check oil LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 425 of 1007

INTERMEDIATE REDUCTION DRIVE

41-22 REPAIRS

Refit

1.Clean pinion shaft, drive flange and housing.

2.Clean oil seal recess.

3.Lubricate and fit bearing to pinion housing.

4.Lubricate new seal.

5.Using a suitable adapter, press seal into

housing.

CAUTION: Oil seal must be flush with end of

pinion housing.

6.Assemble pinion to housing using new

collapsible spacer.

7.Lightly lubricate drive flange splines with

Molybdenum Disulphide grease.

8.Align pinion to drive flange reference marks

and press flange onto pinion shaft until a 2 mm

clearance exists in bearings.

9.Fit pinion assembly to mounting plate and

secure in vice.

10.Fit new pinion nut, hold pinion drive flange

using LRT-51-003 and tighten pinion nut to 150

Nm (111 lbf.ft).

11.Check pinion torque to turn figure.

NOTE: Figure for new bearings is 180 to 200

Ncm.

If original bearing figure is above 20 to 30 Ncm

and below new bearing figure, set to figure

recorded.

If original bearing is below 20 Ncm set to 20 to

30 Ncm.12.If turning torque is too low, carefully tighten nut

and recheck reading. If turning torque is too

high, pinion assembly will have to be

dismantled and a new collapsible spacer fitted.

Reassemble using new nut and recheck turning

torque.

13.Check drive flange run-out using a Dial Test

Indicator (DTI).

CAUTION: The drive flange run-out should

not exceed 0.05 mm.

14.Remove pinion housing from vice and

mounting plate.

15.Fit pinion housing.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - NAS.

Page 446 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-11

Oil seal - torque converter

$% 44.17.11

Remove

1.Remove gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

2.Remove torque converter from gearbox.

Discard 'O' ring from gearbox input shaft.

3.Remove torque converter oil seal from

gearbox. Discard torque converter oil seal.

CAUTION: When removing torque converter

oil seal take care not to damage oil pump

housing.Refit

1.Clean torque converter spigot.

