hood release LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 726 of 1007

HOOD

REPAIRS 76-7-1

HOOD REPAIRS

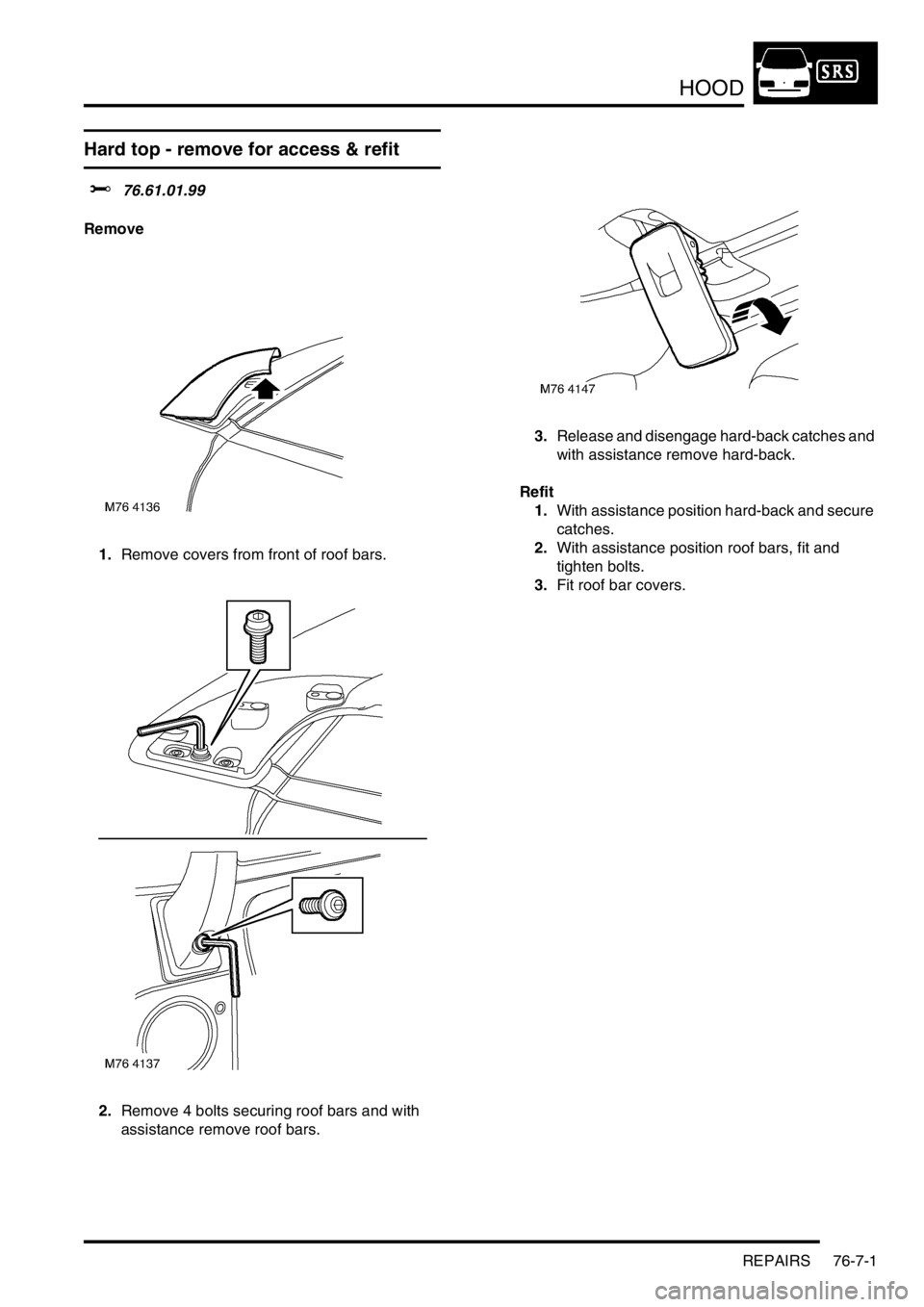

Hard top - remove for access & refit

$% 76.61.01.99

Remove

1.Remove covers from front of roof bars.

2.Remove 4 bolts securing roof bars and with

assistance remove roof bars.3.Release and disengage hard-back catches and

with assistance remove hard-back.

Refit

1.With assistance position hard-back and secure

catches.

2.With assistance position roof bars, fit and

tighten bolts.

3.Fit roof bar covers.

