differential LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 490 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-5

Oil seal - pinion

$% 51.20.01

Remove

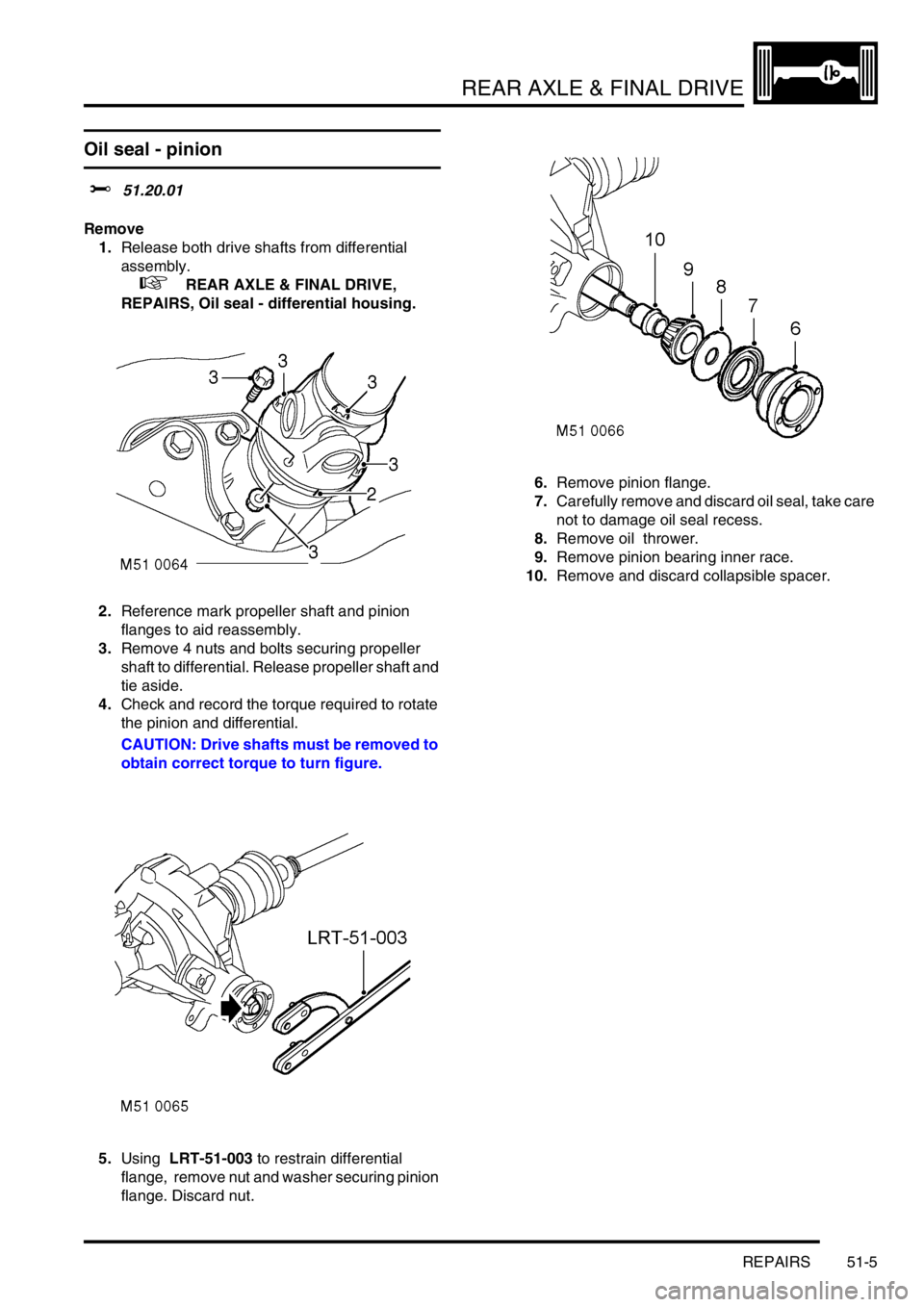

1.Release both drive shafts from differential

assembly.

+ REAR AXLE & FINAL DRIVE,

REPAIRS, Oil seal - differential housing.

