracket from auxiliary housing.

11.Remove two bolts securing PAS pump.

12.Remove 5 bolts and one nut securing auxiliary

housing. Pull housing forward, release PAS

pump and remove housing.

Page 644 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

REPAIRS 30-2-15

Refit

1.Clean old RTV sealant from cylinder head and

cylinder block notches.

2.Clean mating faces of cylinder block, cylinder

head and inlet manifold.

3.Apply RTV sealant to cylinder head and

cylinder block notches.

4.Fit new gasket seals, ensuring ends engage

correctly in notches.

5.Fit new inlet manifold gasket.

6.Position gasket clamps and fit bolts, but do not

tighten at this stage.

7.Position inlet manifold to engine. Fit manifold

bolts and, working in the sequence shown,

tighten bolts initially to 10 Nm (7 lbf.ft) then to

51 Nm (38 lbf.ft).

8.Tighten gasket clamp bolts to 18 Nm (13 lbf.ft).

9.Connect fuel pipe.

10.Clean top hose outlet pipe mating faces.

11.Fit new 'O' ring to outlet pipe.

12.Position outlet pipe, fit bolts and tighten to 22

Nm (16 lbf.ft).

13.Position alternator, fit bolts and tighten to 45

Nm (33 lbf.ft).

14.Position PAS pump to auxiliary housing and

locate housing on engine. Fit bolts and tighten

to 40 Nm (30 lbf.ft).

15.Fit and tighten auxiliary housing nut to 10 Nm (7

lbf.ft).

16.Fit bolts securing PAS pump and tighten to 22

Nm (16 lbf.ft). 17.Position oil cooling pipe bracket fit bolt and

tighten to 22 Nm (16 lbf.ft).

18.Fit and tighten PAS pump high pressure pipe.

19.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

20.Clean PAS pump pulley mating faces.

21.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (16 lbf.ft).

22.Clean ACE pump dowels and dowel holes.

23.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

24.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

25.Secure injector harness and connect injector

multiplugs.

26.Position top hose and secure clips.

27.Fit rocker covers.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - LH.

l

+ ENGINE - V8, REPAIRS, Gasket

- rocker cover - RH.

28.Check and top up PAS fluid

Page 747 of 1672

TRANSFER BOX - LT230SE

41-14 DESCRIPTION AND OPERATION

Transfer box interlock solenoid - Automatic gearbox vehicles

An interlock solenoid is fitted for North America and Japan. The solenoid is located on the top of the transfer box main

casing on vehicles up to 03 model year or on the selector lever assembly on vehicles from 03 model year. The

solenoid is connected to the transfer box relay which, in turn, is controlled by the IDM. The purpose of the solenoid is

to prevent neutral being selected on the transfer box when the ignition key is removed, thereby locking the box in

either high or low ratio.

Mainshaft input gear

The gearbox output shaft is splined into the mainshaft input gear which is supported by taper roller bearings.

Input gear bearing pre-load is achieved by the use of a selective shim located in the bearing housing.

Intermediate gears

The intermediate gear cluster is supported by the taper roller bearings located at each end of the cluster and runs on

the intermediate shaft which, in turn, is supported at the front and rear by the main casing.

A selective spacer, positioned between the gears, pre-loads the intermediate gear bearings when the intermediate

shaft nut is tightened sufficiently to achieve the correct 'torque to turn' of the intermediate gears.

On vehicles from 03 model year, the circlips used to retain the bearings in the intermediate gear are deleted. The bore

of the intermediate gear is machined with a shoulder at each end to locate the bearings.

Differential assembly

The differential assembly is supported at the front and rear by taper roller bearings, the front bearing outer track is

located in the front output housing and the rear bearing outer track is located in the main casing by the rear output

housing. Bearing pre-load is achieved by means of a selective shim located in the front output housing.

The differential rear shaft carries the low range gear, high/low selector sleeve and hub, high range gear and bush and

the differential rear bearing; these components being secured to the shaft by a special staked nut.