Page 727 of 1007

HOOD

76-7-2 REPAIRS

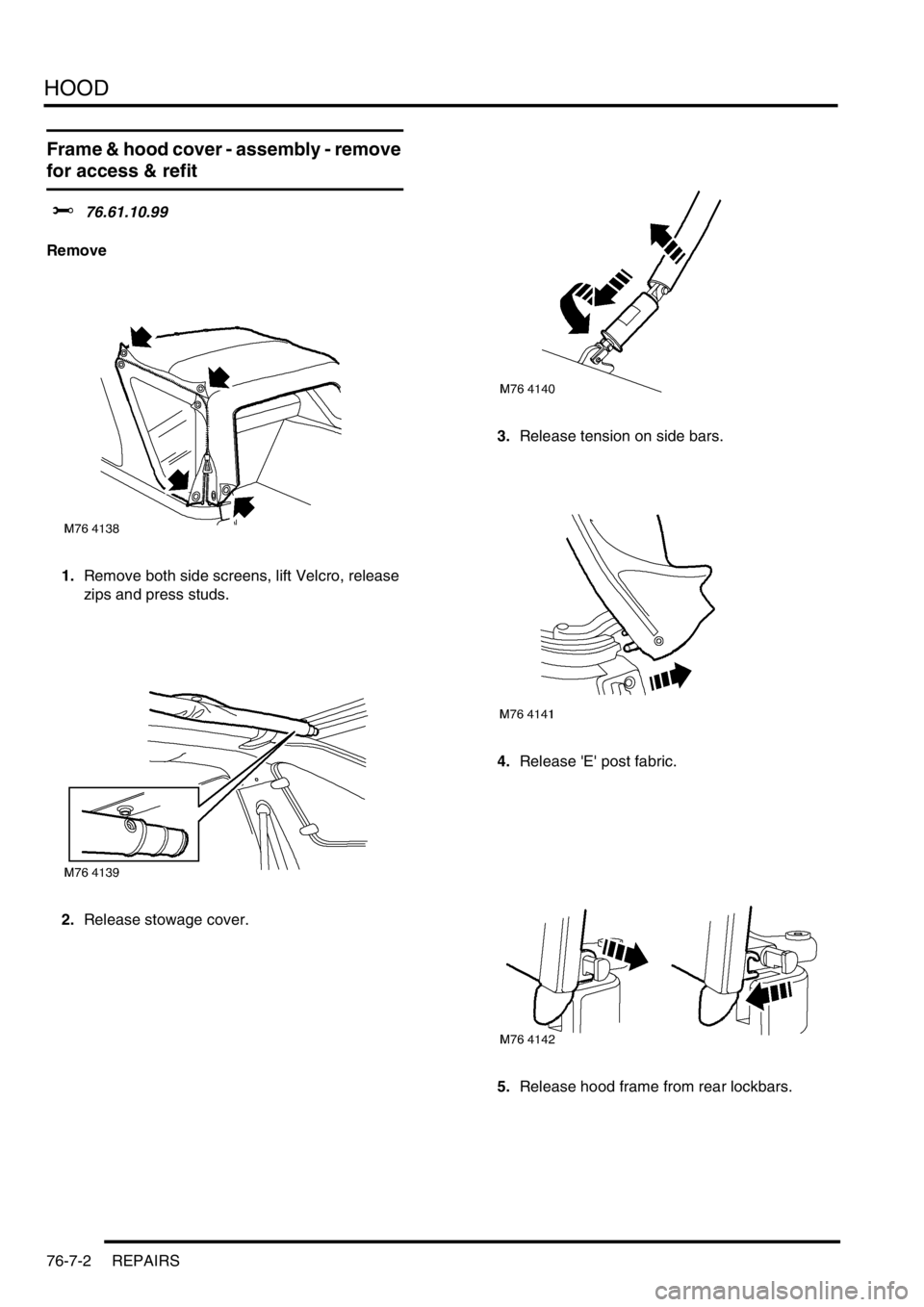

Frame & hood cover - assembly - remove

for access & refit

$% 76.61.10.99

Remove

1.Remove both side screens, lift Velcro, release

zips and press studs.

2.Release stowage cover.3.Release tension on side bars.

4.Release 'E' post fabric.

5.Release hood frame from rear lockbars.

