warning light LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 14 of 1007

CONTENTS

CONTENTS 11

REAR SUSPENSION ................................................................................ 64-1

REPAIRS

Bush - trailing link............................................................................................................................ 64-1

Bearing - hub ................................................................................................................................. 64-2

Damper .......................................................................................................................................... 64-5

Trailing arm .................................................................................................................................... 64-8

Bush - trailing arm .......................................................................................................................... 64-9

Link - adjustable - transverse ......................................................................................................... 64-10

Link - transverse fixed .................................................................................................................... 64-11

Bush - link - transverse .................................................................................................................. 64-12

Sub frame ...................................................................................................................................... 64-13

BRAKES ................................................................................................... 70-1

ADJUSTMENTS

Brake bleed ..................................................................................................................................... 70-1

Cable - handbrake - check and adjust ............................................................................................ 70-2

REPAIRS

Drum - rear ...................................................................................................................................... 70-3

Disc - front....................................................................................................................................... 70-5

Hose - front - primary - LH .............................................................................................................. 70-6

Hose - rear ...................................................................................................................................... 70-7

Cylinder - master - tandem - LHD ................................................................................................... 70-8

Cylinder - master - tandem - RHD................................................................................................... 70-9

Lever assembly - handbrake........................................................................................................... 70-10

Cable - handbrake ......................................................................................................................... 70-11

Switch - handbrake warning ............................................................................................................ 70-12

Switch - stop light ............................................................................................................................ 70-13

Sensor - brake pedal position ........................................................................................................ 70-13

Shoes/pads - front - set................................................................................................................... 70-14

Brake Shoes - rear set .................................................................................................................... 70-15

Servo assembly - LHD .................................................................................................................... 70-17

Servo assembly - RHD ................................................................................................................... 70-19

Vacuum pump - Td4 - manual ........................................................................................................ 70-20

Vacuum pump - Td4 - automatic ..................................................................................................... 70-21

Vacuum - enhancer - KV6 .............................................................................................................. 70-22

Carrier assembly - calliper - front ................................................................................................... 70-23

Wheel cylinder - rear ....................................................................................................................... 70-24

Switch - low fluid level ..................................................................................................................... 70-25

Sensor & harness - front wheel - RH .............................................................................................. 70-25

Sensor & harness - front wheel - LH ............................................................................................... 70-27

Sensor & harness - rear wheel ....................................................................................................... 70-29

Modulator unit ................................................................................................................................. 70-30

Switch - hill descent - from 04MY ................................................................................................... 70-31

Switch - hill descent - up to 03MY................................................................................................... 70-32

Page 23 of 1007

CONTENTS

20 CONTENTS

LIGHTING.................................................................................................. 86-2-1

ADJUSTMENTS

Headlamps - pair - align beam - up to 04MY .................................................................................. 86-2-1

Headlamps - pair - align beam - from 04MY ................................................................................... 86-2-1

REPAIRS

Headlamp assembly - up to 04MY.................................................................................................. 86-2-3

Headlamp assembly - from 04MY .................................................................................................. 86-2-4

Lamp assembly - flasher side repeater - front ................................................................................ 86-2-5

Lamp assembly - tail ....................................................................................................................... 86-2-5

Lamp assembly - number plate ...................................................................................................... 86-2-6

Lamp assembly - fog/driving - from 04MY ...................................................................................... 86-2-6

Lamp assembly - rear ..................................................................................................................... 86-2-7

Lamp assembly - centre high mounted stop (CHMSL) ................................................................... 86-2-7

Lamp assembly - glove compartment ............................................................................................. 86-2-8

Lamp assembly - load space .......................................................................................................... 86-2-8

Switch - headlamp levelling ............................................................................................................ 86-2-9

Switch - glove compartment ........................................................................................................... 86-2-9

Switch - hazard warning ................................................................................................................. 86-2-10

Switch - combined direction indicator/headlight/horn ..................................................................... 86-2-10

Switch - rear fog lamp ..................................................................................................................... 86-2-11

CONTROL UNITS ..................................................................................... 86-3-1

REPAIRS

Control unit - window lift ................................................................................................................. 86-3-1

Relay - power folding mirrors - from 02MY ..................................................................................... 86-3-1

Central Control Unit (CCU) ............................................................................................................. 86-3-2

Control Unit - power fold mirrors - up to 02MY ............................................................................... 86-3-3

