air conditioning LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 4 of 1007

CONTENTS

CONTENTS 1

INTRODUCTION ...................................................................................... 01-1

How To Use This Manual................................................................................................................ 01-1

Repairs and Replacements ............................................................................................................. 01-2

Specifications .................................................................................................................................. 01-2

Abbreviations and Symbols ............................................................................................................ 01-3

GENERAL INFORMATION ...................................................................... 03-1

General precautions ........................................................................................................................ 03-1

Safety instructions ........................................................................................................................... 03-2

Environmental Precautions ............................................................................................................. 03-3

General fitting instructions .............................................................................................................. 03-7

Ball and roller bearings ................................................................................................................... 03-8

Oil seals .......................................................................................................................................... 03-9

Joints and joint faces ...................................................................................................................... 03-10

Locking devices .............................................................................................................................. 03-10

Screw threads ................................................................................................................................. 03-11

Bolt identification ............................................................................................................................. 03-12

Nut identification ............................................................................................................................. 03-13

Flexible pipes and hoses ................................................................................................................ 03-14

Service tools ................................................................................................................................... 03-16

Rolling road testing ......................................................................................................................... 03-17

Fuel handling precautions ............................................................................................................... 03-18

Electrical precautions ...................................................................................................................... 03-19

Supplementary restraint system precautions .................................................................................. 03-20

SRS component manual deployment ............................................................................................. 03-27

SRS component replacement policy ............................................................................................... 03-28

Air conditioning system precautions ............................................................................................... 03-29

Remedial actions ............................................................................................................................ 03-30

Service precautions ........................................................................................................................ 03-30

Air conditioning compressor replacement ....................................................................................... 03-31

Page 5 of 1007

CONTENTS

2CONTENTS

GENERAL DATA ..................................................................................... 04-1

Engine - Td4 Diesel ........................................................................................................................ 04-1

Engine - K1.8 Petrol........................................................................................................................ 04-6

Engine - KV6 Petrol ........................................................................................................................ 04-11

Fuel system - Td4 Diesel ................................................................................................................ 04-16

Fuel system - K1.8 Petrol ............................................................................................................... 04-18

Fuel system - KV6 Petrol ................................................................................................................ 04-18

Cooling system - Td4 Diesel ........................................................................................................... 04-19

Cooling system - K1.8 Petrol .......................................................................................................... 04-19

Cooling system - KV6 Petrol ........................................................................................................... 04-19

Clutch.............................................................................................................................................. 04-20

Manual Gearbox - Getrag ............................................................................................................... 04-21

Manual Gearbox - PG1 ................................................................................................................... 04-22

Intermediate Reduction Drive (IRD)................................................................................................ 04-24

Automatic Gearbox - Jatco ............................................................................................................. 04-25

Rear Axle and Final Drive ............................................................................................................... 04-26

Steering .......................................................................................................................................... 04-27

Front Suspension............................................................................................................................ 04-28

Rear Suspension ............................................................................................................................ 04-30

Brakes............................................................................................................................................. 04-31

Wheels and tyres ............................................................................................................................ 04-32

Tyre pressures ................................................................................................................................ 04-32

Heating and Ventilation................................................................................................................... 04-33

Air Conditioning .............................................................................................................................. 04-33

Electrical - Td4 engine .................................................................................................................... 04-34

Electrical - K1.8 engine ................................................................................................................... 04-34

Electrical - KV6 engine ................................................................................................................... 04-34

Dimensions ..................................................................................................................................... 04-35

Weights ........................................................................................................................................... 04-36

IDENTIFICATION NUMBERS .................................................................. 05-1

Vehicle Identification Number ......................................................................................................... 05-1

Identification Number Locations ..................................................................................................... 05-2

Page 6 of 1007

CONTENTS

CONTENTS 3

TORQUE WRENCH SETTINGS .............................................................. 06-1

Maintenance ................................................................................................................................... 06-1

Engine – Td4................................................................................................................................... 06-2

Engine – K1.8 ................................................................................................................................. 06-4

