check oil LAND ROVER FREELANDER 2001 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 491 of 1007

REAR AXLE & FINAL DRIVE

51-6 REPAIRS

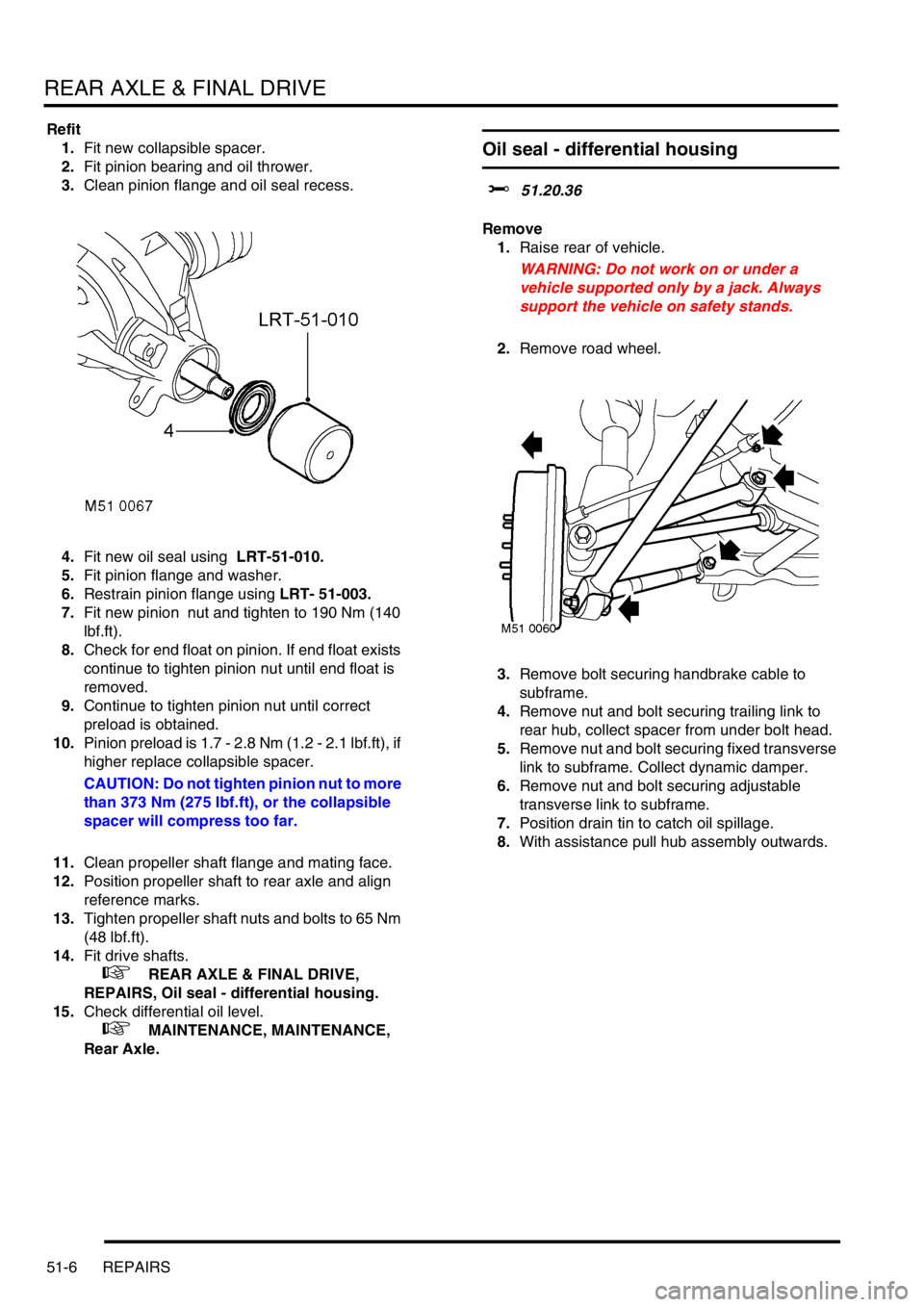

Refit

1.Fit new collapsible spacer.

