battery replacement LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 58 of 1672

GENERAL INFORMATION

03-23

Airbag and pretensioner deployment

Deployment procedures and precautions as detailed

in this manual should be strictly adhered to. Only

personnel who have undergone the appropriate

training should undertake deployment of airbag and

pretensioner modules. The following precautions

must be complied with:

lOnly use deployment equipment approved for

the intended purpose.

lBefore beginning deployment procedure,

ensure deployment tool functions properly by

performing the self test procedure detailed in

SRS section of this manual.

lDeployment of airbag/ pretensioner modules

should be performed in a well ventilated area

which has been designated for the purpose.

lEnsure airbag/pretensioner modules are not

damaged or ruptured before attempting to

deploy.

lNotify the relevant authorities of intention to

deploy airbag and pretensioner units.

lWhen deploying airbag pretensioner units,

ensure that all personnel are at least 15 metres

(45 feet) away from the deployment zone.

lEnsure deployment tool is connected correctly,

in compliance with the instructions detailed in

the SRS section of this manual. In particular,

ensure deployment tool is NOT connected to

battery supply before connecting to airbag

module connector.

lWhen deploying seat belt pretensioners, ensure

pretensioner unit is secured correctly to the

seat.

lWhen removing deployed airbag modules and

pretensioner units, wear protective clothing.

Use gloves and seal deployed units in a plastic

bag.

lFollowing deployment of any component of the

SRS system within the vehicle, all SRS

components must be replaced. DO NOT re-use

or salvage any parts of the SRS system.

lDo not lean over airbag module when

connecting deployment equipment.

If a vehicle is to be scrapped, undeployed airbag

modules and pretensioner units must be manually

deployed. In this case airbags can be deployed in the

vehicle; before deployment, ensure the airbag

module is secure within its correct mounting position.

Deployment of the driver's airbag in the vehicle may

damage the steering wheel; if the vehicle is not being

scrapped, deploy the module outside of the vehicle.

WARNING: During deployment parts of the

airbag module become hot enough to burn you.

Wait 30 minutes after deployment before

touching the airbag module.

SRS Component Replacement Policy

The following information details the policy for

replacement of SRS components; either as a result

of a vehicle accident or as a result of vehicle age.

Impacts which do not deploy the airbags or pre-

tensioners

Check for structural damage in the area of the

impact, paying particular attention to bumper

armatures, longitudinals, crash cans and bracketry.

Impacts which deploy the airbags or pre-

tensioners

The replacement and inspection policy is dependent

on the type and severity of of the crash condition.

The following guidelines are the minimum that

should be exercised as a result of the deployment of

specific SRS components.

If the front airbags or seat belt pre-tensioners are

deployed, the following parts must be replaced:

lSRS DCU.

lDriver airbag module

lPassenger airbag module

lFront seat belt buckle pre-tensioners

lRotary coupler

lDriver's seat belt retractor

lFlyleads (where applicable) connecting airbags

and seat belt pre-tensioners to SRS harness

In addition, the following should be inspected for

damage and replaced as necessary:

lFront passenger's seat belt retractor (webbing,

tongue latching, 'D' loop, body anchorage point)

lRear seat belt buckles (webbing, buckle covers,

body anchorage and tongue latching function)

lFascia moulding adjacent to passenger airbag

module

lSteering wheel (if damage is evident)

lFront seat frames and head restraints (if there is

evidence of damage to the seat frame or

cushion pan)

lSteering column (if adjustment is lost or there

are signs of collapse)

lThird row seats, seat belts and head restraints

(where fitted). Check third row seat latching

mechanism operates correctly.

Periodic replacement of SRS components

The performance of the propellants within airbags

and pre-tensioners will deteriorate over a period of

time. As a result, it is essential that the airbags are

replaced after 10 years and seat belt pre-tensioners

are replaced after 15 years in order to maintain

occupant safety.