Engine – KV6 .................................................................................................................................. 06-6

Emission Control ............................................................................................................................. 06-8

Engine Management System – EDC .............................................................................................. 06-9

Engine Management System – MEMS ........................................................................................... 06-10

Engine Management System – Siemens ........................................................................................ 06-11

Fuel Delivery System – Diesel ........................................................................................................ 06-12

Fuel delivery system – Petrol .......................................................................................................... 06-13

Cooling System – Td4..................................................................................................................... 06-14

Cooling System – K1.8 ................................................................................................................... 06-14

Cooling System – KV6 .................................................................................................................... 06-14

Manifolds and Exhaust System – Td4 ............................................................................................ 06-15

Manifolds and Exhaust Systems – K1.8 ......................................................................................... 06-16

Manifolds and Exhaust Systems – KV6 .......................................................................................... 06-17

Clutch .............................................................................................................................................. 06-18

Manual Gearbox – PG1 .................................................................................................................. 06-19

Manual Gearbox – Getrag .............................................................................................................. 06-20

Intermediate Reduction Drive ......................................................................................................... 06-21

Automatic Gearbox – Jatco ............................................................................................................. 06-22

Driveshafts ...................................................................................................................................... 06-23

Rear Axles and Final Drive ............................................................................................................. 06-24

Steering........................................................................................................................................... 06-25

Front Suspension and Subframe .................................................................................................... 06-26

Rear Suspension and Subframe ..................................................................................................... 06-27

Brakes ............................................................................................................................................. 06-28

Supplementary Restraint Systems .................................................................................................. 06-29

Body ................................................................................................................................................ 06-30

Heating and Ventilation ................................................................................................................... 06-32

Air Conditioning............................................................................................................................... 06-33

Wipers and Washers ....................................................................................................................... 06-34

Electrical ......................................................................................................................................... 06-35

LIFTING AND TOWING ........................................................................... 08-1

Jacking ............................................................................................................................................ 08-1

Towing ............................................................................................................................................ 08-2

Emergency starting ......................................................................................................................... 08-4

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS ...................... 09-1

Capacities ....................................................................................................................................... 09-1

Fluids .............................................................................................................................................. 09-2

Lubrication ...................................................................................................................................... 09-3

Sealants .......................................................................................................................................... 09-4

Page 21 of 1007

CONTENTS

18 CONTENTS

HEATING AND VENTILATION ................................................................. 80-1

REPAIRS

Controls - heater - up to 04MY ....................................................................................................... 80-1

Controls - heater - from 04MY ........................................................................................................ 80-2

Servo - air recirculation .................................................................................................................. 80-3

Switch - recirculation control .......................................................................................................... 80-3

Switch - fan - front heater .............................................................................................................. 80-4

Ventilator - face level - LH ............................................................................................................. 80-5

Plenum - air intake ......................................................................................................................... 80-6

Heater unit ..................................................................................................................................... 80-7

Element - positive temperature co-efficient (PTC) heater - Td4 models......................................... 80-10

Harness - positive temperature co-efficient (PTC) heater - Td4 models ........................................ 80-11

Microswitch - positive temperature co-efficient (PTC) heater - Td4 models ................................... 80-14

Blower assembly ............................................................................................................................ 80-14

Resistor unit - fan motor ................................................................................................................ 80-15

Matrix - heater................................................................................................................................. 80-15

Relay - power - positive temperature co-efficient (PTC) - Td4 models ........................................... 80-16

Relay - control - positive temperature co-efficient (PTC) - Td4 models .......................................... 80-17

Fuel burning heater (FBH) .............................................................................................................. 80-18

Sensor - outside temperature (OT) ................................................................................................. 80-19

Fuel pump - fuel burning heater - up to 03MY ................................................................................ 80-20

Fuel pump - fuel burning heater - from 03MY ................................................................................. 80-21

AIR CONDITIONING ................................................................................. 82-1

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

Refrigerant recovery - recycling and recharge................................................................................ 82-1