The differential assembly comprises front and rear half carriers with integral shafts and with sun and planet gears

mounted on cross shafts within the half carriers. Dished, non-selective thrust washers control the engagement of the

planet gears with the sun gears, whilst selective thrust washers are used to control engagement of the sun gears and

'torque to turn' of the differential. The differential carrier halves are bolted together, a retaining ring providing positive

location of the cross shafts.

The high/low selector shaft and fork are located at the side of the differential, movement of the shaft, fork and selector

sleeve being controlled by the high/low selector finger. A spring loaded detent ball fitted in the main casing, locates

in grooves in the shaft.

On vehicles from 03 model year, the selector fork is modified and fitted with a spring assistor and clips to reduce the

effort required to move the selector lever.

Front output housing

The front output housing carries the front output shaft and flange, high/low cross shaft, housing and selector and on

certain vehicles, the differential lock selector shaft and fork.

The front output shaft is supported in the housing by a single bearing and is splined into the differential front sun gear.

High/low selector

The high/low cross shaft is located in a housing bolted to the top of the output housing and is connected to the high/

low selector finger which locates in a slot in the selector shaft.

Page 751 of 1672

TRANSFER BOX - LT230SE

41-18 DESCRIPTION AND OPERATION

On vehicle fitted with a differential lock, the high/low range selector lever as fitted on previous models also

incorporates the differential lock selector on vehicles from 03 model year.

The lever can be moved forwards or backwards to select high, neutral or low range or sideways to select differential

lock engaged or disengaged, on vehicles with differential lock fitted.

The selector lever assembly comprises an aluminium casting with bosses for location of the two cables, the selector

lever mechanism and a housing for the interlock solenoid (if fitted). The upper face of the casting has threaded holes

which allow for the attachment of the casting to the mounting plate which is attached to the transmission tunnel.

A boss at the front provides location for the differential lock cable. The cable is attached to a lever which in turn is

attached to the selector lever. Movement of the selector lever is passed via the lever to the cable which moves the

differential lock selector shaft.

A second boss provides for the location of the high/low range cable. The cable is attached to a plate which moves in

a forward or rearward direction with the selector lever. On North American and Japanese specification models, plate

movement is prevented by an interlock solenoid when the ignition key is not in the ignition.

When fitted, the interlock solenoid is located on the right hand side of the selector lever casting. The solenoid is fitted

into a cast housing in the casting and retained with a circlip. Sealant is applied over the circlip to seal the solenoid in

the housing to prevent the ingress of dirt and moisture. The solenoid performs the same function as on previous

models, preventing the selection of neutral on the transfer box when the ignition key is not in the ignition.

A setting procedure is required for both the differential lock cable and the high/low range cable.

