remote start LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 456 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-63

Switch - cruise control (set/resume)

$% 19.75.33

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release remote control switches multiplug and

leads from steering wheel base.

4.Disconnect remote control switches multiplug

from harness.

5.Remove 2 screws securing remote control

switches to steering wheel base.

6.Release and remove remote control switches

from steering wheel.

Refit

1.Fit remote control switches to steering wheel

and secure with screws.

2.Connect remote control switches multiplug to

harness.

3.Secure leads and multiplug to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Switch - clutch

$% 19.75.34

Remove

1.Disconnect the multiplug from the clutch switch.

2.Position a container below the clutch switch to

collect the fluid.

3.Unscrew and remove the clutch switch.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Refit

1.Fit the clutch switch and tighten to 10 Nm (7

lbf.ft).

2.Connect the multiplug.

3.Bleed the clutch hydraulic system.

+ CLUTCH - Td5, ADJUSTMENTS,

Clutch hydraulic system - bleed.

Page 544 of 1672

ENGINE MANAGEMENT SYSTEM - V8

REPAIRS 18-2-87

Switch - cruise control (on/off)

$% 19.75.30

Remove

1.Carefully remove switch from instrument cowl.

2.Disconnect multiplug and remove switch.

Refit

1.Position new switch and connect multiplug.

2.Carefully push switch into instrument cowl.