ADJUSTMENTS

Drive belt - compressor - Td4 ......................................................................................................... 82-3

REPAIRS

Drive belt - compressor - Td4 ......................................................................................................... 82-5

Compressor - Td4 ........................................................................................................................... 82-6

Compressor - KV6 .......................................................................................................................... 82-7

Compressor - K1.8.......................................................................................................................... 82-8

Condenser ...................................................................................................................................... 82-10

Receiver drier ................................................................................................................................. 82-12

Switch - control ............................................................................................................................... 82-13

Sensor - refrigerant pressure .......................................................................................................... 82-14

Valve - thermostatic expansion (TXV) ............................................................................................ 82-15

Evaporator ..................................................................................................................................... 82-16

Page 28 of 1007

INTRODUCTION

01-3

Abbreviations and Symbols

A Amperes

AAP Ambient Air Pressure

AAT Ambient Air Temperature

ABDC After Bottom Dead Centre

ABS Anti-Lock Brake System

ABS / TC Anti-lock Brake System / Traction

Control

ac Alternating current

A/C Air Conditioning

ACE Active Cornering Enhancement

ACEA Association of Constructors of

European Automobiles

AFR Air Fuel Ratio

AP Ambient Pressure

ASC Anti-shunt Control

ATC Air Temperature Control

ATDC After Top Dead Centre

AUX Auxiliary

AVC Automatic Volume Control

BBDC Before Bottom Dead Centre

BBUS Battery Backed Up Sounder

BCU Body Control Unit

BDC Bottom Dead Centre

bhp Brake Horse Power

BP Boost Pressure

BPP Brake Pedal Position

BS British Standard

BTDC Before Top Dead Centre

BWD Backward

C Celsius

CAN Controller Area Network

CD Compact Disc

CDC Centre Differential Control

CDL Central Door Locking

CD - ROM Compact Disc - Read Only

Memory

CFC Chlorofluorocarbon

CHMSL Centre High Mounted Stop Lamp

CKP Crankshaft Position

CLV Calculated Load Value

cm Centimetre

cm

2Square centimetre

cm3Cubic centimetre

CMP Camshaft Position

CPP Clutch Pedal Position

CO Carbon Monoxide

CO

2Carbon Dioxide

COB Clear Over Base

CR Common Rail

CVS Canister Vent Solenoid

dB Decibels

DDM Driver's Door Module

deg. Degree, angle or temperature

DI Direct Injection

dia. DiameterDIN Deutsche Industrie Normen

(German Industrial Standards)

dc Direct current

DCV Directional Control Valve

DOHC Double Overhead Camshaft

DSP Digital Signal Processing

DTI Dial Test Indicator

DMF Dual Mass Flywheel

DVD Digital Versatile Disc

EACV Electronic Air Control Valve

EAT Electronic Automatic

Transmission

EBD Electronic Brake pressure

Distribution

ECD European Community Directive

ECM Engine Control Module

ECT Engine Coolant Temperature

ECU Electronic Control Unit

EDC Electronic Diesel Control

EEPROM Electronic Erasable

Programmable Read Only

Memory

EGR Exhaust Gas Recirculation

EKA Emergency Key Access

ELR Emergency Locking Retractor

EN European Norm

EOBD European On Board Diagnostics

EON Enhanced Other Network

ERL Electrical Reference Library

ETC Electronic Traction Control

EUI Electronic Unit Injector

EVAP Evaporative Emission

EVR Electronic Vacuum Regulator

F Fahrenheit

ft. Feet

FBH Fuel Burning Heater

FET Field Effect Transistor

FIP Fuel Injection Pump

FTC Fast Throttle Control

FWD Forward

> Greater than

g Gramme or Gravity

gal. Gallons

GMT Greenwich Mean Time

GPS Global Positioning System

hHour

hc High compression

HC Hydro Carbons

HDC Hill Descent Control

HDOP Height Dilation Of Precision

HDPE High Density Polyethylene

HFS Heated Front Screen

Hg Mercury

HO

2S Heated Oxygen Sensor

HMW High Molecular Weight

Page 34 of 1007

GENERAL INFORMATION

03-3

Brake hydraulics

Observe the following recommendations when

working on the brake system:

lAlways use two spanners when loosening or

tightening brake pipe or hose connections.

