air conditioning LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 91 of 1007

GENERAL DATA

04-28

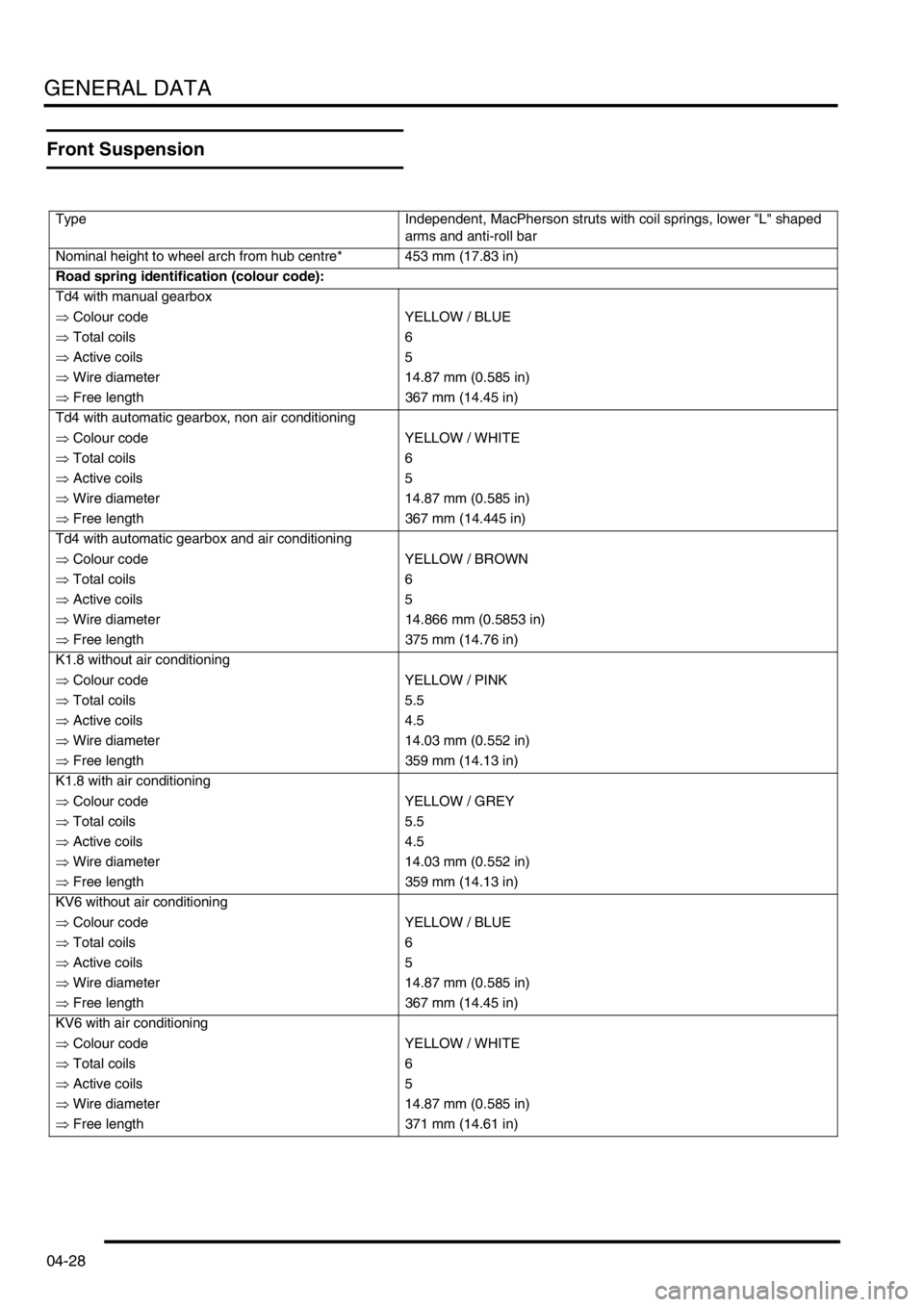

Front Suspension

Type Independent, MacPherson struts with coil springs, lower "L" shaped

arms and anti-roll bar

Nominal height to wheel arch from hub centre* 453 mm (17.83 in)

Road spring identification (colour code):

Td4 with manual gearbox

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

Td4 with automatic gearbox, non air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.445 in)

Td4 with automatic gearbox and air conditioning

⇒ Colour code YELLOW / BROWN

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.866 mm (0.5853 in)

⇒ Free length 375 mm (14.76 in)

K1.8 without air conditioning

⇒ Colour code YELLOW / PINK

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

K1.8 with air conditioning

⇒ Colour code YELLOW / GREY

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

KV6 without air conditioning

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

KV6 with air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 371 mm (14.61 in)

