low beam LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 13 of 1007

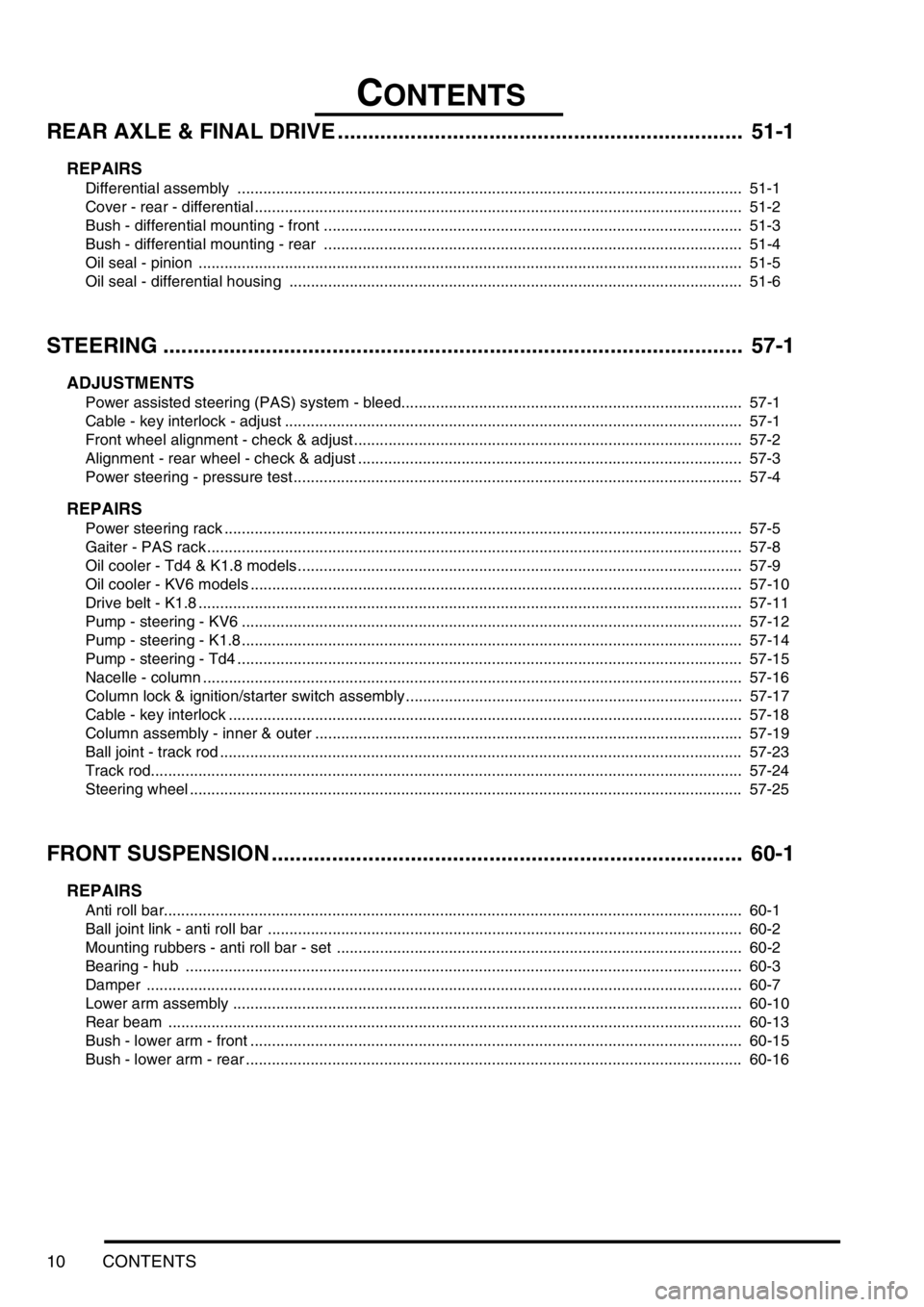

CONTENTS

10 CONTENTS

REAR AXLE & FINAL DRIVE ................................................................... 51-1

REPAIRS

Differential assembly ..................................................................................................................... 51-1

Cover - rear - differential ................................................................................................................. 51-2

Bush - differential mounting - front ................................................................................................. 51-3

Bush - differential mounting - rear ................................................................................................. 51-4

Oil seal - pinion .............................................................................................................................. 51-5

Oil seal - differential housing ......................................................................................................... 51-6

STEERING ................................................................................................ 57-1

ADJUSTMENTS

Power assisted steering (PAS) system - bleed............................................................................... 57-1

Cable - key interlock - adjust .......................................................................................................... 57-1

Front wheel alignment - check & adjust .......................................................................................... 57-2

Alignment - rear wheel - check & adjust ......................................................................................... 57-3

Power steering - pressure test ........................................................................................................ 57-4

REPAIRS

Power steering rack ........................................................................................................................ 57-5

Gaiter - PAS rack ............................................................................................................................ 57-8

Oil cooler - Td4 & K1.8 models ....................................................................................................... 57-9

Oil cooler - KV6 models .................................................................................................................. 57-10

Drive belt - K1.8 .............................................................................................................................. 57-11

Pump - steering - KV6 .................................................................................................................... 57-12

Pump - steering - K1.8 .................................................................................................................... 57-14

Pump - steering - Td4 ..................................................................................................................... 57-15

Nacelle - column ............................................................................................................................. 57-16

Column lock & ignition/starter switch assembly .............................................................................. 57-17

Cable - key interlock ....................................................................................................................... 57-18

Column assembly - inner & outer ................................................................................................... 57-19

Ball joint - track rod ......................................................................................................................... 57-23

Track rod......................................................................................................................................... 57-24

Steering wheel ................................................................................................................................ 57-25

FRONT SUSPENSION .............................................................................. 60-1

REPAIRS

Anti roll bar...................................................................................................................................... 60-1

Ball joint link - anti roll bar .............................................................................................................. 60-2

Mounting rubbers - anti roll bar - set .............................................................................................. 60-2

Bearing - hub ................................................................................................................................. 60-3

Damper .......................................................................................................................................... 60-7

Lower arm assembly ...................................................................................................................... 60-10

Rear beam ..................................................................................................................................... 60-13

Bush - lower arm - front .................................................................................................................. 60-15

Bush - lower arm - rear ................................................................................................................... 60-16