lEnsure that hoses run in a natural curve and are

not kinked or twisted.

lFit brake pipes securely in their retaining clips

and ensure that the pipe run cannot contact a

potential chafing point.

lContainers used for hydraulic brake fluid must

be kept absolutely clean.

lDo not store hydraulic brake fluid in an unsealed

container, it will absorb water and in this

condition would be dangerous to use due to a

lowering of its boiling point.

lDo not allow hydraulic brake fluid to be

contaminated with mineral oil, or put new

hydraulic brake fluid in a container which has

previously contained mineral oil.

lDo not re-use hydraulic brake fluid previously

removed from the system.

lAlways use clean brake fluid or a recommended

alternative to clean hydraulic components.

lFit a blanking cap to a hydraulic union and a

plug to its socket, immediately after

disconnection of pipes and hoses to prevent the

ingress of dirt.

lAbsolute cleanliness must be observed when

working with hydraulic components.

lIt is imperative that the correct brake fittings are

used and that threads of components are

compatible.

Cooling system caps and plugs

Extreme care is necessary when removing engine

cooling system expansion tank caps and coolant

drain or bleed screws when the engine is hot, and

especially if it is overheated.

To avoid the possibility of scalding allow the engine

to cool before attempting coolant cap or plug

removal.

Environmental Precautions

General

This section provides general information which can

help to reduce adverse environmental impacts

incurred through the activities carried out in

workshops.

Emissions to air

Many of the activities that are carried out in

workshops emit gases and fumes which contribute to

global warming, depletion of the ozone layer and/or

the formation of photo-chemical smog at ground

level. By considering and controlling how the

workshop activities are carried out, these gases and

fumes can be minimised, thus reducing the damage

to the environment.

Exhaust fumes

Running car engines is an essential part of workshop

activities and exhaust fumes need to be ventilated to

atmosphere. However, the amount of time engines

are running and the position of the vehicle should be

carefully considered at all times, to reduce the

release of poisonous gases and minimise the

inconvenience to people living nearby.

Solvents

Some of the cleaning agents used are solvent based

and will evaporate to atmosphere if used carelessly,

or if cans are left unsealed. All solvent containers

should be firmly closed when not needed and solvent

should be used sparingly. Suitable alternative

materials may be available to replace some of the

commonly used solvents. Similarly, many paints are

solvent based and the spray should be minimised to

reduce solvent emissions.

Refrigerant

It is illegal to release any refrigerants into the

atmosphere. Discharge and replacement of these

materials from air conditioning units should only be

carried out using the correct equipment.

Checklist

Always adhere to the following:

Engines –

ldon't leave engines running unnecessarily;

lminimise testing times and check where the

exhaust fumes are being blown.

