ignition LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 271 of 1007

ENGINE - K SERIES KV6

12-3-94 OVERHAUL

16.Position injector protection cover - if fitted to RH

fuel rail and secure injector harness to

protection cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Connect coolant bleed hose to inlet manifold

and secure with clip.

19. Up to 03MY:Position ignition coils to LH inlet

manifold.

20. Up to 03MY:Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

21.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

22.Position backplate, fit and tighten bolts to 9 Nm

(7 lbf.ft).

23.Fit new camshaft timing belt.

+ ENGINE - K SERIES KV6,

OVERHAUL, Camshaft timing belt.

24.Clean exhaust manifold and mating face on

cylinder head.

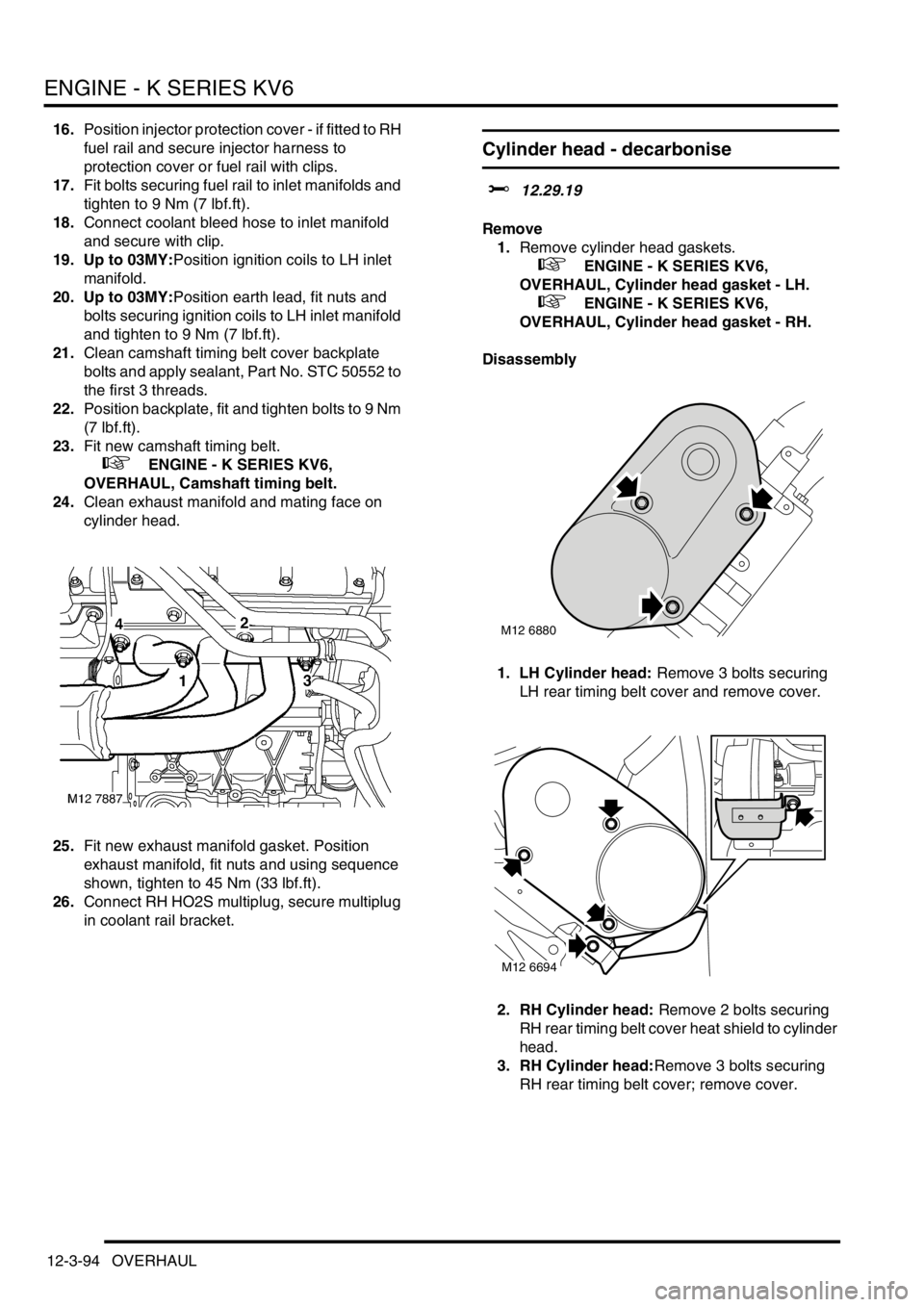

25.Fit new exhaust manifold gasket. Position

exhaust manifold, fit nuts and using sequence

shown, tighten to 45 Nm (33 lbf.ft).

26.Connect RH HO2S multiplug, secure multiplug

in coolant rail bracket.

Cylinder head - decarbonise

$% 12.29.19

Remove

1.Remove cylinder head gaskets.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - LH.

+ ENGINE - K SERIES KV6,

OVERHAUL, Cylinder head gasket - RH.

Disassembly

1. LH Cylinder head: Remove 3 bolts securing

LH rear timing belt cover and remove cover.

2. RH Cylinder head: Remove 2 bolts securing

RH rear timing belt cover heat shield to cylinder

head.

3. RH Cylinder head:Remove 3 bolts securing

RH rear timing belt cover; remove cover.

M12 6880

M12 6694

Page 321 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-16 REPAIRS

Sensor - throttle position (TP) - NAS -

from 03MY

$% 19.22.49

Remove

1.Ensure ignition is switched off.

2.Remove 2 nuts and release throttle pedal and

TP sensor assembly from studs.

3.Disconnect multiplug from TP sensor.

4.Remove throttle pedal and TP sensor

assembly.