Page 65 of 1007

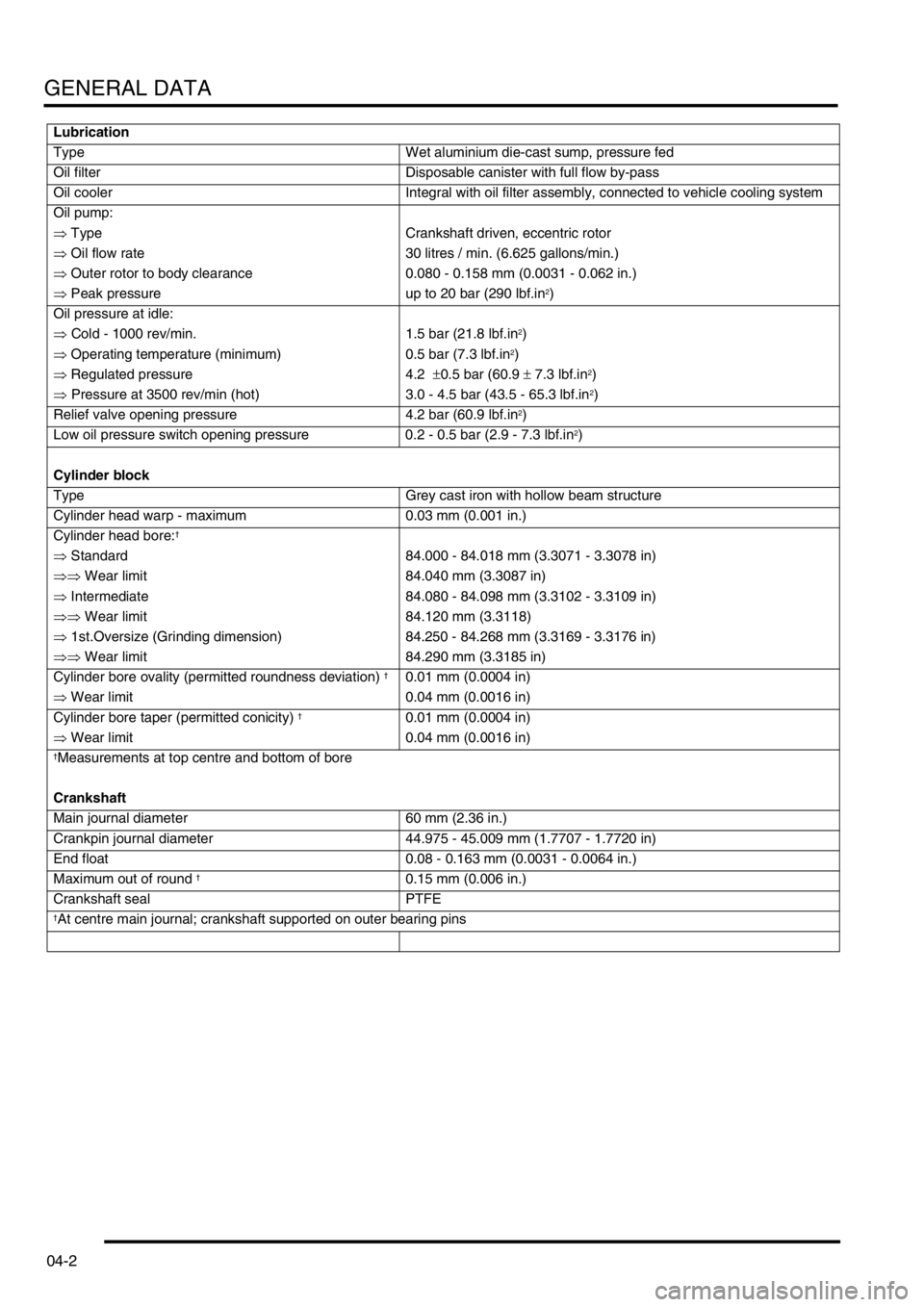

GENERAL DATA

04-2

Lubrication

Type Wet aluminium die-cast sump, pressure fed

Oil filter Disposable canister with full flow by-pass

Oil cooler Integral with oil filter assembly, connected to vehicle cooling system

Oil pump:

⇒ Type Crankshaft driven, eccentric rotor

⇒ Oil flow rate 30 litres / min. (6.625 gallons/min.)

⇒ Outer rotor to body clearance 0.080 - 0.158 mm (0.0031 - 0.062 in.)

⇒ Peak pressure up to 20 bar (290 lbf.in

2)

Oil pressure at idle:

⇒ Cold - 1000 rev/min. 1.5 bar (21.8 lbf.in

2)

⇒ Operating temperature (minimum) 0.5 bar (7.3 lbf.in

2)

⇒ Regulated pressure 4.2 ±0.5 bar (60.9 ± 7.3 lbf.in

2)

⇒ Pressure at 3500 rev/min (hot) 3.0 - 4.5 bar (43.5 - 65.3 lbf.in

2)

Relief valve opening pressure 4.2 bar (60.9 lbf.in

2)

Low oil pressure switch opening pressure 0.2 - 0.5 bar (2.9 - 7.3 lbf.in

2)

Cylinder block

Type Grey cast iron with hollow beam structure

Cylinder head warp - maximum 0.03 mm (0.001 in.)

Cylinder head bore:

†

⇒ Standard 84.000 - 84.018 mm (3.3071 - 3.3078 in)

⇒⇒ Wear limit 84.040 mm (3.3087 in)

⇒ Intermediate 84.080 - 84.098 mm (3.3102 - 3.3109 in)

⇒⇒ Wear limit 84.120 mm (3.3118)

⇒ 1st.Oversize (Grinding dimension) 84.250 - 84.268 mm (3.3169 - 3.3176 in)

⇒⇒ Wear limit 84.290 mm (3.3185 in)

Cylinder bore ovality (permitted roundness deviation)

†0.01 mm (0.0004 in)

⇒ Wear limit 0.04 mm (0.0016 in)

Cylinder bore taper (permitted conicity)

†0.01 mm (0.0004 in)

⇒ Wear limit 0.04 mm (0.0016 in)

†Measurements at top centre and bottom of bore

Crankshaft

Main journal diameter 60 mm (2.36 in.)

Crankpin journal diameter 44.975 - 45.009 mm (1.7707 - 1.7720 in)

End float 0.08 - 0.163 mm (0.0031 - 0.0064 in.)

Maximum out of round

†0.15 mm (0.006 in.)