Page 45 of 1007

GENERAL INFORMATION

03-14

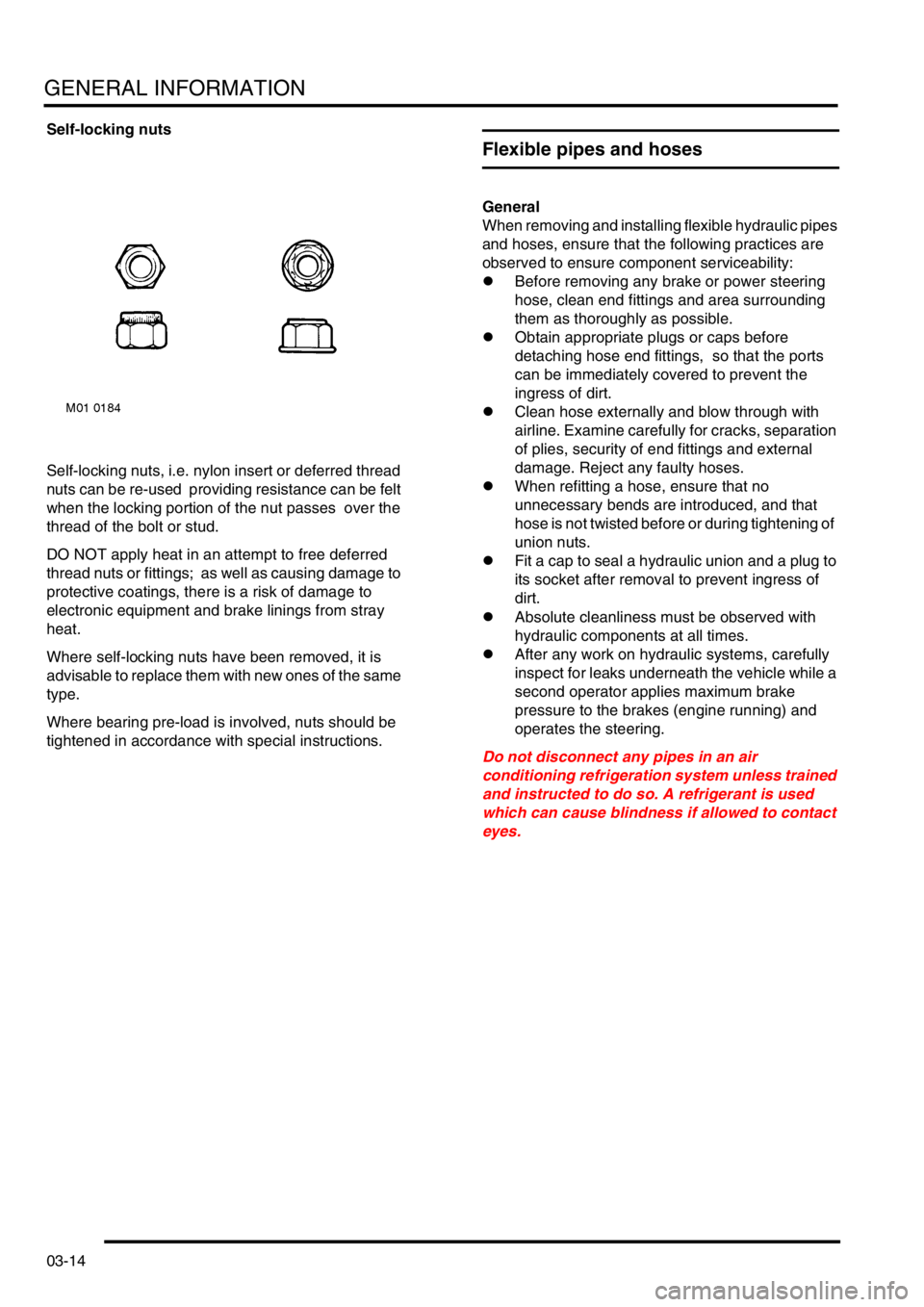

Self-locking nuts

Self-locking nuts, i.e. nylon insert or deferred thread

nuts can be re-used providing resistance can be felt

when the locking portion of the nut passes over the

thread of the bolt or stud.

DO NOT apply heat in an attempt to free deferred

thread nuts or fittings; as well as causing damage to

protective coatings, there is a risk of damage to

electronic equipment and brake linings from stray

heat.

Where self-locking nuts have been removed, it is

advisable to replace them with new ones of the same

type.

Where bearing pre-load is involved, nuts should be

tightened in accordance with special instructions.

