mirror LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 682 of 1007

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-21

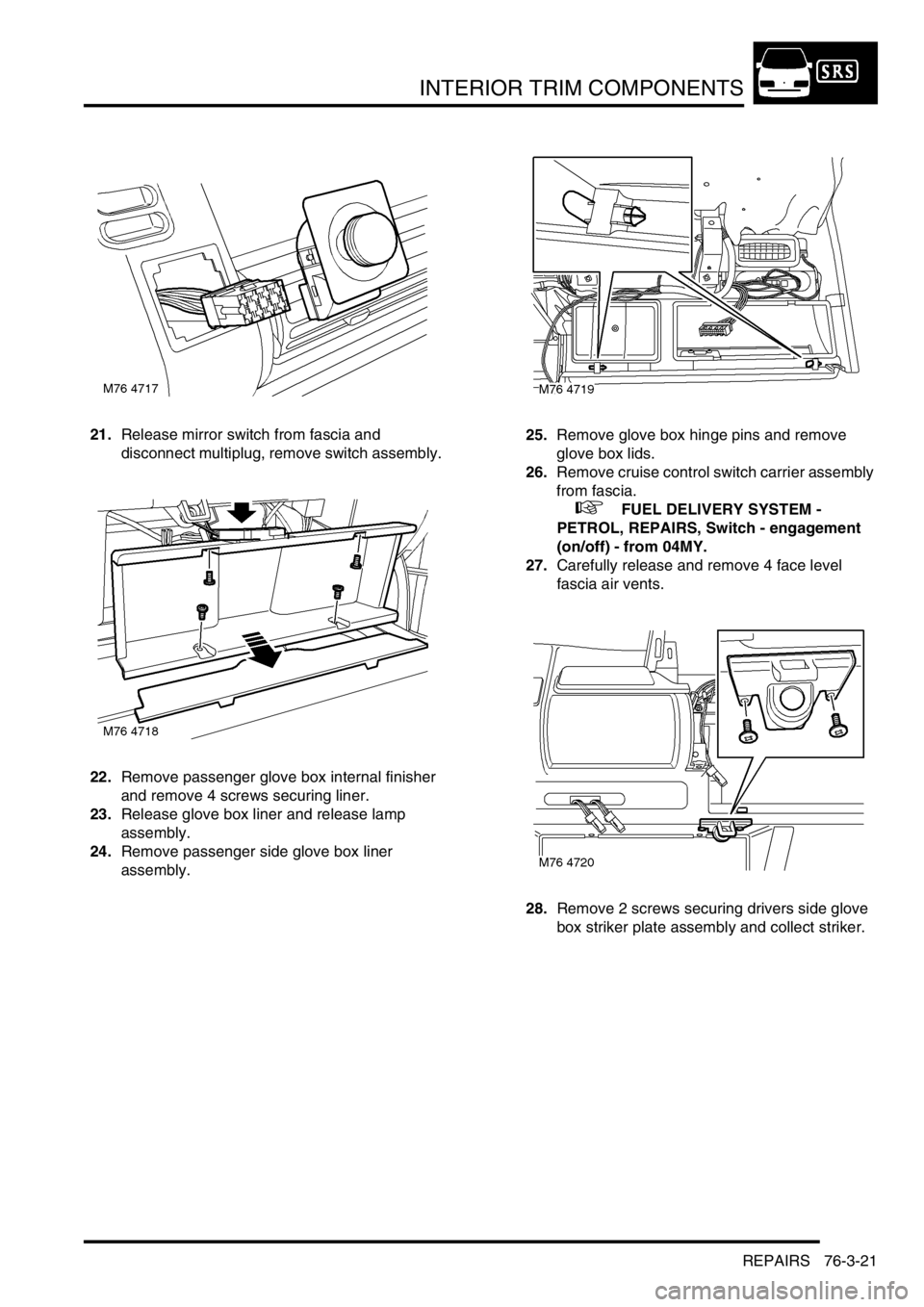

21.Release mirror switch from fascia and

disconnect multiplug, remove switch assembly.

22.Remove passenger glove box internal finisher

and remove 4 screws securing liner.

23.Release glove box liner and release lamp

assembly.

24.Remove passenger side glove box liner

assembly.25.Remove glove box hinge pins and remove

glove box lids.

26.Remove cruise control switch carrier assembly

from fascia.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Switch - engagement

(on/off) - from 04MY.

27.Carefully release and remove 4 face level

fascia air vents.

28.Remove 2 screws securing drivers side glove

box striker plate assembly and collect striker.