Crankshaft seal PTFE

†At centre main journal; crankshaft supported on outer bearing pins

Page 107 of 1007

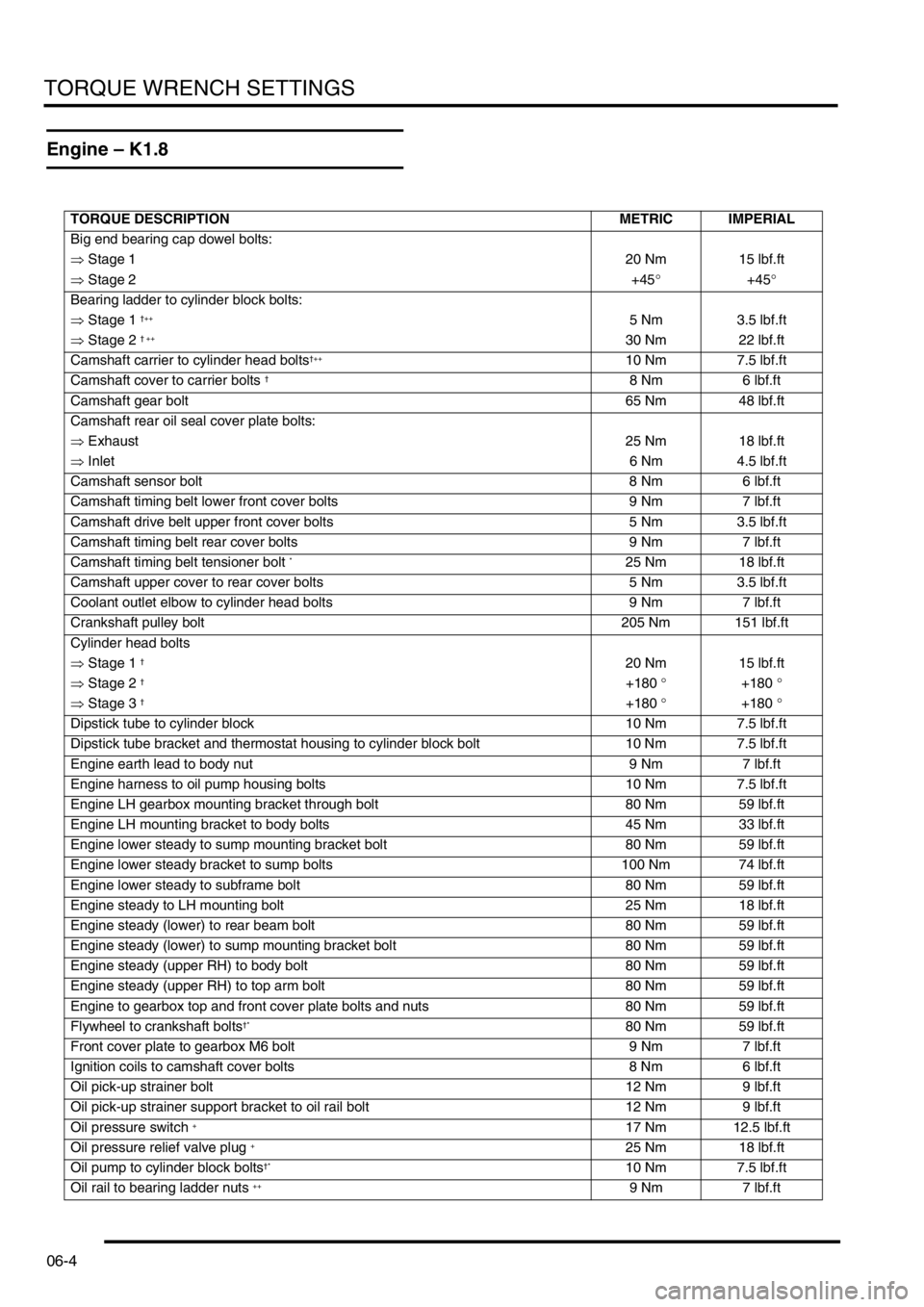

TORQUE WRENCH SETTINGS

06-4

Engine – K1.8

TORQUE DESCRIPTION METRIC IMPERIAL

Big end bearing cap dowel bolts:

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+45°+45°

Bearing ladder to cylinder block bolts:

⇒ Stage 1

†++5 Nm 3.5 lbf.ft

⇒ Stage 2

† ++30 Nm 22 lbf.ft

Camshaft carrier to cylinder head bolts

†++10 Nm 7.5 lbf.ft

Camshaft cover to carrier bolts

†8 Nm 6 lbf.ft

Camshaft gear bolt 65 Nm 48 lbf.ft

Camshaft rear oil seal cover plate bolts:

⇒ Exhaust25 Nm 18 lbf.ft

⇒ Inlet6 Nm 4.5 lbf.ft

Camshaft sensor bolt 8 Nm 6 lbf.ft

Camshaft timing belt lower front cover bolts 9 Nm 7 lbf.ft

Camshaft drive belt upper front cover bolts 5 Nm 3.5 lbf.ft

Camshaft timing belt rear cover bolts 9 Nm 7 lbf.ft

Camshaft timing belt tensioner bolt

* 25 Nm 18 lbf.ft

Camshaft upper cover to rear cover bolts 5 Nm 3.5 lbf.ft

Coolant outlet elbow to cylinder head bolts 9 Nm 7 lbf.ft

Crankshaft pulley bolt 205 Nm 151 lbf.ft

Cylinder head bolts

⇒ Stage 1

†20 Nm 15 lbf.ft

⇒ Stage 2

†+180 °+180 °

⇒ Stage 3

†+180 °+180 °

Dipstick tube to cylinder block 10 Nm 7.5 lbf.ft

Dipstick tube bracket and thermostat housing to cylinder block bolt 10 Nm 7.5 lbf.ft