SECURITY................................................................................................. 86-4-1

REPAIRS

Solenoid/motor - taildoor................................................................................................................. 86-4-1

Switch/push - horn .......................................................................................................................... 86-4-2

Horn ................................................................................................................................................ 86-4-2

Immobilisation - electronic control unit (ECU) - ............................................................................. 86-4-3

Sensor - volumetric - alarm system - 3 door ................................................................................... 86-4-3

Module (ECU) - volumetric - alarm system - 5 door - without sunroof ........................................... 86-4-5

Module (ECU) - volumetric - alarm system - 5 door - with sunroof ................................................ 86-4-7

Receiver - alarm system ................................................................................................................. 86-4-10

Coil - passive immobilisation - alarm system .................................................................................. 86-4-10

Page 24 of 1007

CONTENTS

CONTENTS 21

WINDOWS ................................................................................................ 86-5-1

REPAIRS

Motor & control unit - front door - 3 door ......................................................................................... 86-5-1

Motor & control unit - front door - 5 door ......................................................................................... 86-5-2

Switch - master window - 5 door - from 04MY ................................................................................ 86-5-2

Relay - control - tail door glass ....................................................................................................... 86-5-3

Microswitch - hardtop sensing - 3 door ........................................................................................... 86-5-4

Relay - heated front screen ........................................................................................................... 86-5-5

Switch - backlight heater ................................................................................................................. 86-5-6

IN CAR ENTERTAINMENT ...................................................................... 86-6-1

REPAIRS

Radio - up to 04MY ......................................................................................................................... 86-6-1

Radio/CD - from 04MY .................................................................................................................... 86-6-2

Speaker - rear - 3 door .................................................................................................................... 86-6-3

Speaker - rear - 5 door .................................................................................................................... 86-6-3

Speaker - front ................................................................................................................................ 86-6-4

Aerial - manual - 3 door .................................................................................................................. 86-6-4

Aerial - manual - 5 door .................................................................................................................. 86-6-5

Coaxial lead - front aerial - 3 door ................................................................................................... 86-6-6

Coaxial lead - front aerial - 5 door ................................................................................................... 86-6-7

Speaker - tweeter - front ................................................................................................................. 86-6-8

Speaker - tweeter - rear - 3 door ..................................................................................................... 86-6-9

Amplifier - power ............................................................................................................................ 86-6-10

Sub-woofer assembly .................................................................................................................... 86-6-11

Coaxial lead - extension.................................................................................................................. 86-6-12

HARNESSES ............................................................................................ 86-7-1

REPAIRS

Fuse box - passenger compartment ............................................................................................... 86-7-1

Harness - main ................................................................................................................................ 86-7-2

Harness - tailgate ............................................................................................................................ 86-7-12

Harness - interior lights - 5 door ...................................................................................................... 86-7-15

Harness - front door - 5 door ........................................................................................................... 86-7-15

Harness - rear door ......................................................................................................................... 86-7-16

DRIVER CONTROLS ................................................................................ 86-8-1

REPAIRS

Switch - remote control - audio system .......................................................................................... 86-8-1

Switch - park distance control (PDC) - from 04 MY ........................................................................ 86-8-1

Control unit (ECU) - parking aid - from 04MY ................................................................................. 86-8-2

Sensor - parking aid - rear - from 04MY ......................................................................................... 86-8-2

Sounder - parking aid - rear - from 04MY ....................................................................................... 86-8-3

Switch - handbrake warning ............................................................................................................ 86-8-3

Switch - hazard warning - from 04MY ............................................................................................. 86-8-4

Cigar lighter - front .......................................................................................................................... 86-8-4

Switch - control - exterior mirror ...................................................................................................... 86-8-5

Page 48 of 1007

GENERAL INFORMATION

03-17

SPX Corporation,

665, Eisenhower Drive,

Owatonna,

MN 55060,

USA

( 0018 772979110

) 0018 005787375

Australia

SPX Australia,

28, Clayton Road,

Notting Hill,

Victoria 3168,

Australia

( 00 (61) 00395446222

) 00 (61) 0395445222

e-mail: [email protected]

Japan and East Asia

Jatek Ltd.,

5 - 53, Minawacho 2-chome,

Kohoku-ku,

Yokohama,

Kanagawa 223-0051,

Japan

( 0081 455627700

) 0081 455627800

Rolling road testing

General

IMPORTANT: Use a four wheel rolling road for

brake testing if possible.