Page 683 of 1007

INTERIOR TRIM COMPONENTS

76-3-22 REPAIRS

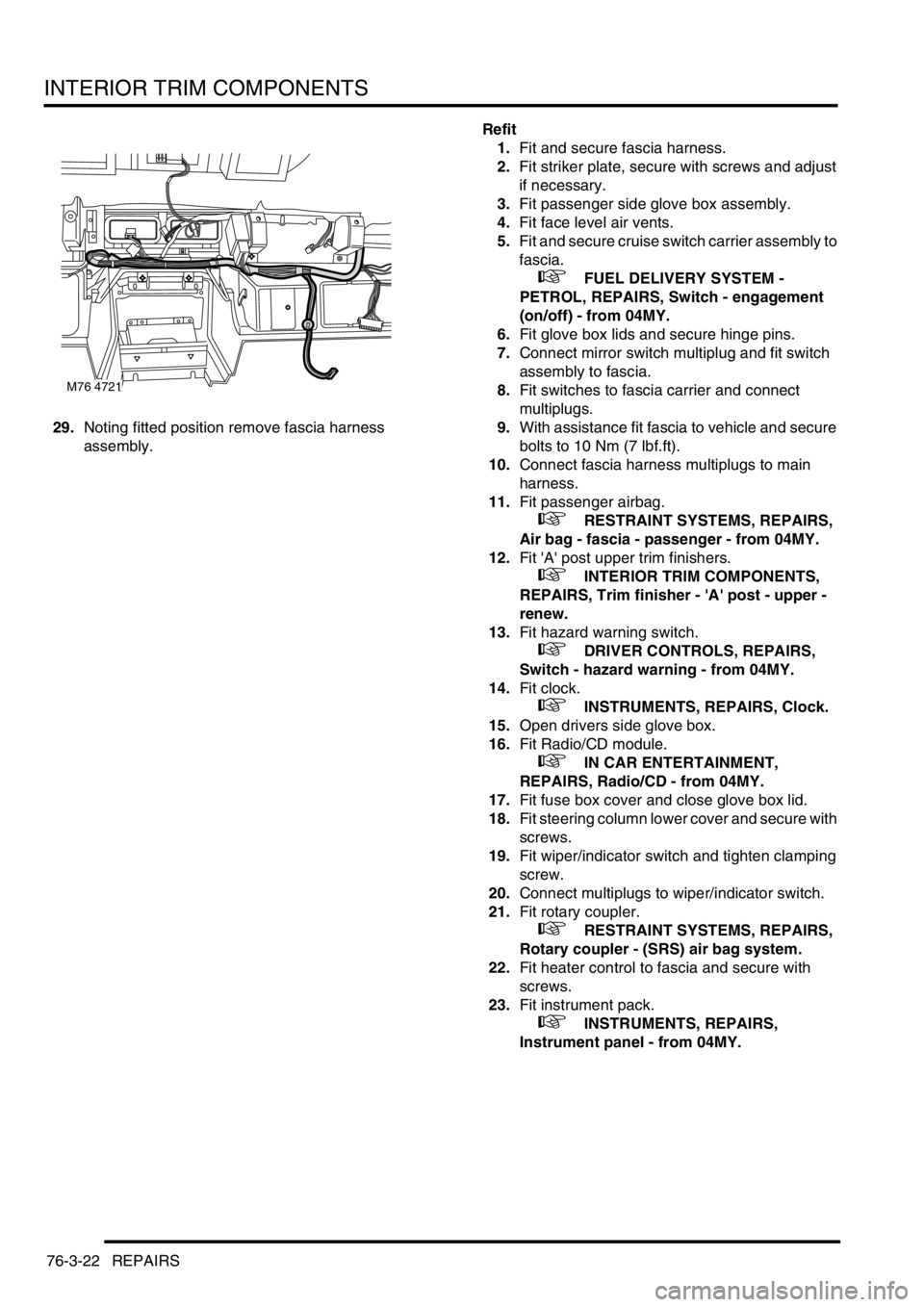

29.Noting fitted position remove fascia harness

assembly.Refit

1.Fit and secure fascia harness.

2.Fit striker plate, secure with screws and adjust

if necessary.

3.Fit passenger side glove box assembly.

4.Fit face level air vents.

5.Fit and secure cruise switch carrier assembly to

fascia.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Switch - engagement

(on/off) - from 04MY.

6.Fit glove box lids and secure hinge pins.

7.Connect mirror switch multiplug and fit switch

assembly to fascia.

8.Fit switches to fascia carrier and connect

multiplugs.

9.With assistance fit fascia to vehicle and secure

bolts to 10 Nm (7 lbf.ft).

10.Connect fascia harness multiplugs to main

harness.

11.Fit passenger airbag.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - fascia - passenger - from 04MY.

12.Fit 'A' post upper trim finishers.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

13.Fit hazard warning switch.

+ DRIVER CONTROLS, REPAIRS,

Switch - hazard warning - from 04MY.

14.Fit clock.

+ INSTRUMENTS, REPAIRS, Clock.

15.Open drivers side glove box.

16.Fit Radio/CD module.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio/CD - from 04MY.

17.Fit fuse box cover and close glove box lid.

18.Fit steering column lower cover and secure with

screws.

19.Fit wiper/indicator switch and tighten clamping

screw.

20.Connect multiplugs to wiper/indicator switch.

21.Fit rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler - (SRS) air bag system.

22.Fit heater control to fascia and secure with

screws.

23.Fit instrument pack.

+ INSTRUMENTS, REPAIRS,

Instrument panel - from 04MY.

M76 4721

Page 692 of 1007

SCREENS

REPAIRS 76-4-1

SCREENS REPAIRS

Windscreen

$% 76.81.01

The following equipment is required: Cutting wire

and handles, Windscreen repair kit, Sealer applicator

gun and Suction cups

Wear protective gloves when handling glass,

solvents and primers.

Wear suitable eye protection when removing and

refitting glass.

Remove

1.Remove air intake panel.

+ HEATING AND VENTILATION,

REPAIRS, Plenum - air intake.

2.Remove sun visors and sun visor retaining

clips.

3.Remove 'A' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

4.Remove retaining stud from front of headlining.

5.Remove interior mirror.

6.Fit protection to bonnet and areas around

screen.

7.Cover heater ducts with masking tape.

8.Cover interior of vehicle with protective sheet.

9.Make knife cut in sealant at bottom of 'A' post.