Page 115 of 1672

MAINTENANCE

10-6 PROCEDURES

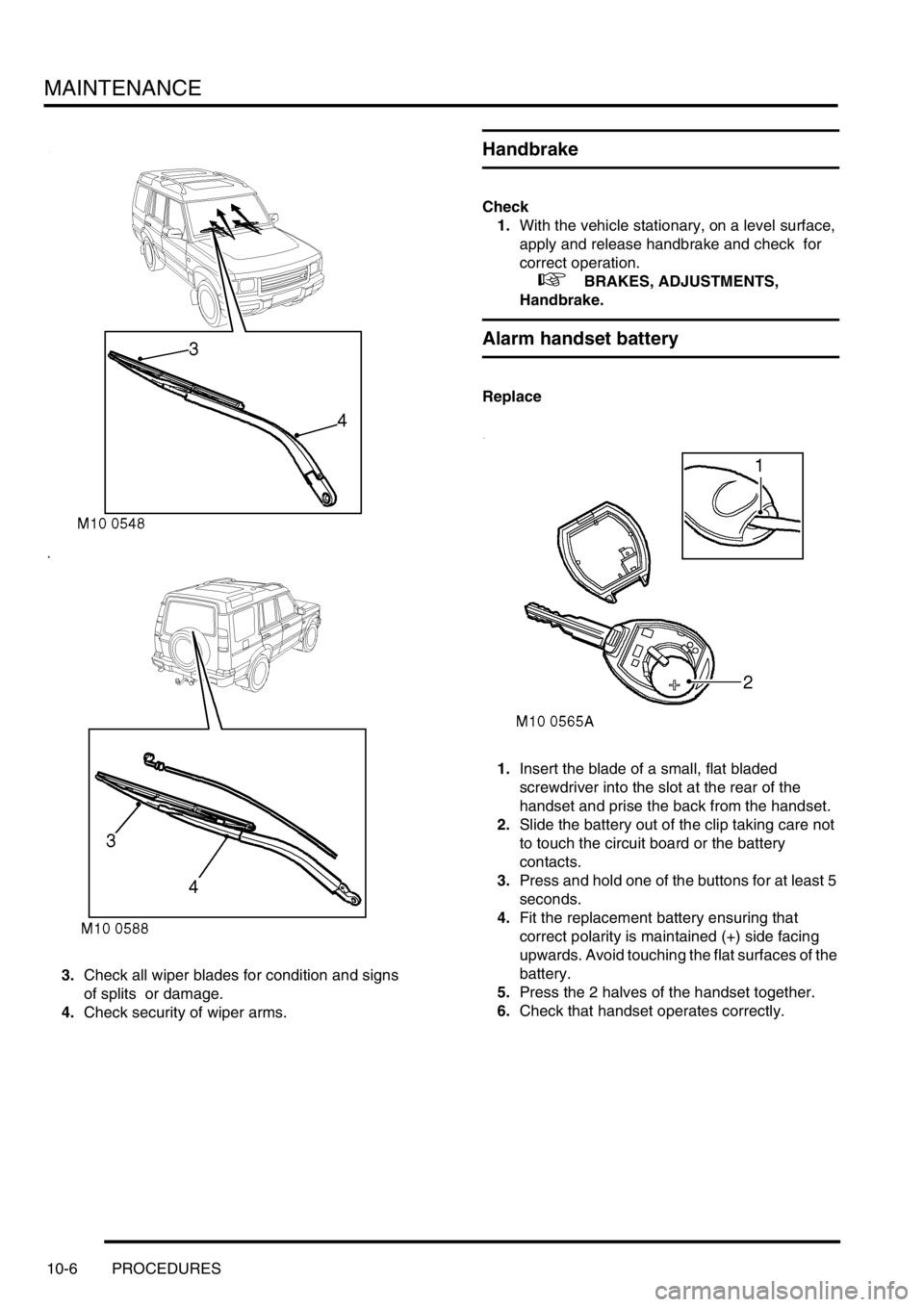

3.Check all wiper blades for condition and signs

of splits or damage.

4.Check security of wiper arms.

Handbrake

Check

1.With the vehicle stationary, on a level surface,

apply and release handbrake and check for

correct operation.

+ BRAKES, ADJUSTMENTS,

Handbrake.

Alarm handset battery

Replace

1.Insert the blade of a small, flat bladed

screwdriver into the slot at the rear of the

handset and prise the back from the handset.

2.Slide the battery out of the clip taking care not

to touch the circuit board or the battery

contacts.

3.Press and hold one of the buttons for at least 5

seconds.

4.Fit the replacement battery ensuring that

correct polarity is maintained (+) side facing

upwards. Avoid touching the flat surfaces of the

battery.

5.Press the 2 halves of the handset together.

6.Check that handset operates correctly.

Page 124 of 1672

MAINTENANCE

PROCEDURES 10-15

Centrifuge rotor – diesel engine

Replace

1.Replace centrifuge rotor.

+ ENGINE - Td5, REPAIRS, Rotor -

centrifuge.

Engine oil filter - diesel engine

Replace

1.Replace oil filter.

+ ENGINE - Td5, REPAIRS, Filter - oil.