The front and rear wheels cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively applying more torque to the rear

wheels if the front wheels start to slip.

DO NOT attempt to drive individual wheels with

vehicle supported on floor jacks or stands.

Four wheel rolling road

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing, except any that may apply to the tyres.

Before testing a vehicle with anti-lock brakes on a

four wheel rolling road, disconnect the ABS

modulator. The ABS function will not work, the ABS

warning light will illuminate. Normal braking will be

available.

Two wheel rolling road

ABS will not function on a two wheel rolling road. The

ABS light will illuminate during testing. Normal

braking will be available.

If brake testing on a two wheel rolling road is

necessary, the following precautions should be

taken:

lpropeller shaft to the rear axle is removed/

disconnected;

lneutral selected in gearbox;

lhill descent control not selected.

When checking brakes, run engine at idle speed to

maintain servo vacuum.

Page 49 of 1007

GENERAL INFORMATION

03-18

Fuel handling precautions

Fuel vapour is highly inflammable and in confined

spaces is also explosive and toxic. The vapour is

heavier than air and will always fall to the lowest

level. The vapour can easily be distributed

throughout a workshop by air currents;

consequently, even a small spillage of fuel is

potentially very dangerous.

The following information provides basic precautions

which must be observed if petrol (gasoline) is to be

handled safely. It also outlines other areas of risk

which must not be ignored. This information is issued

for basic guidance only, if in doubt consult your local

Fire Officer.

General

Always have a fire extinguisher containing FOAM,

CO

2, GAS or POWDER close at hand when handling

or draining fuel or when dismantling fuel systems.

Fire extinguishers should also be located in areas

where fuel containers are stored.

Always disconnect the vehicle battery before

carrying out dismantling or draining work on a fuel

system.

Whenever fuel is being handled, drained or stored, or

when fuel systems are being dismantled, all forms of

ignition must be extinguished or removed; any

leadlamps must be flameproof and kept clear of

spillage.

WARNING: No one should be permitted to repair

components associated with fuel without first

having specialist training.

WARNING: Do not remove fuel system

components while the vehicle is over a pit.Fuel tank draining

Fuel tank draining should be carried out in

accordance with the procedure outlined in the FUEL

DELIVERY section of this manual and observing the

following precautions:

WARNING: Fuel must not be extracted or drained

from any vehicle while it is over a pit. Extraction

or draining of fuel must be carried out in a well

ventilated area.

The capacity of containers must be more than

adequate for the amount of fuel to be extracted or

drained. The container should be clearly marked

with its contents and placed in a safe storage

area which meets the requirements of local

authority regulations.

WARNING: When fuel has been drained from a

fuel tank the precautions governing naked lights

and ignition sources should be maintained.

Fuel tank removal

When the fuel line is secured to the fuel tank outlet by

a spring steel clip, the clip must be released before

the fuel line is disconnected or the fuel tank is

removed. This procedure will avoid the possibility of

residual petrol fumes in the fuel tank being ignited

when the clip is released.

As an added precaution, fuel tanks should have a

'FUEL VAPOUR' warning label attached to them as

soon as they are removed from the vehicle.

Fuel tank repairs

No attempt should be made to repair a plastic fuel

tank. If the structure of the tank is damaged, a new

tank must be fitted.

Body repairs

Plastic fuel pipes are particularly susceptible to heat,

even at relatively low temperature, and can be

melted by heat conducted from some distance away.

When body repairs involve the use of heat, all fuel

pipes which run in the vicinity of the repair area must

be removed, and the tank outlet plugged.

Page 151 of 1007

MAINTENANCE

10-4 MAINTENANCE

Seats and Seat Belts

Check

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return

under its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check for correct operation of seat belt height

adjusters.

8.Check security of seat belt buckle mountings.

9.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure.

Release seat belt buckle and check for correct

operation.

10.Check tightness of accessible seat belt

mountings.

Lamps, Horns and Warning Indicators

Check

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of

brake lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

10.Switch on headlamps (with ignition switch at 'O'

position) and check light reminder warning

operates when door is opened.