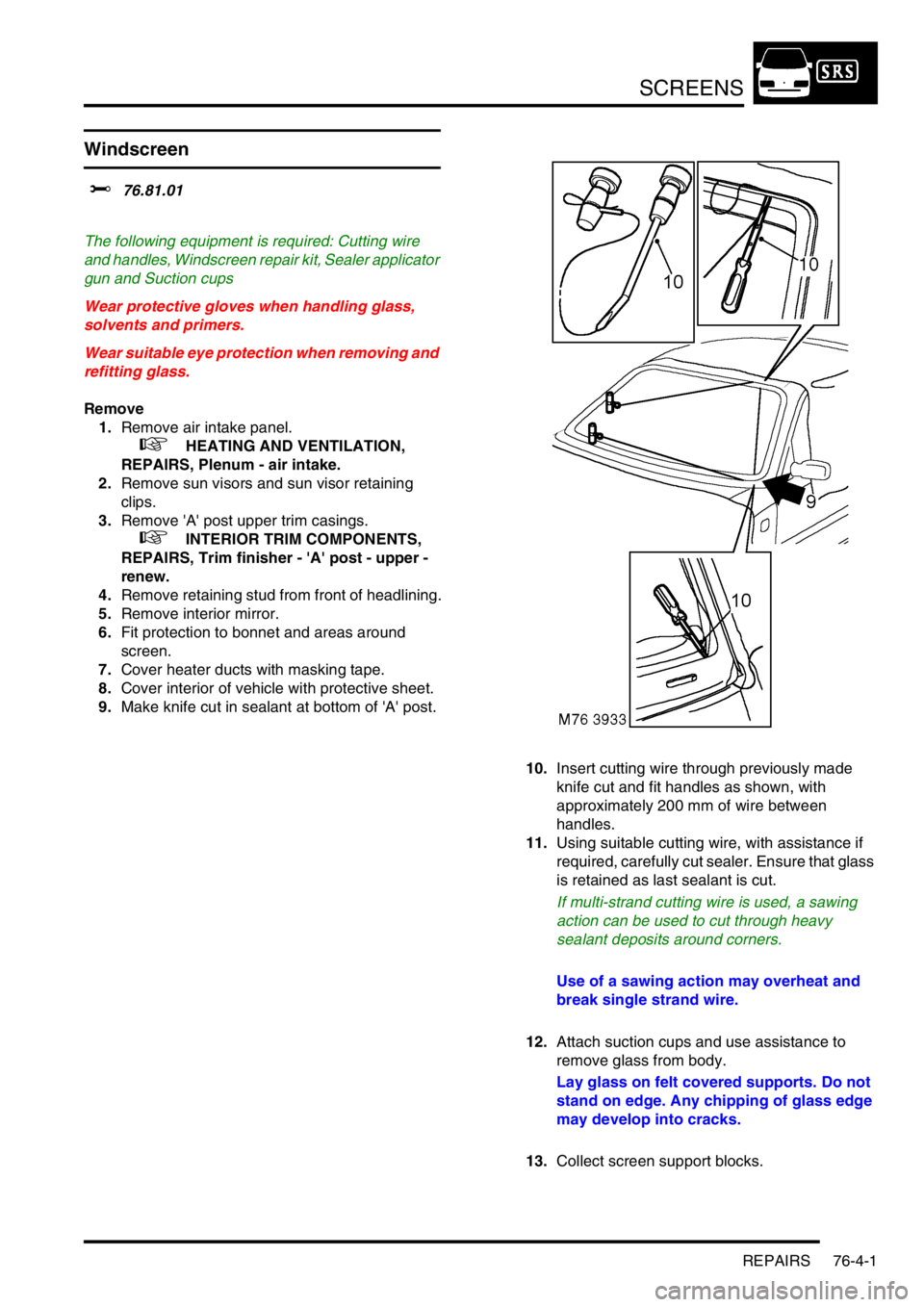

10.Insert cutting wire through previously made

knife cut and fit handles as shown, with

approximately 200 mm of wire between

handles.

11.Using suitable cutting wire, with assistance if

required, carefully cut sealer. Ensure that glass

is retained as last sealant is cut.

If multi-strand cutting wire is used, a sawing

action can be used to cut through heavy

sealant deposits around corners.

Use of a sawing action may overheat and

break single strand wire.

12.Attach suction cups and use assistance to

remove glass from body.

Lay glass on felt covered supports. Do not

stand on edge. Any chipping of glass edge

may develop into cracks.

13.Collect screen support blocks.

Page 693 of 1007

SCREENS

76-4-2 REPAIRS

Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4.Fit spacer blocks to body.

5.With assistance, locate screen to body.

6.Apply masking tape reference marks to aid

fitment.

7.With assistance, remove screen and place

aside.

8.Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9.Apply etch primer to any bare metal on frame.

10.Apply bonding agent to screen and allow to

cure.

11.Apply primer over etch primer on frame.

12.Apply activator over old sealer on frame.

13.Allow activator to cure.