Engine earth lead to body nut 9 Nm 7 lbf.ft

Engine harness to oil pump housing bolts 10 Nm 7.5 lbf.ft

Engine LH gearbox mounting bracket through bolt 80 Nm 59 lbf.ft

Engine LH mounting bracket to body bolts 45 Nm 33 lbf.ft

Engine lower steady to sump mounting bracket bolt 80 Nm 59 lbf.ft

Engine lower steady bracket to sump bolts 100 Nm 74 lbf.ft

Engine lower steady to subframe bolt 80 Nm 59 lbf.ft

Engine steady to LH mounting bolt 25 Nm 18 lbf.ft

Engine steady (lower) to rear beam bolt 80 Nm 59 lbf.ft

Engine steady (lower) to sump mounting bracket bolt 80 Nm 59 lbf.ft

Engine steady (upper RH) to body bolt 80 Nm 59 lbf.ft

Engine steady (upper RH) to top arm bolt 80 Nm 59 lbf.ft

Engine to gearbox top and front cover plate bolts and nuts 80 Nm 59 lbf.ft

Flywheel to crankshaft bolts

†*80 Nm 59 lbf.ft

Front cover plate to gearbox M6 bolt 9 Nm 7 lbf.ft

Ignition coils to camshaft cover bolts 8 Nm 6 lbf.ft

Oil pick-up strainer bolt 12 Nm 9 lbf.ft

Oil pick-up strainer support bracket to oil rail bolt 12 Nm 9 lbf.ft

Oil pressure switch

+17 Nm 12.5 lbf.ft

Oil pressure relief valve plug

+25 Nm 18 lbf.ft

Oil pump to cylinder block bolts

†*10 Nm 7.5 lbf.ft

Oil rail to bearing ladder nuts

++9 Nm 7 lbf.ft

Page 129 of 1007

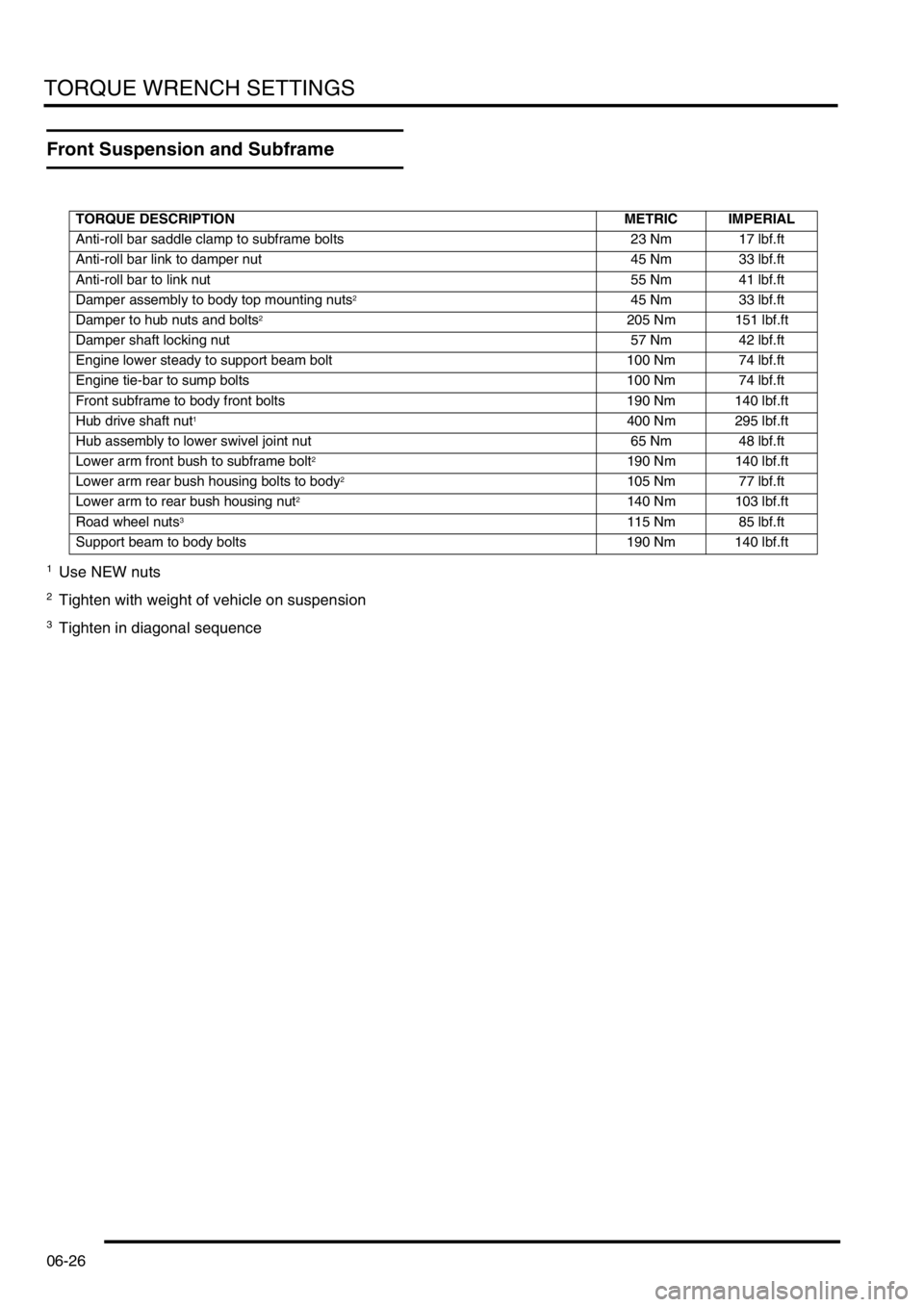

TORQUE WRENCH SETTINGS

06-26

Front Suspension and Subframe

1 Use NEW nuts

2 Tighten with weight of vehicle on suspension

3 Tighten in diagonal sequence

TORQUE DESCRIPTION METRIC IMPERIAL

Anti-roll bar saddle clamp to subframe bolts 23 Nm 17 lbf.ft

Anti-roll bar link to damper nut 45 Nm 33 lbf.ft

Anti-roll bar to link nut 55 Nm 41 lbf.ft