Flexible pipes and hoses

General

When removing and installing flexible hydraulic pipes

and hoses, ensure that the following practices are

observed to ensure component serviceability:

lBefore removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

lObtain appropriate plugs or caps before

detaching hose end fittings, so that the ports

can be immediately covered to prevent the

ingress of dirt.

lClean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any faulty hoses.

lWhen refitting a hose, ensure that no

unnecessary bends are introduced, and that

hose is not twisted before or during tightening of

union nuts.

lFit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of

dirt.

lAbsolute cleanliness must be observed with

hydraulic components at all times.

lAfter any work on hydraulic systems, carefully

inspect for leaks underneath the vehicle while a

second operator applies maximum brake

pressure to the brakes (engine running) and

operates the steering.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

Page 60 of 1007

GENERAL INFORMATION

03-29

Air conditioning system precautions

General

The air conditioning system contains fluids and

components which could be potentially hazardous to

the service engineer or the environment if not

serviced and handled correctly. The following

guidelines are intended to alert the service engineer

to potential sources of danger and emphasise the

importance of ensuring the integrity of the Air

Conditioning operating conditions and components

fitted to the vehicle.

Where necessary, additional specific precautions are

detailed in the relevant sections of this Manual which

should be referred to prior to commencing repair

operations.

The refrigerant used in the air conditioning system is

HFC-134a (Hydrofluorocarbon) R134a. Always

adhere to the following precautions:

WARNING: Servicing must only be carried out by

personnel familiar with both the vehicle system

and the charging and testing equipment. All

operations must be carried out in a well

ventilated area away from open flame and heat

sources.

WARNING: Do not allow a refrigerant container to

be heated by direct flame or to be placed near

any heating appliance. A refrigerant container

must not be heated above 50

°C.

Do not leave a container of refrigerant without its

cap fitted. Do not transport a container of

refrigerant that is unrestrained, especially in the

boot of a car.

WARNING: Do not smoke or weld in areas where

R134a is in use. Inhalation of concentrations of

vapour can cause dizziness, disorientation,

incoordination, narcosis, nausea or vomiting.

R134a is odourless and colourless. Do not

handle or discharge in an enclosed area, or any

area where the vapour and liquid can come in

contact with a naked flame or hot metal. R134a is

not flammable but can cause a highly toxic gas.

WARNING: Do not allow fluids other than R134a

or compressor lubricant to enter the air

conditioning system. Spontaneous combustion

may occur.WARNING: R134a is a hazardous liquid and when

handled incorrectly can cause serious injury.

Suitable protective clothing, consisting of face

protection, heat proof gloves, rubber boots and

rubber apron or waterproof overalls, must be

worn when carrying out operations on the air

conditioning system.

WARNING: Due to its low evaporating

temperature, R134a must be handled with care.

R134a splashed on any part of the body will

cause immediate freezing of that area. Also,

refrigerant cylinders and replenishment trolleys

when discharging will freeze skin to them if

contact is made.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without first

discharging the system.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

WARNING: Refrigerant must always be recycled

before re-use to ensure that the purity of the

refrigerant is high enough for safe use in the air

conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance with

SAE J1991. Other equipment may not recycle

refrigerant to the required level of purity.

A R134a Refrigerant Recovery Recycling

Recharging Station must not be used with any

other type of refrigerant.

Refrigerant R134a from domestic and

commercial sources must not be used in motor

vehicle air conditioning systems.

Page 61 of 1007

GENERAL INFORMATION

03-30

Remedial actions

If an accident involving R134a should occur, conduct

the following remedial actions:

lIf liquid R134a enters the eye, do not rub it.

Gently run large quantities of eye wash over

affected eye to raise the temperature. If an eye

wash is not available, cool clean water may be

used to flush the eye. After rinsing, cover the

eye with a clean pad and seek immediate

medical attention.

lIf liquid R134a is splashed onto the skin, run

large quantities of water over the affected area

to raise the temperature. Implement the same

action if the skin comes in contact with

discharging cylinders. Wrap the contaminated

body parts in blankets (or similar materials) and

seek immediate medical attention.

lIf the debilitating effects of inhalation of R134a

vapour is suspected, seek fresh air. If the

affected person is unconscious, move them

away from the contaminated area to fresh air

and apply artificial respiration and/or oxygen

and seek immediate medical attention.