Page 728 of 1007

HOOD

REPAIRS 76-7-3

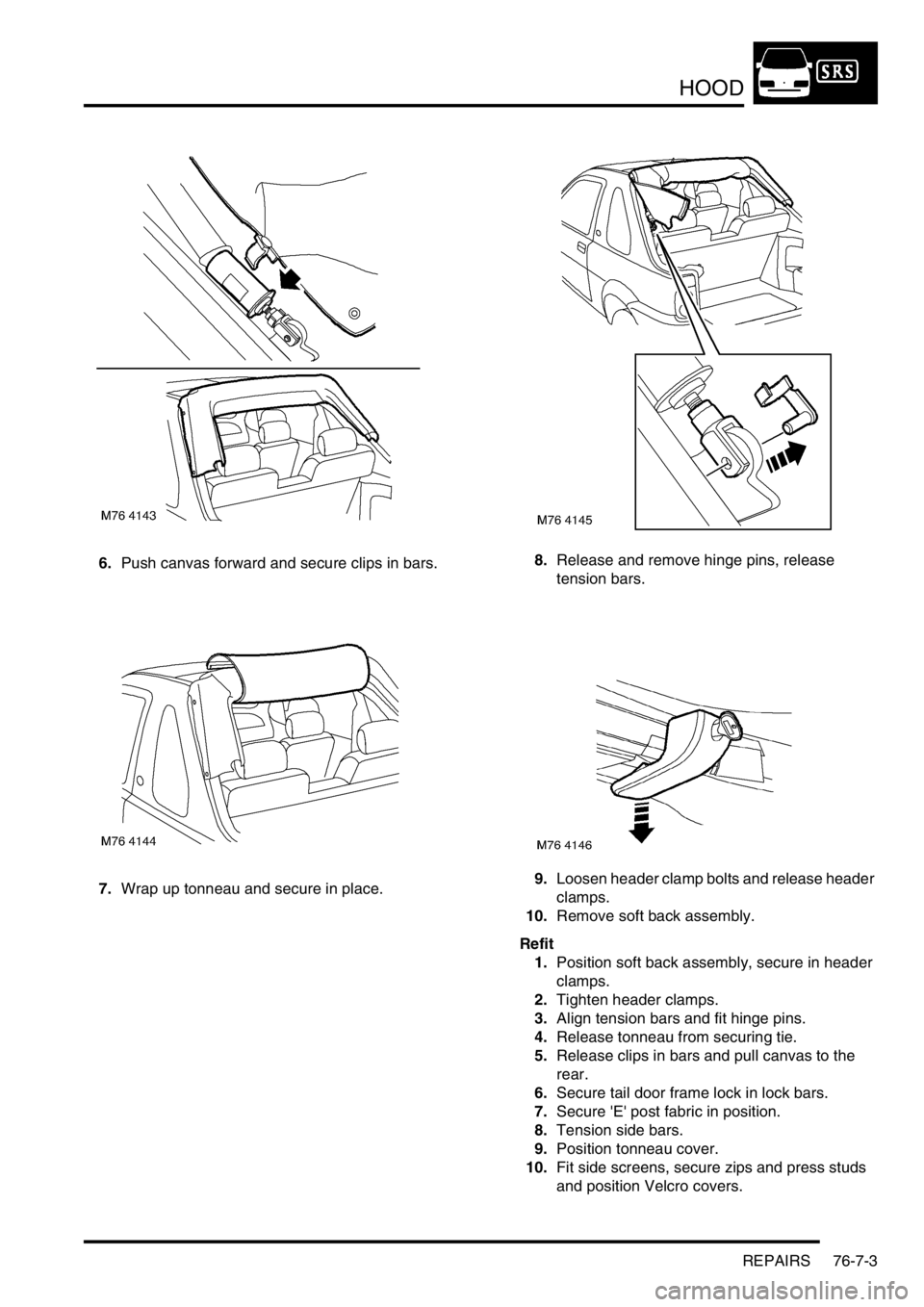

6.Push canvas forward and secure clips in bars.

7.Wrap up tonneau and secure in place.8.Release and remove hinge pins, release

tension bars.

9.Loosen header clamp bolts and release header

clamps.

10.Remove soft back assembly.

Refit

1.Position soft back assembly, secure in header

clamps.

2.Tighten header clamps.

3.Align tension bars and fit hinge pins.

4.Release tonneau from securing tie.

5.Release clips in bars and pull canvas to the

rear.

6.Secure tail door frame lock in lock bars.

7.Secure 'E' post fabric in position.

8.Tension side bars.

9.Position tonneau cover.

10.Fit side screens, secure zips and press studs

and position Velcro covers.