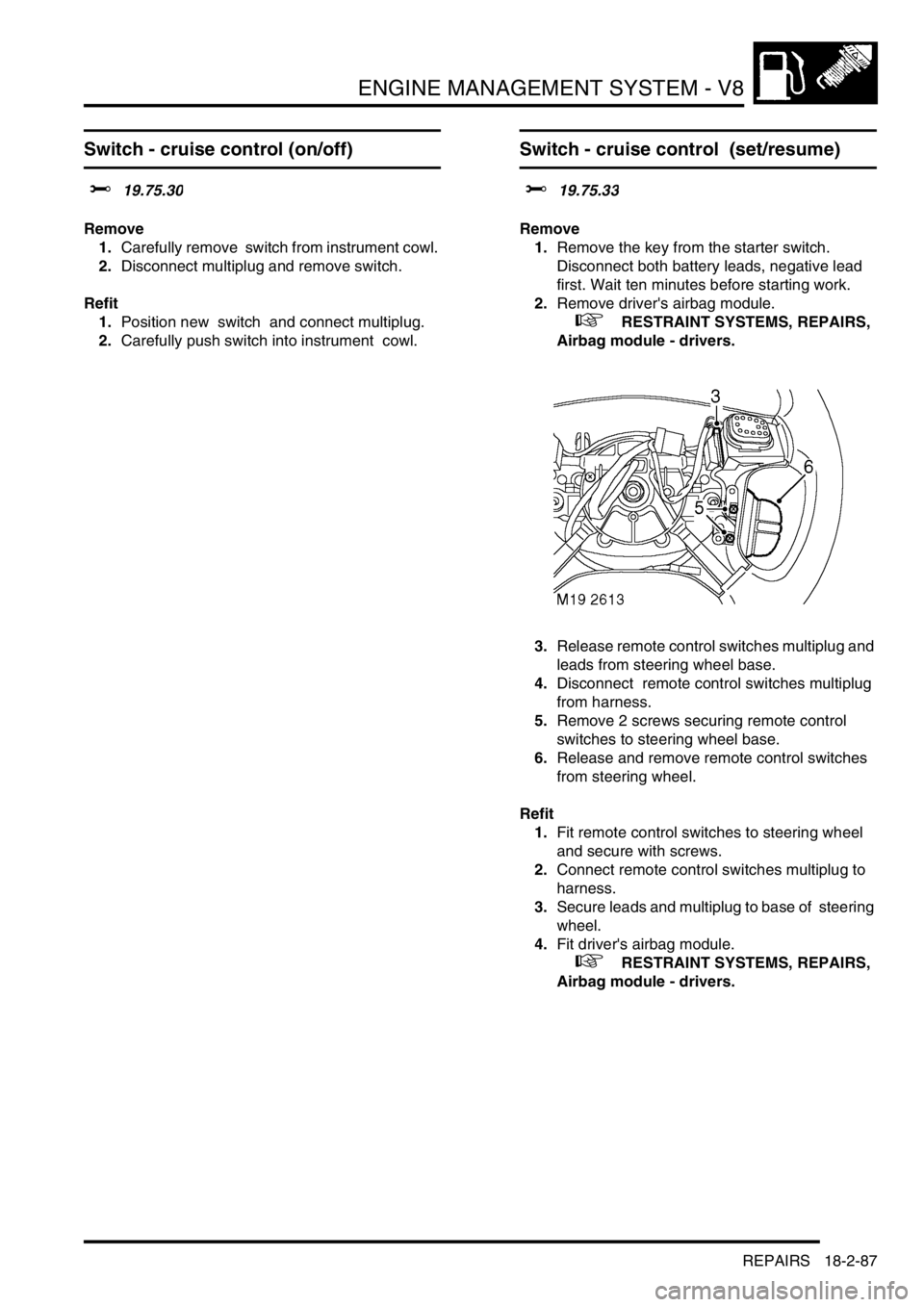

Switch - cruise control (set/resume)

$% 19.75.33

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release remote control switches multiplug and

leads from steering wheel base.

4.Disconnect remote control switches multiplug

from harness.

5.Remove 2 screws securing remote control

switches to steering wheel base.

6.Release and remove remote control switches

from steering wheel.

Refit

1.Fit remote control switches to steering wheel

and secure with screws.

2.Connect remote control switches multiplug to

harness.

3.Secure leads and multiplug to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Page 1023 of 1672