Damper assembly to body top mounting nuts

245 Nm 33 lbf.ft

Damper to hub nuts and bolts

2205 Nm 151 lbf.ft

Damper shaft locking nut 57 Nm 42 lbf.ft

Engine lower steady to support beam bolt 100 Nm 74 lbf.ft

Engine tie-bar to sump bolts 100 Nm 74 lbf.ft

Front subframe to body front bolts 190 Nm 140 lbf.ft

Hub drive shaft nut

1400 Nm 295 lbf.ft

Hub assembly to lower swivel joint nut 65 Nm 48 lbf.ft

Lower arm front bush to subframe bolt

2190 Nm 140 lbf.ft

Lower arm rear bush housing bolts to body

2105 Nm 77 lbf.ft

Lower arm to rear bush housing nut

2140 Nm 103 lbf.ft

Road wheel nuts

3115 Nm 85 lbf.ft

Support beam to body bolts 190 Nm 140 lbf.ft

Page 206 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-29

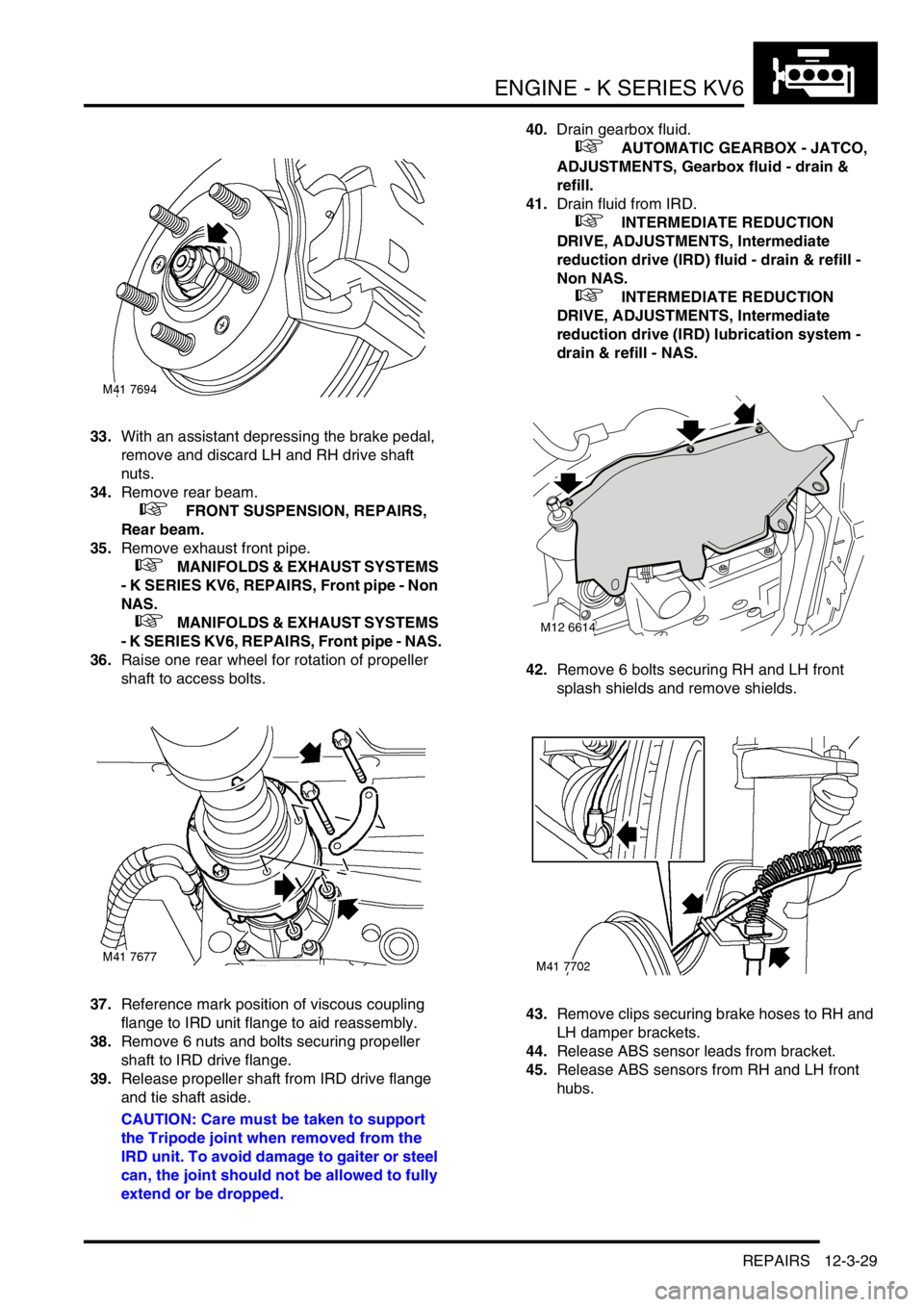

33.With an assistant depressing the brake pedal,

remove and discard LH and RH drive shaft

nuts.

34.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

35.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

36.Raise one rear wheel for rotation of propeller

shaft to access bolts.

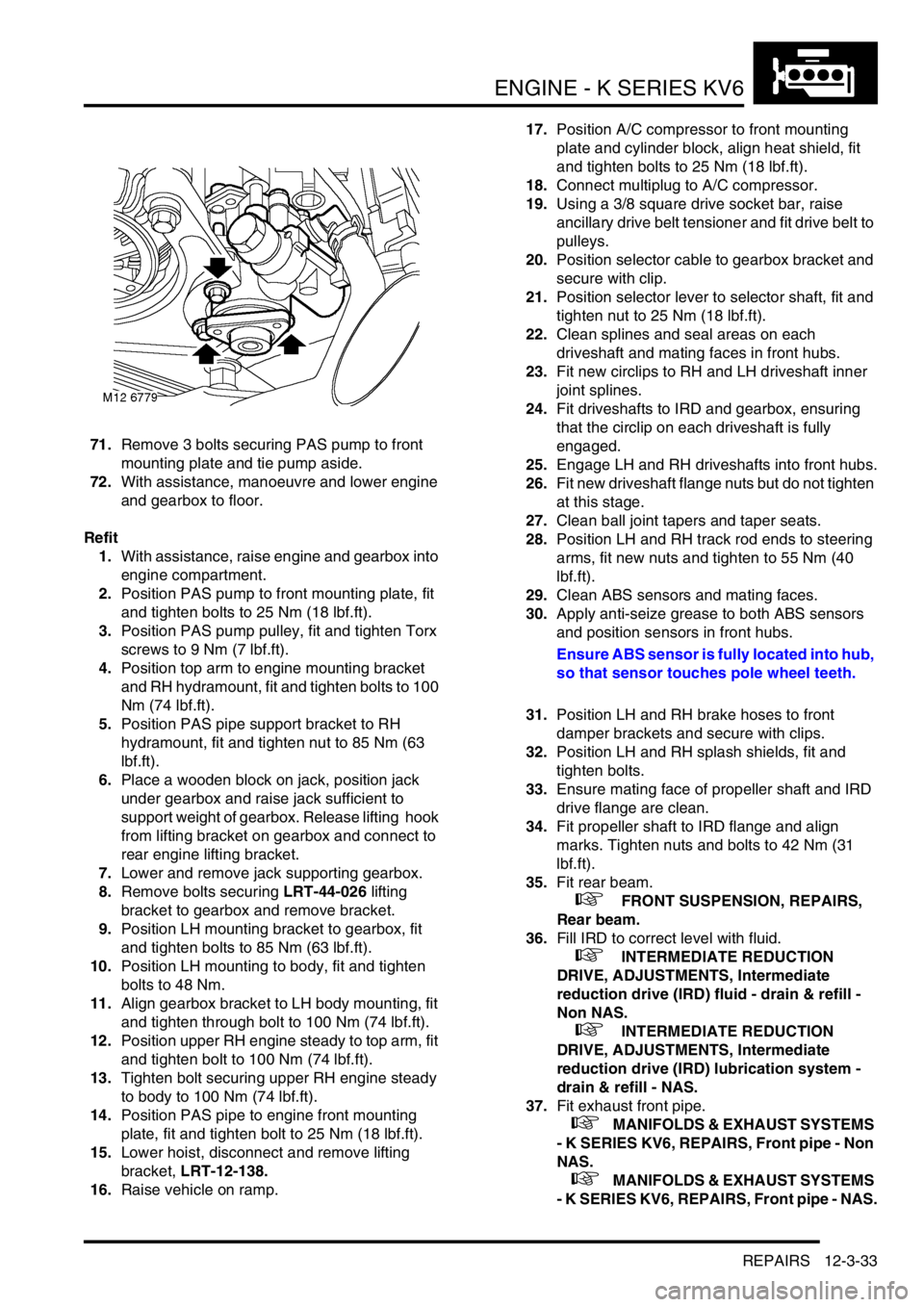

37.Reference mark position of viscous coupling

flange to IRD unit flange to aid reassembly.

38.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

39.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.40.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

41.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

42.Remove 6 bolts securing RH and LH front

splash shields and remove shields.

43.Remove clips securing brake hoses to RH and

LH damper brackets.

44.Release ABS sensor leads from bracket.

45.Release ABS sensors from RH and LH front

hubs.