Page 729 of 1007

HOOD

76-7-4 REPAIRS

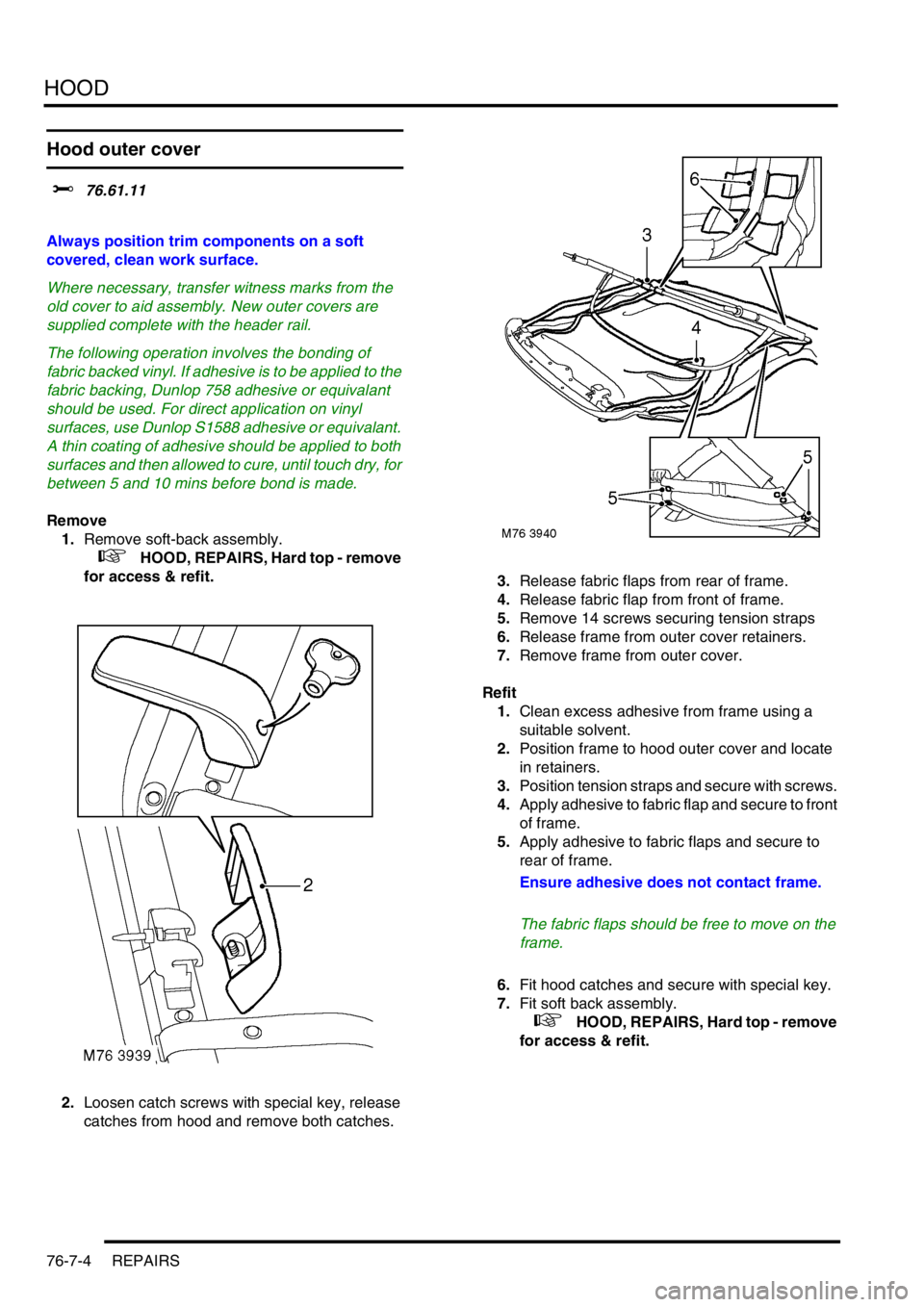

Hood outer cover

$% 76.61.11

Always position trim components on a soft

covered, clean work surface.

Where necessary, transfer witness marks from the

old cover to aid assembly. New outer covers are

supplied complete with the header rail.

The following operation involves the bonding of

fabric backed vinyl. If adhesive is to be applied to the

fabric backing, Dunlop 758 adhesive or equivalant

should be used. For direct application on vinyl

surfaces, use Dunlop S1588 adhesive or equivalant.

A thin coating of adhesive should be applied to both

surfaces and then allowed to cure, until touch dry, for

between 5 and 10 mins before bond is made.

Remove

1.Remove soft-back assembly.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

2.Loosen catch screws with special key, release

catches from hood and remove both catches. 3.Release fabric flaps from rear of frame.

4.Release fabric flap from front of frame.

5.Remove 14 screws securing tension straps

6.Release frame from outer cover retainers.

7.Remove frame from outer cover.

Refit

1.Clean excess adhesive from frame using a

suitable solvent.

2.Position frame to hood outer cover and locate

in retainers.

3.Position tension straps and secure with screws.

4.Apply adhesive to fabric flap and secure to front

of frame.

5.Apply adhesive to fabric flaps and secure to

rear of frame.

Ensure adhesive does not contact frame.

The fabric flaps should be free to move on the

frame.

6.Fit hood catches and secure with special key.