2.Clean torque converter oil seal recess in

gearbox. Lubricate torque converter oil seal

with clean transmission fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

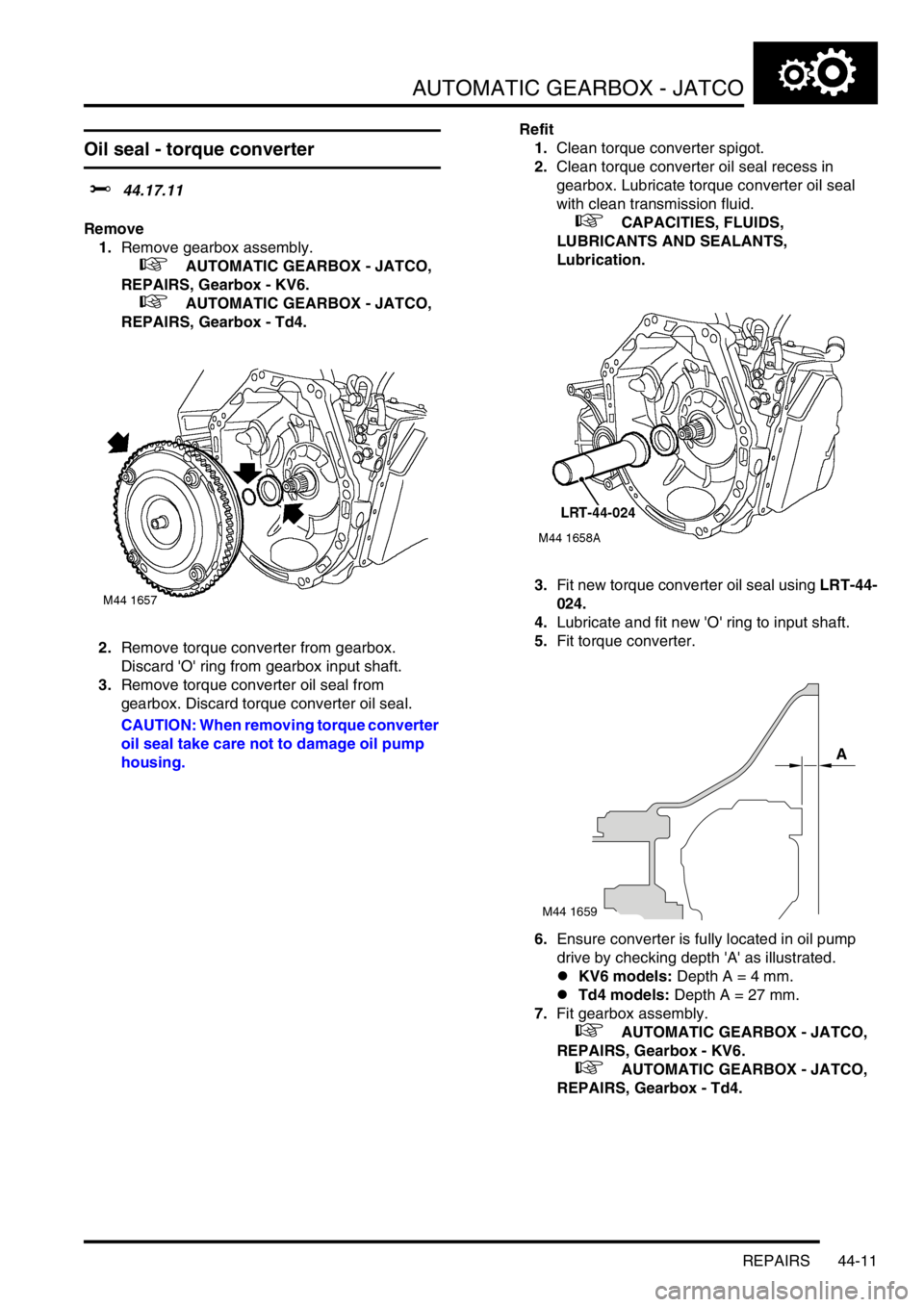

3.Fit new torque converter oil seal using LRT-44-

024.

4.Lubricate and fit new 'O' ring to input shaft.

5.Fit torque converter.

6.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated.

lKV6 models: Depth A = 4 mm.

lTd4 models: Depth A = 27 mm.

7.Fit gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

M44 1659

A

Page 451 of 1007

AUTOMATIC GEARBOX - JATCO

44-16 REPAIRS

35.Remove 2 top bolts securing gearbox to

engine.

36.Release gearbox from 2 dowels.

37.Remove gearbox assembly.

38.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Disconnect lifting equipment.

7.Clean CKP sensor and mating face.

8.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

9.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

10.Connect hoses to fluid cooler.

11.Clean fluid cooler unions.

12.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

13.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

14.Clean starter motor mating faces.

15.Position starter motor to gearbox, align CKP

sensor multiplug bracket, fit and tighten bolts to

45 Nm (33 lbf.ft).

16.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

17.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

18.Align marks on drive plate to torque converter.

19.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

20.Clean torque converter access plate.

M44 1689

A

M44 1668

Page 457 of 1007

AUTOMATIC GEARBOX - JATCO

44-22 REPAIRS

42.Remove 2 top bolts securing gearbox to

engine.

43.Release gearbox from 2 dowels.

44.Manoeuvre and lower gearbox to floor.

45.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

7.Position LH mounting to body, fit and tighten

bolts to 48 Nm (35 lbf.ft).

8.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

9.Disconnect lifting equipment.

10.Remove nuts and bolts securing lifting brackets

to gearbox and remove brackets.

11.Connect engine and gearbox harness

multiplugs to main harness.

12.Secure multiplugs to clips.

13.Position engine earth lead and secure with bolt.

14.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - KV6.

15.Clean throttle housing and manifold chamber

mating faces.

16.Fit new seal to inlet manifold chamber.

17.Position throttle housing to manifold chamber,

fit Torx screws and tighten to 7 Nm (7 lbf.ft).

18.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

19.Connect hose to cruise control actuator.

20.Secure breather hoses to throttle housing, if

fitted.

21.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

22.Clean CKP sensor and mating face.