Page 802 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-5

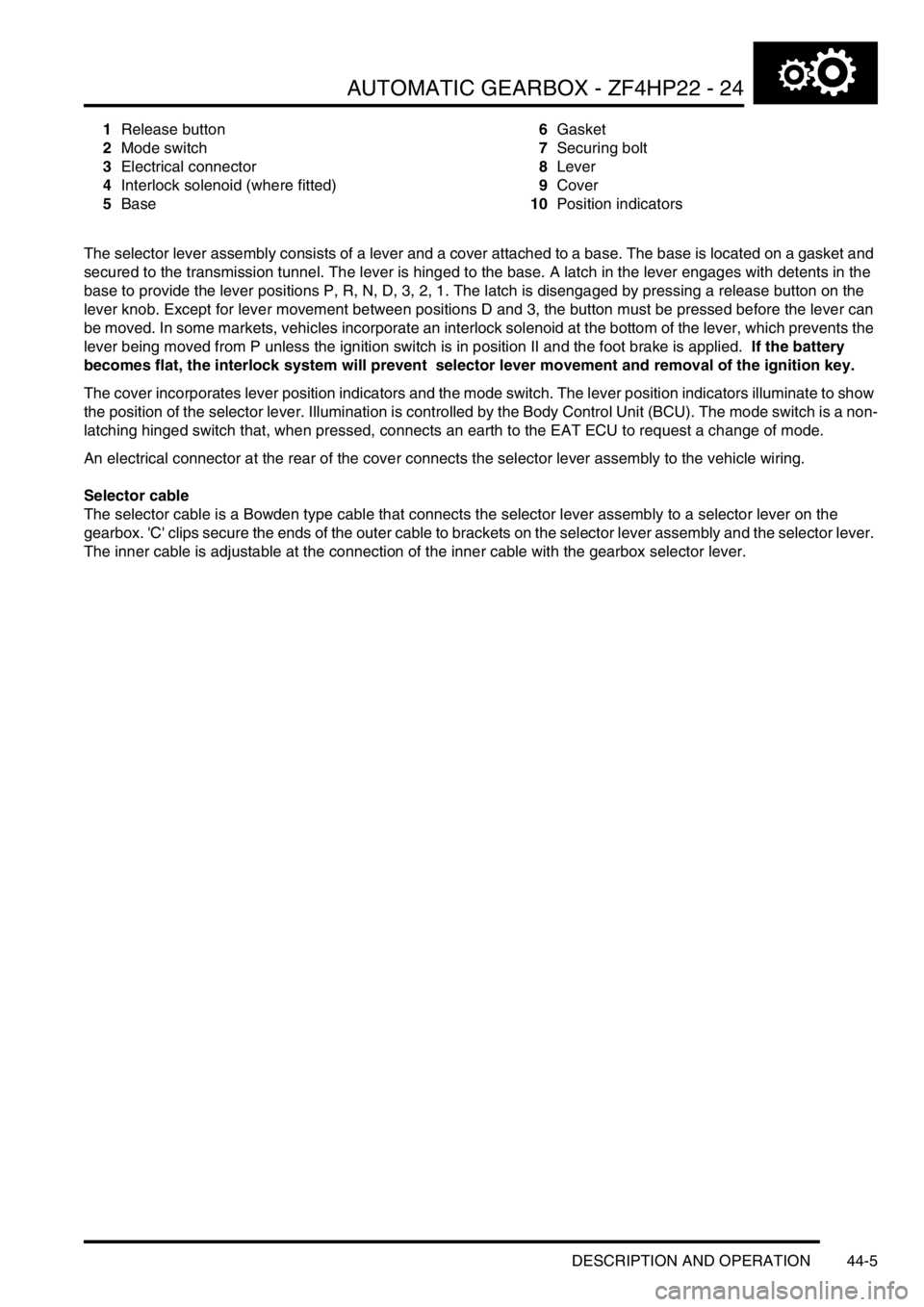

1Release button

2Mode switch

3Electrical connector

4Interlock solenoid (where fitted)

5Base6Gasket

7Securing bolt

8Lever

9Cover

10Position indicators

The selector lever assembly consists of a lever and a cover attached to a base. The base is located on a gasket and

secured to the transmission tunnel. The lever is hinged to the base. A latch in the lever engages with detents in the

base to provide the lever positions P, R, N, D, 3, 2, 1. The latch is disengaged by pressing a release button on the

lever knob. Except for lever movement between positions D and 3, the button must be pressed before the lever can

be moved. In some markets, vehicles incorporate an interlock solenoid at the bottom of the lever, which prevents the

lever being moved from P unless the ignition switch is in position II and the foot brake is applied. If the battery

becomes flat, the interlock system will prevent selector lever movement and removal of the ignition key.

The cover incorporates lever position indicators and the mode switch. The lever position indicators illuminate to show

the position of the selector lever. Illumination is controlled by the Body Control Unit (BCU). The mode switch is a non-

latching hinged switch that, when pressed, connects an earth to the EAT ECU to request a change of mode.

An electrical connector at the rear of the cover connects the selector lever assembly to the vehicle wiring.