Page 96 of 1007

GENERAL DATA

04-33

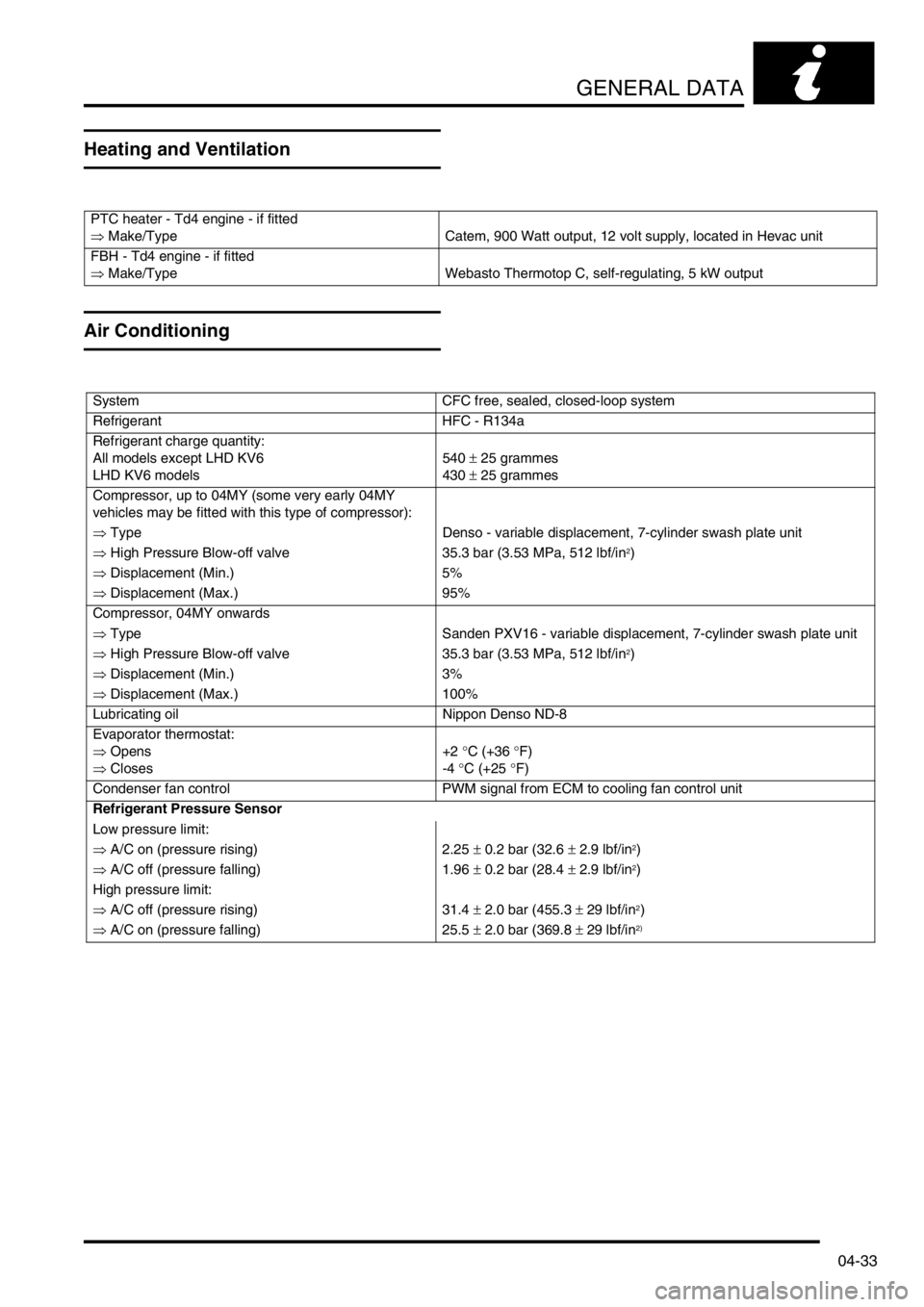

Heating and Ventilation

Air Conditioning

PTC heater - Td4 engine - if fitted

⇒ Make/Type Catem, 900 Watt output, 12 volt supply, located in Hevac unit

FBH - Td4 engine - if fitted

⇒ Make/Type Webasto Thermotop C, self-regulating, 5 kW output

System CFC free, sealed, closed-loop system

Refrigerant HFC - R134a

Refrigerant charge quantity:

All models except LHD KV6

LHD KV6 models540 ± 25 grammes

430 ± 25 grammes

Compressor, up to 04MY (some very early 04MY

vehicles may be fitted with this type of compressor):

⇒ Type Denso - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 5%

⇒ Displacement (Max.) 95%

Compressor, 04MY onwards

⇒ Type Sanden PXV16 - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 3%

⇒ Displacement (Max.) 100%

Lubricating oil Nippon Denso ND-8

Evaporator thermostat:

⇒ Opens

⇒ Closes+2 °C (+36 °F)

-4 °C (+25 °F)

Condenser fan control PWM signal from ECM to cooling fan control unit

Refrigerant Pressure Sensor

Low pressure limit:

⇒ A/C on (pressure rising) 2.25 ± 0.2 bar (32.6 ± 2.9 lbf/in

2)

⇒ A/C off (pressure falling) 1.96 ± 0.2 bar (28.4 ± 2.9 lbf/in

2)

High pressure limit:

⇒ A/C off (pressure rising) 31.4 ± 2.0 bar (455.3 ± 29 lbf/in

2)

⇒ A/C on (pressure falling) 25.5 ± 2.0 bar (369.8 ± 29 lbf/in

2)

Page 136 of 1007

TORQUE WRENCH SETTINGS

06-33

Air Conditioning

TORQUE DESCRIPTION METRIC IMPERIAL

A/C compressor to mounting bracket bolts (Td4 & K1.8) 25 Nm 18 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (Td4 & K1.8) 45 Nm 33 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (KV6) 45 Nm 33 lbf.ft

A/C compressor support bracket to sump bolt (Td4) 10 Nm 7.5 lbf.ft

A/C compressor drive belt tensioner clamp bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor drive belt tensioner pivot bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor upper and lower securing bolts (KV6) 25 Nm 18 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