Refit

1.Position throttle pedal and TP sensor assembly

and connect multiplug.

2.Fit throttle pedal and TP sensor assembly to

studs and tighten nuts to 25 Nm (18 lbf.ft).

Page 323 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-2 ADJUSTMENTS

Throttle cable - check and adjust - K1.8

$% 19.20.05

Check

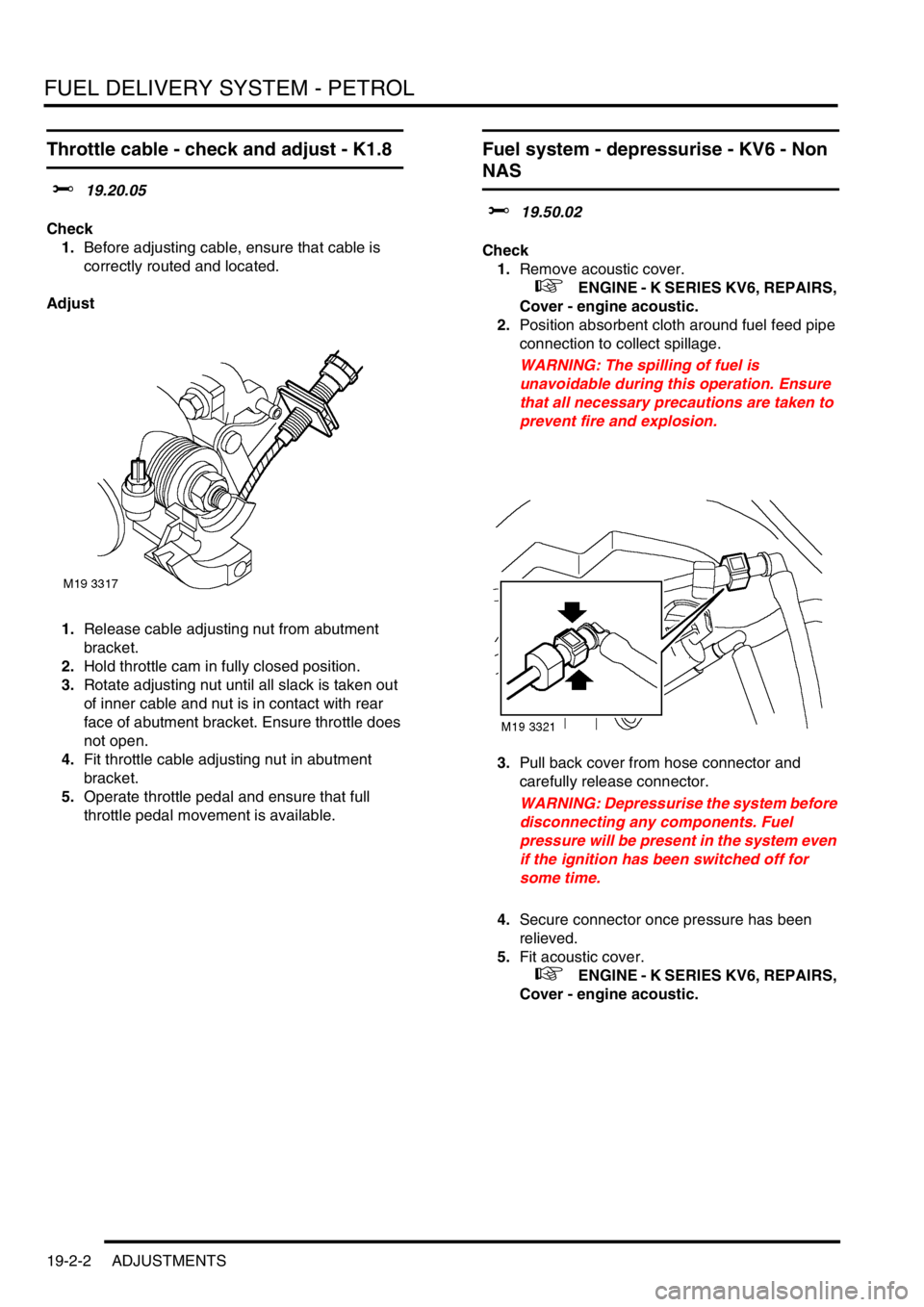

1.Before adjusting cable, ensure that cable is

correctly routed and located.

Adjust

1.Release cable adjusting nut from abutment

bracket.

2.Hold throttle cam in fully closed position.

3.Rotate adjusting nut until all slack is taken out

of inner cable and nut is in contact with rear

face of abutment bracket. Ensure throttle does

not open.

4.Fit throttle cable adjusting nut in abutment

bracket.

5.Operate throttle pedal and ensure that full

throttle pedal movement is available.

Fuel system - depressurise - KV6 - Non

NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Pull back cover from hose connector and

carefully release connector.

WARNING: Depressurise the system before

disconnecting any components. Fuel

pressure will be present in the system even

if the ignition has been switched off for

some time.

4.Secure connector once pressure has been

relieved.