Selector cable

The selector cable is a Bowden type cable that connects the selector lever assembly to a selector lever on the

gearbox. 'C' clips secure the ends of the outer cable to brackets on the selector lever assembly and the selector lever.

The inner cable is adjustable at the connection of the inner cable with the gearbox selector lever.

Page 807 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-10 DESCRIPTION AND OPERATION

The lock-up and brake clutches are operated by pressurised transmission fluid from the valve block in the sump. A

manual valve and four solenoid valves, also known as Motorised Valves (MV), control the supply of pressurised

transmission fluid from the valve block:

lThe manual valve controls the supply in P, R, N and D.

lSolenoid valves MV 1 and MV 2 control the supplies that operate the brake clutches for shift control.

lSolenoid valve MV 3 controls the supply that operates the lock-up clutch.

lSolenoid valve MV 4 modulates the pressure of the supplies to the brake clutches, to control shift quality.

Operation of the manual valve is controlled by the selector lever assembly. In the gearbox, a selector shaft engages

with the manual valve. The selector shaft is connected to the selector lever assembly via the selector cable and a

selector lever on the left side of the gearbox. The selector shaft also operates a mechanism that locks the output shaft

when P is selected.

Operation of the solenoid valves is controlled by the EAT ECU.

An output shaft speed sensor in the gearbox housing outputs a signal to the EAT ECU. The EAT ECU compares

output shaft speed with engine speed to determine the engaged gear, and output shaft speed with vehicle speed to

confirm the range selected on the transfer box.

A bayonet lock electrical connector in the gearbox casing, to the rear of the selector lever, connects the solenoid

valves and the output shaft speed sensor to the vehicle wiring.

A pressed steel sump encloses the valve block and collects transmission fluid draining from the gearbox housing. A

suction pipe and filter on the underside of the valve block connect to the inlet side of the fluid pump. A magnet is

installed in the sump to collect any magnetic particles that may be present. A level plug and a drain plug are installed

in the sump for servicing.

Rear extension housing

The rear extension housing provides the interface between the gearbox housing and the transfer box. A splined

extension shaft, secured to the gearbox output shaft by a bolt, transmits the drive from the gearbox to the transfer

box. A seal in the rear of the housing prevents leakage past the extension shaft. A breather pipe, attached to the left

side of the rear extension housing, ventilates the interior of the gearbox and rear extension housings to atmosphere.

The open end of the breather pipe is located in the engine compartment at the right front corner of the engine sump

on gearboxes fitted to early vehicles and is clipped to the top of the gearbox on later vehicles.