Condenser bracket to radiator bolts 8 Nm 6 lbf.ft

Receiver drier to condenser bolts 12 Nm 9 lbf.ft

Refrigerant pressure sensor 10 Nm 7.5 lbf.ft

TXV to bulkhead Allen screws 25 Nm 18 lbf.ft

Page 366 of 1007

COOLING SYSTEM - K SERIES KV6

ADJUSTMENTS 26-3-1

COOLING SYS TEM - K SER IES KV6 ADJUST ME NTS

Coolant - drain and refill

$% 26.10.01

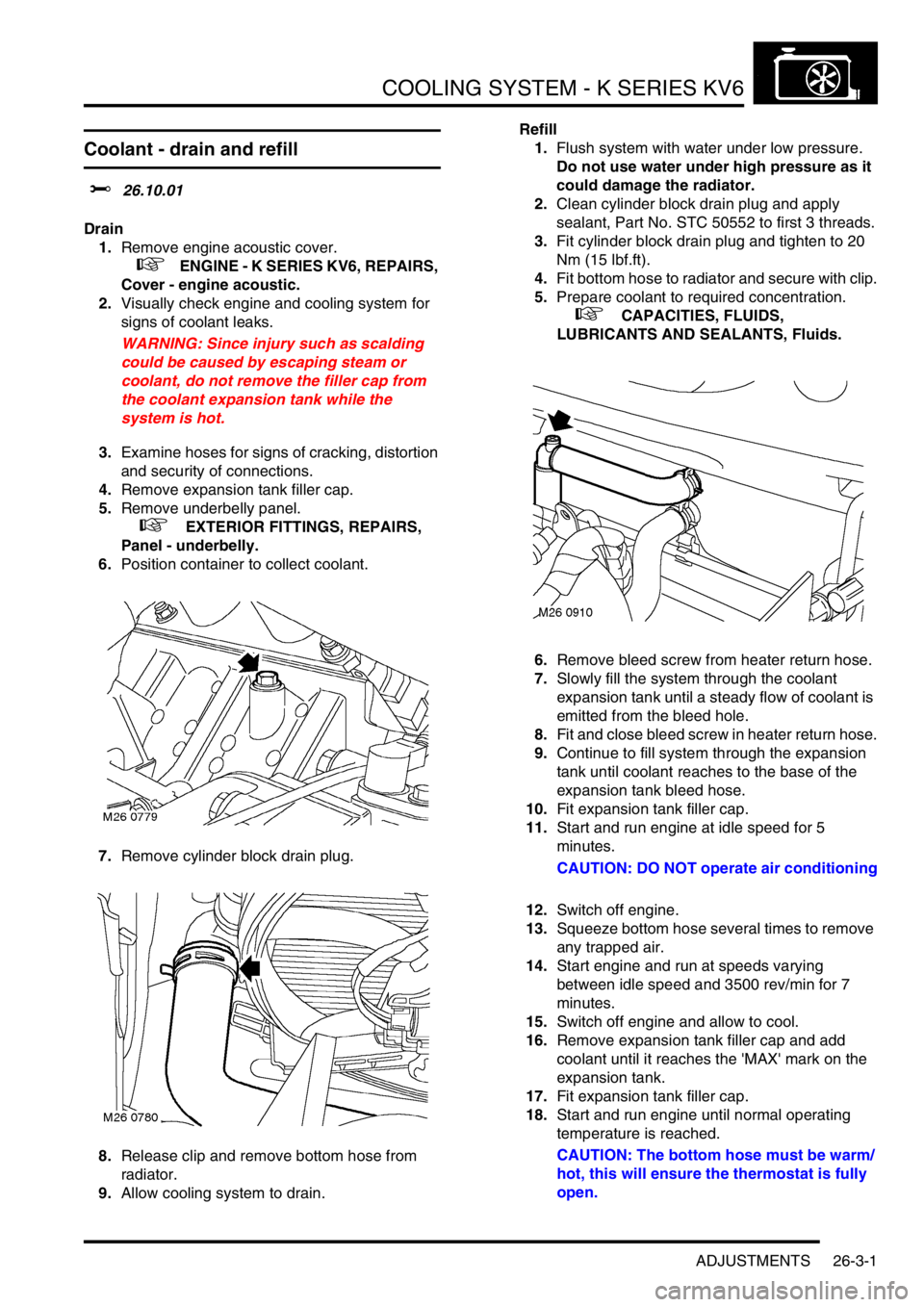

Drain

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Visually check engine and cooling system for

signs of coolant leaks.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Remove expansion tank filler cap.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Position container to collect coolant.

7.Remove cylinder block drain plug.

8.Release clip and remove bottom hose from

radiator.

9.Allow cooling system to drain.Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Clean cylinder block drain plug and apply

sealant, Part No. STC 50552 to first 3 threads.

3.Fit cylinder block drain plug and tighten to 20

Nm (15 lbf.ft).

4.Fit bottom hose to radiator and secure with clip.

5.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

6.Remove bleed screw from heater return hose.

7.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

8.Fit and close bleed screw in heater return hose.

9.Continue to fill system through the expansion

tank until coolant reaches to the base of the

expansion tank bleed hose.

10.Fit expansion tank filler cap.

11.Start and run engine at idle speed for 5

minutes.

CAUTION: DO NOT operate air conditioning

12.Switch off engine.