Engine oil filter – V8 engine

WARNING: Avoid excessive skin contact with

used engine oil. Used engine oil contains

potentially harmful contaminants which may

cause skin cancer or other serious skin

disorders.

Replace

1.Disconnect battery.

2.Position suitable container beneath oil filter.

3.Using a strap type filter wrench, remove filter

element, discard element.

4.Smear sealing ring of replacement filter

element with engine oil.

5.Fit filter element, tighten two thirds of a turn by

hand or to 17 Nm (13 lbf.ft).

6.Top-up engine with recommended grade of oil

to correct mark on dipstick.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

7.Connect battery.

8.Run engine and check for oil leaks from filter.

9.Stop engine, wait for oil to return to sump.

10.Re-check oil level and top-up if necessary.

Page 440 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-47

REPAIRS

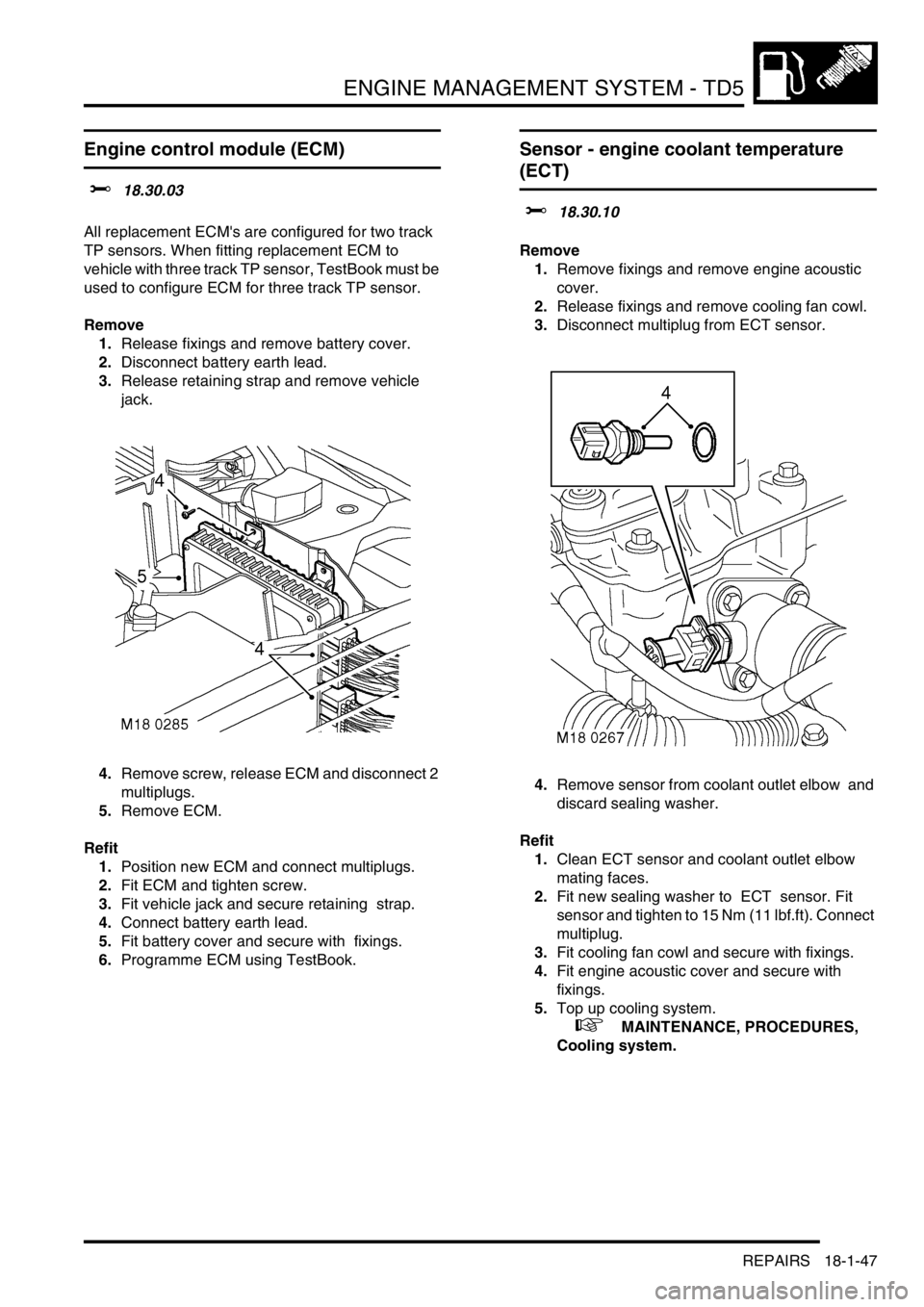

Engine control module (ECM)

$% 18.30.03

All replacement ECM's are configured for two track

TP sensors. When fitting replacement ECM to

vehicle with three track TP sensor, TestBook must be

used to configure ECM for three track TP sensor.