REAR SUSPENSION

64-18 DESCRIPTION AND OPERATION

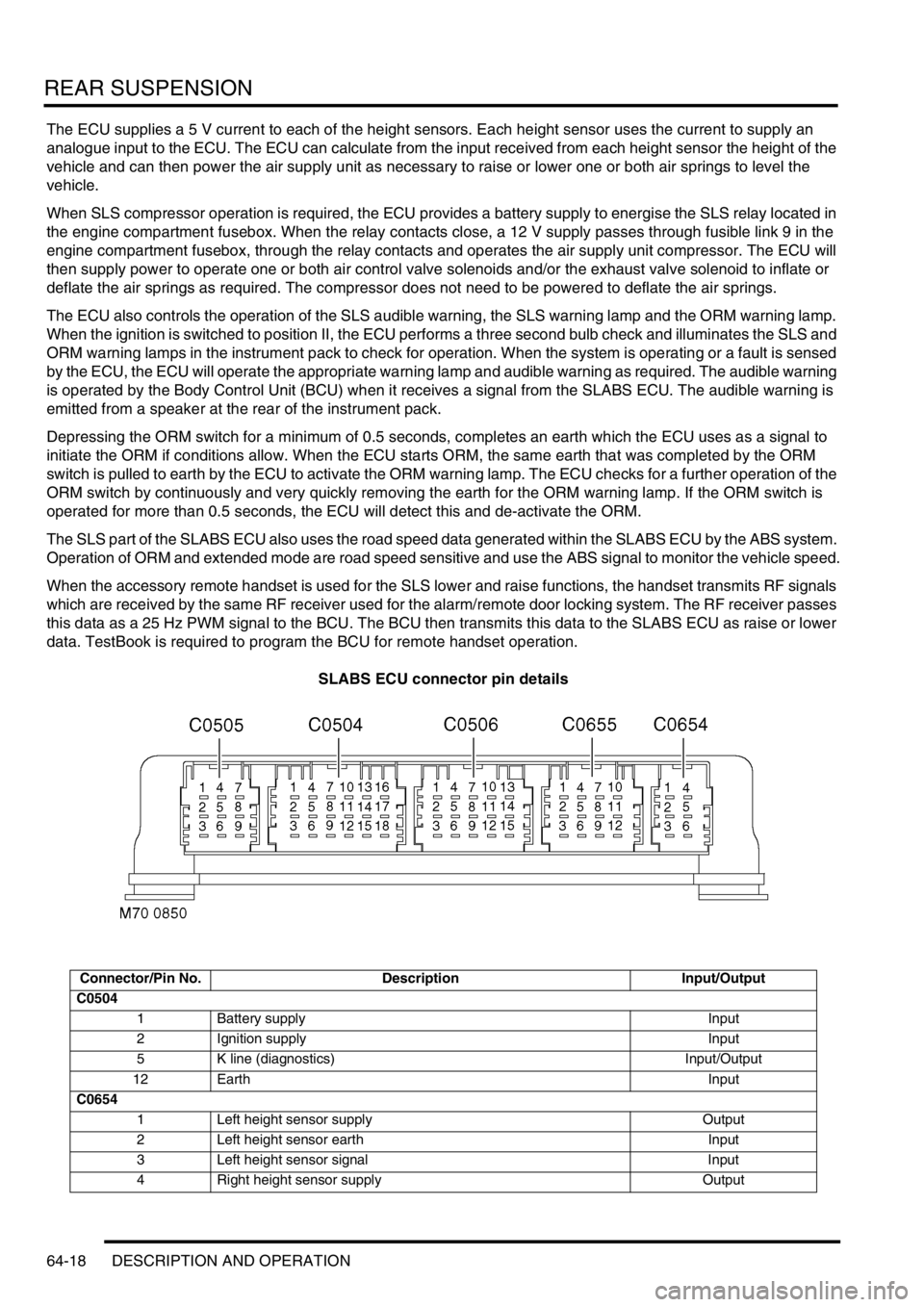

The ECU supplies a 5 V current to each of the height sensors. Each height sensor uses the current to supply an

analogue input to the ECU. The ECU can calculate from the input received from each height sensor the height of the

vehicle and can then power the air supply unit as necessary to raise or lower one or both air springs to level the

vehicle.

When SLS compressor operation is required, the ECU provides a battery supply to energise the SLS relay located in

the engine compartment fusebox. When the relay contacts close, a 12 V supply passes through fusible link 9 in the

engine compartment fusebox, through the relay contacts and operates the air supply unit compressor. The ECU will

then supply power to operate one or both air control valve solenoids and/or the exhaust valve solenoid to inflate or

deflate the air springs as required. The compressor does not need to be powered to deflate the air springs.

The ECU also controls the operation of the SLS audible warning, the SLS warning lamp and the ORM warning lamp.

When the ignition is switched to position II, the ECU performs a three second bulb check and illuminates the SLS and

ORM warning lamps in the instrument pack to check for operation. When the system is operating or a fault is sensed

by the ECU, the ECU will operate the appropriate warning lamp and audible warning as required. The audible warning

is operated by the Body Control Unit (BCU) when it receives a signal from the SLABS ECU. The audible warning is

emitted from a speaker at the rear of the instrument pack.

Depressing the ORM switch for a minimum of 0.5 seconds, completes an earth which the ECU uses as a signal to

initiate the ORM if conditions allow. When the ECU starts ORM, the same earth that was completed by the ORM

switch is pulled to earth by the ECU to activate the ORM warning lamp. The ECU checks for a further operation of the

ORM switch by continuously and very quickly removing the earth for the ORM warning lamp. If the ORM switch is

operated for more than 0.5 seconds, the ECU will detect this and de-activate the ORM.

The SLS part of the SLABS ECU also uses the road speed data generated within the SLABS ECU by the ABS system.

Operation of ORM and extended mode are road speed sensitive and use the ABS signal to monitor the vehicle speed.

When the accessory remote handset is used for the SLS lower and raise functions, the handset transmits RF signals

which are received by the same RF receiver used for the alarm/remote door locking system. The RF receiver passes

this data as a 25 Hz PWM signal to the BCU. The BCU then transmits this data to the SLABS ECU as raise or lower

data. TestBook is required to program the BCU for remote handset operation.

SLABS ECU connector pin details

Connector/Pin No. Description Input/Output

C0504

1 Battery supply Input

2 Ignition supply Input

5 K line (diagnostics) Input/Output

12 EarthInput

C0654

1 Left height sensor supply Output

2 Left height sensor earth Input

3 Left height sensor signal Input

4 Right height sensor supply Output

Page 1026 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-21

Normal ride height

When the vehicle is stationary, a door is open and the ignition is off, the SLS system will allow the rear of the vehicle

to lower to within 20 mm of the normal ride height as load is removed from the vehicle. The SLS system will only

operate the compressor to raise the rear of the vehicle when the engine is running, unless requested using the remote

handset.

Off-road mode (ORM)

ORM is used to raise the rear of the vehicle from normal ride height to the ORM ride height of 100 mm between the

tip of the bump stop and the axle.

ORM is activated by depressing the ORM switch located on the fascia for not less than 0.5 seconds. With the engine

running, all doors closed and the vehicle speed below 18 mph (30 km/h), the audible warning will sound once and the

ORM warning lamp in the instrument pack will start to flash when the switch is released. The compressor will be

started and the air control valves will be energised by the ECU to inflate the air springs and raise the rear of the vehicle.

When the full ORM height is reached, the ECU will terminate compressor operation and close the air valves. The ORM

warning lamp will stop flashing and remain continuously illuminated to inform the driver that the SLS system is in ORM.