5.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 350 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-29

Pump - fuel

$% 19.45.08

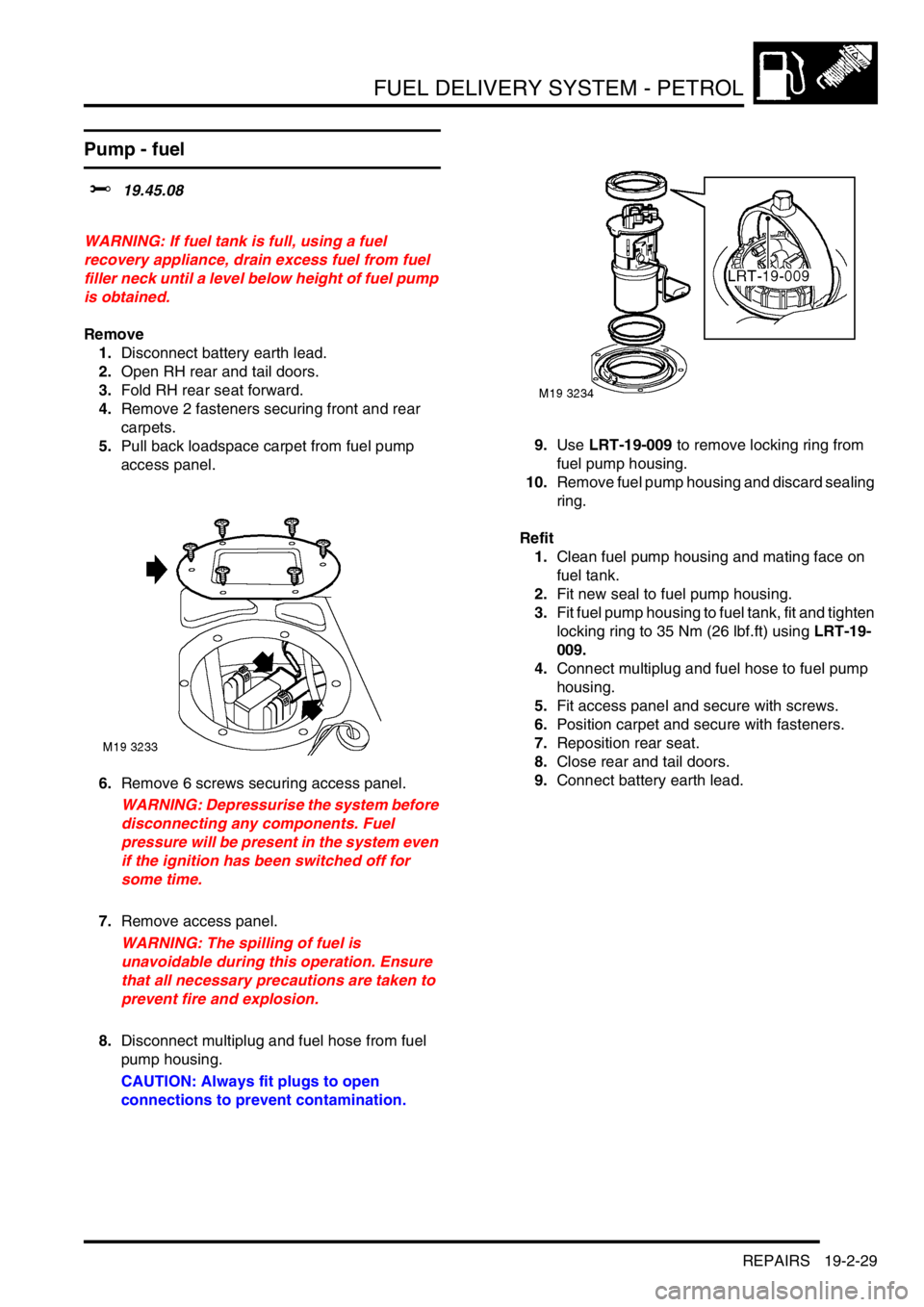

WARNING: If fuel tank is full, using a fuel

recovery appliance, drain excess fuel from fuel

filler neck until a level below height of fuel pump

is obtained.

Remove

1.Disconnect battery earth lead.

2.Open RH rear and tail doors.

3.Fold RH rear seat forward.

4.Remove 2 fasteners securing front and rear

carpets.

5.Pull back loadspace carpet from fuel pump

access panel.

6.Remove 6 screws securing access panel.

WARNING: Depressurise the system before

disconnecting any components. Fuel

pressure will be present in the system even

if the ignition has been switched off for

some time.

7.Remove access panel.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

8.Disconnect multiplug and fuel hose from fuel

pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.9.Use LRT-19-009 to remove locking ring from

fuel pump housing.

10.Remove fuel pump housing and discard sealing

ring.

Refit

1.Clean fuel pump housing and mating face on

fuel tank.

2.Fit new seal to fuel pump housing.

3.Fit fuel pump housing to fuel tank, fit and tighten

locking ring to 35 Nm (26 lbf.ft) using LRT-19-

009.

4.Connect multiplug and fuel hose to fuel pump

housing.

5.Fit access panel and secure with screws.

6.Position carpet and secure with fasteners.

7.Reposition rear seat.

8.Close rear and tail doors.

9.Connect battery earth lead.