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Release retaining strap and remove vehicle

jack.

4.Remove screw, release ECM and disconnect 2

multiplugs.

5.Remove ECM.

Refit

1.Position new ECM and connect multiplugs.

2.Fit ECM and tighten screw.

3.Fit vehicle jack and secure retaining strap.

4.Connect battery earth lead.

5.Fit battery cover and secure with fixings.

6.Programme ECM using TestBook.

Sensor - engine coolant temperature

(ECT)

$% 18.30.10

Remove

1.Remove fixings and remove engine acoustic

cover.

2.Release fixings and remove cooling fan cowl.

3.Disconnect multiplug from ECT sensor.

4.Remove sensor from coolant outlet elbow and

discard sealing washer.

Refit

1.Clean ECT sensor and coolant outlet elbow

mating faces.

2.Fit new sealing washer to ECT sensor. Fit

sensor and tighten to 15 Nm (11 lbf.ft). Connect

multiplug.

3.Fit cooling fan cowl and secure with fixings.

4.Fit engine acoustic cover and secure with

fixings.

5.Top up cooling system.

+ MAINTENANCE, PROCEDURES,

Cooling system.

Page 464 of 1672

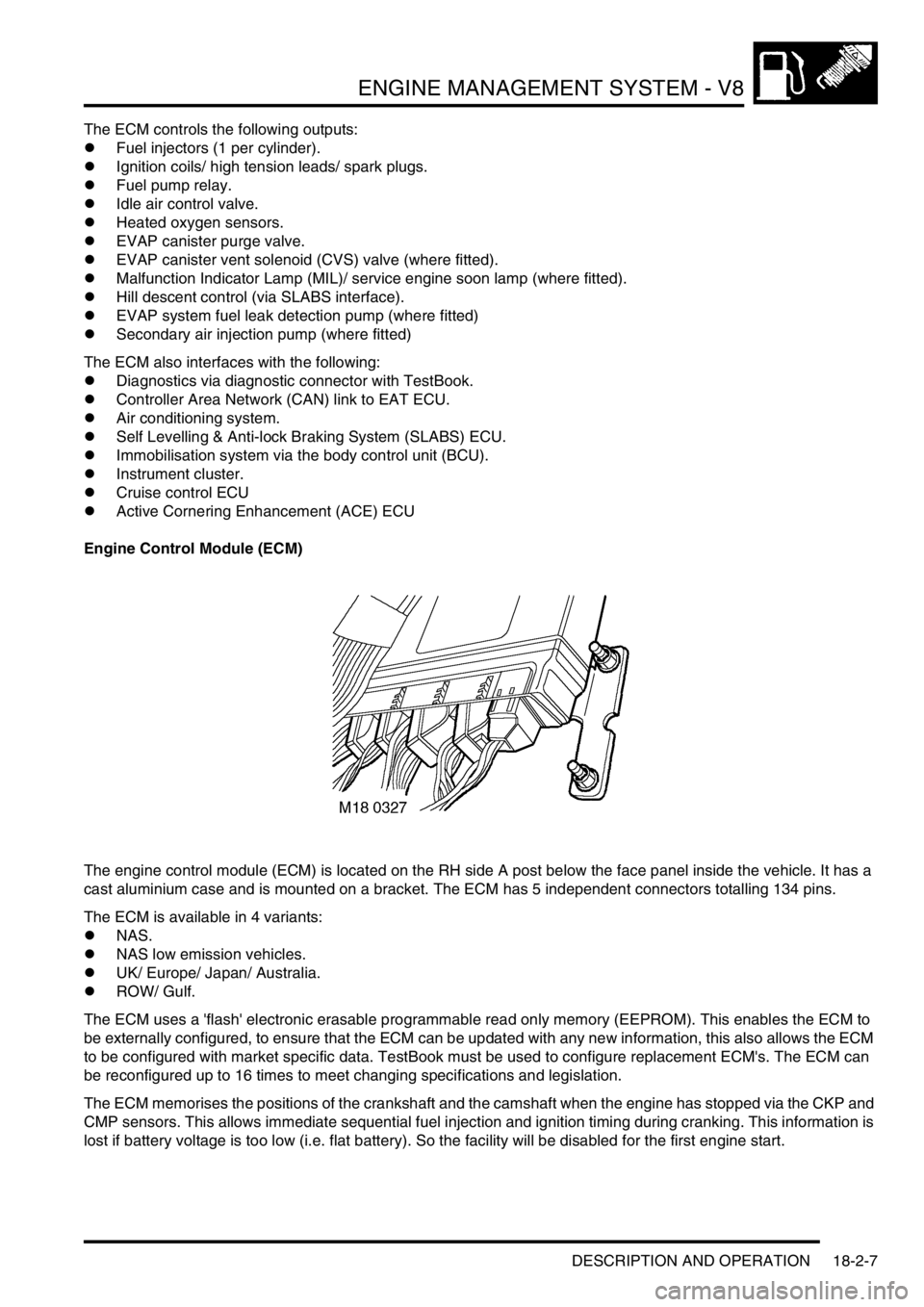

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-7

The ECM controls the following outputs:

lFuel injectors (1 per cylinder).

lIgnition coils/ high tension leads/ spark plugs.

lFuel pump relay.

lIdle air control valve.

lHeated oxygen sensors.

lEVAP canister purge valve.

lEVAP canister vent solenoid (CVS) valve (where fitted).

lMalfunction Indicator Lamp (MIL)/ service engine soon lamp (where fitted).

lHill descent control (via SLABS interface).

lEVAP system fuel leak detection pump (where fitted)

lSecondary air injection pump (where fitted)

The ECM also interfaces with the following:

lDiagnostics via diagnostic connector with TestBook.

lController Area Network (CAN) link to EAT ECU.

lAir conditioning system.

lSelf Levelling & Anti-lock Braking System (SLABS) ECU.

lImmobilisation system via the body control unit (BCU).

lInstrument cluster.

lCruise control ECU

lActive Cornering Enhancement (ACE) ECU