2.Fit pinion bearing and oil thrower.

3.Clean pinion flange and oil seal recess.

4.Fit new oil seal using LRT-51-010.

5.Fit pinion flange and washer.

6.Restrain pinion flange using LRT- 51-003.

7.Fit new pinion nut and tighten to 190 Nm (140

lbf.ft).

8.Check for end float on pinion. If end float exists

continue to tighten pinion nut until end float is

removed.

9.Continue to tighten pinion nut until correct

preload is obtained.

10.Pinion preload is 1.7 - 2.8 Nm (1.2 - 2.1 lbf.ft), if

higher replace collapsible spacer.

CAUTION: Do not tighten pinion nut to more

than 373 Nm (275 lbf.ft), or the collapsible

spacer will compress too far.

11.Clean propeller shaft flange and mating face.

12.Position propeller shaft to rear axle and align

reference marks.

13.Tighten propeller shaft nuts and bolts to 65 Nm

(48 lbf.ft).

14.Fit drive shafts.

+ REAR AXLE & FINAL DRIVE,

REPAIRS, Oil seal - differential housing.

15.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

Oil seal - differential housing

$% 51.20.36

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove bolt securing handbrake cable to

subframe.

4.Remove nut and bolt securing trailing link to

rear hub, collect spacer from under bolt head.

5.Remove nut and bolt securing fixed transverse

link to subframe. Collect dynamic damper.

6.Remove nut and bolt securing adjustable

transverse link to subframe.

7.Position drain tin to catch oil spillage.

8.With assistance pull hub assembly outwards.