M44 1689

A

M44 1668

Page 461 of 1007

AUTOMATIC GEARBOX - JATCO

44-26 REPAIRS

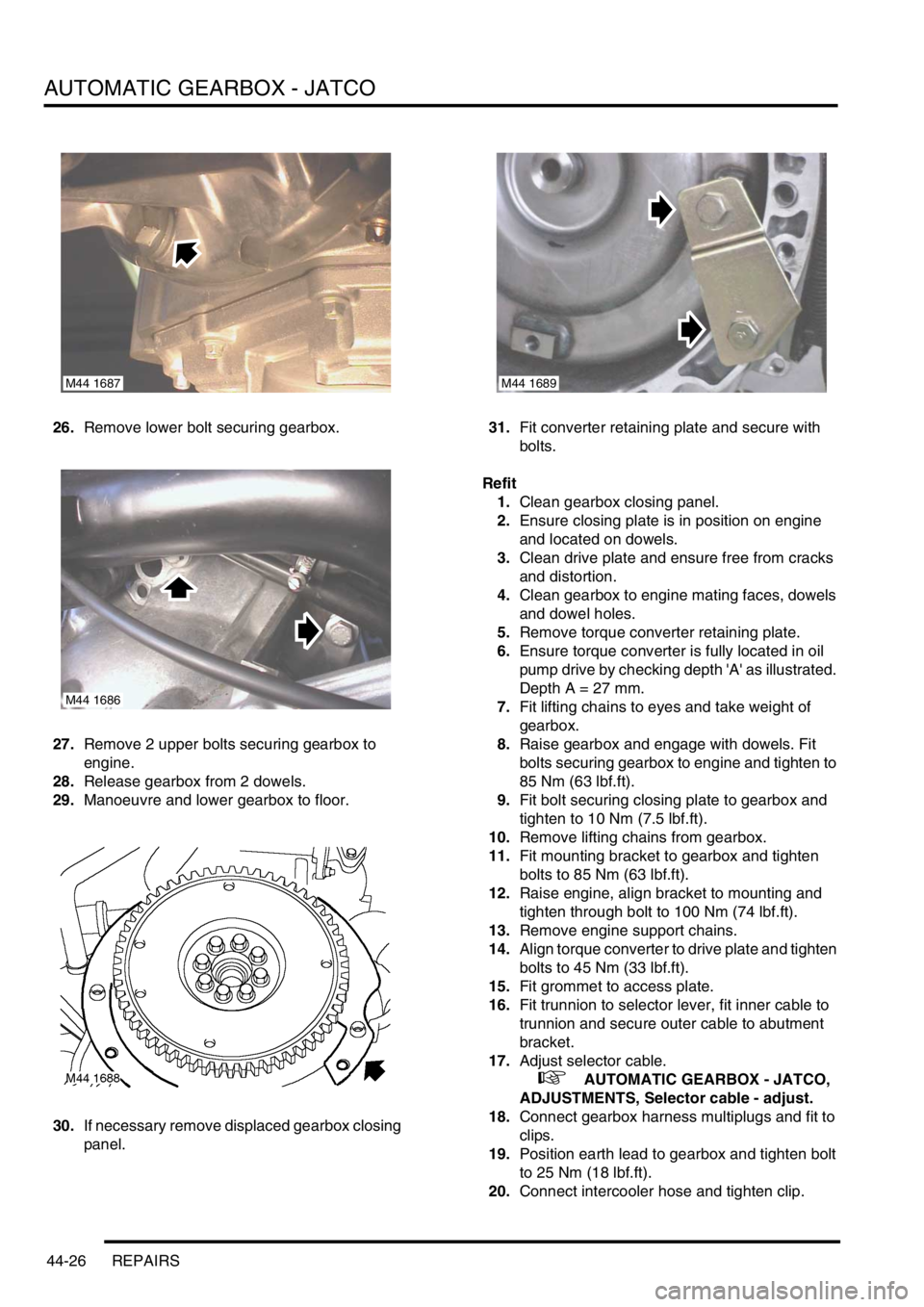

26.Remove lower bolt securing gearbox.

27.Remove 2 upper bolts securing gearbox to

engine.

28.Release gearbox from 2 dowels.

29.Manoeuvre and lower gearbox to floor.

30.If necessary remove displaced gearbox closing

panel.31.Fit converter retaining plate and secure with

bolts.

Refit

1.Clean gearbox closing panel.

2.Ensure closing plate is in position on engine

and located on dowels.

3.Clean drive plate and ensure free from cracks

and distortion.

4.Clean gearbox to engine mating faces, dowels

and dowel holes.

5.Remove torque converter retaining plate.

6.Ensure torque converter is fully located in oil

pump drive by checking depth 'A' as illustrated.

Depth A = 27 mm.

7.Fit lifting chains to eyes and take weight of

gearbox.

8.Raise gearbox and engage with dowels. Fit

bolts securing gearbox to engine and tighten to

85 Nm (63 lbf.ft).

9.Fit bolt securing closing plate to gearbox and

tighten to 10 Nm (7.5 lbf.ft).

10.Remove lifting chains from gearbox.

11.Fit mounting bracket to gearbox and tighten

bolts to 85 Nm (63 lbf.ft).

12.Raise engine, align bracket to mounting and

tighten through bolt to 100 Nm (74 lbf.ft).

13.Remove engine support chains.

14.Align torque converter to drive plate and tighten

bolts to 45 Nm (33 lbf.ft).

15.Fit grommet to access plate.