2.Reference mark propeller shaft and pinion

flanges to aid reassembly.

3.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

4.Check and record the torque required to rotate

the pinion and differential.

CAUTION: Drive shafts must be removed to

obtain correct torque to turn figure.

5.Using LRT-51-003 to restrain differential

flange, remove nut and washer securing pinion

flange. Discard nut.6.Remove pinion flange.

7.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

8.Remove oil thrower.

9.Remove pinion bearing inner race.

10.Remove and discard collapsible spacer.

Page 491 of 1007

REAR AXLE & FINAL DRIVE

51-6 REPAIRS

Refit

1.Fit new collapsible spacer.

2.Fit pinion bearing and oil thrower.

3.Clean pinion flange and oil seal recess.

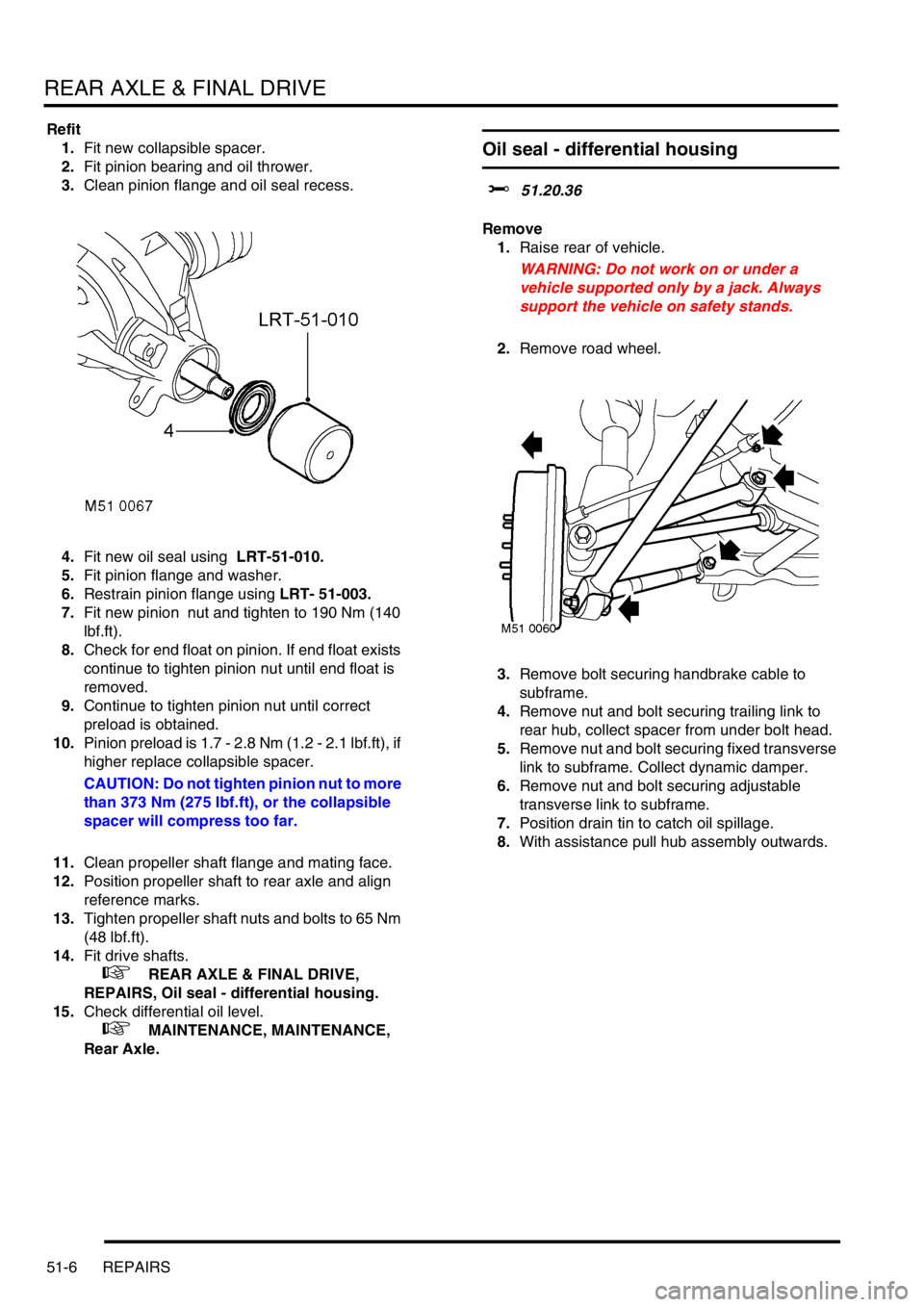

4.Fit new oil seal using LRT-51-010.

5.Fit pinion flange and washer.

6.Restrain pinion flange using LRT- 51-003.

7.Fit new pinion nut and tighten to 190 Nm (140

lbf.ft).

8.Check for end float on pinion. If end float exists

continue to tighten pinion nut until end float is

removed.

9.Continue to tighten pinion nut until correct

preload is obtained.

10.Pinion preload is 1.7 - 2.8 Nm (1.2 - 2.1 lbf.ft), if

higher replace collapsible spacer.

CAUTION: Do not tighten pinion nut to more

than 373 Nm (275 lbf.ft), or the collapsible

spacer will compress too far.

11.Clean propeller shaft flange and mating face.

12.Position propeller shaft to rear axle and align

reference marks.

13.Tighten propeller shaft nuts and bolts to 65 Nm

(48 lbf.ft).

14.Fit drive shafts.

+ REAR AXLE & FINAL DRIVE,

REPAIRS, Oil seal - differential housing.

15.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

Oil seal - differential housing

$% 51.20.36

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove bolt securing handbrake cable to

subframe.

4.Remove nut and bolt securing trailing link to

rear hub, collect spacer from under bolt head.

5.Remove nut and bolt securing fixed transverse

link to subframe. Collect dynamic damper.

6.Remove nut and bolt securing adjustable

transverse link to subframe.

7.Position drain tin to catch oil spillage.

8.With assistance pull hub assembly outwards.