Page 492 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-7

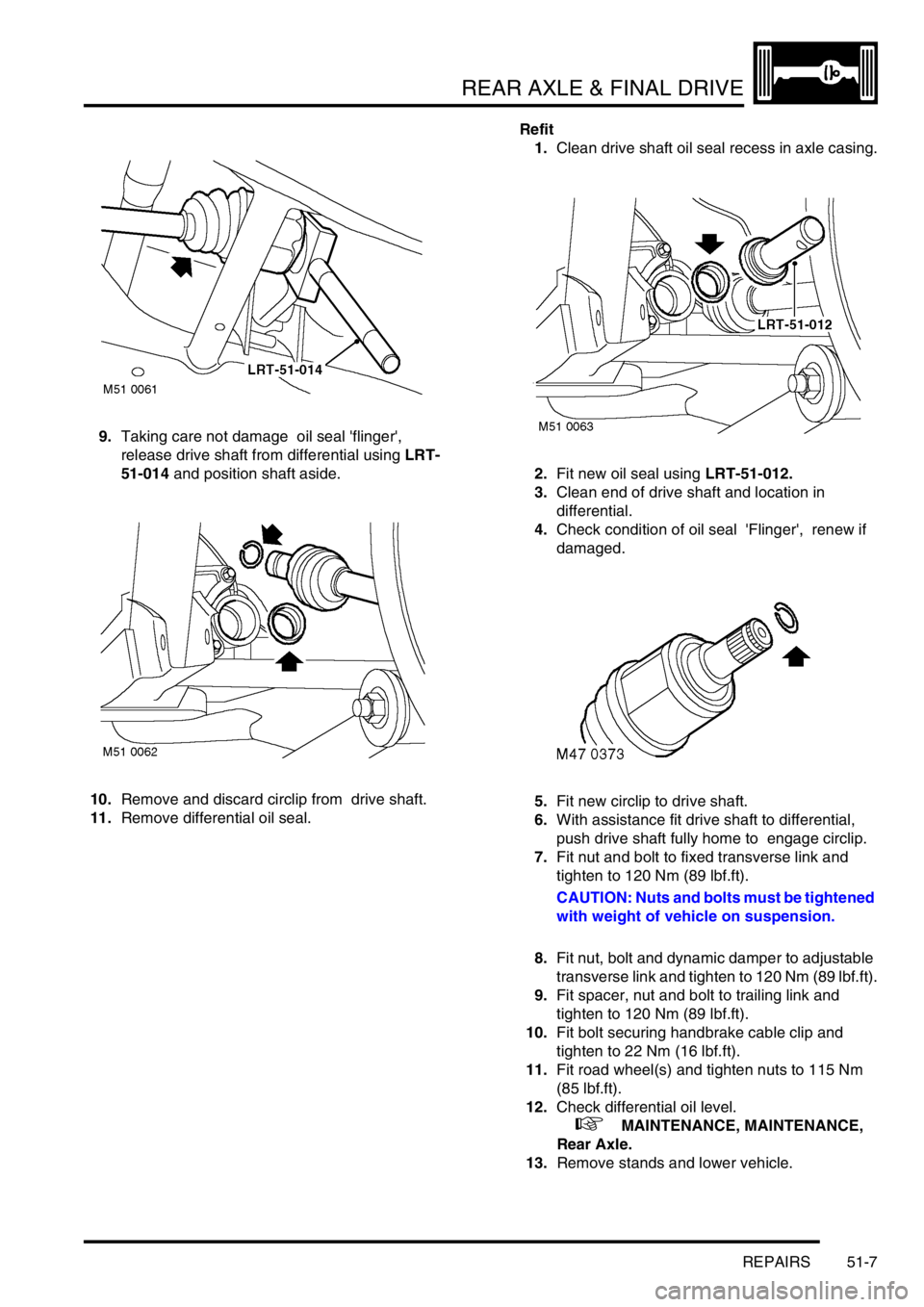

9.Taking care not damage oil seal 'flinger',

release drive shaft from differential using LRT-

51-014 and position shaft aside.

10.Remove and discard circlip from drive shaft.

11.Remove differential oil seal.Refit

1.Clean drive shaft oil seal recess in axle casing.

2.Fit new oil seal using LRT-51-012.

3.Clean end of drive shaft and location in

differential.

4.Check condition of oil seal 'Flinger', renew if

damaged.

5.Fit new circlip to drive shaft.

6.With assistance fit drive shaft to differential,

push drive shaft fully home to engage circlip.

7.Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

8.Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

9.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

10.Fit bolt securing handbrake cable clip and

tighten to 22 Nm (16 lbf.ft).

11.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

12.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

13.Remove stands and lower vehicle.