Page 356 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-35

Fuel rail - KV6 - Non NAS

$% 19.60.04.99

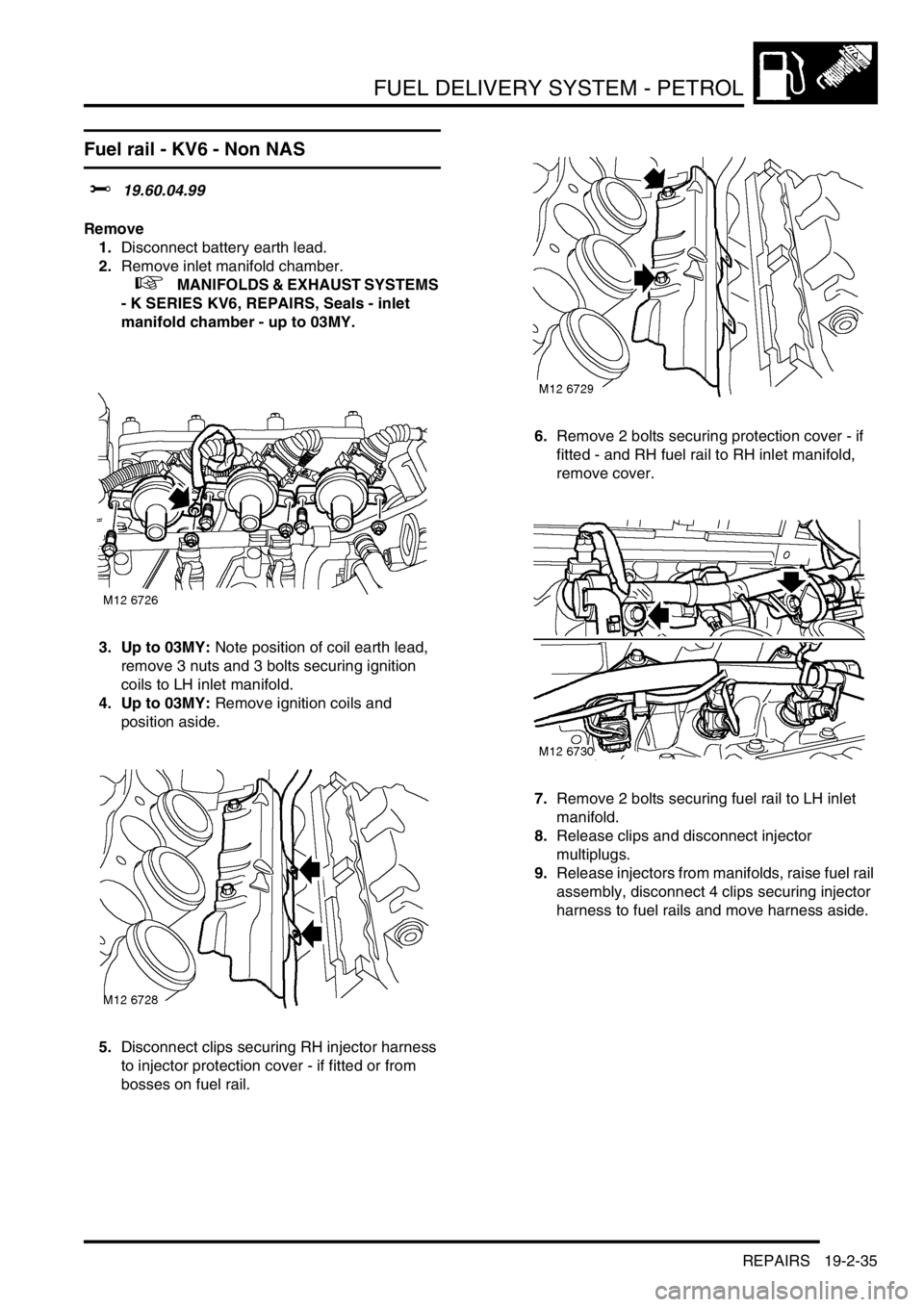

Remove

1.Disconnect battery earth lead.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

3. Up to 03MY: Note position of coil earth lead,

remove 3 nuts and 3 bolts securing ignition

coils to LH inlet manifold.

4. Up to 03MY: Remove ignition coils and

position aside.

5.Disconnect clips securing RH injector harness

to injector protection cover - if fitted or from

bosses on fuel rail.6.Remove 2 bolts securing protection cover - if

fitted - and RH fuel rail to RH inlet manifold,

remove cover.

7.Remove 2 bolts securing fuel rail to LH inlet

manifold.

8.Release clips and disconnect injector

multiplugs.

9.Release injectors from manifolds, raise fuel rail

assembly, disconnect 4 clips securing injector

harness to fuel rails and move harness aside.