14.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

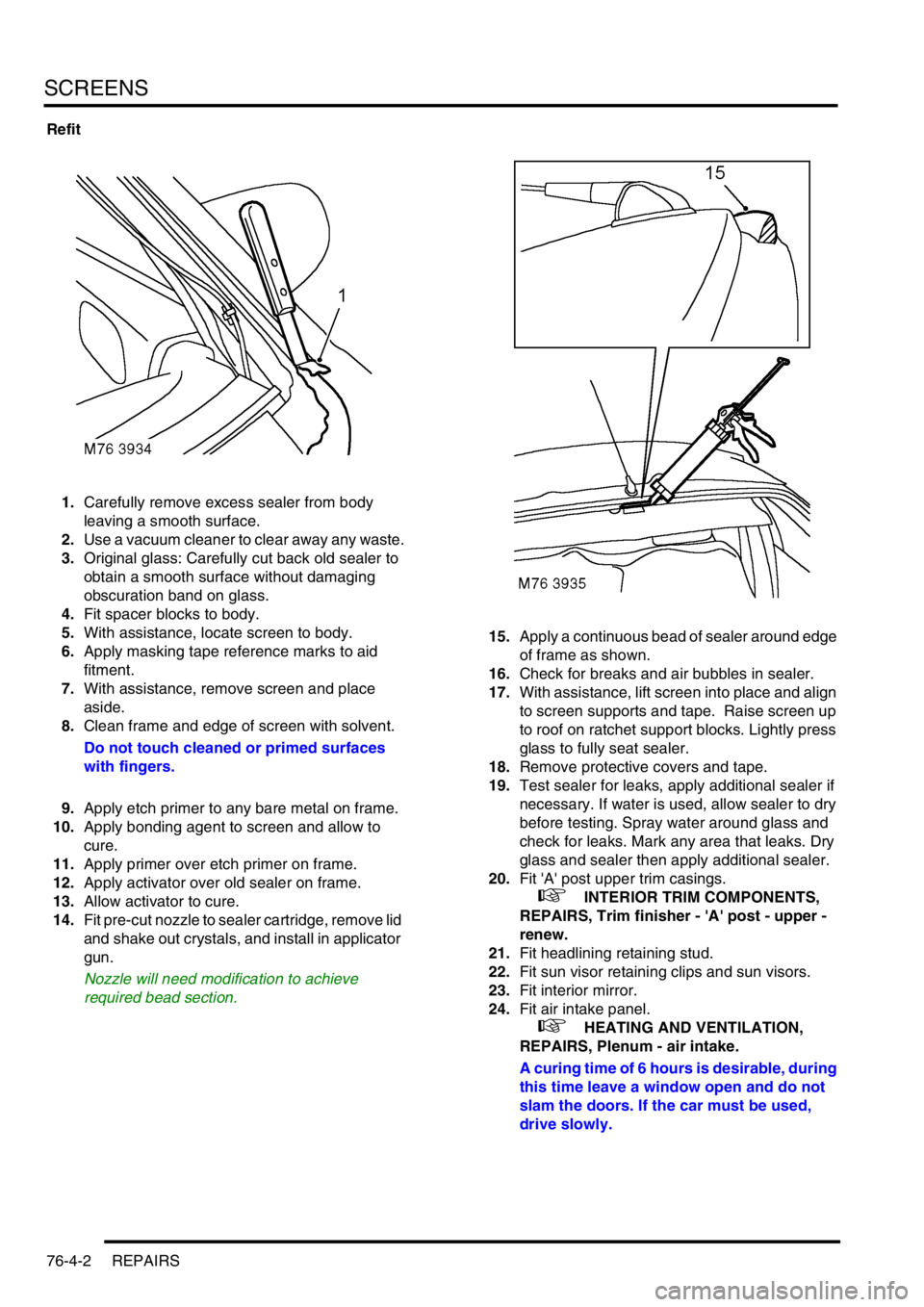

required bead section.15.Apply a continuous bead of sealer around edge

of frame as shown.

16.Check for breaks and air bubbles in sealer.

17.With assistance, lift screen into place and align

to screen supports and tape. Raise screen up

to roof on ratchet support blocks. Lightly press

glass to fully seat sealer.

18.Remove protective covers and tape.

19.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

20.Fit 'A' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

21.Fit headlining retaining stud.

22.Fit sun visor retaining clips and sun visors.

23.Fit interior mirror.

24.Fit air intake panel.

+ HEATING AND VENTILATION,

REPAIRS, Plenum - air intake.

A curing time of 6 hours is desirable, during

this time leave a window open and do not

slam the doors. If the car must be used,

drive slowly.