Page 510 of 1007

STEERING

REPAIRS 57-17

Column lock & ignition/starter switch

assembly

$% 57.40.31

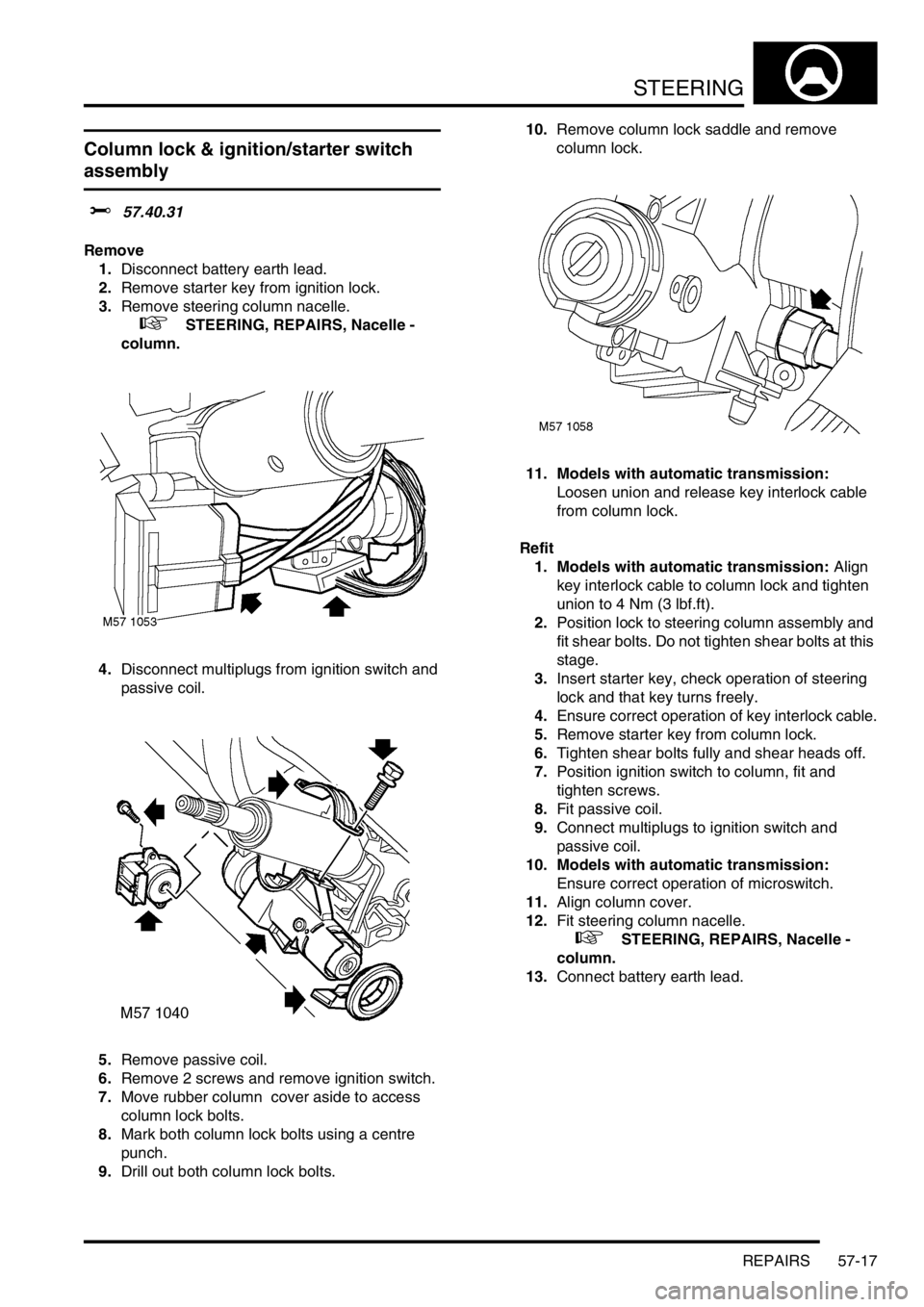

Remove

1.Disconnect battery earth lead.

2.Remove starter key from ignition lock.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

4.Disconnect multiplugs from ignition switch and

passive coil.

5.Remove passive coil.

6.Remove 2 screws and remove ignition switch.

7.Move rubber column cover aside to access

column lock bolts.

8.Mark both column lock bolts using a centre

punch.

9.Drill out both column lock bolts.10.Remove column lock saddle and remove

column lock.

11. Models with automatic transmission:

Loosen union and release key interlock cable

from column lock.

Refit

1. Models with automatic transmission: Align

key interlock cable to column lock and tighten

union to 4 Nm (3 lbf.ft).

2.Position lock to steering column assembly and

fit shear bolts. Do not tighten shear bolts at this

stage.

3.Insert starter key, check operation of steering

lock and that key turns freely.

4.Ensure correct operation of key interlock cable.

5.Remove starter key from column lock.

6.Tighten shear bolts fully and shear heads off.

7.Position ignition switch to column, fit and

tighten screws.

8.Fit passive coil.

9.Connect multiplugs to ignition switch and

passive coil.

10. Models with automatic transmission:

Ensure correct operation of microswitch.

11.Align column cover.

12.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

13.Connect battery earth lead.

Page 512 of 1007

STEERING

REPAIRS 57-19

Refit

1.Position cable, align to heater and steering

column bracket and secure in retaining clips.

2.Align key interlock cable to column lock and

tighten union to 4 Nm (3 lbf.ft).

3.Fit height adjuster clamp bolt and tighten nut to

10 Nm (7.5 lbf.ft). Ensure bolt and plastic stop

are correctly located in slot in column bracket.

4.Fit height adjuster lever and tighten bolt 12 Nm

(9 lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

5.Connect cable to interlock mechanism.