Page 492 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-7

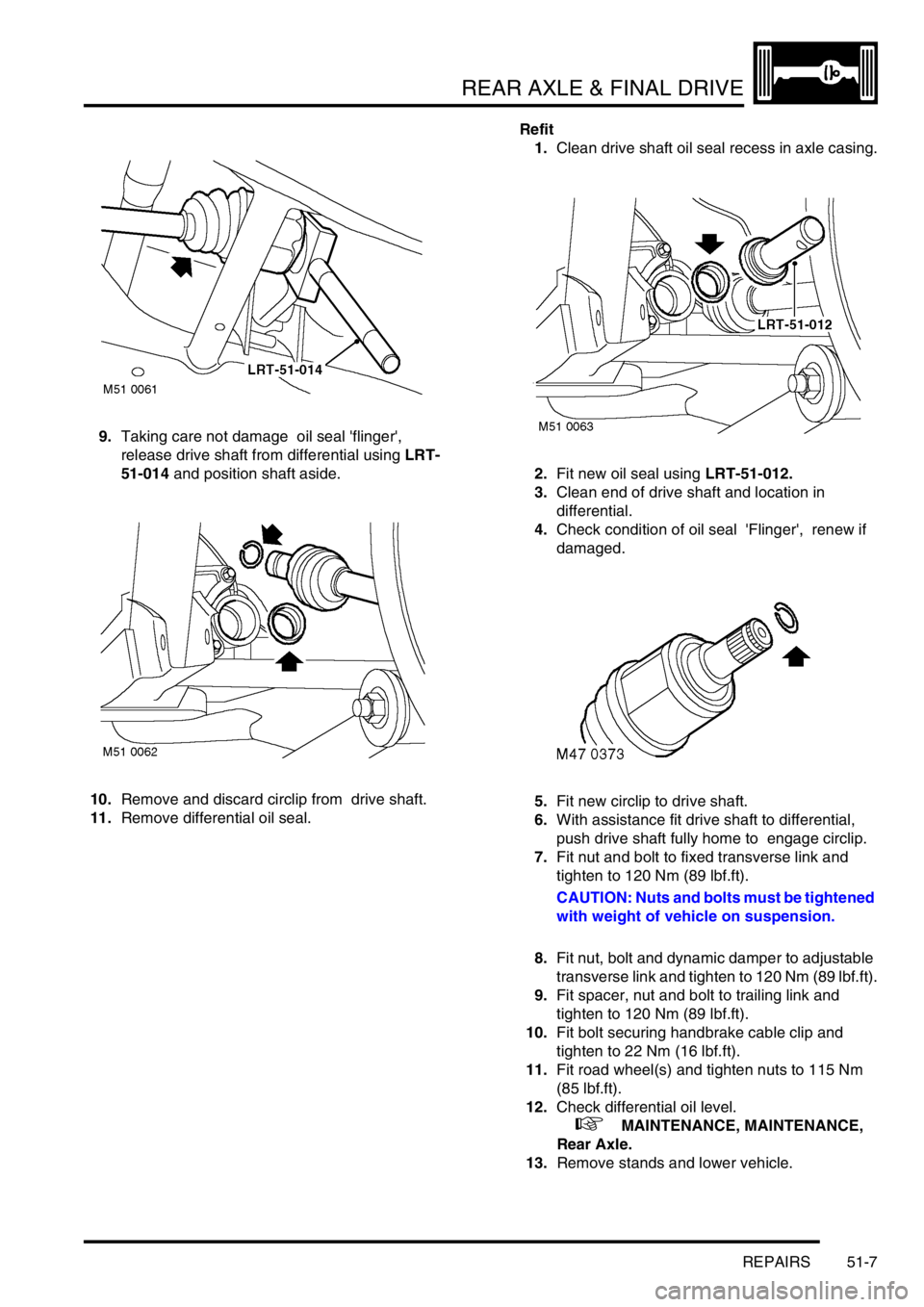

9.Taking care not damage oil seal 'flinger',

release drive shaft from differential using LRT-

51-014 and position shaft aside.

10.Remove and discard circlip from drive shaft.

11.Remove differential oil seal.Refit

1.Clean drive shaft oil seal recess in axle casing.

2.Fit new oil seal using LRT-51-012.

3.Clean end of drive shaft and location in

differential.

4.Check condition of oil seal 'Flinger', renew if

damaged.

5.Fit new circlip to drive shaft.

6.With assistance fit drive shaft to differential,

push drive shaft fully home to engage circlip.

7.Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

8.Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

9.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

10.Fit bolt securing handbrake cable clip and

tighten to 22 Nm (16 lbf.ft).

11.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

12.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

13.Remove stands and lower vehicle.