M12 6614

Page 210 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-33

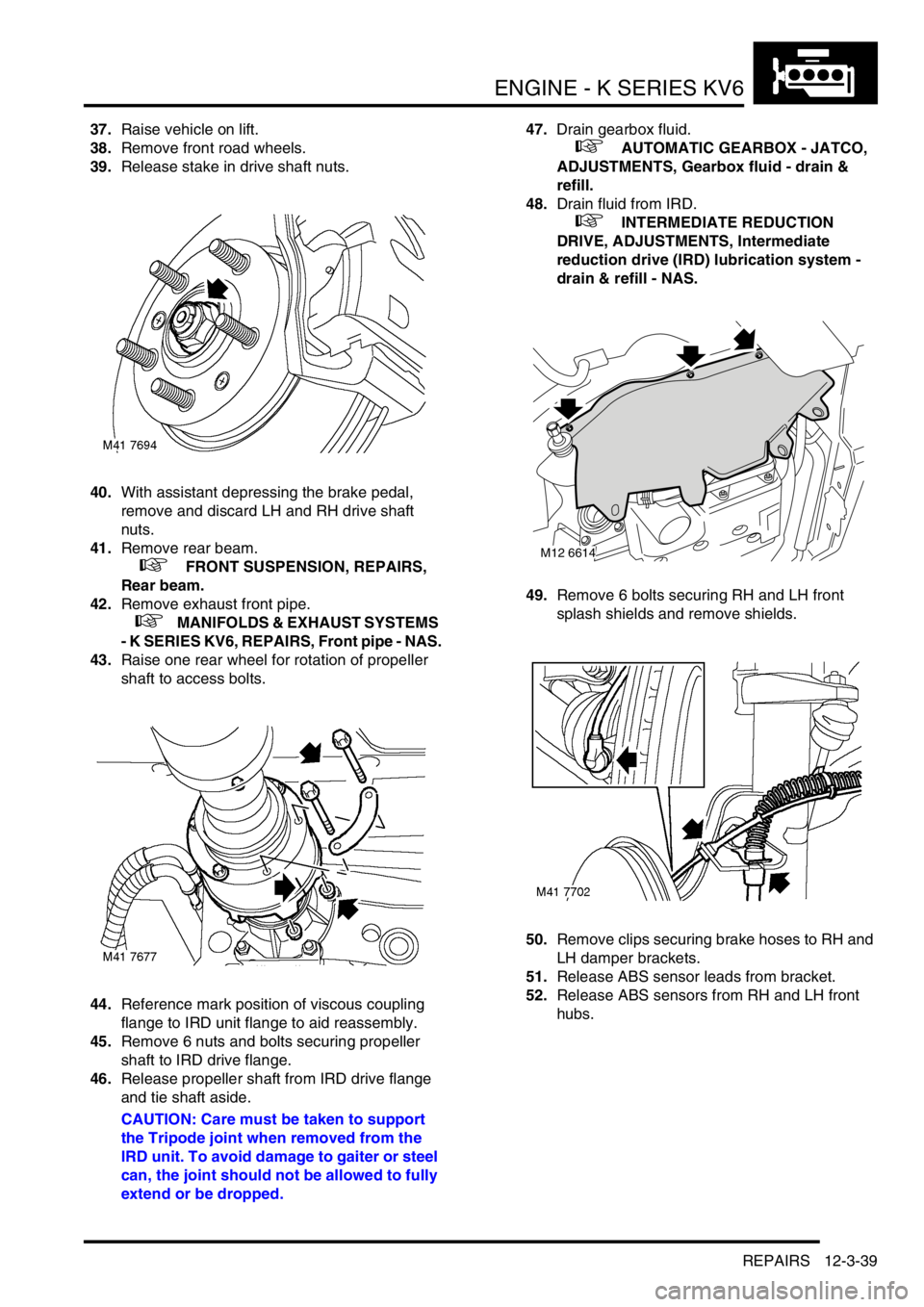

71.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

72.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm (18 lbf.ft).

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm (74 lbf.ft).

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm (63

lbf.ft).

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.

8.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm (18 lbf.ft).

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on ramp.17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

18.Connect multiplug to A/C compressor.

19.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm (18 lbf.ft).

22.Clean splines and seal areas on each

driveshaft and mating faces in front hubs.

23.Fit new circlips to RH and LH driveshaft inner

joint splines.

24.Fit driveshafts to IRD and gearbox, ensuring

that the circlip on each driveshaft is fully

engaged.

25.Engage LH and RH driveshafts into front hubs.

26.Fit new driveshaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm (40

lbf.ft).

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

Ensure ABS sensor is fully located into hub,

so that sensor touches pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

Page 216 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-39

37.Raise vehicle on lift.

38.Remove front road wheels.

39.Release stake in drive shaft nuts.

40.With assistant depressing the brake pedal,

remove and discard LH and RH drive shaft

nuts.

41.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

42.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

43.Raise one rear wheel for rotation of propeller

shaft to access bolts.

44.Reference mark position of viscous coupling

flange to IRD unit flange to aid reassembly.

45.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

46.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.47.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

48.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

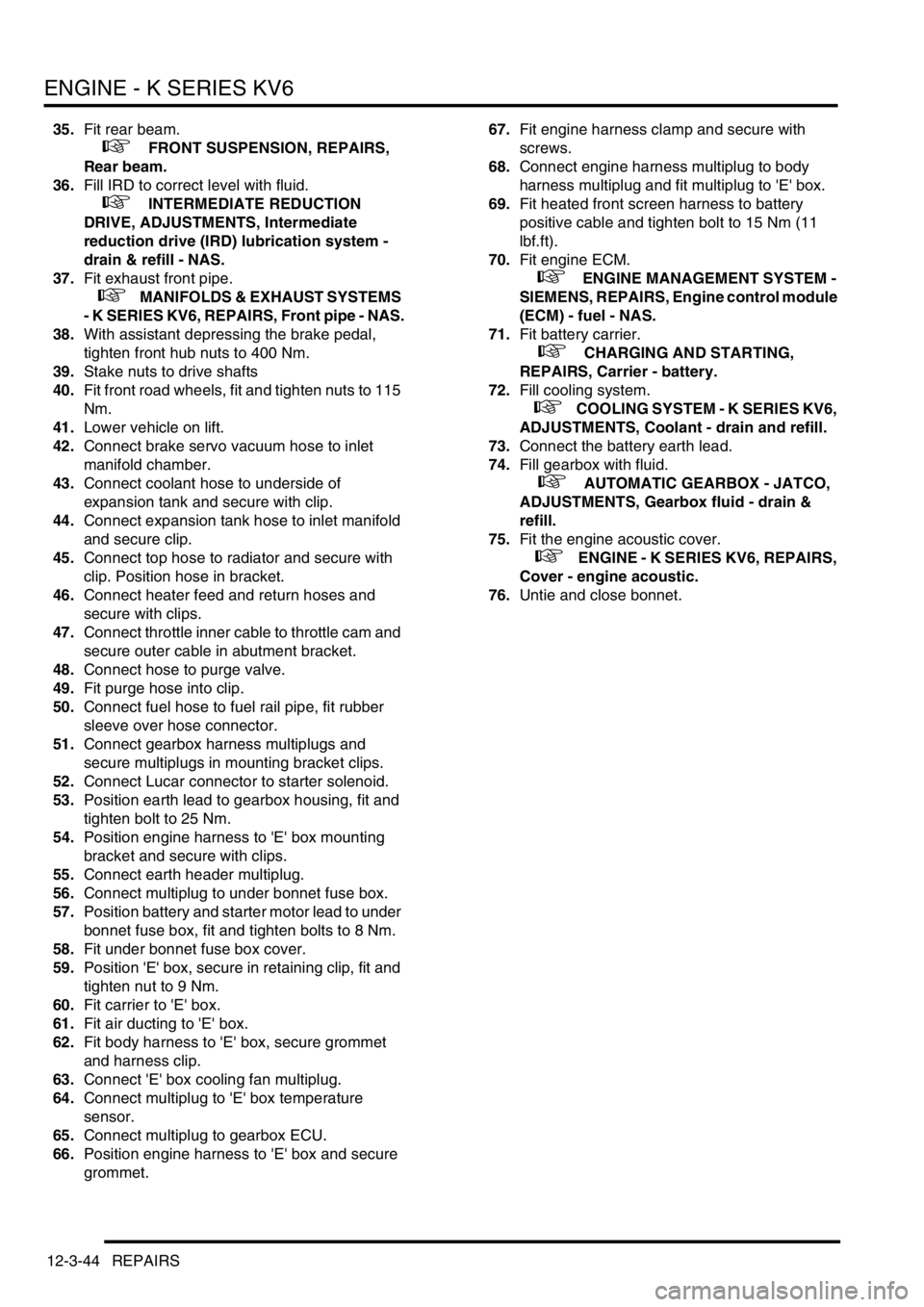

49.Remove 6 bolts securing RH and LH front

splash shields and remove shields.