13.Squeeze bottom hose several times to remove

any trapped air.

14.Start engine and run at speeds varying

between idle speed and 3500 rev/min for 7

minutes.

15.Switch off engine and allow to cool.

16.Remove expansion tank filler cap and add

coolant until it reaches the 'MAX' mark on the

expansion tank.

17.Fit expansion tank filler cap.

18.Start and run engine until normal operating

temperature is reached.

CAUTION: The bottom hose must be warm/

hot, this will ensure the thermostat is fully

open.

Page 369 of 1007

COOLING SYSTEM - K SERIES KV6

26-3-4 REPAIRS

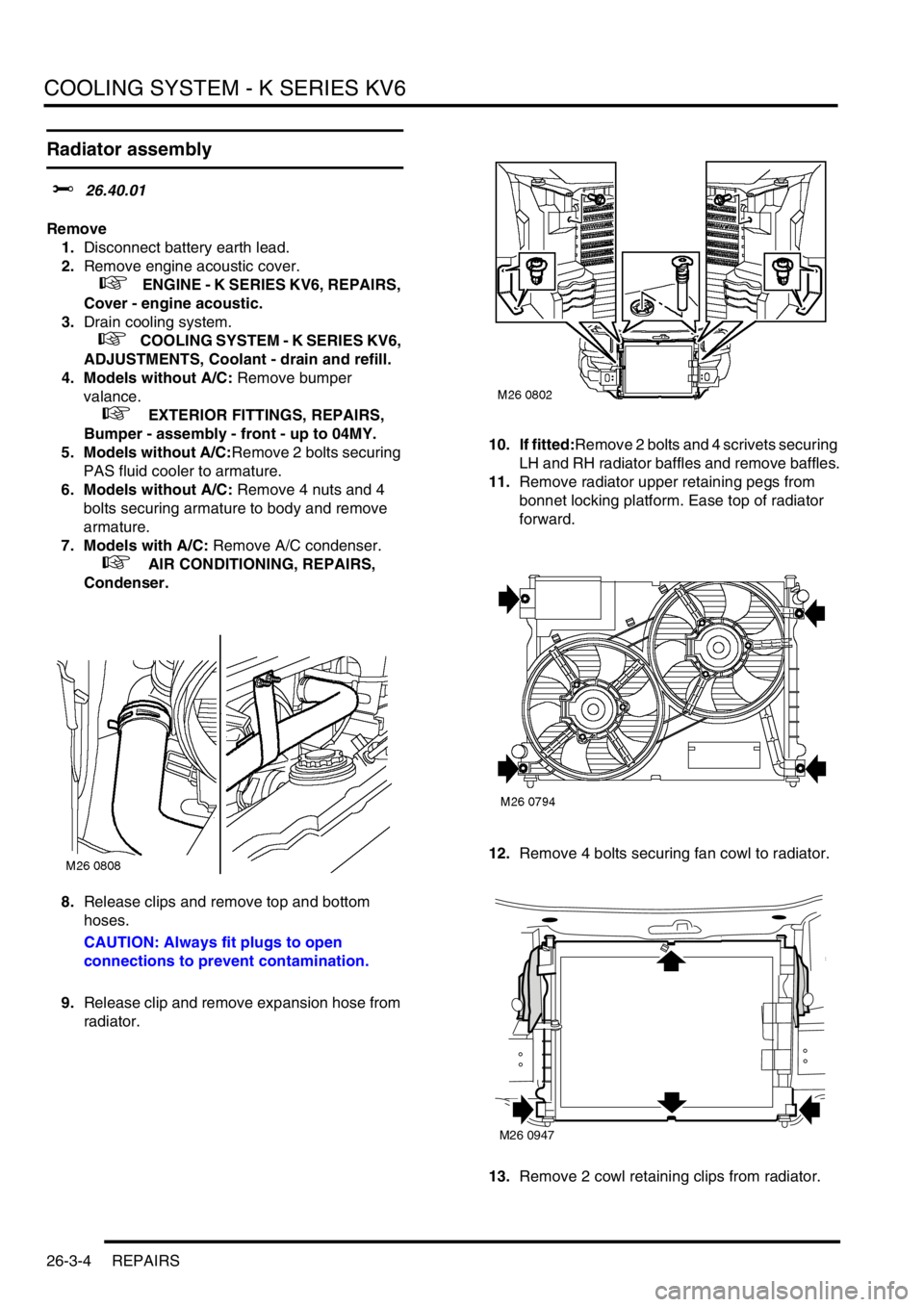

Radiator assembly

$% 26.40.01

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Drain cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

4. Models without A/C: Remove bumper

valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5. Models without A/C:Remove 2 bolts securing

PAS fluid cooler to armature.

6. Models without A/C: Remove 4 nuts and 4

bolts securing armature to body and remove

armature.

7. Models with A/C: Remove A/C condenser.

+ AIR CONDITIONING, REPAIRS,

Condenser.

8.Release clips and remove top and bottom

hoses.

CAUTION: Always fit plugs to open

connections to prevent contamination.

9.Release clip and remove expansion hose from

radiator.10. If fitted:Remove 2 bolts and 4 scrivets securing

LH and RH radiator baffles and remove baffles.

11.Remove radiator upper retaining pegs from

bonnet locking platform. Ease top of radiator

forward.

12.Remove 4 bolts securing fan cowl to radiator.

13.Remove 2 cowl retaining clips from radiator.