6.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

7.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

8.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

9.Connect battery earth lead.

Column assembly - inner & outer

$% 57.41.01

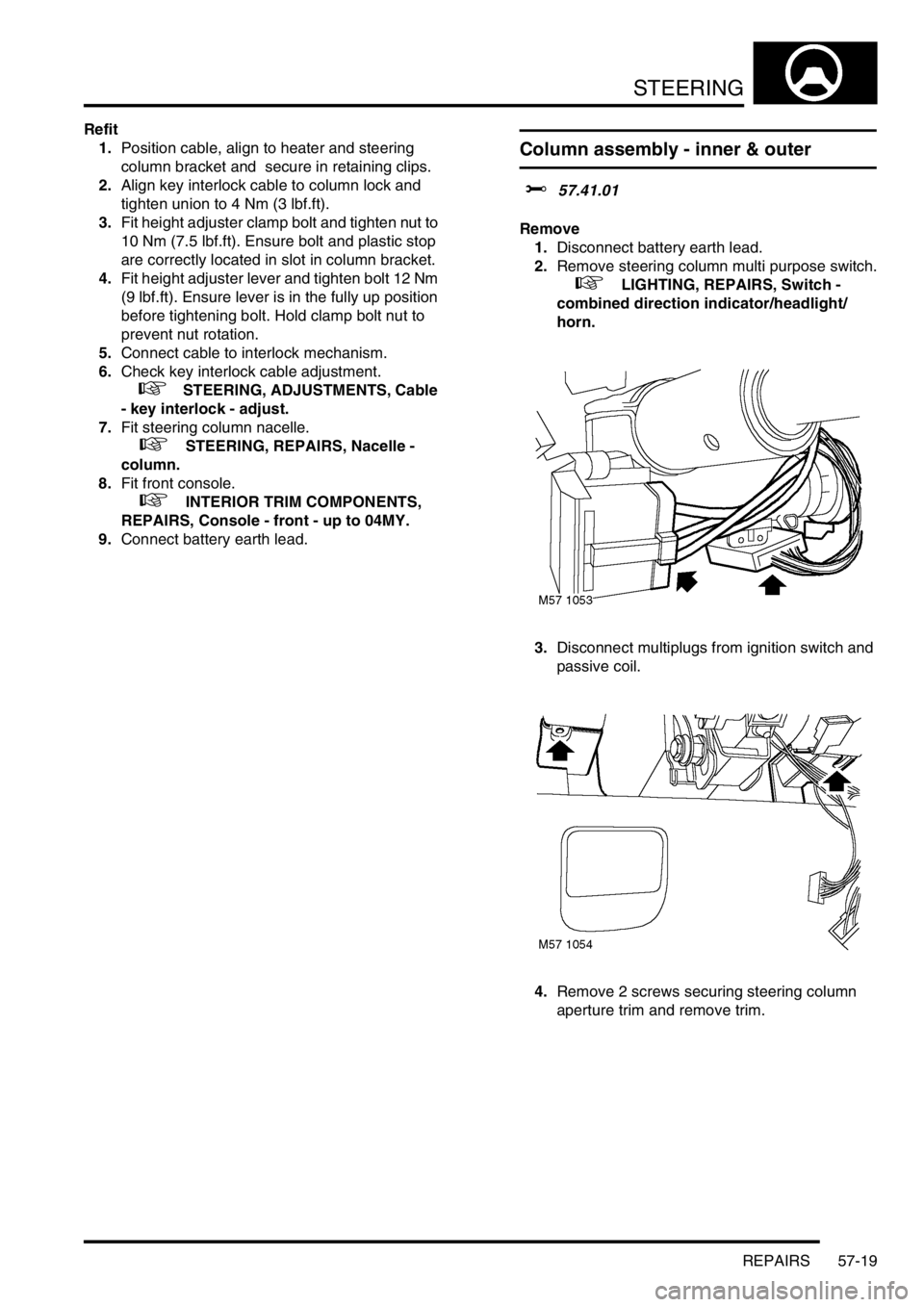

Remove

1.Disconnect battery earth lead.