16.Fit trunnion to selector lever, fit inner cable to

trunnion and secure outer cable to abutment

bracket.

17.Adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

18.Connect gearbox harness multiplugs and fit to

clips.

19.Position earth lead to gearbox and tighten bolt

to 25 Nm (18 lbf.ft).

20.Connect intercooler hose and tighten clip.

M44 1687

M44 1686

M44 1689

Page 469 of 1007

DRIVESHAFTS

47-2 REPAIRS

12.Remove 2 bolts securing damper to hub.

13.Release hub from damper.

14.Release drive shaft from hub.

15.Position container to catch oil spillage

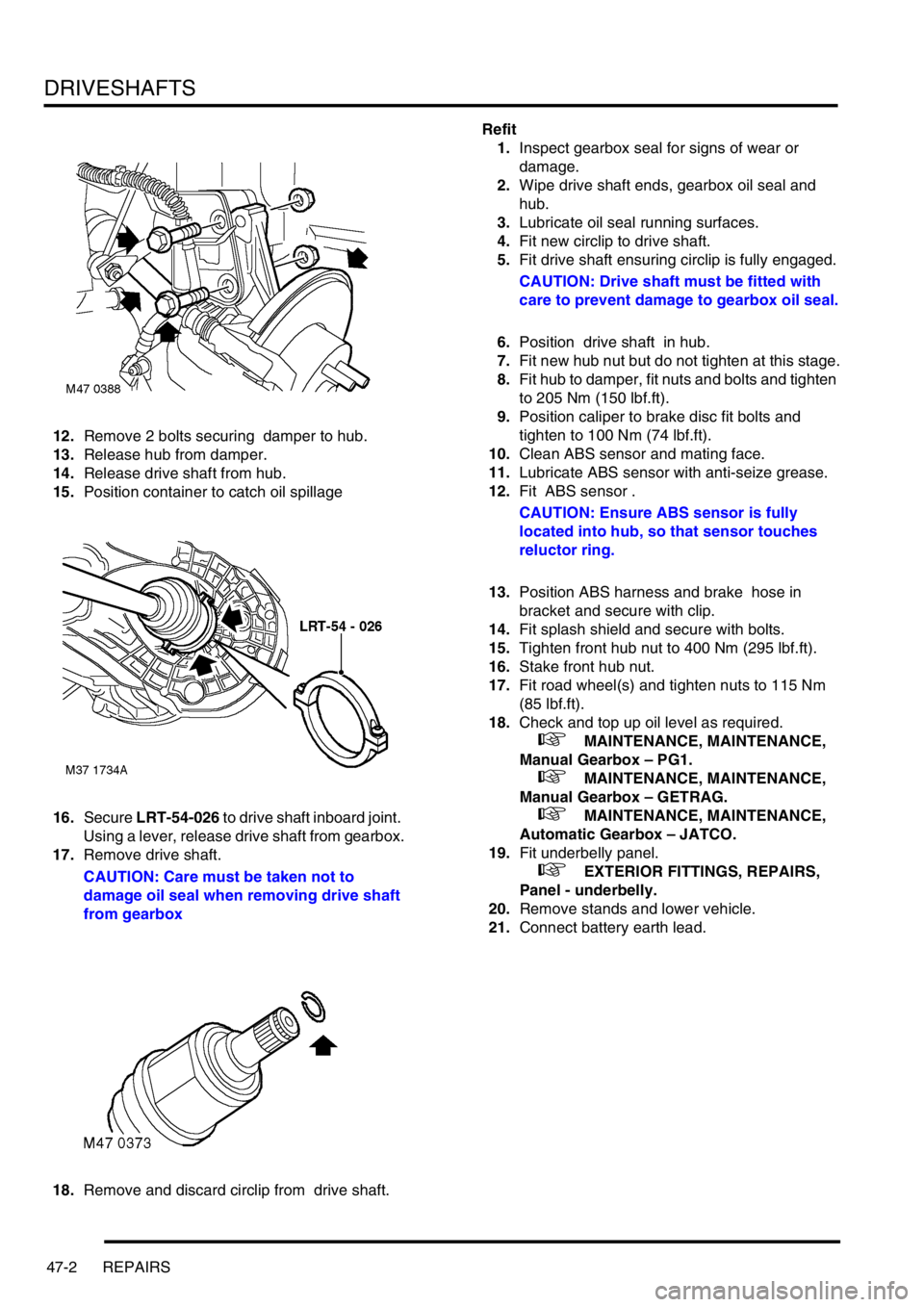

16.Secure LRT-54-026 to drive shaft inboard joint.

Using a lever, release drive shaft from gearbox.