7.Fit soft back assembly.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

Page 730 of 1007

HOOD

REPAIRS 76-7-5

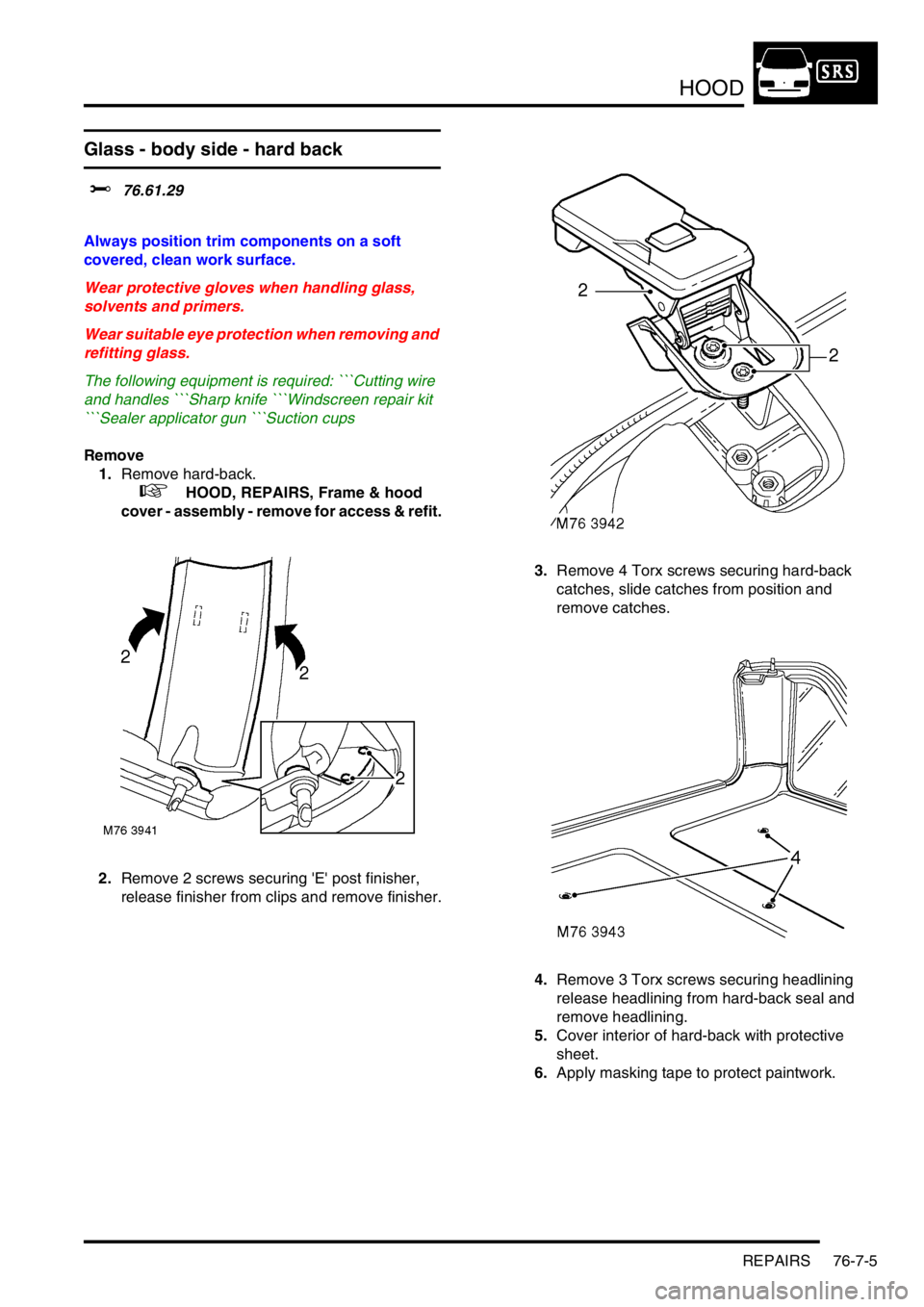

Glass - body side - hard back

$% 76.61.29

Always position trim components on a soft

covered, clean work surface.

Wear protective gloves when handling glass,

solvents and primers.

Wear suitable eye protection when removing and

refitting glass.