Engine Control Module (ECM)

The engine control module (ECM) is located on the RH side A post below the face panel inside the vehicle. It has a

cast aluminium case and is mounted on a bracket. The ECM has 5 independent connectors totalling 134 pins.

The ECM is available in 4 variants:

lNAS.

lNAS low emission vehicles.

lUK/ Europe/ Japan/ Australia.

lROW/ Gulf.

The ECM uses a 'flash' electronic erasable programmable read only memory (EEPROM). This enables the ECM to

be externally configured, to ensure that the ECM can be updated with any new information, this also allows the ECM

to be configured with market specific data. TestBook must be used to configure replacement ECM's. The ECM can

be reconfigured up to 16 times to meet changing specifications and legislation.

The ECM memorises the positions of the crankshaft and the camshaft when the engine has stopped via the CKP and

CMP sensors. This allows immediate sequential fuel injection and ignition timing during cranking. This information is

lost if battery voltage is too low (i.e. flat battery). So the facility will be disabled for the first engine start.

Page 1270 of 1672

PANEL REPAIRS

REPAIRS 77-2-21

REPAIRS

Front bulkhead assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

5. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

6. Diesel models: Remove gearbox fluid cooler.

7.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8.Release headlamp levelling motors and

position aside.

9.Release headlamp wiring and position aside.

10.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove battery tray.

12.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

13.Remove 2 earth leads from LH of front

bulkhead.

14.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

15. Models with A/C: Release and remove A/C

pipes.

16.Remove RH and LH crush cans.

17.Remove bonnet release cable.

18.Support bonnet in open position

19.Remove bonnet locking mechanism.

20.Remove VIN plate.

21.Remove 2 bolts securing front bulkhead

assembly to chassis.