M26 0947

Page 370 of 1007

COOLING SYSTEM - K SERIES KV6

REPAIRS 26-3-5

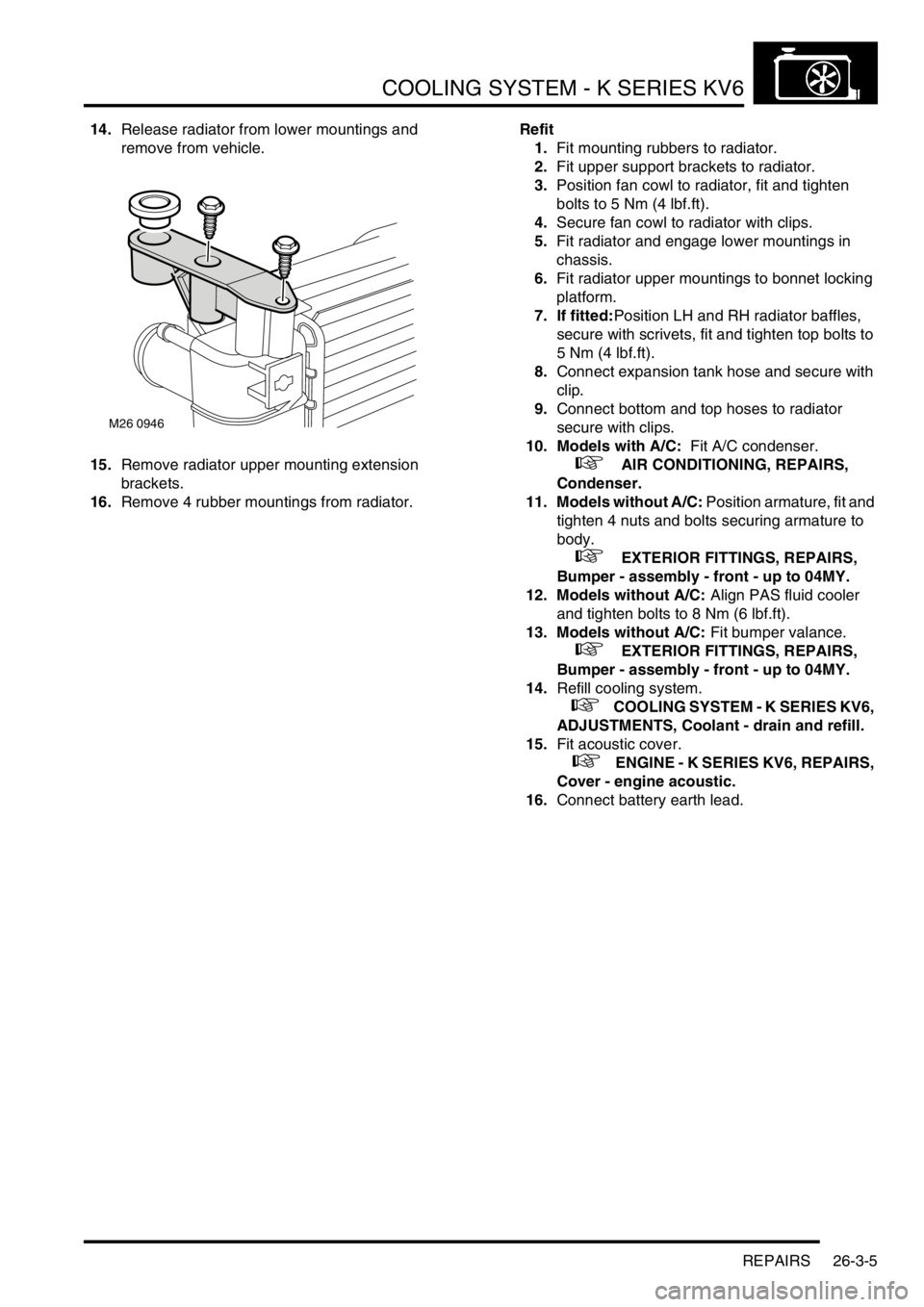

14.Release radiator from lower mountings and

remove from vehicle.

15.Remove radiator upper mounting extension

brackets.

16.Remove 4 rubber mountings from radiator.Refit

1.Fit mounting rubbers to radiator.

2.Fit upper support brackets to radiator.

3.Position fan cowl to radiator, fit and tighten

bolts to 5 Nm (4 lbf.ft).

4.Secure fan cowl to radiator with clips.

5.Fit radiator and engage lower mountings in

chassis.

6.Fit radiator upper mountings to bonnet locking

platform.

7. If fitted:Position LH and RH radiator baffles,

secure with scrivets, fit and tighten top bolts to

5 Nm (4 lbf.ft).

8.Connect expansion tank hose and secure with

clip.

9.Connect bottom and top hoses to radiator

secure with clips.

10. Models with A/C: Fit A/C condenser.

+ AIR CONDITIONING, REPAIRS,

Condenser.

11. Models without A/C: Position armature, fit and

tighten 4 nuts and bolts securing armature to

body.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

12. Models without A/C: Align PAS fluid cooler

and tighten bolts to 8 Nm (6 lbf.ft).

13. Models without A/C: Fit bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

14.Refill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

15.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

16.Connect battery earth lead.