When ORM is no longer required, depressing the ORM switch for not less than 0.5 seconds with all doors closed will

lower the SLS to normal ride height. The audible warning will sound once and the ORM warning lamp will flash as the

suspension lowers. The ECU energises the air control valves and the exhaust valve to release air pressure from the

air springs. When standard ride height is reached the ORM warning lamp will extinguish and the ECU will de-energise

the air control valves and the exhaust valve solenoids.

If the SLS is in ORM and the vehicle speed exceeds 18 mph (30 km/h), the ECU will lower the SLS to standard ride

height. The driver will be informed of this by an audible warning and the ORM warning lamp flashing as the suspension

lowers. When normal ride height is achieved, the ORM warning lamp will extinguish.

At sea level, the time to change the SLS from normal ride height to ORM or visa versa will take between 15 and 20

seconds.

If the ECU determines that conditions are not correct for SLS operation, i.e.; axle articulation or system fault, the

audible warning will sound three times to inform the driver that the ORM request has not been granted.

Extended mode

The extended mode is automatically operated by the ECU and requires no input from the driver. Extended mode

operates when the chassis is grounded causing the rear wheels to spin. This information is generated by the ABS

function of the SLABS ECU.

When the ECU senses that the chassis is grounded and the vehicle speed is less than 6 mph (10 km/h), the ECU will

operate the compressor and energise the air control valves for 25 seconds to raise the rear of the vehicle. This

operates irrespective of the mode that the SLS system is in at that time. To inform the driver, the ORM warning lamp

will flash continuously at all times that the system is in extended mode.

The driver can exit the extended mode by depressing the ORM switch for not less than 0.5 seconds or by exceeding

8 mph (13 km/h).

Remote handset SLS control

The remote handset is an accessory item which allows the SLS to be operated between normal ride height and bump

stop height to allow easier connection and disconnection of trailers. The remote handset is similar in appearance to

that of the remote door locking handset but does not have an integral key. A circular button with an arrow is used to

raise the SLS and an oval button with the 'Land Rover' logo is used to lower the SLS.

The remote handset control requires all doors to be closed and the ignition to be in position II, but the engine does

not need to be running.

Page 1027 of 1672

REAR SUSPENSION

64-22 DESCRIPTION AND OPERATION

Pressing the lower button will signal the SLABS ECU, via the RF receiver and the BCU, to energise the exhaust valve

and air control valves. The SLS will lower up to 60 mm (2.36 in) below normal ride height if the button is held. If the

button is released the SLS will stop at that point.

Pressing the raise button will signal the SLABS ECU, via the RF receiver and the BCU, to start the compressor and

energise the exhaust valve and air control valves. The SLS will raise to normal ride height if the button is held. If the

button is released the SLS will stop at that point.

When raising or lowering the SLS using the remote handset, the SLS warning lamp will flash and the audible warning

will sound when the system is operating. When the SLS is fully lowered the warning lamp will stay illuminated. The

SLS will reset to normal ride height if the vehicle speed exceeds 3 mph (5 km/h) for 10 seconds when the SLS is

lowered.

Transportation mode

Transportation mode must be used when the vehicle is transported on a trailer and secured by the chassis. The

transportation mode can only be enabled and disabled with TestBook.

The transportation mode lowers the rear suspension onto the bump stops with the engine not running. When the

suspension is in transportation mode, the SLS warning lamp is continuously illuminated when the ignition is in position

II.

When the engine is started in transportation mode, the SLS system will raise the rear suspension until a gap of 25

mm (1 in.) exists between the bump stop and the axle. The SLS warning lamp will flash continuously while the SLS

system is raising the suspension. When the gap between the bump stop and the axle is achieved, the warning lamp

will illuminate continuously.

When TestBook is used to disable the transportation mode, the rear suspension will raise to normal ride height when

the engine is running.

Page 1471 of 1672

BODY CONTROL UNIT

86-3-2 DESCRIPTION AND OPERATION

Power supply

Battery supply to the BCU and the IDM is provided through a 10 A fuse located in the engine compartment fuse box.

The BCU unit receives an ignition switched power supply (ignition switch position II) input via a 10 A fuse in the

passenger compartment fuse box.

The BCU receives a signal when the ignition switch is turned to the crank position, it then supplies an earth path to

the starter relay coil, to enable the crank operation by supplying power through the starter relay contacts to the starter

motor.

Battery voltage is monitored and BCU operation will function normally between 8 and 18 volts. Between 5.7 and 8

volts the BCU is in the 'under volts' state. The status of the battery is used to determine which outputs may be driven.