Page 357 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-36 REPAIRS

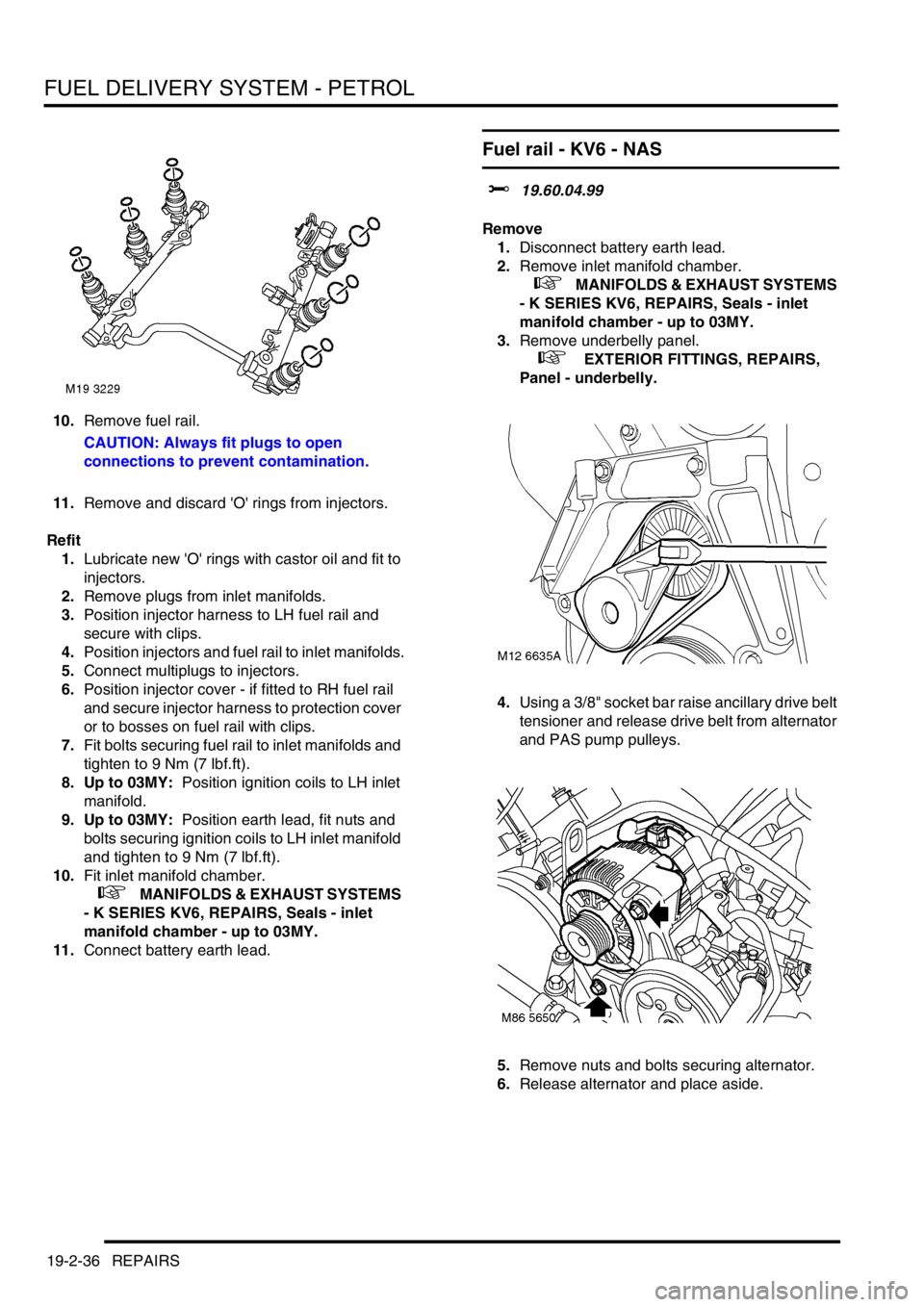

10.Remove fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11.Remove and discard 'O' rings from injectors.

Refit

1.Lubricate new 'O' rings with castor oil and fit to

injectors.

2.Remove plugs from inlet manifolds.

3.Position injector harness to LH fuel rail and

secure with clips.

4.Position injectors and fuel rail to inlet manifolds.

5.Connect multiplugs to injectors.

6.Position injector cover - if fitted to RH fuel rail

and secure injector harness to protection cover

or to bosses on fuel rail with clips.

7.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

8. Up to 03MY: Position ignition coils to LH inlet

manifold.

9. Up to 03MY: Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

10.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

11.Connect battery earth lead.

Fuel rail - KV6 - NAS

$% 19.60.04.99

Remove

1.Disconnect battery earth lead.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Using a 3/8" socket bar raise ancillary drive belt

tensioner and release drive belt from alternator

and PAS pump pulleys.

5.Remove nuts and bolts securing alternator.

6.Release alternator and place aside.