Page 548 of 1007

REAR SUSPENSION

REPAIRS 64-13

Sub frame

$% 64.35.78

Remove

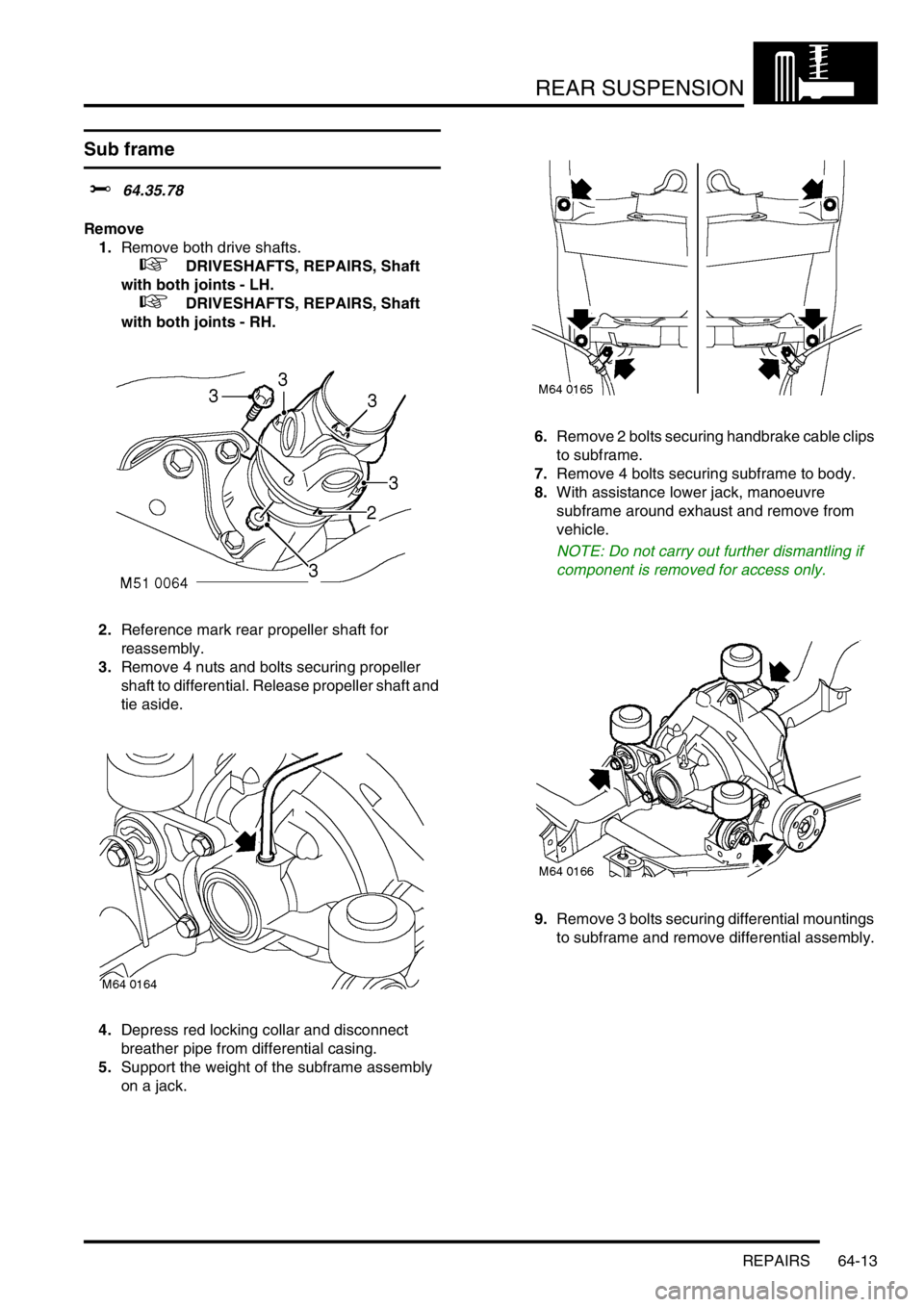

1.Remove both drive shafts.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - LH.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Reference mark rear propeller shaft for

reassembly.

3.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

4.Depress red locking collar and disconnect

breather pipe from differential casing.

5.Support the weight of the subframe assembly

on a jack.6.Remove 2 bolts securing handbrake cable clips

to subframe.

7.Remove 4 bolts securing subframe to body.

8.With assistance lower jack, manoeuvre

subframe around exhaust and remove from

vehicle.

NOTE: Do not carry out further dismantling if

component is removed for access only.

9.Remove 3 bolts securing differential mountings

to subframe and remove differential assembly.