If a voltage supply above 18 volts is experienced, outputs will not normally be driven except for those functions which

are required during cranking (robust immobilisation, antenna coil, crank enable relay and feed to gear position switch

contacts W, X, Y, Z). In the over voltage state the vehicle can be driven, but all other functions are disabled and

outputs are switched off (power windows, heated screen, direction indicators etc.).

All functions are disabled on power up until communications between the BCU and IDM have been established. If

communications cannot be established, operation will commence with degraded functionality.

Battery supply to the IDM is provided through the inertia switch and a 10 A fuse in the engine compartment fuse box.

If the inertia switch contacts are closed battery voltage is available at the IDM; if the inertia switch contacts are open

there is no battery supply to the IDM. The supply condition of the IDM is signalled to the BCU via the serial bus. If the

inertia switch is operated (contacts open) the change in state is detected by the BCU which unlocks the doors if the

ignition switch is in position II and the alarm is not set.

The BCU is earthed through a hard-wire connection.

Inputs and outputs

The BCU and IDM process inputs and provide the necessary outputs for control and operation of the vehicle's 'body'

systems.

BCU inputs

The BCU processes signals received from the following components:

lDoor latch switches.

lDriver's door key lock/ unlock switches.

lBonnet activated security system.

lVolumetric sensors.

lCentral Door Locking (CDL) switches.

lRemote transmitter (via receiver unit).

lInertia fuel cut-off switch.

lIgnition switch.

lFuel flap release switch.

The input voltages (V

in) for BCU digital signals are defined as follows:

lLogic 1 when V

in ≥ 6V.

lLogic 0 when V

in ≤ 2V.

BCU input voltages between 2 and 6 volts are indeterminate and cannot be guaranteed.

Analogue input voltages are measured as a ratio with respect to battery voltage.

Page 1482 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-13

Anti-theft system

The BCU controls the logical switching operations for enabling and activating the anti-theft system. Features include:

lPerimetric protection – monitors the condition of doors and hinged panels.

lVolumetric protection – monitors the vehicle's interior space.

lRemote locking, superlocking and unlocking functions.

lEngine immobilisation and remobilisation.

lAdvanced mislock detection and automatic compensation.

lEKA code functions.

lCustomer configuration options.

lMarket configuration options.

Immobilisation

The immobilisation system comprises the following components:

lRF receiver.

lRF transmitter/ transponder.

lTransponder coil.

lBCU.

lDoor switches, door lock switches and bonnet switch.

lIDM.

lECM.

lStarter solenoid relay.

lStatus LED.

Alarm sounder Alarm Audible warnings are given by the security system sounder only.

Both Audible warnings are given by both the security system sounder

and the vehicle horn.

Vehicle Audible warnings are given by the vehicle horn only.

BBUS Audible warnings are given by the security system sounder,

vehicle horn and BBUS.

Disabled Audible warnings are not given.

Acclimatisation locking Disabled The vehicle cannot be locked if the ignition is on.

Enabled The vehicle can be locked if the ignition is on and the engine is

running.

Alarm tamper Disabled The security system LED does not flash when the security system

has been tampered with.

Enabled The security system LED flashes when the security system has

been tampered with.

Engine immobilised LED off The security system LED does not flash when the engine is

immobilised.

LED flash The security system LED flashes when the engine is immobilised.

Low battery warning Disabled The security system LED does not flash when the remote

transmitter battery is low.

Enabled The security system LED flashes when the remote transmitter

battery is low.

Emergency Key Access

(EKA)Disabled EKA is disabled.

Enabled EKA is enabled and the door locks operate electrically.

No unlock EKA is enabled, but the door locks do not operate electrically. Function Option Details

Page 1485 of 1672

BODY CONTROL UNIT

86-3-16 DESCRIPTION AND OPERATION

Headlamps

The BCU contains a feature which allow the vehicle headlamps to be turned on when the remote transmitter is

pressed (courtesy headlamps).

For markets with daylight running lamps, the BCU controls the logical operation of the daylight running lamps. Options

are daylight running lamps are on if the main beam headlamps are off, or the daylight running lamps are on with main

and dipped beam off and the gearbox not in Park.

Front fog lamps

For markets with front fog lamps fitted, the BCU controls the operation of the front fog lamps. Options can be selected

so that the fog lamps will operate with or without the headlamps on main beam.