2.Remove steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

3.Disconnect multiplugs from ignition switch and

passive coil.

4.Remove 2 screws securing steering column

aperture trim and remove trim.

Page 515 of 1007

STEERING

57-22 REPAIRS

Refit

1.Remove column from vice.

2.Fit new cable ties to steering column.

3. Models with automatic transmission: Fit key

interlock cable clip.

4.Position steering column to vehicle, locate

steering column on PAS rack, aligning column

coupling with PAS rack input flag.

5.Locate steering column on studs fit nuts but do

not tighten at this stage.

6.Fit bolts and snubber to pivot mountings and

tighten bolts to 14 Nm (10 lbf.ft).

7.Tighten nuts to 14 Nm (10 lbf.ft).

8.Fit and tighten PAS rack pinion clamp bolt to 32

Nm (24 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

9. Models with automatic transmission:

Remove clamp bolt from height adjuster and

position key interlock cable.

10. Models with automatic transmission: Fit

height adjuster clamp bolt and tighten nut to 10

Nm (7.5 lbf.ft). Ensure bolt and plastic stop are

correctly located in slot in column bracket.

11. Models with automatic transmission: Fit

height adjuster lever and tighten bolt 12 Nm (9

lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

12. Models with automatic transmission:

Remove starter key from column lock.

13. Models with automatic transmission: Align

key interlock cable to column lock and tighten

union to 4 Nm (3 lbf.ft).

14. Models with automatic

transmission:Position lock to steering column

assembly and fit shear bolts. Do not tighten

shear bolts at this stage.

15. Models with automatic transmission: Insert

starter key, check operation of steering lock

and that key turns freely.

16. Models with automatic transmission:

Ensure correct operation of key interlock cable.

17. Models with automatic transmission:

Remove starter key from column lock.

18. Models with automatic transmission:

Tighten shear bolts fully and shear heads off.

19. Models with automatic transmission: Fit

passive coil.

20. Models with automatic transmission:

Position ignition switch to column, fit and

tighten screws.

21. Models with automatic transmission:

Secure key interlock cable in clip.

22. Models with automatic transmission:

Ensure key interlock cable is correctly fitted.23.Fit side support bolt and tighten to 10 Nm (7.5

lbf.ft).

24.Position harness and secure cable ties.

25.Fit fusebox cover and close glove box lid.

26.Connect multiplugs to column switch and

passive coil.

27.Fit aperture trim and secure with screws.

28. Fit steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

29.Connect battery earth lead.