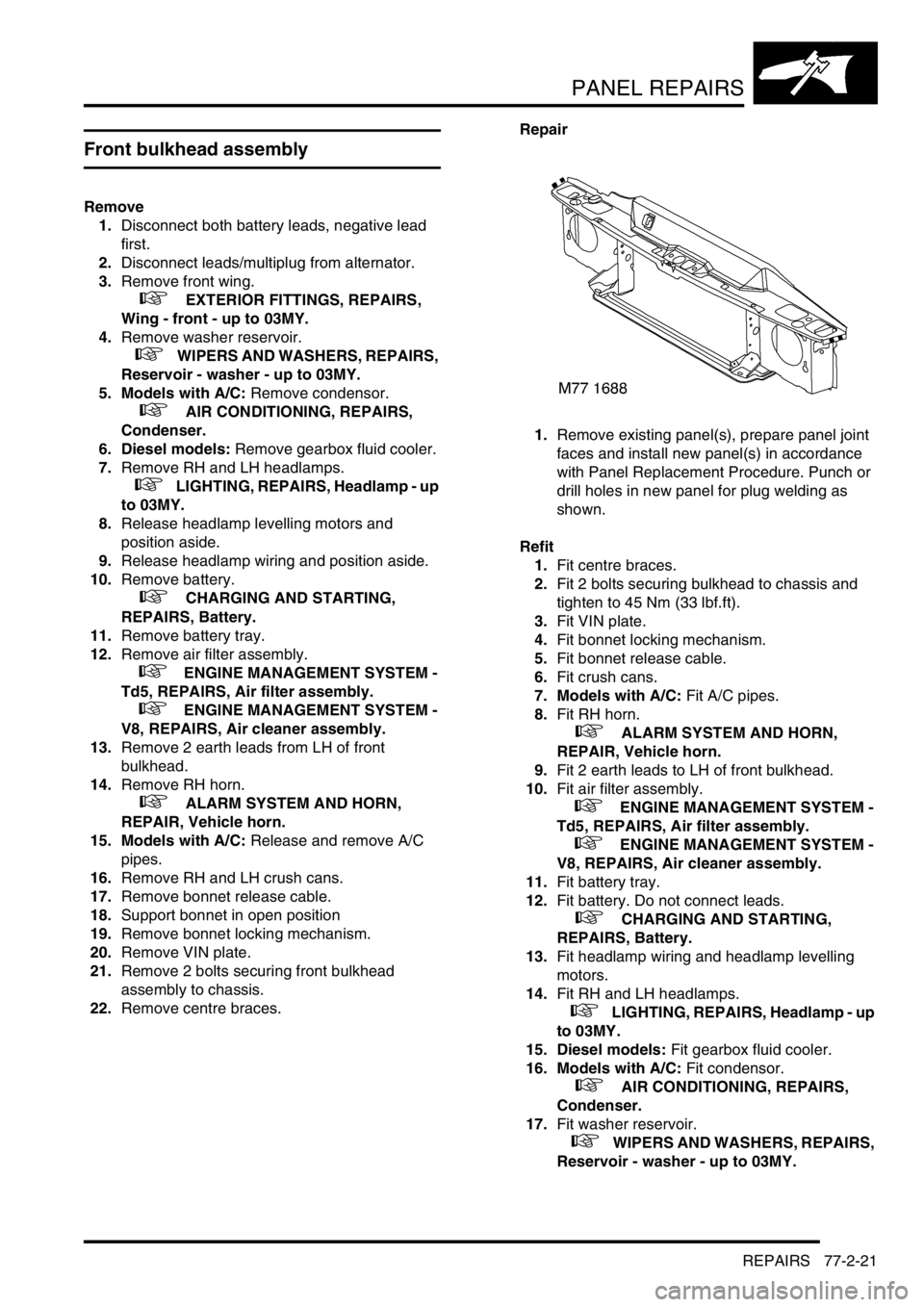

22.Remove centre braces.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten to 45 Nm (33 lbf.ft).

3.Fit VIN plate.

4.Fit bonnet locking mechanism.

5.Fit bonnet release cable.

6.Fit crush cans.

7. Models with A/C: Fit A/C pipes.

8.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

9.Fit 2 earth leads to LH of front bulkhead.

10.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Fit battery tray.

12.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Fit headlamp wiring and headlamp levelling

motors.