50.Remove clips securing brake hoses to RH and

LH damper brackets.

51.Release ABS sensor leads from bracket.

52.Release ABS sensors from RH and LH front

hubs.

M12 6614

Page 221 of 1007

ENGINE - K SERIES KV6

12-3-44 REPAIRS

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm.

39.Stake nuts to drive shafts

40.Fit front road wheels, fit and tighten nuts to 115

Nm.

41.Lower vehicle on lift.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket.

48.Connect hose to purge valve.

49.Fit purge hose into clip.

50.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

51.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

52.Connect Lucar connector to starter solenoid.

53.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm.

54.Position engine harness to 'E' box mounting

bracket and secure with clips.

55.Connect earth header multiplug.

56.Connect multiplug to under bonnet fuse box.

57.Position battery and starter motor lead to under

bonnet fuse box, fit and tighten bolts to 8 Nm.

58.Fit under bonnet fuse box cover.

59.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm.

60.Fit carrier to 'E' box.

61.Fit air ducting to 'E' box.

62.Fit body harness to 'E' box, secure grommet

and harness clip.

63.Connect 'E' box cooling fan multiplug.

64.Connect multiplug to 'E' box temperature

sensor.

65.Connect multiplug to gearbox ECU.

66.Position engine harness to 'E' box and secure

grommet.67.Fit engine harness clamp and secure with

screws.

68.Connect engine harness multiplug to body

harness multiplug and fit multiplug to 'E' box.

69.Fit heated front screen harness to battery

positive cable and tighten bolt to 15 Nm (11

lbf.ft).

70.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - fuel - NAS.

71.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

72.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

73.Connect the battery earth lead.

74.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

75.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

76.Untie and close bonnet.

Page 409 of 1007

INTERMEDIATE REDUCTION DRIVE

41-6 REPAIRS

Refit

1.Clean mating faces of IRD and gearbox.

2.Lubricate and fit new 'O' ring

3.With assistance, fit IRD.

4.Fit bolts securing IRD to gearbox and tighten

sufficiently only to pull mating faces of IRD and

gearbox together at this stage.

5.Fit IRD support brackets, tighten sufficiently to

pull mating faces together.

6.Final tighten bolts securing IRD to gearbox to

90 Nm (66 lbf.ft).

7.Final tighten bolts securing IRD support

brackets in the following sequence:

lM8 bolts securing support brackets to IRD

37 Nm (22 lbf.ft)

lM10 bolts securing support brackets to IRD

50 Nm (22 lbf.ft)

l3 bolts securing support bracket to cylinder

block 25 Nm (18 lbf.ft)

l3 bolts securing support bracket to sump at

45 Nm (33 lbf.ft).

8.Position lower engine steady, 'TOP' mark

uppermost. Fit bolt but do not tighten at this

stage.

9.Connect coolant hoses and secure with clips.

10.Connect breather hose to IRD housing.

11.Clean propeller shaft flange and mating face.

12.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

13.Inspect drive shaft oil seal, renew if worn or

damaged.14.Clean drive shaft and flange splines.

15.Fit new circlip to drive shaft.

16.With assistance, pull hub outwards, align drive

shaft and fit to IRD taking care not to damage

oil seal.

17.Fit splash shield and secure with bolts.

18.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- Td4, REPAIRS, Exhaust pipe - front.

19.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

20.Final tighten bolt securing lower engine steady

to IRD support bracket to 100 Nm (74 lbf.ft).

21.Remove stand(s) and lower vehicle.

22.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

23.Fill gearbox with fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

24.Connect battery earth lead.

25.Refill cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

Page 412 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-9

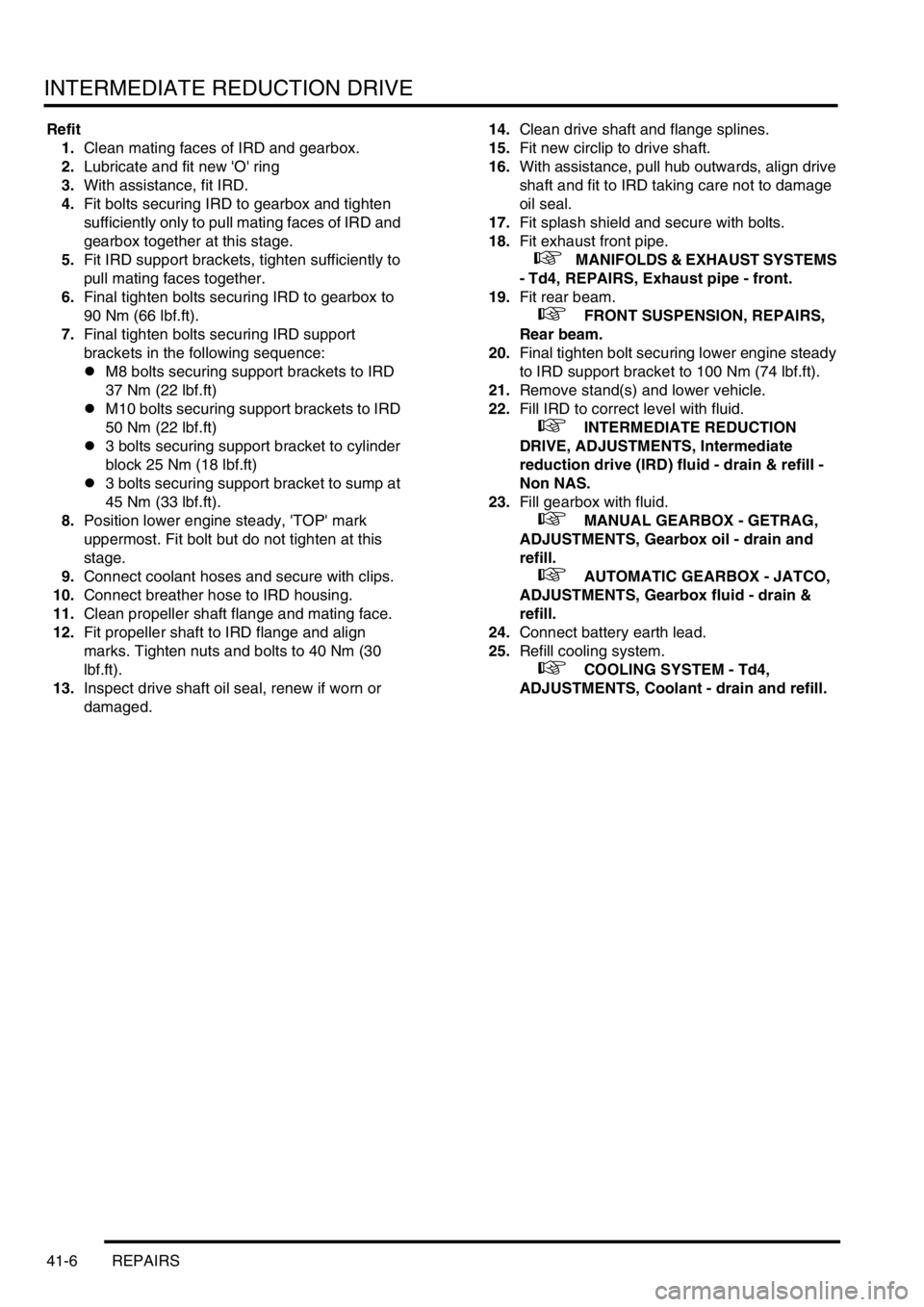

24.Remove 3 bolts securing IRD support bracket

to sump and remove bracket.