17.Remove drive shaft.

CAUTION: Care must be taken not to

damage oil seal when removing drive shaft

from gearbox

18.Remove and discard circlip from drive shaft.Refit

1.Inspect gearbox seal for signs of wear or

damage.

2.Wipe drive shaft ends, gearbox oil seal and

hub.

3.Lubricate oil seal running surfaces.

4.Fit new circlip to drive shaft.

5.Fit drive shaft ensuring circlip is fully engaged.

CAUTION: Drive shaft must be fitted with

care to prevent damage to gearbox oil seal.

6.Position drive shaft in hub.

7.Fit new hub nut but do not tighten at this stage.

8.Fit hub to damper, fit nuts and bolts and tighten

to 205 Nm (150 lbf.ft).

9.Position caliper to brake disc fit bolts and

tighten to 100 Nm (74 lbf.ft).

10.Clean ABS sensor and mating face.

11.Lubricate ABS sensor with anti-seize grease.

12.Fit ABS sensor .

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

reluctor ring.

13.Position ABS harness and brake hose in

bracket and secure with clip.

14.Fit splash shield and secure with bolts.

15.Tighten front hub nut to 400 Nm (295 lbf.ft).

16.Stake front hub nut.

17.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18.Check and top up oil level as required.

+ MAINTENANCE, MAINTENANCE,

Manual Gearbox – PG1.

+ MAINTENANCE, MAINTENANCE,

Manual Gearbox – GETRAG.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

19.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

20.Remove stands and lower vehicle.

21.Connect battery earth lead.

Page 471 of 1007

DRIVESHAFTS

47-4 REPAIRS

12.Remove 2 bolts securing damper to hub.

13.Release hub from damper.

14.Release drive shaft from hub.

15.Position container to catch oil spillage.

16.Secure LRT-54-026 to drive shaft inboard joint.

Using a lever, release drive shaft from gearbox.

17.Remove drive shaft.

CAUTION: Care must be taken not to

damage oil seal when removing drive shaft

from gearbox18.Remove and discard circlip from drive shaft.

Refit

1.Inspect gearbox seal for signs of wear or

damage.

2.Wipe drive shaft ends, gearbox oil seal and

hub.

3.Lubricate oil seal running surfaces.

4.Fit new circlip to drive shaft.

5.Fit drive shaft ensuring circlip is fully engaged.

CAUTION: Drive shaft must be fitted with

care to prevent damage to gearbox oil seal.

6.Position drive shaft in hub.

7.Fit new hub nut but do not tighten at this stage.

8.Fit hub to damper, fit nuts and bolts and tighten

to 205 Nm (150 lbf.ft).

9.Position caliper to brake disc fit bolts and

tighten to 100 Nm (74 lbf.ft).

10.Clean ABS sensor and mating face.

11.Lubricate ABS sensor with anti-seize grease.

12.Fit ABS sensor .

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

reluctor ring.

13.Position ABS harness and brake hose in

bracket and secure with clip.

14.Fit splash shield and secure with bolts.

15.Tighten front hub nut to 400 Nm (295 lbf.ft).

16.Stake front hub nut.

17.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18.Check and top up oil level as required.

+ MAINTENANCE, MAINTENANCE,

Intermediate Reduction Drive - Non NAS

models.

19.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

20.Remove stands and lower vehicle.

21.Connect battery earth lead.