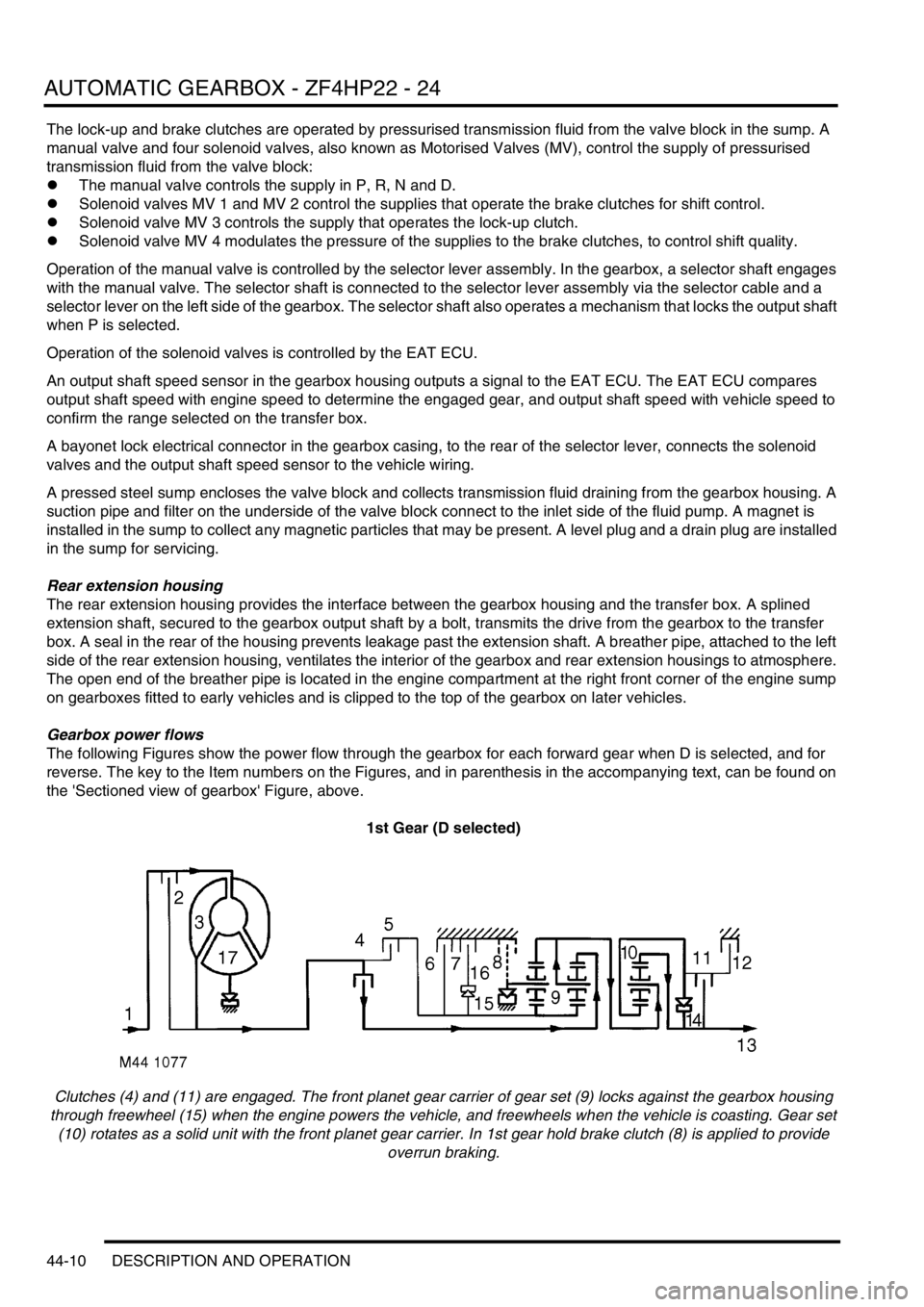

Gearbox power flows

The following Figures show the power flow through the gearbox for each forward gear when D is selected, and for

reverse. The key to the Item numbers on the Figures, and in parenthesis in the accompanying text, can be found on

the 'Sectioned view of gearbox' Figure, above.

1st Gear (D selected)

Clutches (4) and (11) are engaged. The front planet gear carrier of gear set (9) locks against the gearbox housing

through freewheel (15) when the engine powers the vehicle, and freewheels when the vehicle is coasting. Gear set

(10) rotates as a solid unit with the front planet gear carrier. In 1st gear hold brake clutch (8) is applied to provide

overrun braking.

Page 893 of 1672

STEERING

57-6 DESCRIPTION AND OPERATION

Tilt adjustment

The column tilt adjuster lever mechanism is located on the LH side of the steering column and allows the upper column

tube, nacelle and steering wheel assemblies to be tilted up or down a maximum of 7.5

° or 47 mm (NAS vehicles have

a smaller range of movement than the ROW vehicles).

The pawl of the mechanism is attached to the lower column and is allowed to pivot, a toothed quadrant is fixed to the

upper column tube.

When the lever on the LH side of the steering column is raised the mechanism releases the pawl from the toothed

quadrant, this allows the column to be moved. When the lever is released two return springs pull the pawl into

engagement with the toothed quadrant.

Steering column lock (All except NAS)

The steering column lock houses the ignition switch, ignition illumination light ring, key lock barrel and the alarm

passive coil. The steering lock is attached to the upper column with two shear bolts. The bolts are tightened to a

torque which shears off the heads of the bolts preventing easy removal of the steering lock.