Page 770 of 1007

PANEL REPAIRS

WELDING PROCEDURES 77-2-15

WE LDING PROCEDURE S

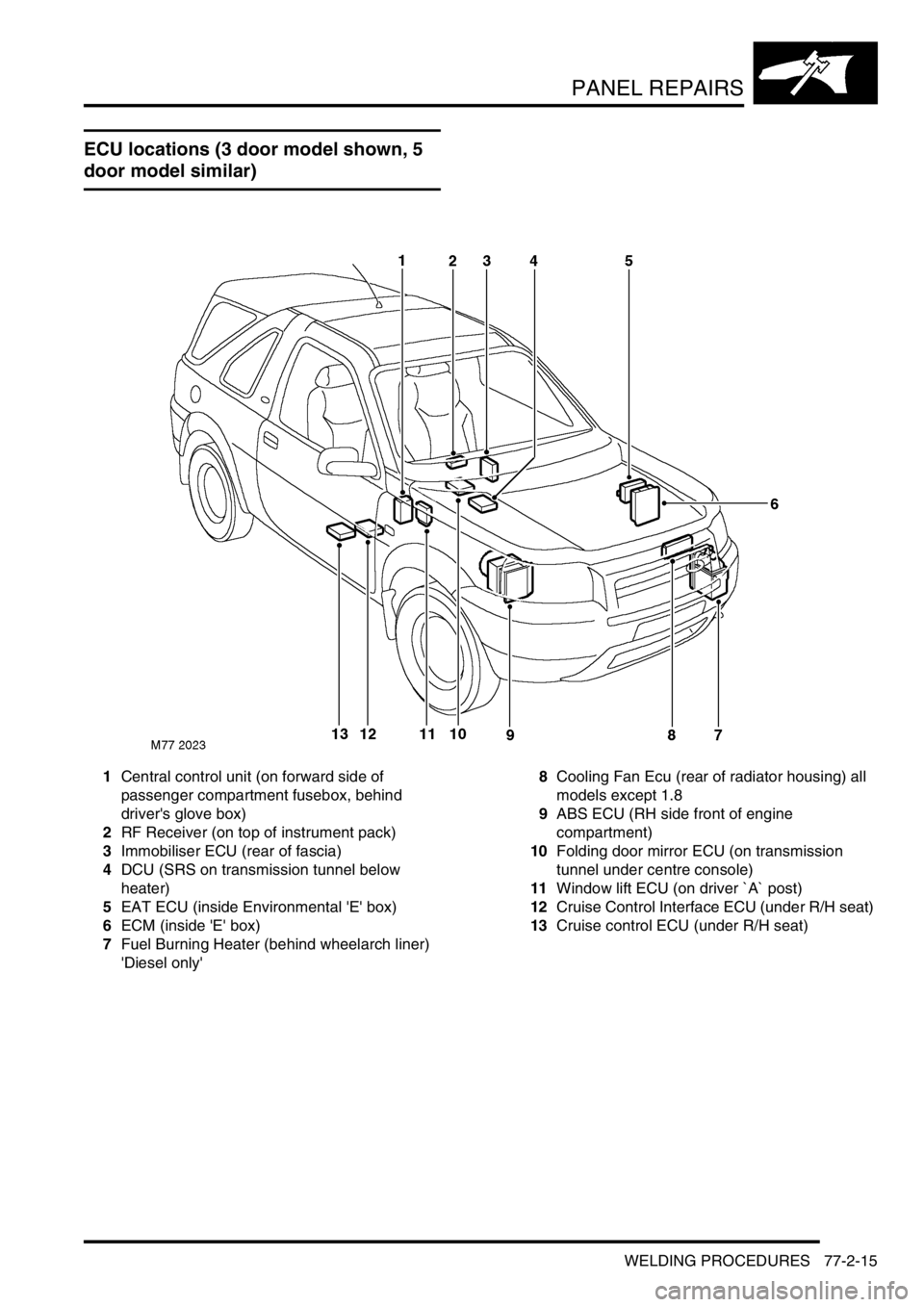

ECU locations (3 door model shown, 5

door model similar)

1Central control unit (on forward side of

passenger compartment fusebox, behind

driver's glove box)

2RF Receiver (on top of instrument pack)

3Immobiliser ECU (rear of fascia)

4DCU (SRS on transmission tunnel below

heater)

5EAT ECU (inside Environmental 'E' box)

6ECM (inside 'E' box)

7Fuel Burning Heater (behind wheelarch liner)

'Diesel only'8Cooling Fan Ecu (rear of radiator housing) all

models except 1.8

9ABS ECU (RH side front of engine

compartment)

10Folding door mirror ECU (on transmission

tunnel under centre console)

11Window lift ECU (on driver `A` post)

12Cruise Control Interface ECU (under R/H seat)

13Cruise control ECU (under R/H seat)

Page 862 of 1007

CORROSION PREVENTION AND SEALING

LEAK DETECTION 77-4-31

LEAK DETECT ION

Water Leaks

Where water leakage is involved, always adopt a logical approach to the problem using a combination of skill,

experience and intuition. Do not reach a conclusion based only on visual evidence, such as assuming that a wet

footwell is caused by a leak emanating from the windscreen. It will often be found that the source of the leak is

elsewhere. Use of the correct procedure will increase the chance of locating a leak, however obscure it may seem.

Tools and equipment

The following tools and equipment are recommended for the purpose of detection and rectification of water leaks:

1Garden sprayer (hand-operated).

2Wet/dry vacuum cleaner.

3Dry, absorbent cloths.

4Battery torch.

5Small mirror.

6Weatherstrip locating tool.

7Trim panel remover.

8Small wooden or plastic wedges.

9Dry compressed air supply.

10Hot air blower.

11Sealer applicators.

12Ultrasonic leak detector.

During leak detection, the vehicle should be considered in three basic sections:

lThe front interior space.

lThe rear passenger space.

lThe loadspace or boot.

Testing

From the information supplied by the customer it should be possible for the bodyshop operator to locate the starting

point from which the leak may be detected. After the area of the leak has been identified, find the actual point of entry

into the vehicle.

A simple and effective means in the first instance is an ordinary garden spray with provision for pressure and jet

adjustment, which will allow water to be directed in a jet or turned into a fine spray. Use a mirror and a battery-powered

torch (NOT a mains voltage inspection lamp) to see into dark corners.

The sequence of testing is particularly important. Start at the lowest point and work slowly upwards, to avoid testing

in one area while masking the leak in another. For example, if testing started at the level of the windscreen, any water

cascading into the plenum chamber could leak through a bulkhead grommet and into the footwells. Even at this point

it could still be wrongly assumed that the windscreen seal was at fault.

Another important part of identifying a water leak is by visual examination of door aperture seals, grommets and

weatherstrips for damage, deterioration or misalignment, together with the fit of the door itself against the seals.