The following equipment is required: ```Cutting wire

and handles ```Sharp knife ```Windscreen repair kit

```Sealer applicator gun ```Suction cups

Remove

1.Remove hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Remove 2 screws securing 'E' post finisher,

release finisher from clips and remove finisher.3.Remove 4 Torx screws securing hard-back

catches, slide catches from position and

remove catches.

4.Remove 3 Torx screws securing headlining

release headlining from hard-back seal and

remove headlining.

5.Cover interior of hard-back with protective

sheet.

6.Apply masking tape to protect paintwork.

Page 732 of 1007

HOOD

REPAIRS 76-7-7

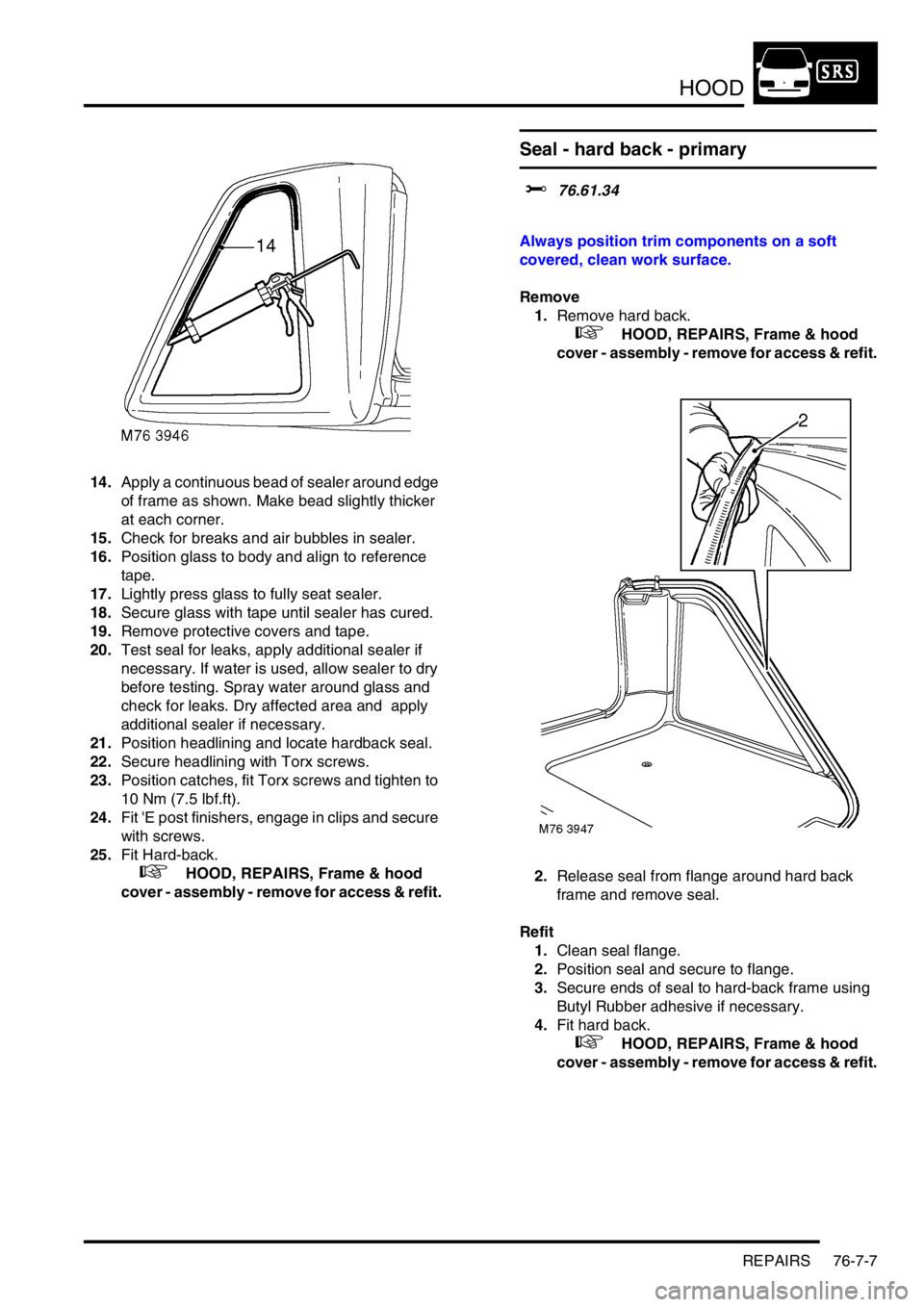

14.Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

15.Check for breaks and air bubbles in sealer.

16.Position glass to body and align to reference

tape.

17.Lightly press glass to fully seat sealer.

18.Secure glass with tape until sealer has cured.

19.Remove protective covers and tape.

20.Test seal for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Dry affected area and apply

additional sealer if necessary.

21.Position headlining and locate hardback seal.

22.Secure headlining with Torx screws.