The steering lock operates by a bolt, which emerges when the ignition key is turned to position 'O' and the ignition key

removed. The bolt engages in a lock collar located on the upper shaft in the upper column tube. The lock collar is

attached to the upper shaft by a 'wave form' interference ring. If a high torque is applied via the steering wheel with

the lock engaged, the lock collar will slip on the upper shaft. This prevents damage to the steering lock, yet still

prevents the vehicle from being driven.

Steering column lock (NAS only)

The steering column lock houses the ignition switch, ignition illumination light ring, key lock barrel and the alarm

passive coil. The steering lock is attached to the upper column with two shear bolts. The bolts are tightened to a

torque which shears off the heads of the bolts preventing easy removal of the steering lock.

The steering column lock operates by a bolt, which emerges when the ignition key is turned to position 'O' and the

ignition key removed. The bolt engages in a groove machined into the upper shaft in the column tube.

Steering wheel

The steering wheel comprises a cast centre and wire frame onto which the soft polyurethane foam is moulded. The

steering wheel is located on the upper column shaft by a spline and is secured with a nut. A remote radio control switch

(if fitted) is located on the LH side of the steering wheel, a cruise control switch may be located on the RH side. Horn

switches are located on each side of the centre of the steering wheel and protrude through the airbag module cover.

Both switches are connected by wires to the rotary coupler connector.

Intermediate shaft

One end of the intermediate shaft is attached to the steering column lower shaft by a splined universal joint and a bolt,

the universal joint is part of a rubber coupling assembly. The rubber coupling assembly is covered by a heat shield

and connects to the lower section of the intermediate shaft via a decouple joint. The rubber coupling reduces the

shocks felt by the driver through the steering wheel. A second universal joint on the other end of the intermediate shaft

is held in by a bolt. The universal joint is splined and engages with the splined rotor (input) shaft of the steering box.

The decouple joint consists of a metal plate that has open ended slots, the plate is bolted through the slots into the

other half of the decouple joint. The top half of the decouple joint has a slot that accepts the lower section of the

intermediate shaft. The slotted metal plate clamps the lower section of the intermediate shaft to the top section. An

indicator clip is installed between the slotted metal plate and the top half of the decouple joint.

If the intermediate shaft is compressed in an accident, the slotted metal plate in the decouple joint will disengage if

sufficient force is applied to the front end of the shaft. If the forces involved do not disengage the shaft, the red

indicator clip located in the decouple joint will break off if the shaft moves. The intermediate shaft cannot be repaired

and must be replaced as an assembly if accident damage occurs.

Page 914 of 1672

STEERING

REPAIRS 57-27

REPAIRS

Power steering box - V8

$% 57.10.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheel.

3.Ensure steering wheel is centralised and fit

centralising bolt to steering box. Remove key

from steering lock and engage column lock.

4.Remove 3 bolts securing intermediate shaft

and universal joint.

5.Push intermediate shaft upwards, release and

remove universal joint.

CAUTION: Do not turn the steering wheel

with the intermediate shaft or universal joint

disconnected as damage to the rotary

coupler and the steering wheel switches

may occur.

6.Position container to catch oil spillage.