Sealing

When the point of the leak has been detected, it will then be necessary to rectify it using the following procedure:

1Renew all door aperture seals and weatherstrips which have suffered damage, misalignment or deterioration.

2Check all body seals to ensure that they are correctly located on their mounting flanges/faces using a lipping

tool if necessary.

3Dry out body seams to be treated using compressed air and/or a hot air blower as necessary.

4Apply sealant on the outside of the joint wherever possible to ensure the exclusion of water.

5When rectifying leaks between a screen glass and its weatherstrip (or in the case of direct glazing, between the

glass and bodywork), avoid removing the glass if possible. Apply the approved material at the appropriate

location (i.e. glass to weatherstrip or glass to body).

Page 944 of 1007

CONTROL UNITS

REPAIRS 86-3-1

CONTROL UNITS REPAIRS

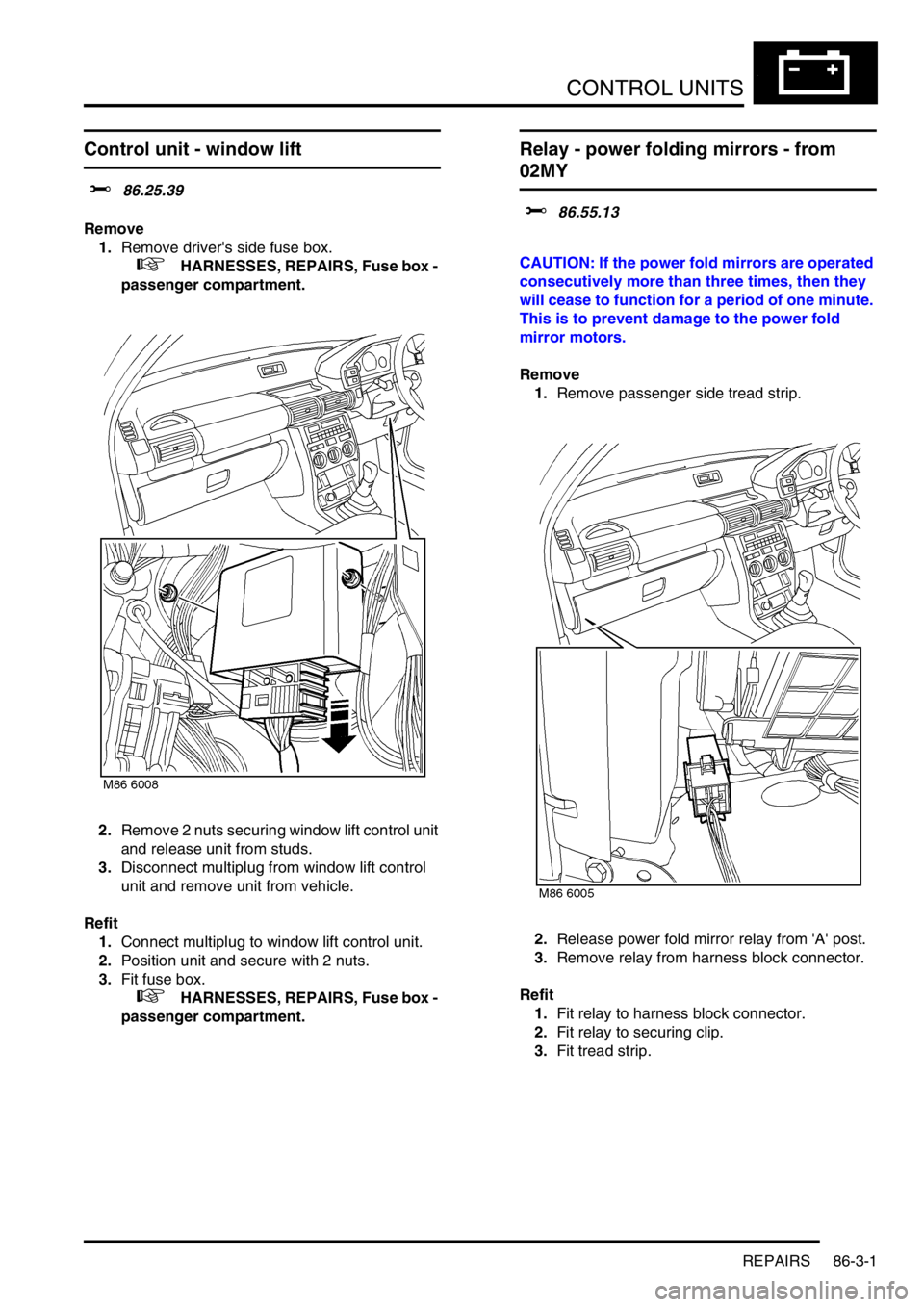

Control unit - window lift

$% 86.25.39

Remove

1.Remove driver's side fuse box.

+ HARNESSES, REPAIRS, Fuse box -

passenger compartment.

2.Remove 2 nuts securing window lift control unit

and release unit from studs.

3.Disconnect multiplug from window lift control

unit and remove unit from vehicle.

Refit

1.Connect multiplug to window lift control unit.

2.Position unit and secure with 2 nuts.

3.Fit fuse box.

+ HARNESSES, REPAIRS, Fuse box -

passenger compartment.

Relay - power folding mirrors - from

02MY

$% 86.55.13

CAUTION: If the power fold mirrors are operated

consecutively more than three times, then they

will cease to function for a period of one minute.