Page 358 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-37

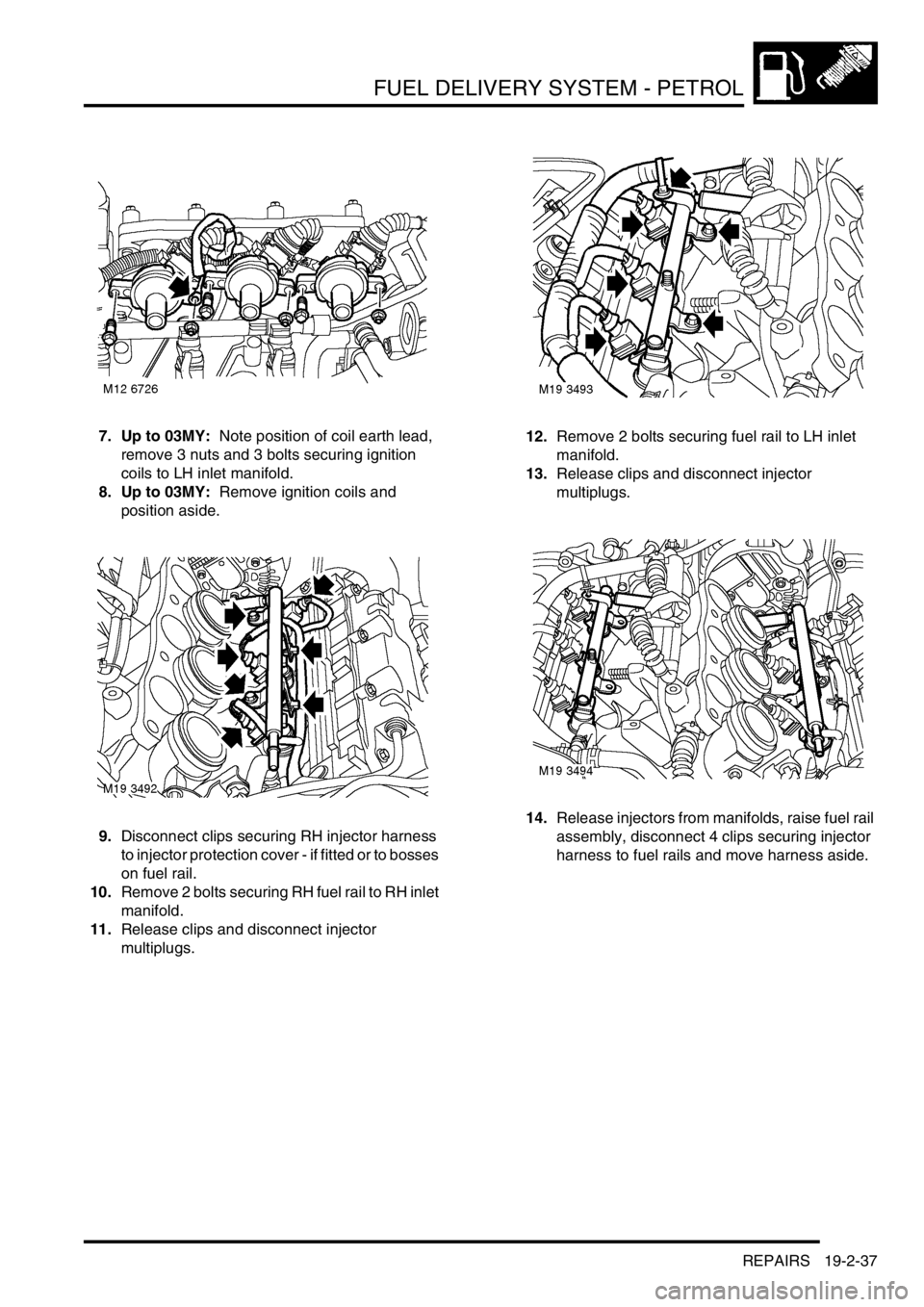

7. Up to 03MY: Note position of coil earth lead,

remove 3 nuts and 3 bolts securing ignition

coils to LH inlet manifold.

8. Up to 03MY: Remove ignition coils and

position aside.

9.Disconnect clips securing RH injector harness

to injector protection cover - if fitted or to bosses

on fuel rail.

10.Remove 2 bolts securing RH fuel rail to RH inlet

manifold.

11.Release clips and disconnect injector

multiplugs.12.Remove 2 bolts securing fuel rail to LH inlet

manifold.

13.Release clips and disconnect injector

multiplugs.

14.Release injectors from manifolds, raise fuel rail

assembly, disconnect 4 clips securing injector

harness to fuel rails and move harness aside.

Page 359 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-38 REPAIRS

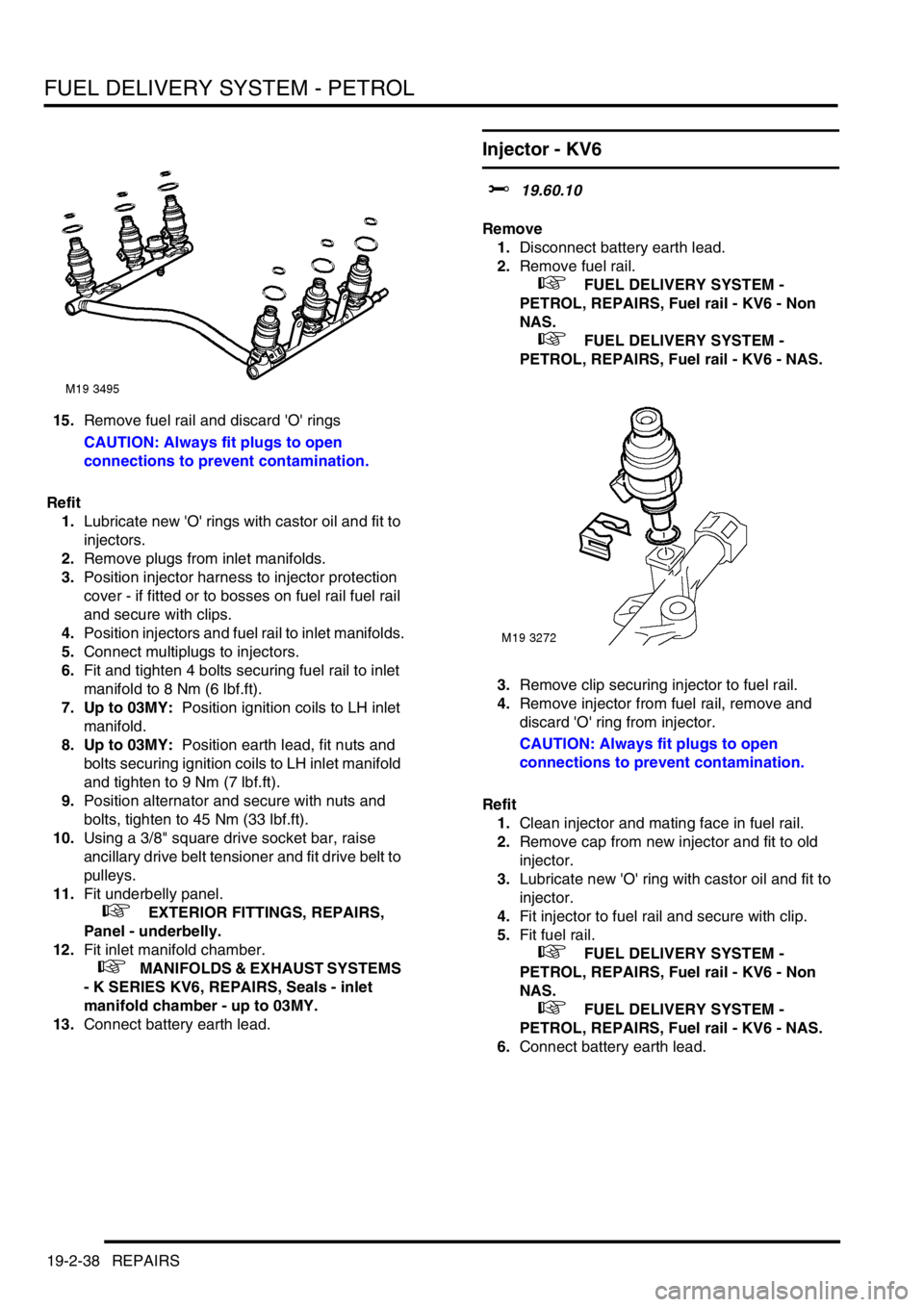

15.Remove fuel rail and discard 'O' rings

CAUTION: Always fit plugs to open

connections to prevent contamination.

Refit

1.Lubricate new 'O' rings with castor oil and fit to

injectors.