Page 917 of 1672

STEERING

57-30 REPAIRS

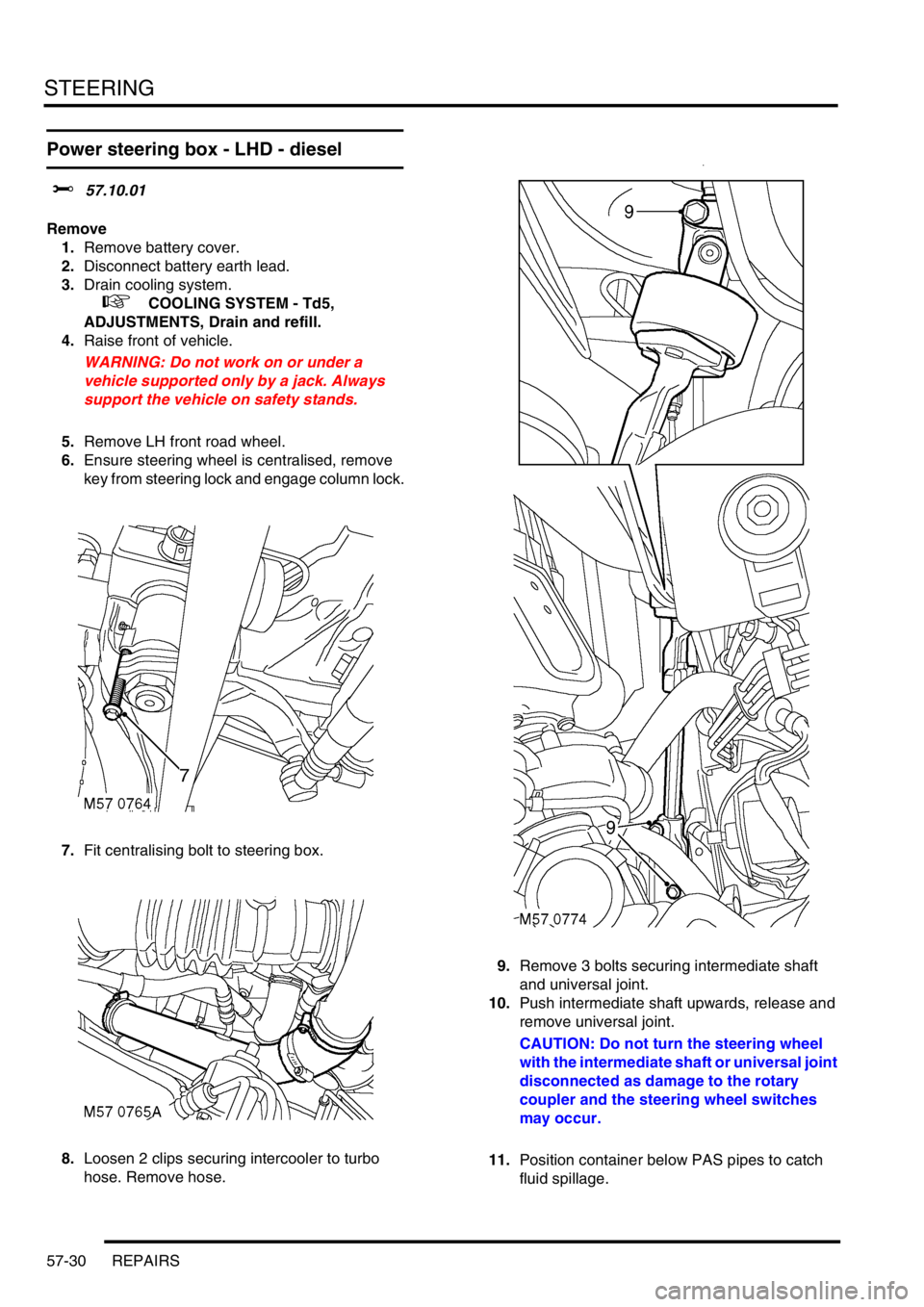

Power steering box - LHD - diesel

$% 57.10.01

Remove

1.Remove battery cover.

2.Disconnect battery earth lead.

3.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

4.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

5.Remove LH front road wheel.

6.Ensure steering wheel is centralised, remove

key from steering lock and engage column lock.

7.Fit centralising bolt to steering box.

8.Loosen 2 clips securing intercooler to turbo

hose. Remove hose.9.Remove 3 bolts securing intermediate shaft

and universal joint.

10.Push intermediate shaft upwards, release and

remove universal joint.

CAUTION: Do not turn the steering wheel

with the intermediate shaft or universal joint

disconnected as damage to the rotary

coupler and the steering wheel switches

may occur.

11.Position container below PAS pipes to catch

fluid spillage.