23.Position catches, fit Torx screws and tighten to

10 Nm (7.5 lbf.ft).

24.Fit 'E post finishers, engage in clips and secure

with screws.

25.Fit Hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Seal - hard back - primary

$% 76.61.34

Always position trim components on a soft

covered, clean work surface.

Remove

1.Remove hard back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Release seal from flange around hard back

frame and remove seal.

Refit

1.Clean seal flange.

2.Position seal and secure to flange.

3.Secure ends of seal to hard-back frame using

Butyl Rubber adhesive if necessary.

4.Fit hard back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 734 of 1007

HOOD

REPAIRS 76-7-9

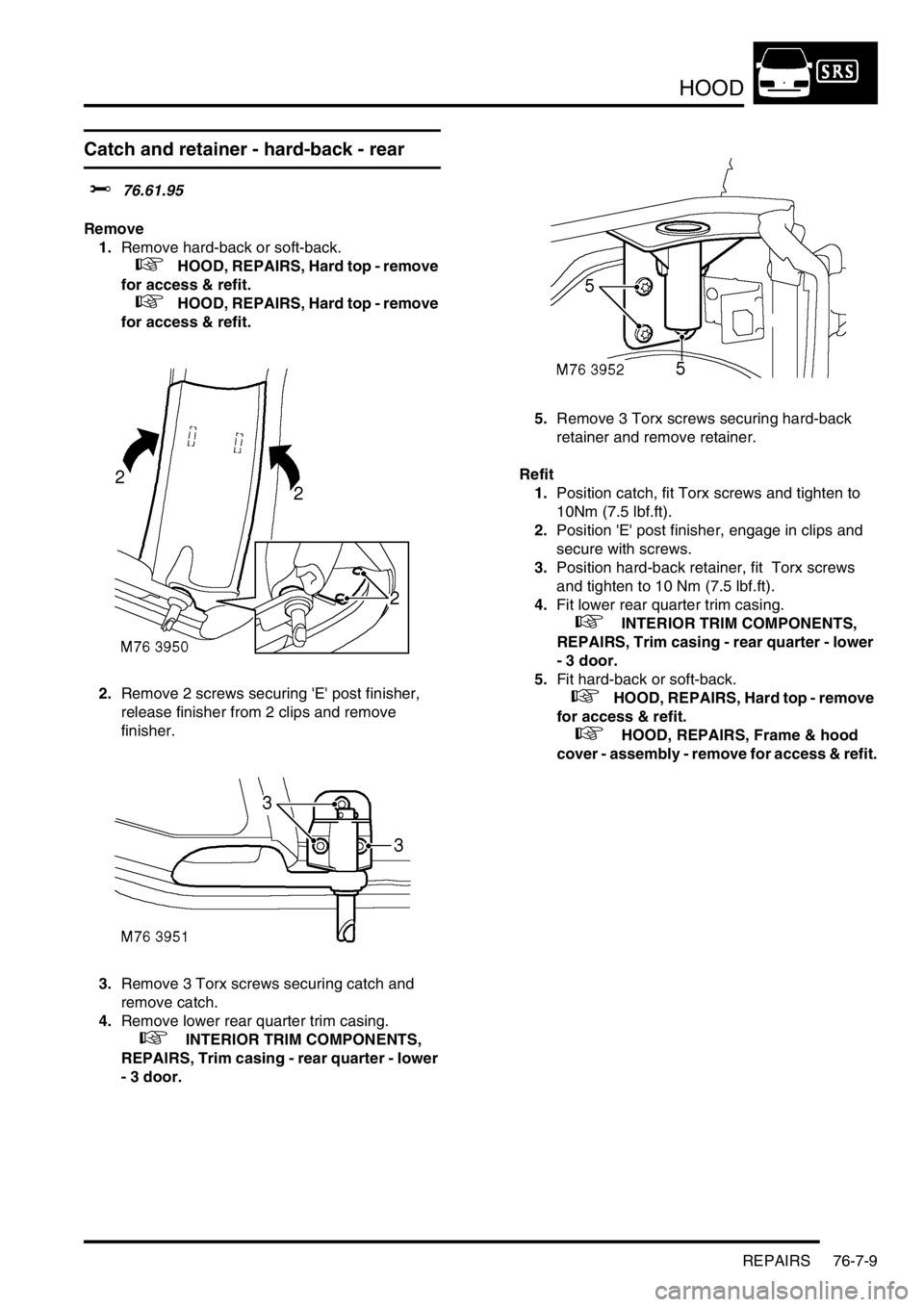

Catch and retainer - hard-back - rear

$% 76.61.95

Remove

1.Remove hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

2.Remove 2 screws securing 'E' post finisher,

release finisher from 2 clips and remove

finisher.

3.Remove 3 Torx screws securing catch and

remove catch.

4.Remove lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.5.Remove 3 Torx screws securing hard-back

retainer and remove retainer.

Refit