Page 474 of 1007

DRIVESHAFTS

REPAIRS 47-7

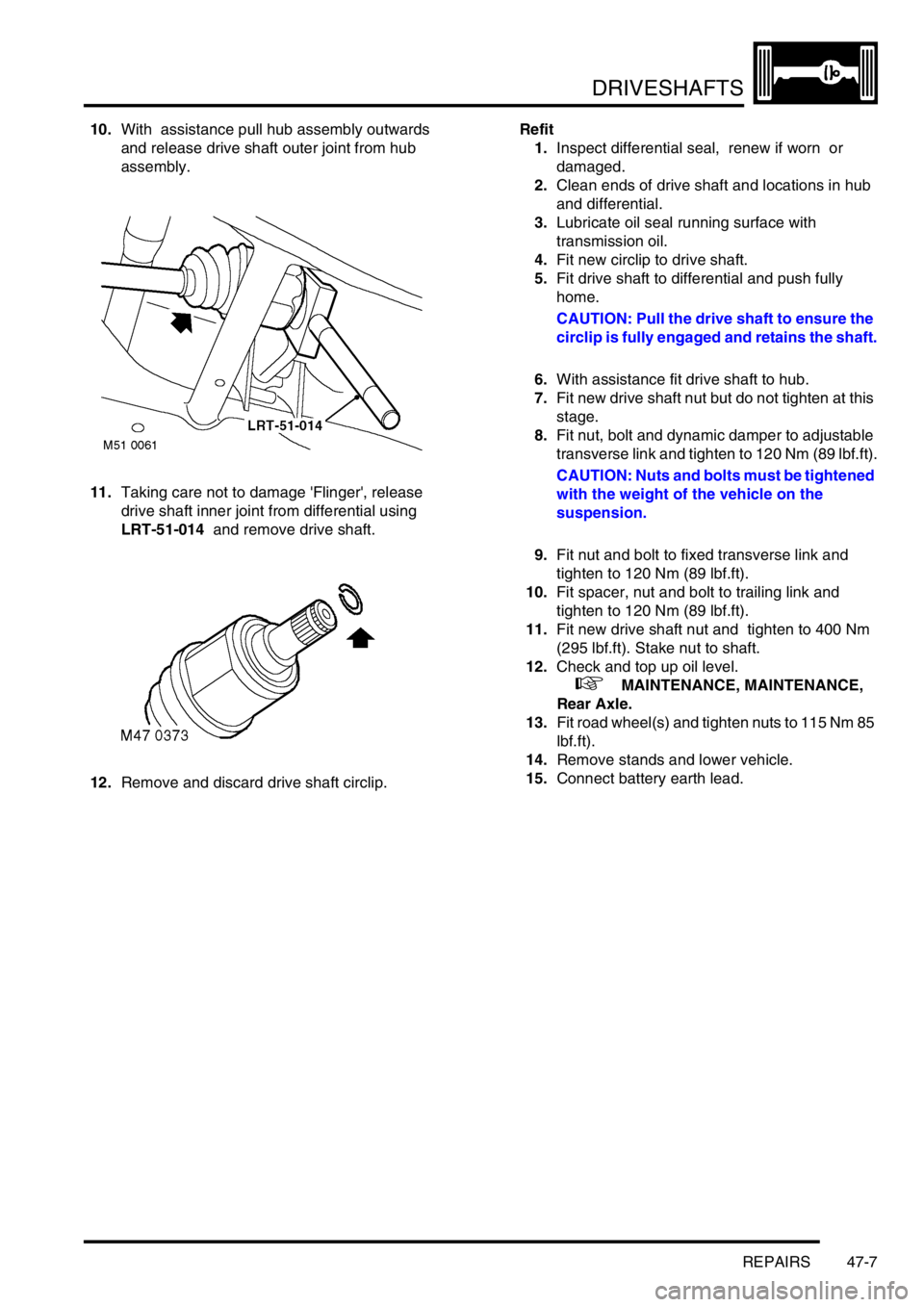

10.With assistance pull hub assembly outwards

and release drive shaft outer joint from hub

assembly.

11.Taking care not to damage 'Flinger', release

drive shaft inner joint from differential using

LRT-51-014 and remove drive shaft.

12.Remove and discard drive shaft circlip.Refit

1.Inspect differential seal, renew if worn or

damaged.

2.Clean ends of drive shaft and locations in hub

and differential.

3.Lubricate oil seal running surface with

transmission oil.

4.Fit new circlip to drive shaft.

5.Fit drive shaft to differential and push fully

home.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

6.With assistance fit drive shaft to hub.

7.Fit new drive shaft nut but do not tighten at this

stage.

8.Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.

9.Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

10.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

11.Fit new drive shaft nut and tighten to 400 Nm

(295 lbf.ft). Stake nut to shaft.

12.Check and top up oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

13.Fit road wheel(s) and tighten nuts to 115 Nm 85

lbf.ft).

14.Remove stands and lower vehicle.

15.Connect battery earth lead.