14.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

15. Diesel models: Fit gearbox fluid cooler.

16. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

17.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

Page 1272 of 1672

PANEL REPAIRS

REPAIRS 77-2-23

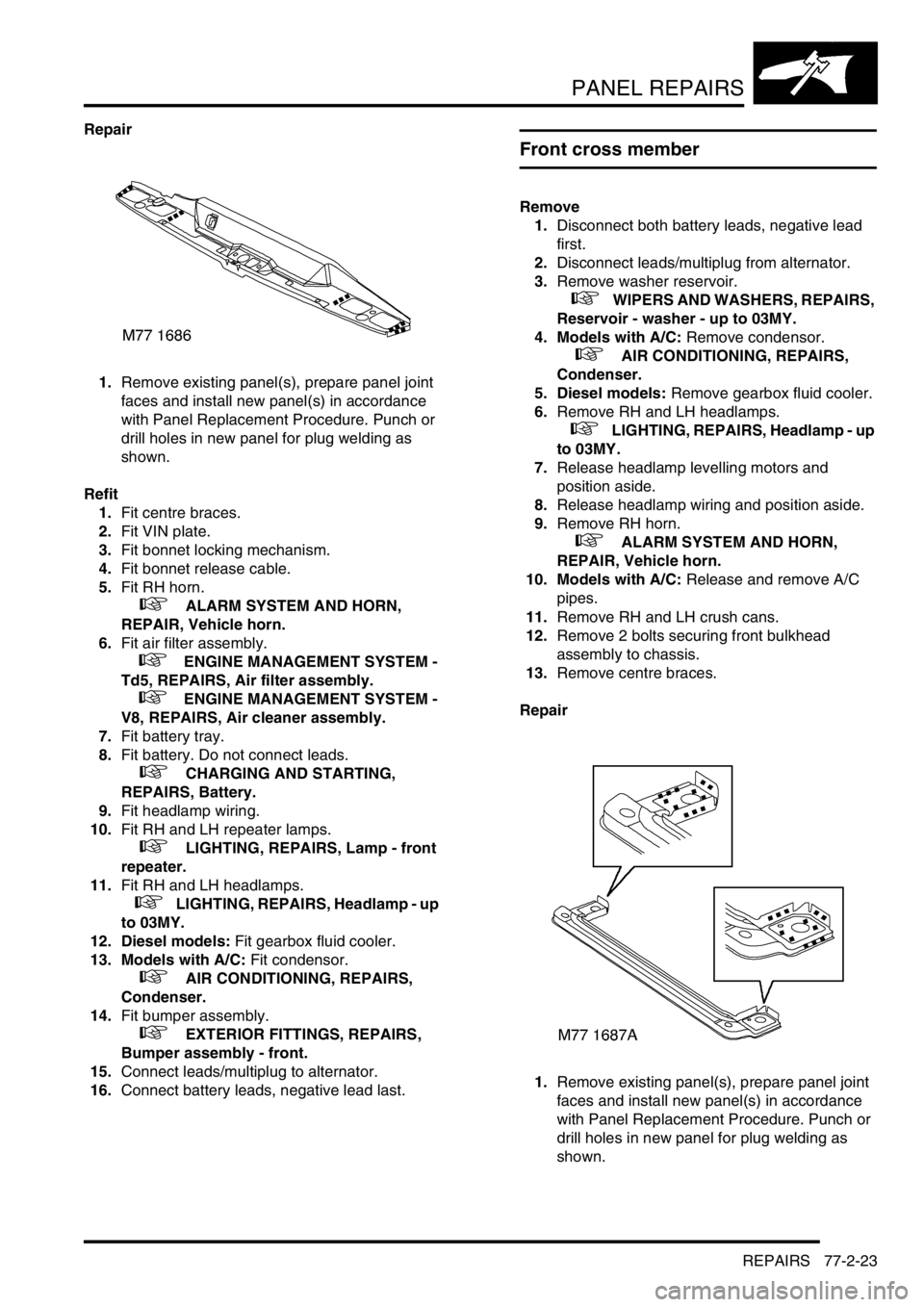

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit VIN plate.

3.Fit bonnet locking mechanism.

4.Fit bonnet release cable.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

7.Fit battery tray.

8.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Fit headlamp wiring.

10.Fit RH and LH repeater lamps.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

11.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Front cross member

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Release headlamp levelling motors and

position aside.

8.Release headlamp wiring and position aside.

9.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

10. Models with A/C: Release and remove A/C

pipes.

11.Remove RH and LH crush cans.

12.Remove 2 bolts securing front bulkhead

assembly to chassis.

13.Remove centre braces.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 1274 of 1672

PANEL REPAIRS

REPAIRS 77-2-25

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit crush can.

4. Models with A/C: Fit A/C pipes.

5.Fit horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit battery and battery tray. Do not connect

leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

7.Fit headlamp wiring and headlamp levelling

motors.

8.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.9.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

10. Diesel models: Fit gearbox fluid cooler.

11. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

12.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

13.Connect leads/multiplug to alternator.

14.Connect battery leads, negative lead last.

M77 1741A

Page 1275 of 1672

PANEL REPAIRS

77-2-26 REPAIRS

Headlamp mounting panel - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Remove 2 earth leads from LH of front

bulkhead.

12.Release and remove A/C pipes.

13.Remove crush can.

14.Remove bonnet release cable.

15.Remove 2 bolts securing front bulkhead

assembly to chassis.