2.Remove plugs from inlet manifolds.

3.Position injector harness to injector protection

cover - if fitted or to bosses on fuel rail fuel rail

and secure with clips.

4.Position injectors and fuel rail to inlet manifolds.

5.Connect multiplugs to injectors.

6.Fit and tighten 4 bolts securing fuel rail to inlet

manifold to 8 Nm (6 lbf.ft).

7. Up to 03MY: Position ignition coils to LH inlet

manifold.

8. Up to 03MY: Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

9.Position alternator and secure with nuts and

bolts, tighten to 45 Nm (33 lbf.ft).

10.Using a 3/8" square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

11.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

12.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

13.Connect battery earth lead.

Injector - KV6

$% 19.60.10

Remove

1.Disconnect battery earth lead.

2.Remove fuel rail.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Fuel rail - KV6 - Non

NAS.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Fuel rail - KV6 - NAS.

3.Remove clip securing injector to fuel rail.

4.Remove injector from fuel rail, remove and

discard 'O' ring from injector.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Refit

1.Clean injector and mating face in fuel rail.

2.Remove cap from new injector and fit to old

injector.

3.Lubricate new 'O' ring with castor oil and fit to

injector.

4.Fit injector to fuel rail and secure with clip.

5.Fit fuel rail.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Fuel rail - KV6 - Non

NAS.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Fuel rail - KV6 - NAS.

6.Connect battery earth lead.

Page 510 of 1007

STEERING

REPAIRS 57-17

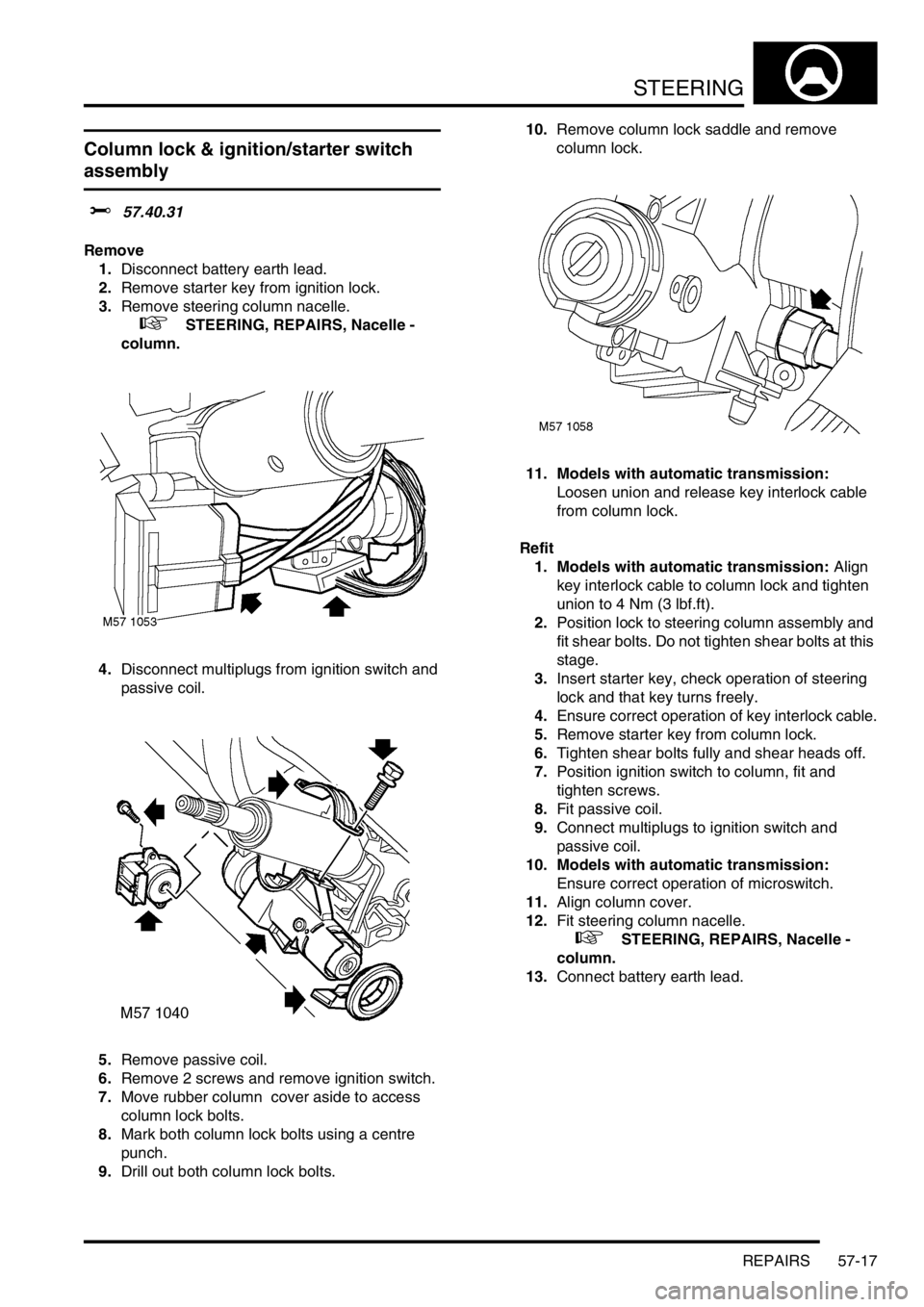

Column lock & ignition/starter switch

assembly

$% 57.40.31

Remove

1.Disconnect battery earth lead.

2.Remove starter key from ignition lock.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

4.Disconnect multiplugs from ignition switch and

passive coil.

5.Remove passive coil.

6.Remove 2 screws and remove ignition switch.