Page 487 of 1007

REAR AXLE & FINAL DRIVE

51-2 REPAIRS

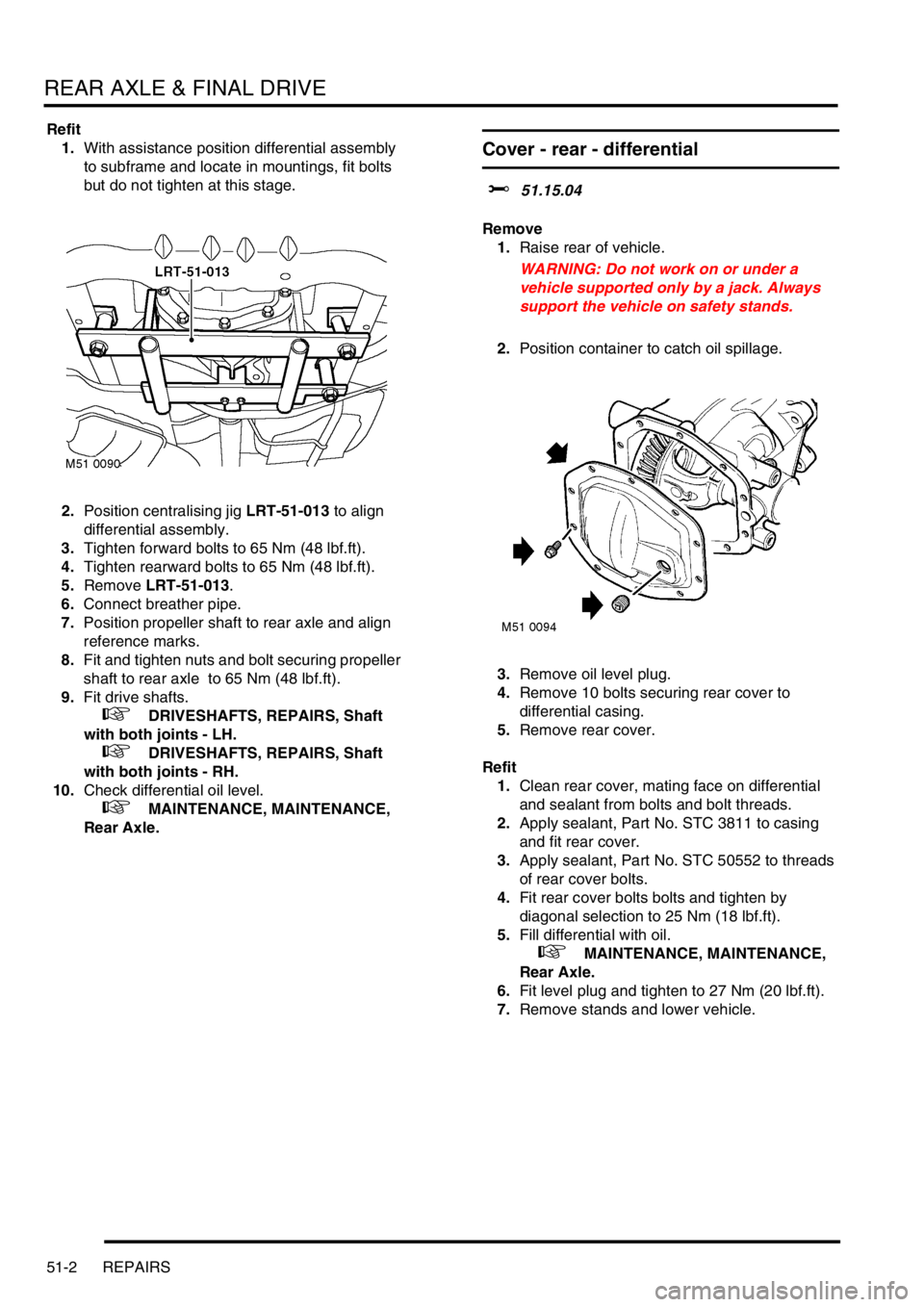

Refit

1.With assistance position differential assembly

to subframe and locate in mountings, fit bolts

but do not tighten at this stage.

2.Position centralising jig LRT-51-013 to align

differential assembly.

3.Tighten forward bolts to 65 Nm (48 lbf.ft).

4.Tighten rearward bolts to 65 Nm (48 lbf.ft).

5.Remove LRT-51-013.

6.Connect breather pipe.

7.Position propeller shaft to rear axle and align

reference marks.

8.Fit and tighten nuts and bolt securing propeller

shaft to rear axle to 65 Nm (48 lbf.ft).

9.Fit drive shafts.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - LH.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

10.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

Cover - rear - differential

$% 51.15.04

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch oil spillage.

3.Remove oil level plug.

4.Remove 10 bolts securing rear cover to

differential casing.

5.Remove rear cover.

Refit

1.Clean rear cover, mating face on differential

and sealant from bolts and bolt threads.

2.Apply sealant, Part No. STC 3811 to casing

and fit rear cover.

3.Apply sealant, Part No. STC 50552 to threads

of rear cover bolts.

4.Fit rear cover bolts bolts and tighten by

diagonal selection to 25 Nm (18 lbf.ft).

5.Fill differential with oil.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

6.Fit level plug and tighten to 27 Nm (20 lbf.ft).

7.Remove stands and lower vehicle.