M26 0946

Page 888 of 1007

AIR CONDITIONING

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING 82-1

AIR CONDITIONING REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

Refrigerant recovery - recycling and

recharge

$% 82.30.02

Refrigerant recovery

WARNING: Servicing must only be carried

out by personnel familiar with both the

vehicle system and the charging and testing

equipment. All operations must be carried

out in a well ventilated area away from open

flame and heat sources.

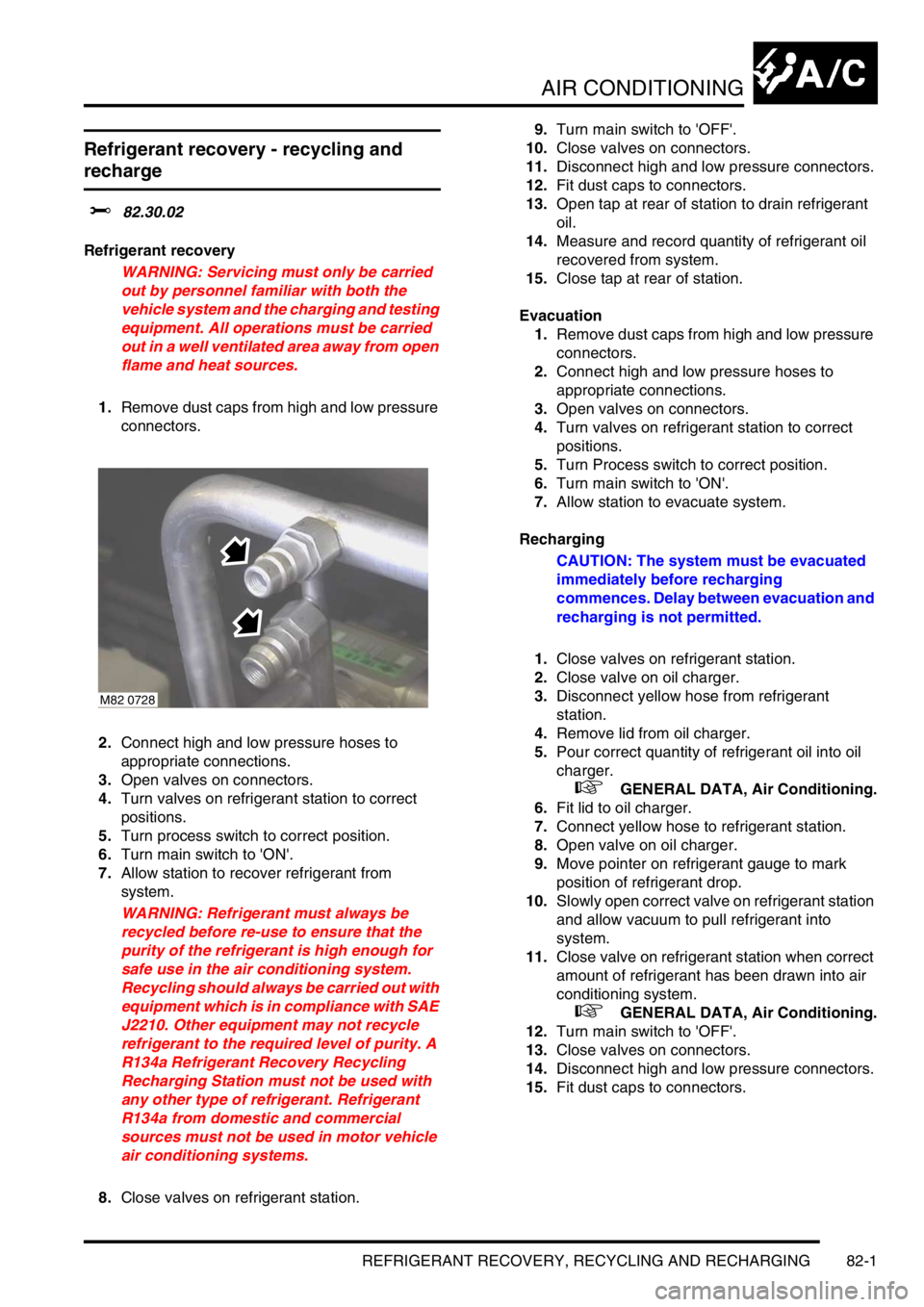

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to recover refrigerant from

system.

WARNING: Refrigerant must always be

recycled before re-use to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system.

Recycling should always be carried out with

equipment which is in compliance with SAE

J2210. Other equipment may not recycle

refrigerant to the required level of purity. A

R134a Refrigerant Recovery Recycling

Recharging Station must not be used with

any other type of refrigerant. Refrigerant

R134a from domestic and commercial

sources must not be used in motor vehicle

air conditioning systems.

8.Close valves on refrigerant station.9.Turn main switch to 'OFF'.

10.Close valves on connectors.

11.Disconnect high and low pressure connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant

oil.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to evacuate system.

Recharging

CAUTION: The system must be evacuated

immediately before recharging

commences. Delay between evacuation and

recharging is not permitted.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant

station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

+ GENERAL DATA, Air Conditioning.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into

system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

+ GENERAL DATA, Air Conditioning.

12.Turn main switch to 'OFF'.

13.Close valves on connectors.

14.Disconnect high and low pressure connectors.

15.Fit dust caps to connectors.