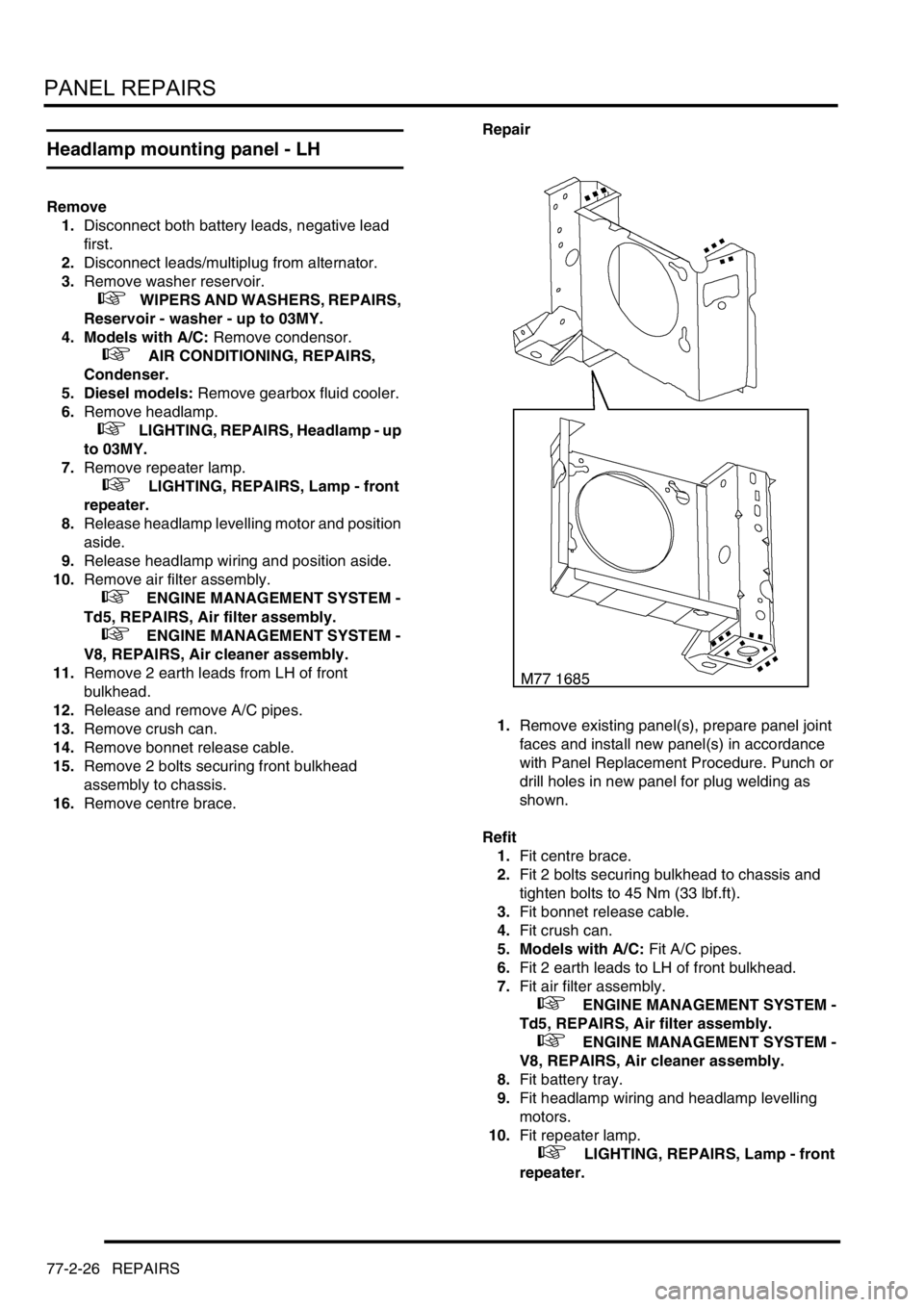

16.Remove centre brace.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit bonnet release cable.

4.Fit crush can.

5. Models with A/C: Fit A/C pipes.

6.Fit 2 earth leads to LH of front bulkhead.

7.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

8.Fit battery tray.

9.Fit headlamp wiring and headlamp levelling

motors.

10.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

Page 1277 of 1672

PANEL REPAIRS

77-2-28 REPAIRS

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit brake pipes to valance.

4.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

5.Fit PAS/ACE reservoir, refill fluids to correct

levelsand bleed ACE system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Fluids.6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

7.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

8.Connect leads/multiplug to alternator.

9.Connect battery leads, negative lead last.

M77 1743

M77 1690A