Page 490 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-5

Oil seal - pinion

$% 51.20.01

Remove

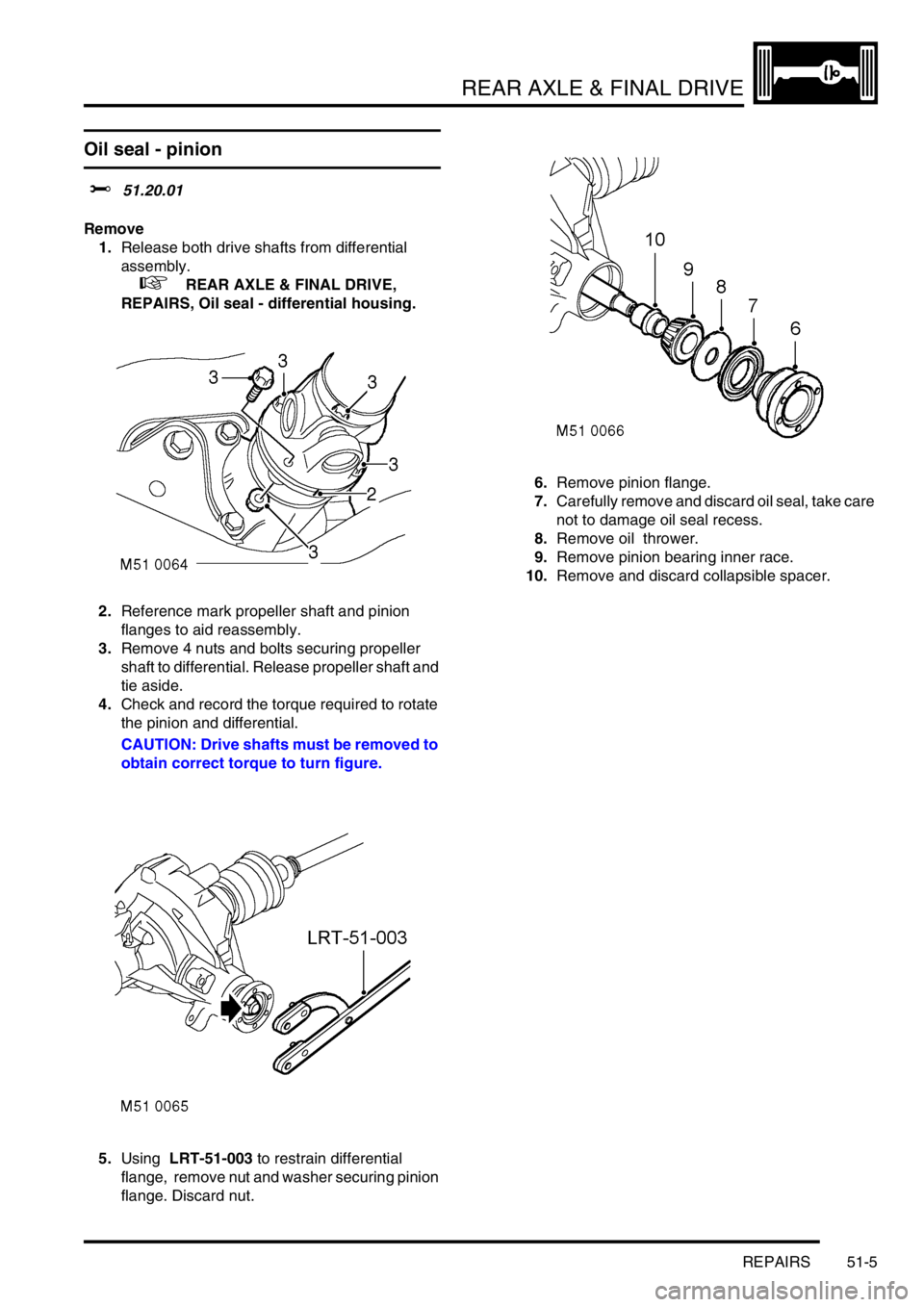

1.Release both drive shafts from differential

assembly.

+ REAR AXLE & FINAL DRIVE,

REPAIRS, Oil seal - differential housing.

2.Reference mark propeller shaft and pinion

flanges to aid reassembly.

3.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

4.Check and record the torque required to rotate

the pinion and differential.

CAUTION: Drive shafts must be removed to

obtain correct torque to turn figure.

5.Using LRT-51-003 to restrain differential

flange, remove nut and washer securing pinion

flange. Discard nut.6.Remove pinion flange.

7.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

8.Remove oil thrower.

9.Remove pinion bearing inner race.

10.Remove and discard collapsible spacer.