7.Move rubber column cover aside to access

column lock bolts.

8.Mark both column lock bolts using a centre

punch.

9.Drill out both column lock bolts.10.Remove column lock saddle and remove

column lock.

11. Models with automatic transmission:

Loosen union and release key interlock cable

from column lock.

Refit

1. Models with automatic transmission: Align

key interlock cable to column lock and tighten

union to 4 Nm (3 lbf.ft).

2.Position lock to steering column assembly and

fit shear bolts. Do not tighten shear bolts at this

stage.

3.Insert starter key, check operation of steering

lock and that key turns freely.

4.Ensure correct operation of key interlock cable.

5.Remove starter key from column lock.

6.Tighten shear bolts fully and shear heads off.

7.Position ignition switch to column, fit and

tighten screws.

8.Fit passive coil.

9.Connect multiplugs to ignition switch and

passive coil.

10. Models with automatic transmission:

Ensure correct operation of microswitch.

11.Align column cover.

12.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

13.Connect battery earth lead.

Page 512 of 1007

STEERING

REPAIRS 57-19

Refit

1.Position cable, align to heater and steering

column bracket and secure in retaining clips.

2.Align key interlock cable to column lock and

tighten union to 4 Nm (3 lbf.ft).

3.Fit height adjuster clamp bolt and tighten nut to

10 Nm (7.5 lbf.ft). Ensure bolt and plastic stop

are correctly located in slot in column bracket.

4.Fit height adjuster lever and tighten bolt 12 Nm

(9 lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

5.Connect cable to interlock mechanism.

6.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

7.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

8.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

9.Connect battery earth lead.

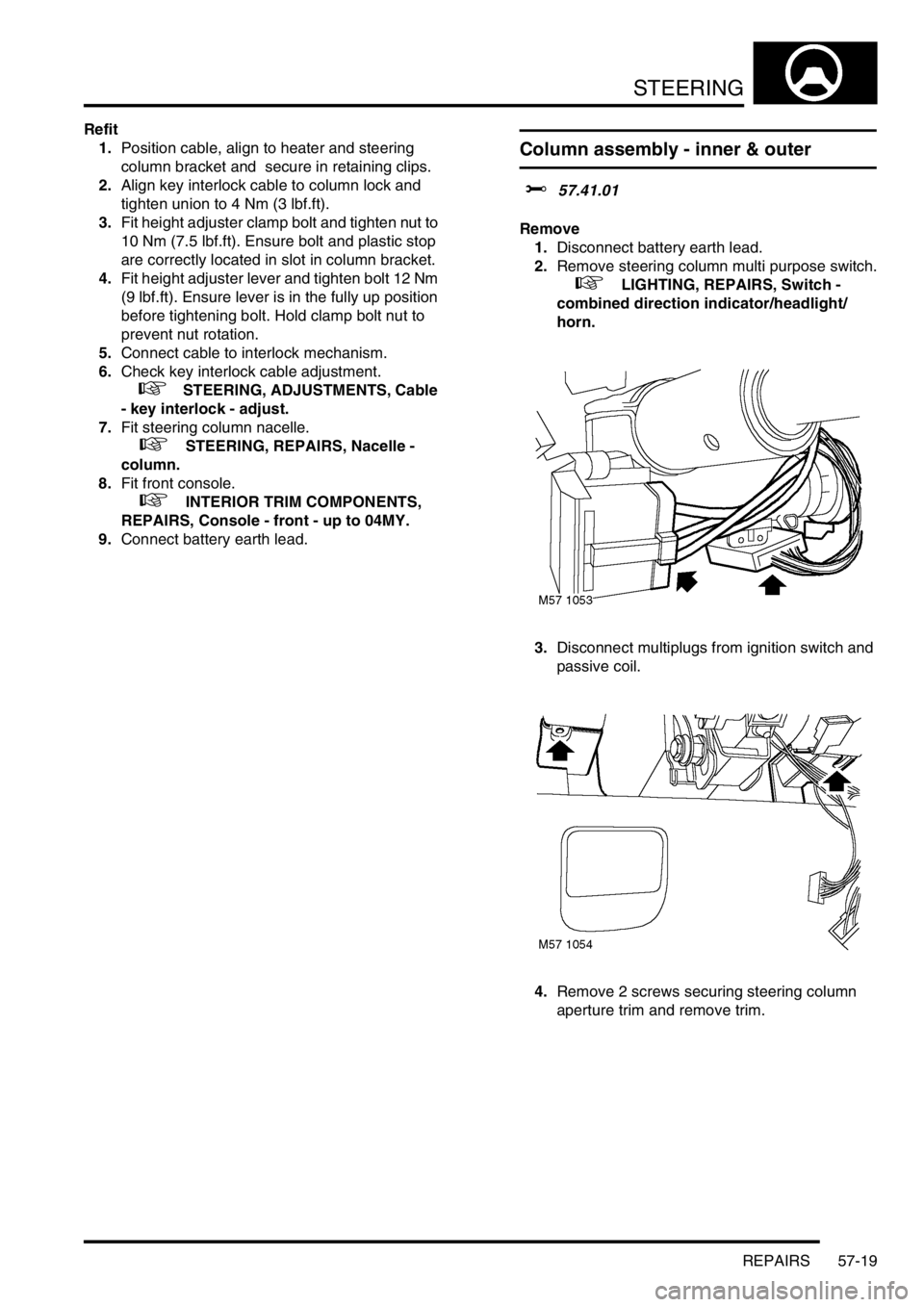

Column assembly - inner & outer

$% 57.41.01

Remove

1.Disconnect battery earth lead.

2.Remove steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

3.Disconnect multiplugs from ignition switch and

passive coil.

4.Remove 2 screws securing steering column

aperture trim and remove trim.