Instrument pack

The BCU communicates with the instrument pack via a serial data bus.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

lThe instrument pack provides the BCU and IDM with details of vehicle speed.

lSignals are provided from the IDM to the instrument pack and BCU when the direction indicator lamps are active.

lFor certain markets, the BCU provides a signal to the instrument pack for indicating when the transfer box is in

neutral.

lThe IDM can signal the instrument pack to illuminate a trailer warning lamp. This operates when the IDM senses

that the current drawn by the indicator circuit exceeds a preset threshold.

lThe odometer reading displayed on the instrument pack LCD screen is also stored in non volatile memory in the

BCU. Whenever the ignition is turned from position I to position II, the instrument pack and the BCU compare

their stored values.

lThe gear selector position is displayed on the instrument pack LCD screen under the direction of the BCU.

Starting

The starting system comprises a starter motor and solenoid located at the rear right hand side of the engine. A starter

relay controlled by the BCU is used to supply battery power for starter solenoid operation. The starter motor receives

its feed directly from the battery.

Cruise control

The BCU processes several signals used for cruise control:

lWhen the brake pedal is pressed, a low voltage brake lamp signal is sent via the BCU to the cruise control ECU.

lThe gear position switch sends an input via the BCU to the cruise control ECU if the selector lever is in Park,

Neutral or Reverse.

lA voltage supply is fed from the BCU to the cruise control SET+ switch.

lA voltage supply is fed from the BCU to the cruise control RES switch.

On vehicles with automatic transmission, if the BCU receives an input from the gear position switch or the brake pedal

switch, the BCU sends a signal to the cruise control ECU to cancel or inhibit cruise control operation.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - cruise control.

Shift interlock (where fitted)

On automatic gearbox models, the BCU and IDM combine with an interlock relay located in the passenger

compartment fuse box to operate a shift interlock solenoid, so that the gear selector lever cannot be moved out of

Park until certain logical conditions have been satisfied. Operation of the interlock may be affected, if the battery

becomes discharged.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

Page 1513 of 1672

ALARM SYSTEM AND HORN

86-4-4 DESCRIPTION AND OPERATION

Alarm system block diagram

1Body Control Unit (BCU)

2Remote handset

3Receiver

4Fuel cut off switch

5Ignition switch

6Central door locking switch

7Volumetric sensors

8Bonnet activated alarm switch

9Drivers door key lock/unlock switches

10Door latch switches 11Fuel flap release switch

12Intelligent Driver Module (IDM)

13Battery Backed Up Sounder (BBUS)

14Alarm sounder

15Vehicle horns

16Direction indicators

17Door lock actuators

18Engine Control Module (ECM)

19Starter motor

Page 1514 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-5

Description

General

The anti-theft system deters the theft of the vehicle with both active and passive systems. The active systems monitor

the vehicle perimeter and, in some markets the vehicle interior, for intrusion. If the system detects intrusion, an alarm

sounds. The passive systems include a vehicle immobiliser as well as protection against intrusion through super

locking the doors. The vehicle is immobilised whenever the ignition key is removed from the ignition switch. Super

locking prevents the interior door handles from opening the doors. In addition, there are many features and functions

that enhance system operation.

It is possible to perform the various functions associated with the anti-theft system remotely. To accomplish this, the

handset generates a radio frequency when the lock button or unlock button is depressed. This signal is transmitted

to the Body Control Unit (BCU) via a receiver located in front of rear sunroof beneath the headlining. Precise alignment

of the handset to the receiver is not necessary. The approximate operating range between the handset and the

receiver is 10 metres (33 feet).

It is important to understand the configuration of the system on each particular vehicle. There are many

different combinations of features with dedicated operating modes. System configuration for each vehicle

can be determined using TestBook.

The anti-theft system is controlled centrally by the BCU, which is located below and behind the passenger glovebox.

A serial communication link communicates between the Intelligent Driver Module (IDM) located within the fusebox,

the BCU and the LED located in the instrument panel.

The state of the alarm is stored in the BCU. If the battery is disconnected while the alarm is armed, the alarm will be

triggered when the battery is reconnected.

NOTE: Disconnecting the battery while the alarm is armed triggers the alarm. Always disarm the alarm system before

disconnecting the battery.

The BCU also receives inputs from the following components:

lIgnition key in sensor.

lIgnition switch.

lFuel cut off switch.

lFuel flap release switch.

The BCU also interacts with the following components:

lStarter relay.

lVehicle horns.

lDirection indicators.

lFuel flap release actuator.

lCourtesy lamps.