M82 0728

Page 890 of 1007

AIR CONDITIONING

ADJUSTMENTS 82-3

ADJUST ME NTS

Drive belt - compressor - Td4

$% 82.10.01

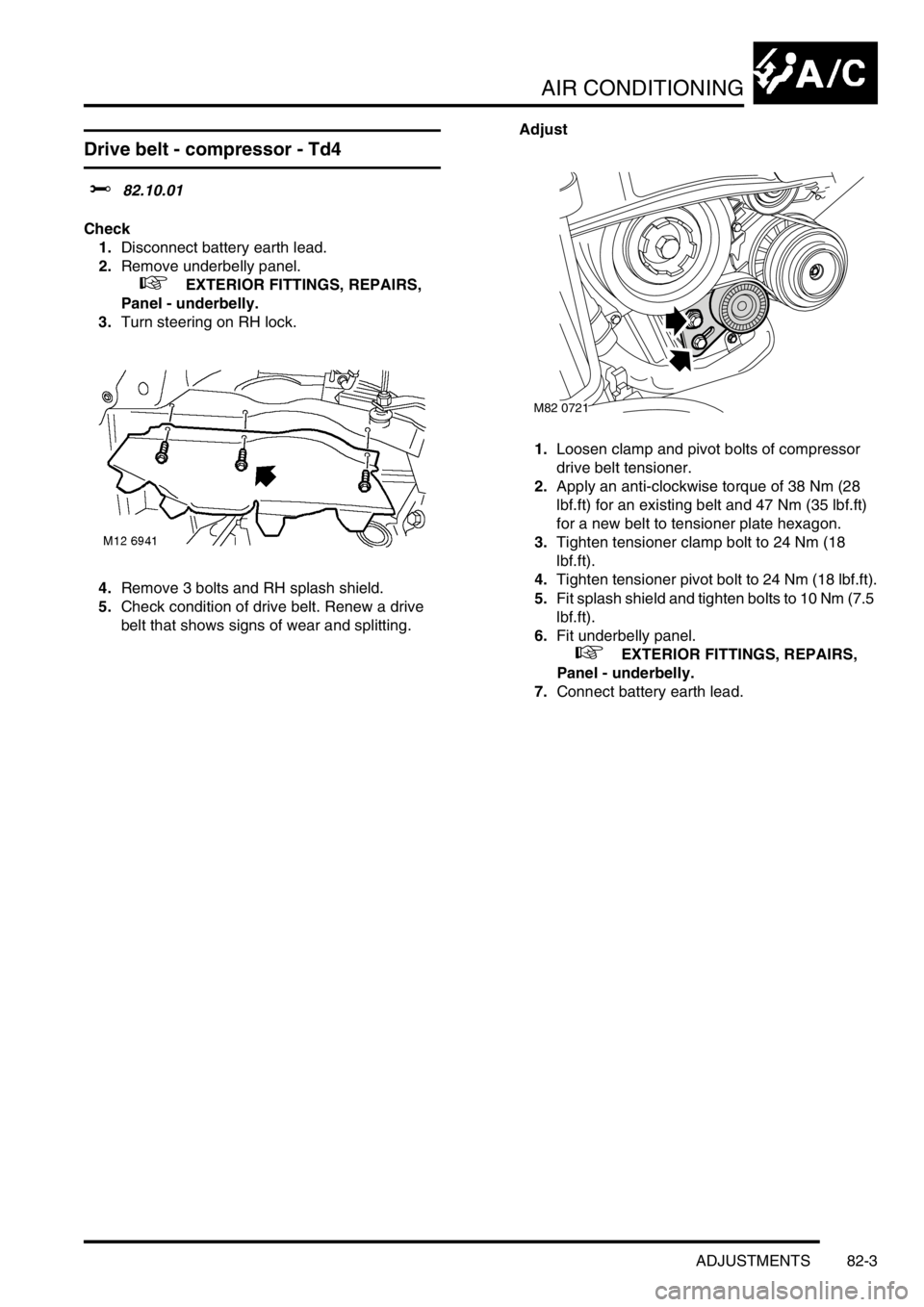

Check

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Turn steering on RH lock.

4.Remove 3 bolts and RH splash shield.

5.Check condition of drive belt. Renew a drive

belt that shows signs of wear and splitting.Adjust

1.Loosen clamp and pivot bolts of compressor

drive belt tensioner.

2.Apply an anti-clockwise torque of 38 Nm (28

lbf.ft) for an existing belt and 47 Nm (35 lbf.ft)

for a new belt to tensioner plate hexagon.

3.Tighten tensioner clamp bolt to 24 Nm (18

lbf.ft).

4.Tighten tensioner pivot bolt to 24 Nm (18 lbf.ft).

5.Fit splash shield and tighten bolts to 10 Nm (7.5

lbf.ft).

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Connect battery earth lead.

M82 0721

Page 892 of 1007

AIR CONDITIONING

REPAIRS 82-5

REPAIRS

Drive belt - compressor - Td4

$% 82.10.02

Remove

1.Disconnect battery earth lead.

2.Remove ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

3.Loosen clamp and pivot bolts of compressor

drive belt tensioner.

4.Remove compressor drive belt.Refit

1.Ensure compressor drive belt and compressor,

crankshaft and tensioner pulleys are clean.

2.Fit compressor drive belt.

3.Adjust compressor drive belt.

+ AIR CONDITIONING,

ADJUSTMENTS, Drive belt - compressor -

Td4.

4.Fit ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

5.Connect battery earth lead.