Page 549 of 1007

REAR SUSPENSION

64-14 REPAIRS

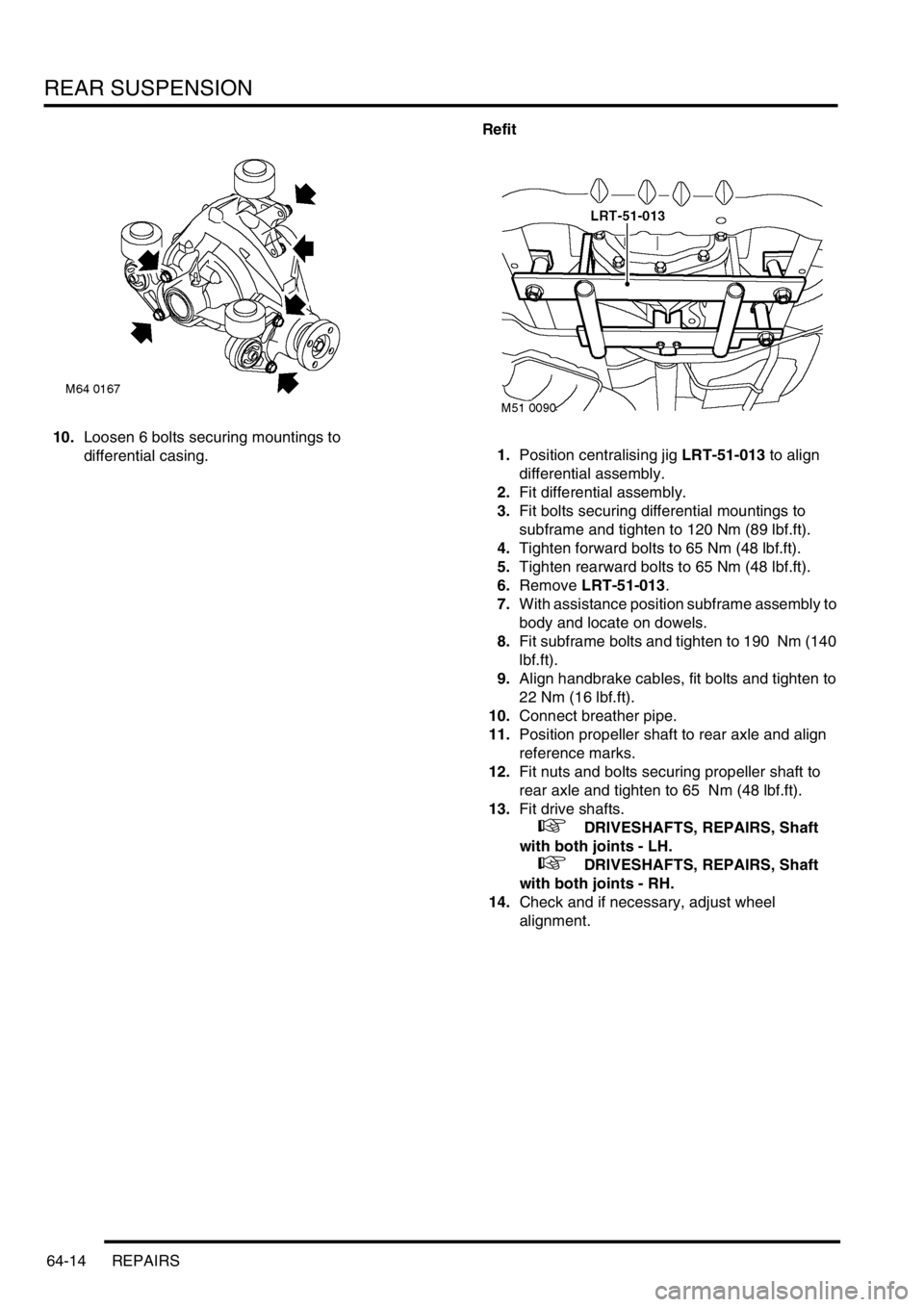

10.Loosen 6 bolts securing mountings to

differential casing.Refit

1.Position centralising jig LRT-51-013 to align

differential assembly.

2.Fit differential assembly.

3.Fit bolts securing differential mountings to

subframe and tighten to 120 Nm (89 lbf.ft).

4.Tighten forward bolts to 65 Nm (48 lbf.ft).

5.Tighten rearward bolts to 65 Nm (48 lbf.ft).

6.Remove LRT-51-013.

7.With assistance position subframe assembly to

body and locate on dowels.

8.Fit subframe bolts and tighten to 190 Nm (140

lbf.ft).

9.Align handbrake cables, fit bolts and tighten to

22 Nm (16 lbf.ft).

10.Connect breather pipe.

11.Position propeller shaft to rear axle and align

reference marks.

12.Fit nuts and bolts securing propeller shaft to

rear axle and tighten to 65 Nm (48 lbf.ft).

13.Fit drive shafts.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - LH.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

14.Check and if necessary, adjust wheel

alignment.