1.Position catch, fit Torx screws and tighten to

10Nm (7.5 lbf.ft).

2.Position 'E' post finisher, engage in clips and

secure with screws.

3.Position hard-back retainer, fit Torx screws

and tighten to 10 Nm (7.5 lbf.ft).

4.Fit lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

5.Fit hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 961 of 1007

WINDOWS

86-5-4 REPAIRS

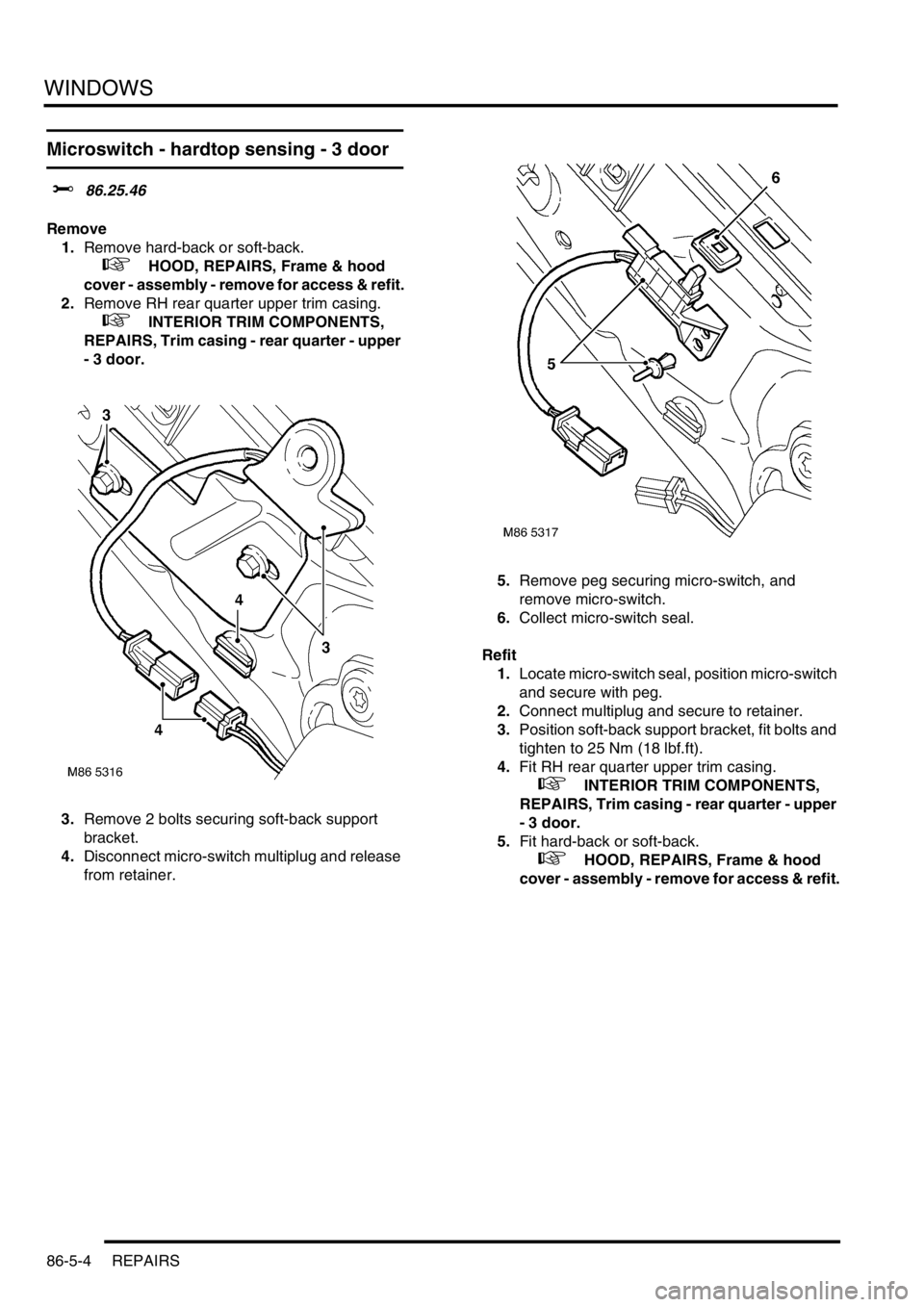

Microswitch - hardtop sensing - 3 door

$% 86.25.46

Remove

1.Remove hard-back or soft-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Remove RH rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 3 door.

3.Remove 2 bolts securing soft-back support

bracket.

4.Disconnect micro-switch multiplug and release

from retainer.5.Remove peg securing micro-switch, and

remove micro-switch.

6.Collect micro-switch seal.

Refit

1.Locate micro-switch seal, position micro-switch

and secure with peg.

2.Connect multiplug and secure to retainer.

3.Position soft-back support bracket, fit bolts and

tighten to 25 Nm (18 lbf.ft).

4.Fit RH rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 3 door.

5.Fit hard-back or soft-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.