Page 914 of 1007

CHARGING AND STARTING

ADJUSTMENTS 86-1-1

CHARGING AND STARTING ADJUST ME NTS

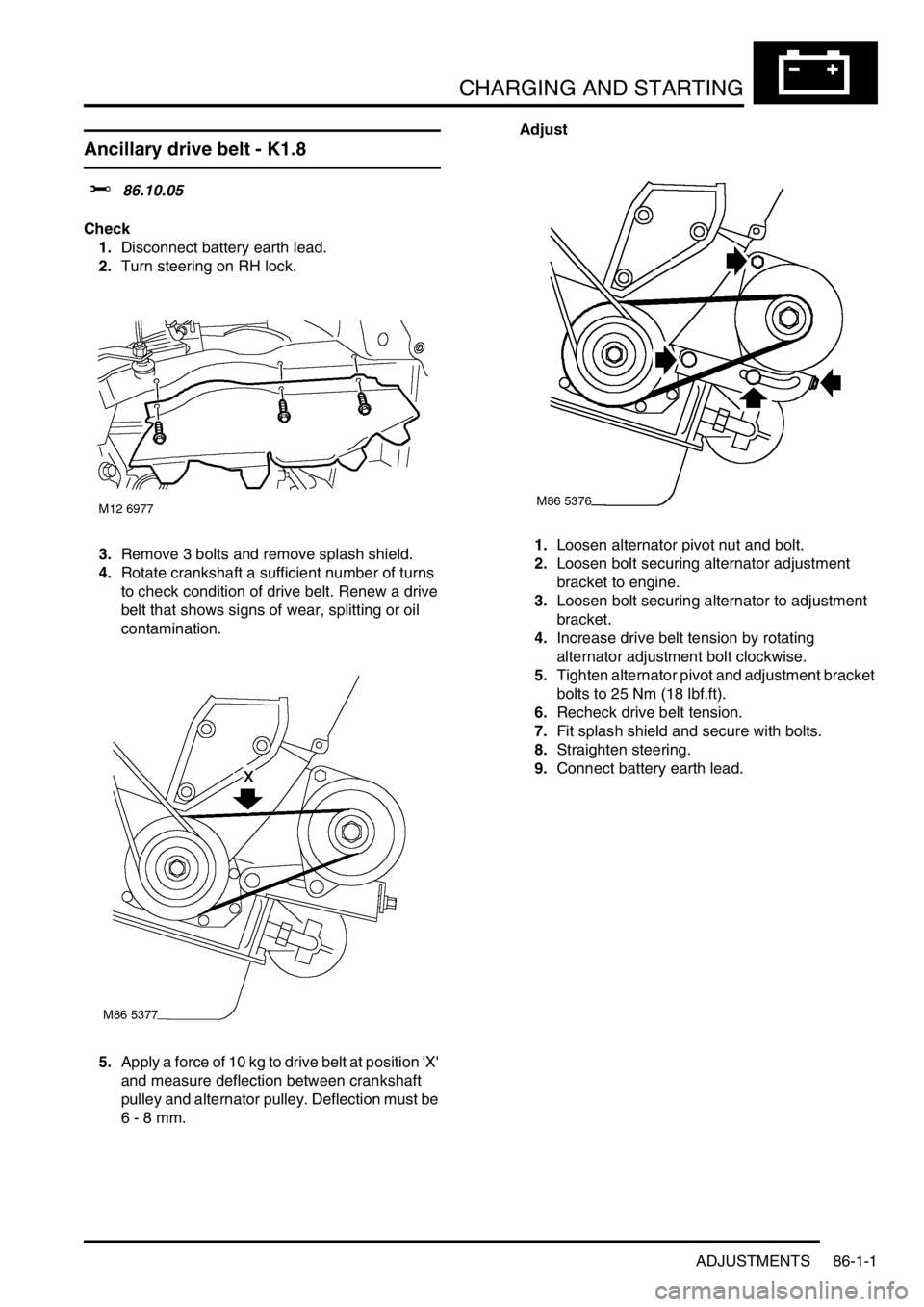

Ancillary drive belt - K1.8

$% 86.10.05

Check

1.Disconnect battery earth lead.

2.Turn steering on RH lock.

3.Remove 3 bolts and remove splash shield.

4.Rotate crankshaft a sufficient number of turns

to check condition of drive belt. Renew a drive

belt that shows signs of wear, splitting or oil

contamination.

5.Apply a force of 10 kg to drive belt at position 'X'

and measure deflection between crankshaft

pulley and alternator pulley. Deflection must be

6 - 8 mm.Adjust

1.Loosen alternator pivot nut and bolt.

2.Loosen bolt securing alternator adjustment

bracket to engine.

3.Loosen bolt securing alternator to adjustment

bracket.

4.Increase drive belt tension by rotating

alternator adjustment bolt clockwise.

5.Tighten alternator pivot and adjustment bracket

bolts to 25 Nm (18 lbf.ft).

6.Recheck drive belt tension.

7.Fit splash shield and secure with bolts.

8.Straighten steering.

9.Connect battery earth lead.