This is to prevent damage to the power fold

mirror motors.

Remove

1.Remove passenger side tread strip.

2.Release power fold mirror relay from 'A' post.

3.Remove relay from harness block connector.

Refit

1.Fit relay to harness block connector.

2.Fit relay to securing clip.

3.Fit tread strip.

Page 946 of 1007

CONTROL UNITS

REPAIRS 86-3-3

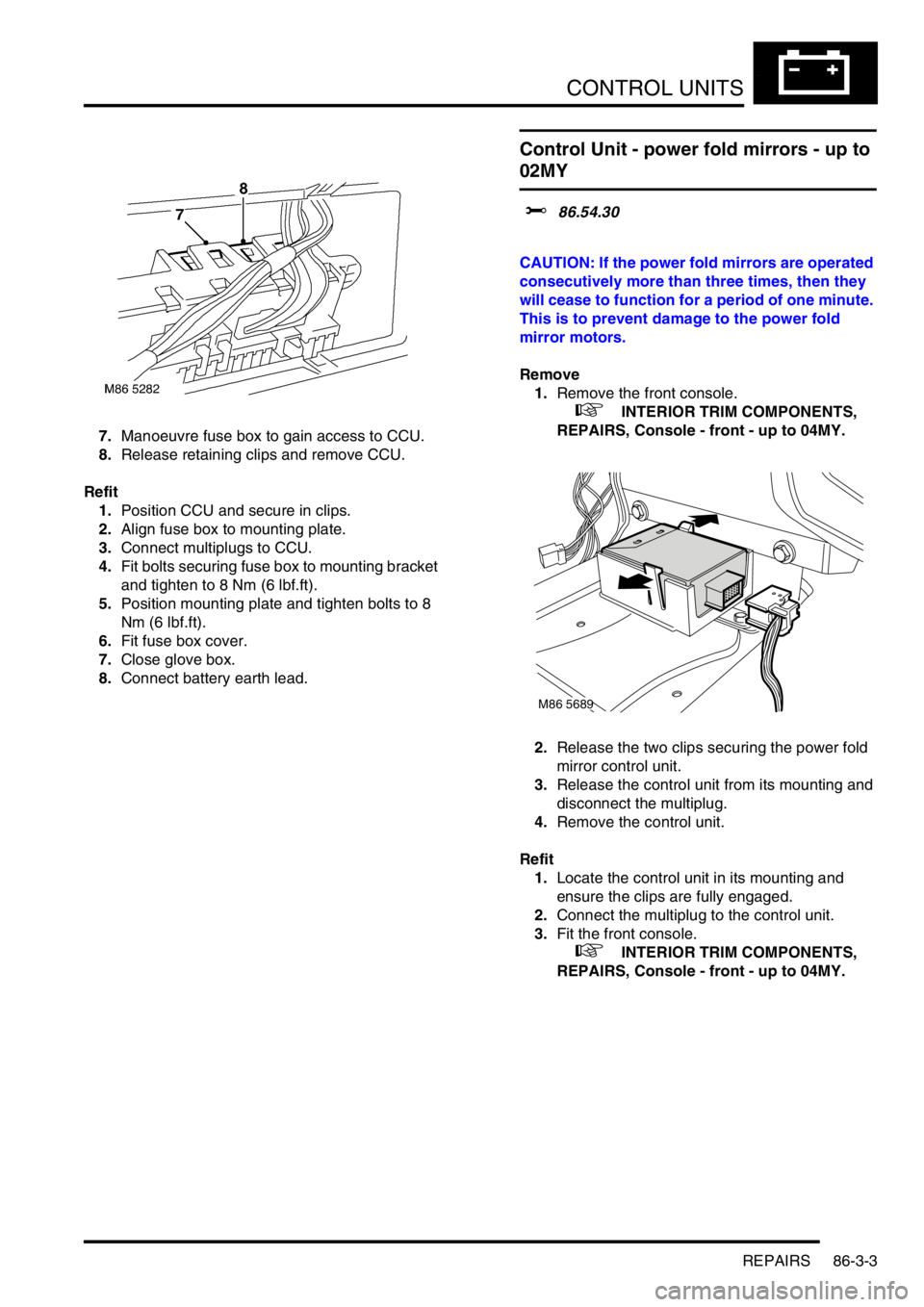

7.Manoeuvre fuse box to gain access to CCU.

8.Release retaining clips and remove CCU.

Refit

1.Position CCU and secure in clips.

2.Align fuse box to mounting plate.

3.Connect multiplugs to CCU.

4.Fit bolts securing fuse box to mounting bracket

and tighten to 8 Nm (6 lbf.ft).

5.Position mounting plate and tighten bolts to 8

Nm (6 lbf.ft).

6.Fit fuse box cover.

7.Close glove box.

8.Connect battery earth lead.

Control Unit - power fold mirrors - up to

02MY

$% 86.54.30

CAUTION: If the power fold mirrors are operated

consecutively more than three times, then they

will cease to function for a period of one minute.

This is to prevent damage to the power fold

mirror motors.

Remove

1.Remove the front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

2.Release the two clips securing the power fold

mirror control unit.

3.Release the control unit from its mounting and

disconnect the multiplug.

4.Remove the control unit.

Refit

1.Locate the control unit in its mounting and

ensure the clips are fully engaged.

2.Connect the multiplug to the control unit.