25.Remove 4 bolts securing IRD.

26.With assistance, release IRD from gearbox and

remove.

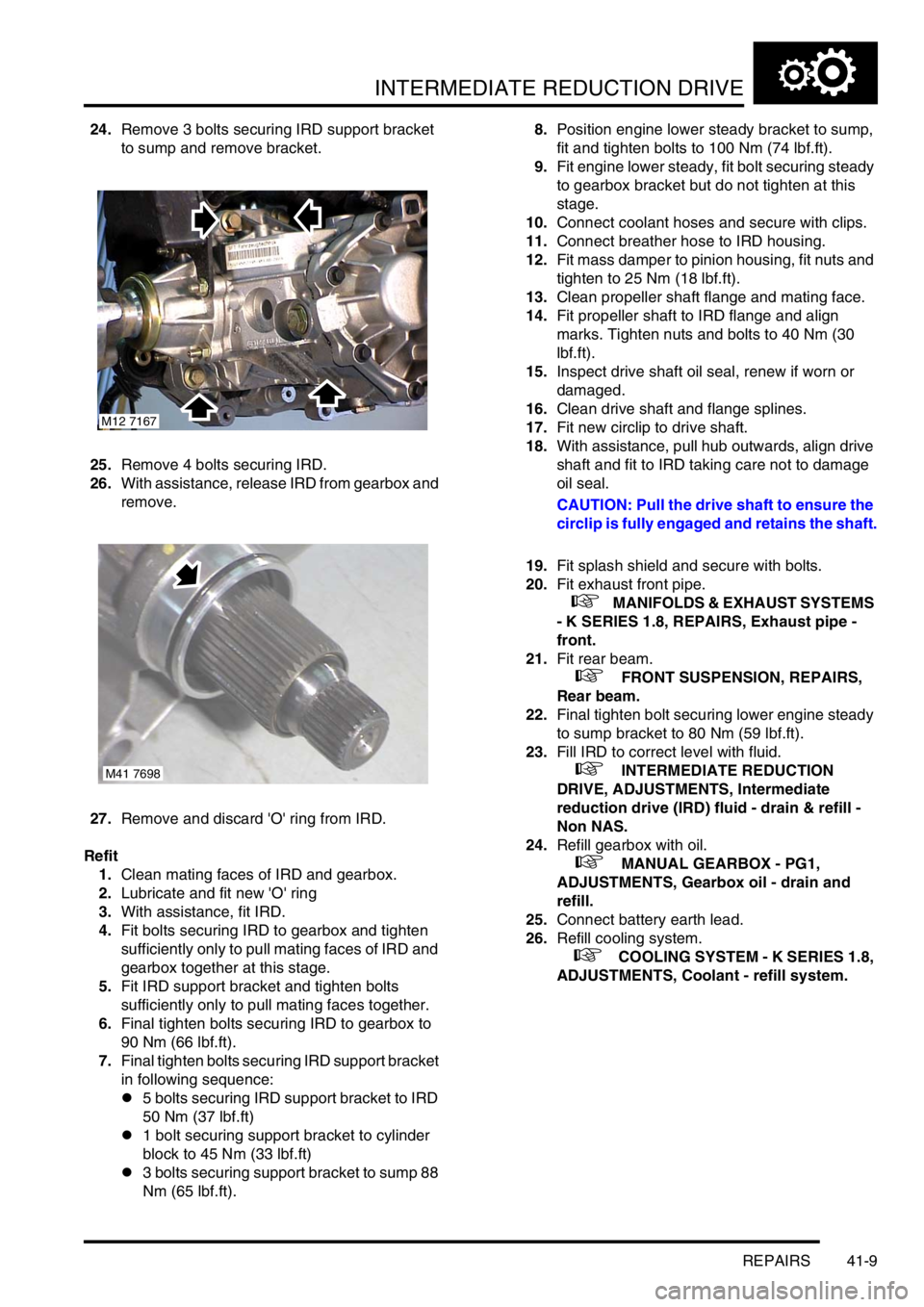

27.Remove and discard 'O' ring from IRD.

Refit

1.Clean mating faces of IRD and gearbox.

2.Lubricate and fit new 'O' ring

3.With assistance, fit IRD.

4.Fit bolts securing IRD to gearbox and tighten

sufficiently only to pull mating faces of IRD and

gearbox together at this stage.

5.Fit IRD support bracket and tighten bolts

sufficiently only to pull mating faces together.

6.Final tighten bolts securing IRD to gearbox to

90 Nm (66 lbf.ft).

7.Final tighten bolts securing IRD support bracket

in following sequence:

l5 bolts securing IRD support bracket to IRD

50 Nm (37 lbf.ft)

l1 bolt securing support bracket to cylinder

block to 45 Nm (33 lbf.ft)

l3 bolts securing support bracket to sump 88

Nm (65 lbf.ft).8.Position engine lower steady bracket to sump,

fit and tighten bolts to 100 Nm (74 lbf.ft).

9.Fit engine lower steady, fit bolt securing steady

to gearbox bracket but do not tighten at this

stage.

10.Connect coolant hoses and secure with clips.

11.Connect breather hose to IRD housing.

12.Fit mass damper to pinion housing, fit nuts and

tighten to 25 Nm (18 lbf.ft).

13.Clean propeller shaft flange and mating face.

14.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

15.Inspect drive shaft oil seal, renew if worn or

damaged.

16.Clean drive shaft and flange splines.

17.Fit new circlip to drive shaft.

18.With assistance, pull hub outwards, align drive

shaft and fit to IRD taking care not to damage

oil seal.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

19.Fit splash shield and secure with bolts.

20.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

front.

21.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

22.Final tighten bolt securing lower engine steady

to sump bracket to 80 Nm (59 lbf.ft).

23.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

24.Refill gearbox with oil.

+ MANUAL GEARBOX - PG1,

ADJUSTMENTS, Gearbox oil - drain and

refill.

25.Connect battery earth lead.

26.Refill cooling system.

+ COOLING SYSTEM - K SERIES 1.8,

ADJUSTMENTS, Coolant - refill system.

M12 7167

M41 7698