Page 915 of 1007

CHARGING AND STARTING

86-1-2 ADJUSTMENTS

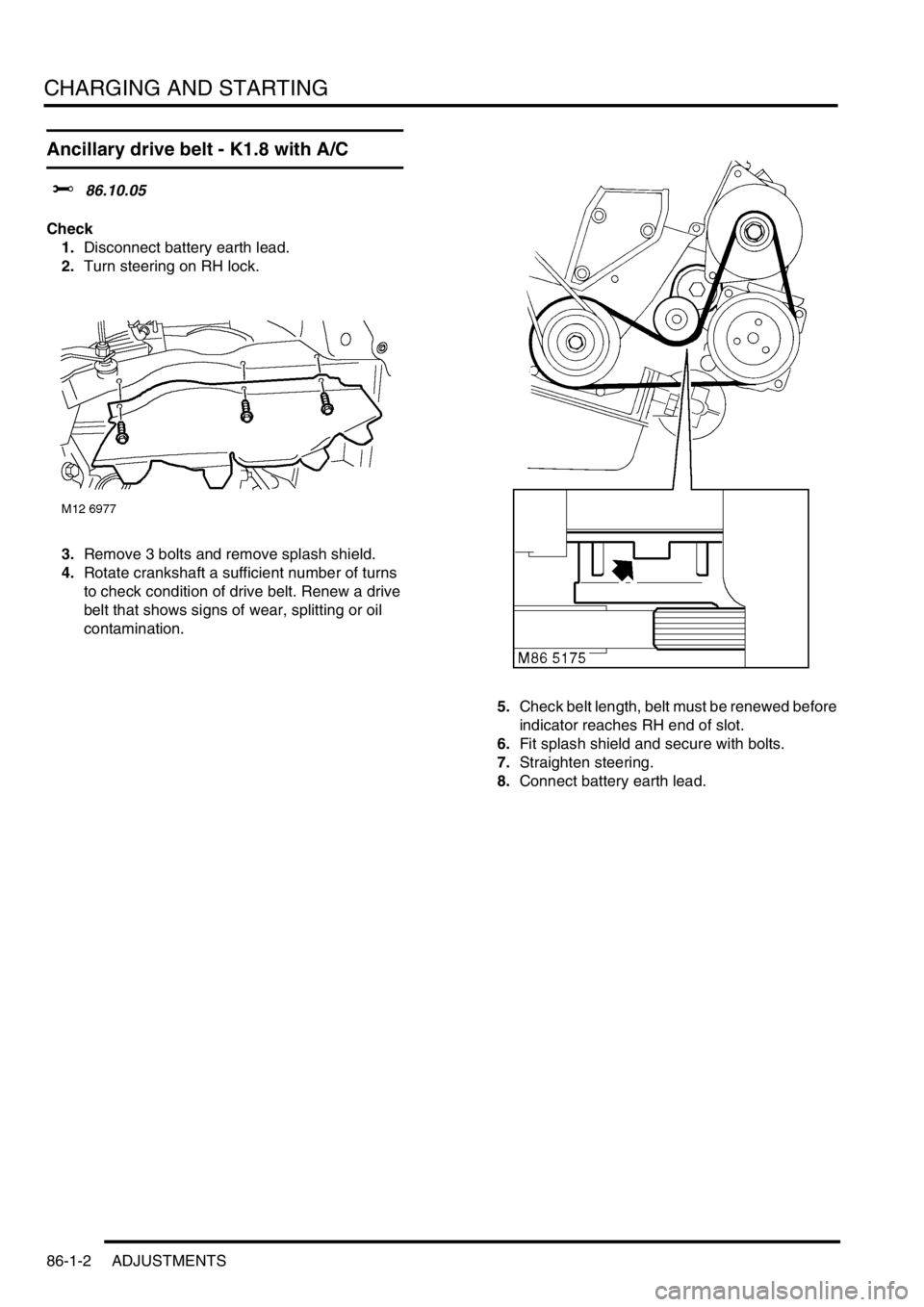

Ancillary drive belt - K1.8 with A/C

$% 86.10.05

Check

1.Disconnect battery earth lead.

2.Turn steering on RH lock.

3.Remove 3 bolts and remove splash shield.

4.Rotate crankshaft a sufficient number of turns

to check condition of drive belt. Renew a drive

belt that shows signs of wear, splitting or oil

contamination.

5.Check belt length, belt must be renewed before

indicator reaches RH end of slot.

6.Fit splash shield and secure with bolts.

7.Straighten steering.

8.Connect battery earth lead.