Service precautions

Observe the following precautions when handling

components used in the air conditioning system:

lAir conditioning units must not be lifted by their

hoses, pipes or capillary lines.

lHoses and lines must not be subjected to any

twist or stress - the efficiency of the system will

be impaired by kinks or restrictions. Ensure that

hoses are correctly positioned before tightening

couplings, and ensure that all clips and supports

are utilised.

lFlexible hoses should not be positioned close to

the exhaust manifold (less than 100mm) unless

protected by heat shielding.

lCompleted assemblies must be checked for

refrigeration lines touching metal panels. Any

direct contact of components and panels may

transmit noise and so must be eliminated.

lThe appropriate torque wrench must be used

when tightening refrigerant connections to the

stipulated value. An additional spanner must be

used to hold the union to prevent twisting of the

pipe when tightening connections.

lBefore connecting any hose or pipe, ensure that

refrigerant oil is applied to the seat of the new

'O' ring seals, BUT NOT to the threads of the

connection.

lAll protective plugs must remain in place to seal

the component until immediately prior to

connection.

lEnsure components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters it.

lComponents must not remain uncapped for

longer than 15 minutes. In the event of a delay,

the caps must be fitted.

lWhen disconnecting, immediately cap all air

conditioning pipes to prevent ingress of dirt and

moisture into the system.

lThe modulator (receiver/drier) contains

desiccant which absorbs moisture. It must be

positively sealed at all times. A modulator that

has been left uncapped must not be used, fit a

new unit.

lThe modulator should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection

of the system.

lWhenever the refrigerant system is opened, the

modulator must be renewed immediately before

evacuating and recharging the system.

lUse alcohol and a clean lint-free cloth to clean

dirty connections.

lEnsure that all new parts fitted are marked for

use with R134a.

Page 62 of 1007

GENERAL INFORMATION

03-31

When a major repair has been completed, a leak test

should be conducted; refer to the air conditioning

section of this manual for the correct procedure.

Refrigerant oil

Use an approved refrigerant lubricating oil:

ND Oil 8

CAUTION: Do not use any other type of

refrigerant oil.

CAUTION: Refrigerant oil easily absorbs water

and must not be stored for long periods. Do not

pour unused oil back into the container.

When renewing system components, add the

quantities of refrigerant oil recommended in the Air

Conditioning section of this manual.

Compressor

A new compressor is sealed and pressurised with

Nitrogen gas. When fitting a new compressor, slowly

release the sealing cap; gas pressure should be

heard to vent as the seal is broken.

CAUTION: A new compressor should always be

sealed and could be pressurised with nitrogen

gas. To avoid possible oil loss, release the

sealing cap(s) slowly. Do not remove the cap(s)

until immediately prior to connecting the air

conditioning pipes to the compressor.

Rapid refrigerant discharge

If the air conditioning system is involved in accident

damage and the system is punctured, the refrigerant

will discharge rapidly. The rapid discharge of

refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled in accordance with the 'Air

Conditioning Compressor Replacement Procedure'.

Air conditioning compressor

replacement

A new compressor is supplied filled with a full charge

of (X cm3) of refrigerant oil.

A new compressor is supplied with an oil fill (X cm) of

120 cm

3.

A calculated quantity of oil must be drained from the

new compressor before fitting. To calculate the

quantity of oil to be drained:

1Remove the drain plug from the old

compressor.

2Invert the compressor and gravity drain the oil

into a calibrated measuring cylinder. Rotate the

compressor clutch to ensure the compressor is

completely drained.

3Note the quantity of oil drained (Y cm

3).

4Calculate the quantity of oil to be drained from

the new compressor using the following

formula:

X cm

3 – (Y cm3 + 20 cm3) = Q cm3

5Remove the drain plug from the new

compressor and drain Q cm3 of oil.

6Fit and tighten the compressor drain plug.

System components

When renewing system components, add the

following quantities of refrigerant oil:

lCondenser = 40 cm

3

lEvaporator = 30 cm 3

lReceiver drier = 15 cm 3

lPipe or hose = 5 cm 3