M82 0721

Page 893 of 1007

AIR CONDITIONING

82-6REPAIRS

Compressor - Td4

$% 82.10.20

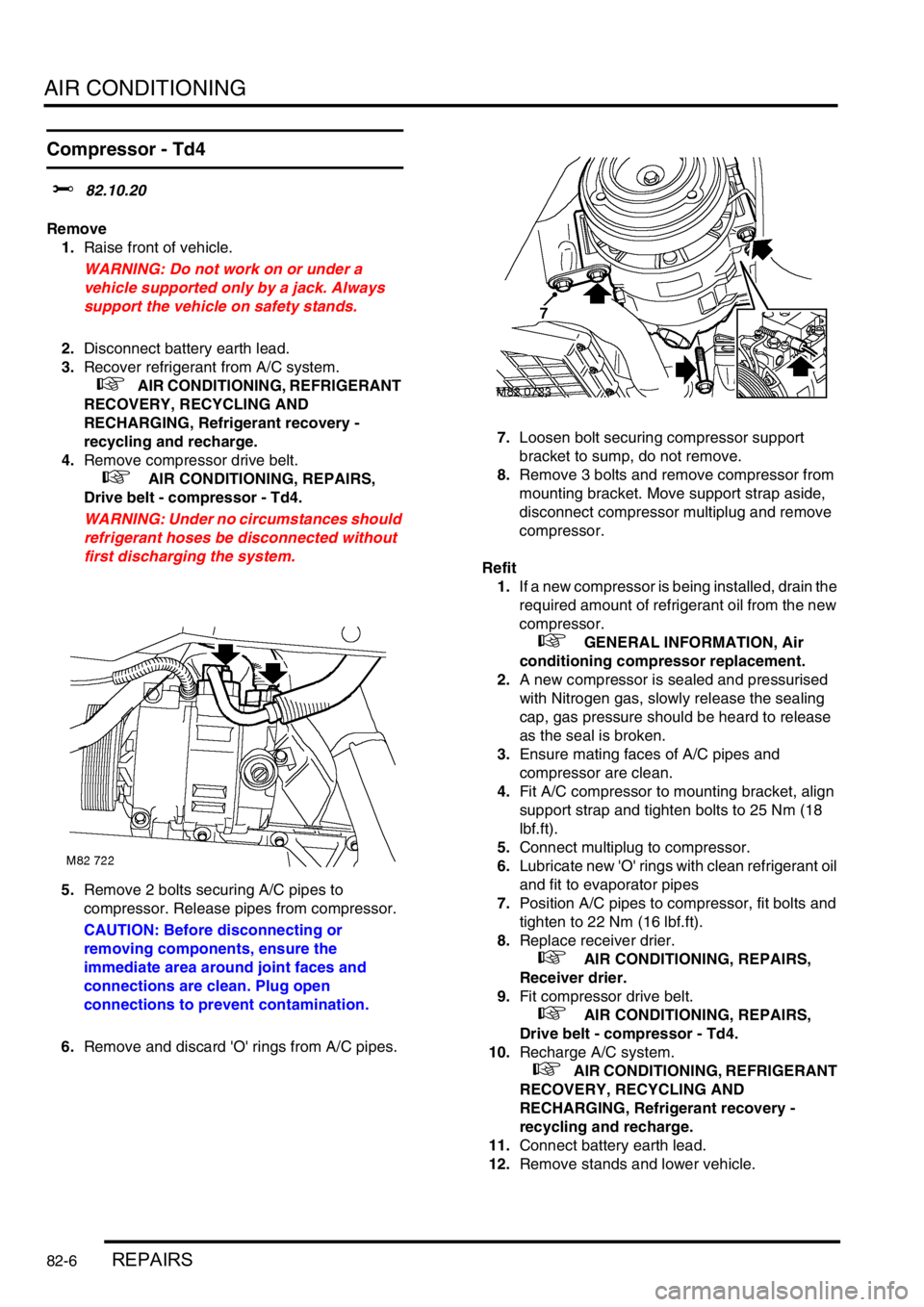

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Disconnect battery earth lead.

3.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

4.Remove compressor drive belt.

+ AIR CONDITIONING, REPAIRS,

Drive belt - compressor - Td4.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without

first discharging the system.

5.Remove 2 bolts securing A/C pipes to

compressor. Release pipes from compressor.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

6.Remove and discard 'O' rings from A/C pipes.7.Loosen bolt securing compressor support

bracket to sump, do not remove.

8.Remove 3 bolts and remove compressor from

mounting bracket. Move support strap aside,

disconnect compressor multiplug and remove

compressor.

Refit

1.If a new compressor is being installed, drain the

required amount of refrigerant oil from the new

compressor.

+ GENERAL INFORMATION, Air

conditioning compressor replacement.

2.A new compressor is sealed and pressurised

with Nitrogen gas, slowly release the sealing

cap, gas pressure should be heard to release

as the seal is broken.

3.Ensure mating faces of A/C pipes and

compressor are clean.

4.Fit A/C compressor to mounting bracket, align

support strap and tighten bolts to 25 Nm (18

lbf.ft).

5.Connect multiplug to compressor.

6.Lubricate new 'O' rings with clean refrigerant oil

and fit to evaporator pipes

7.Position A/C pipes to compressor, fit bolts and

tighten to 22 Nm (16 lbf.ft).

8.Replace receiver drier.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

9.Fit compressor drive belt.

+ AIR CONDITIONING, REPAIRS,

Drive belt - compressor - Td4.

10.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

11.Connect battery earth lead.

12.Remove stands and lower vehicle.