3.Fit the front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

M86 5689

Page 990 of 1007

HARNESSES

REPAIRS 86-7-15

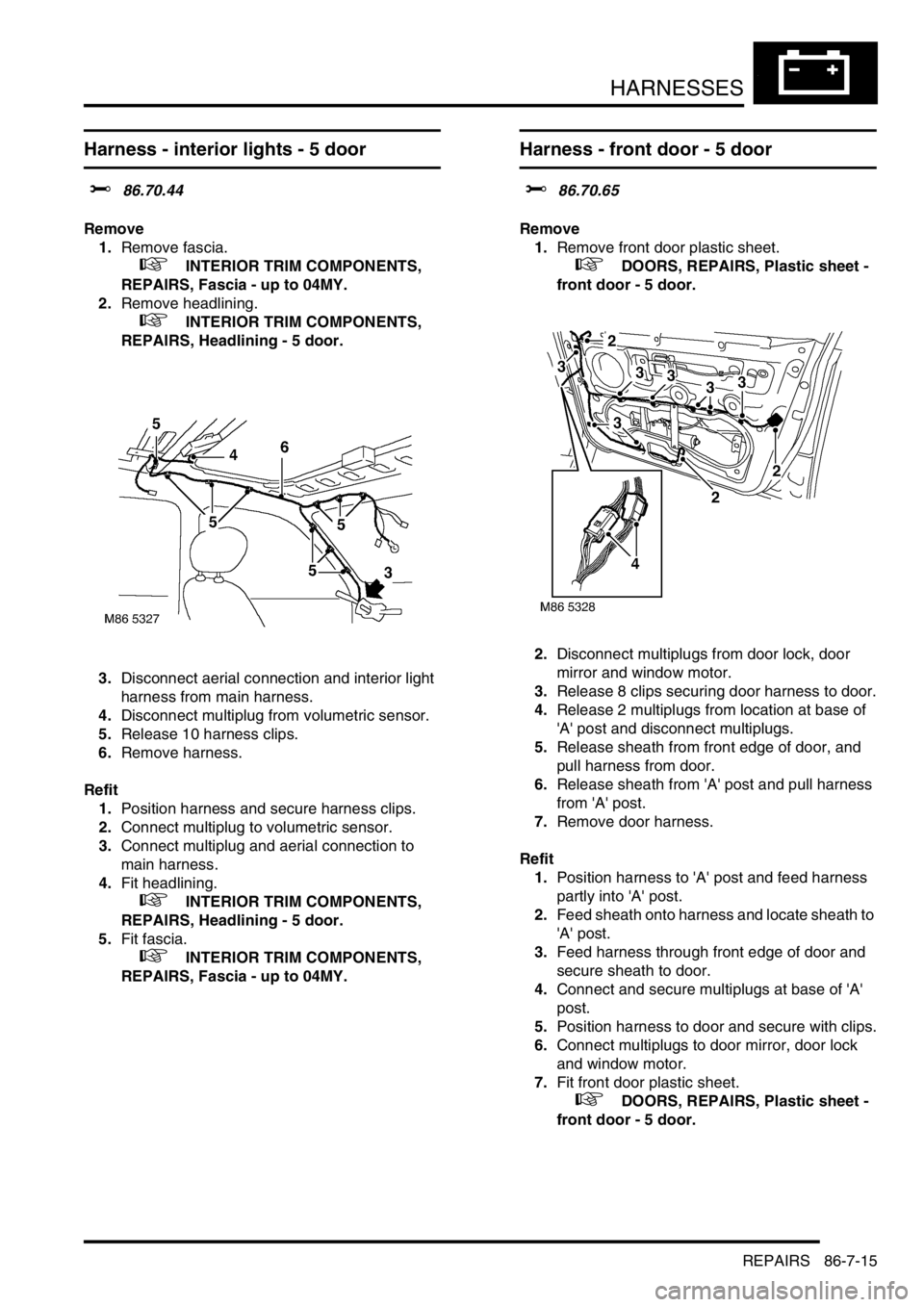

Harness - interior lights - 5 door

$% 86.70.44

Remove

1.Remove fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

2.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.

3.Disconnect aerial connection and interior light

harness from main harness.

4.Disconnect multiplug from volumetric sensor.

5.Release 10 harness clips.

6.Remove harness.

Refit

1.Position harness and secure harness clips.

2.Connect multiplug to volumetric sensor.

3.Connect multiplug and aerial connection to

main harness.

4.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 5 door.

5.Fit fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

Harness - front door - 5 door

$% 86.70.65

Remove

1.Remove front door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

front door - 5 door.

2.Disconnect multiplugs from door lock, door

mirror and window motor.

3.Release 8 clips securing door harness to door.

4.Release 2 multiplugs from location at base of

'A' post and disconnect multiplugs.

5.Release sheath from front edge of door, and

pull harness from door.

6.Release sheath from 'A' post and pull harness

from 'A' post.

7.Remove door harness.

Refit

1.Position harness to 'A' post and feed harness

partly into 'A' post.

2.Feed sheath onto harness and locate sheath to

'A' post.

3.Feed harness through front edge of door and

secure sheath to door.

4.Connect and secure multiplugs at base of 'A'

post.

5.Position harness to door and secure with clips.

6.Connect multiplugs to door mirror, door lock

and window motor.

7.Fit front door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

front door - 5 door.

Page 996 of 1007

DRIVER CONTROLS

REPAIRS 86-8-5

Switch - control - exterior mirror

$% 86.65.75

Remove

1.Release mirror switch from fascia and

disconnect multiplug.

Refit

1.Position switch, connect multiplug and secure

switch to fascia.