Page 169 of 1007

MAINTENANCE

10-22 MAINTENANCE

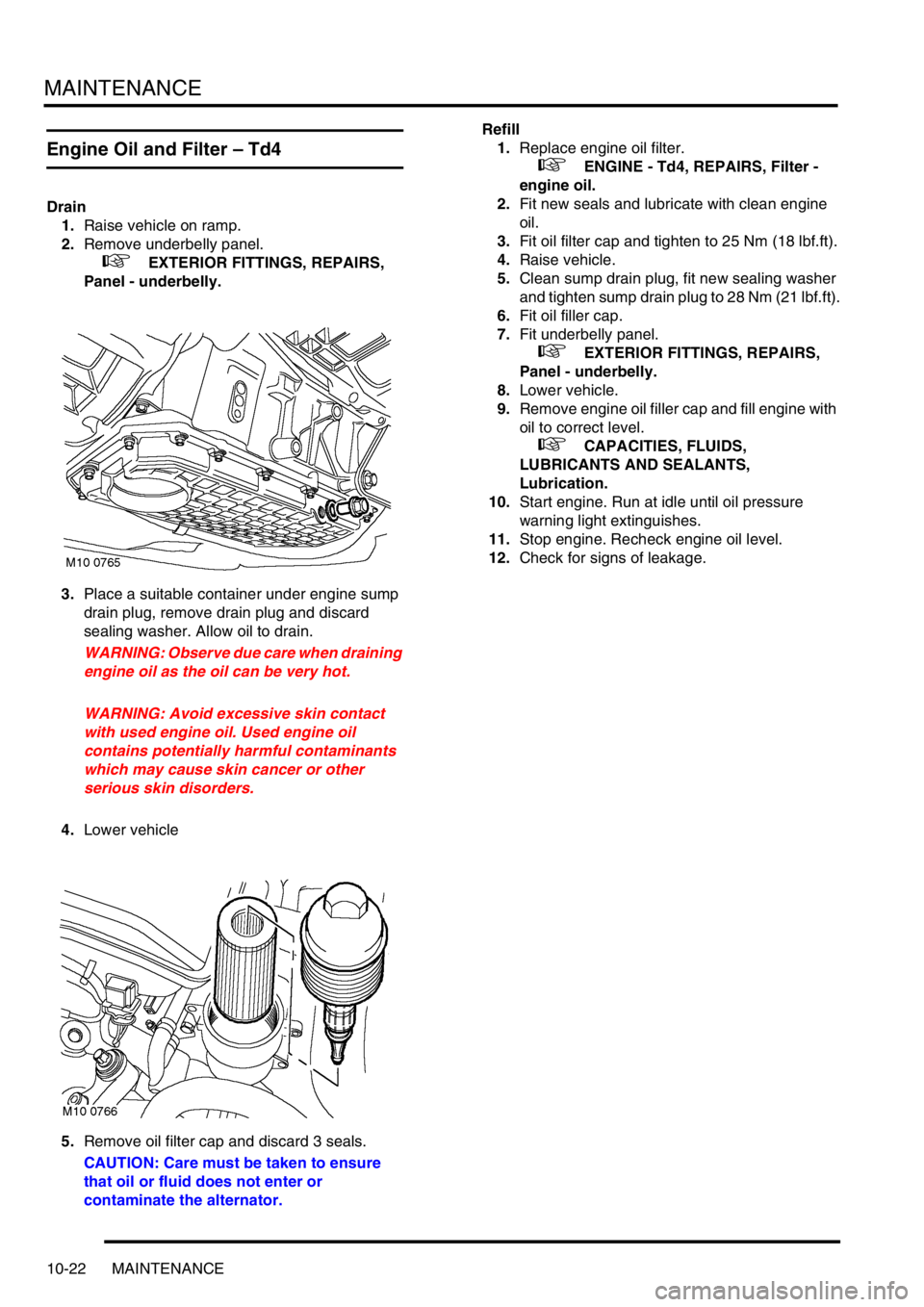

Engine Oil and Filter – Td4

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove drain plug and discard

sealing washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Lower vehicle

5.Remove oil filter cap and discard 3 seals.

CAUTION: Care must be taken to ensure

that oil or fluid does not enter or

contaminate the alternator.Refill

1.Replace engine oil filter.

+ ENGINE - Td4, REPAIRS, Filter -

engine oil.

2.Fit new seals and lubricate with clean engine

oil.

3.Fit oil filter cap and tighten to 25 Nm (18 lbf.ft).

4.Raise vehicle.

5.Clean sump drain plug, fit new sealing washer

and tighten sump drain plug to 28 Nm (21 lbf.ft).

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Start engine. Run at idle until oil pressure

warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 170 of 1007

MAINTENANCE

MAINTENANCE 10-23

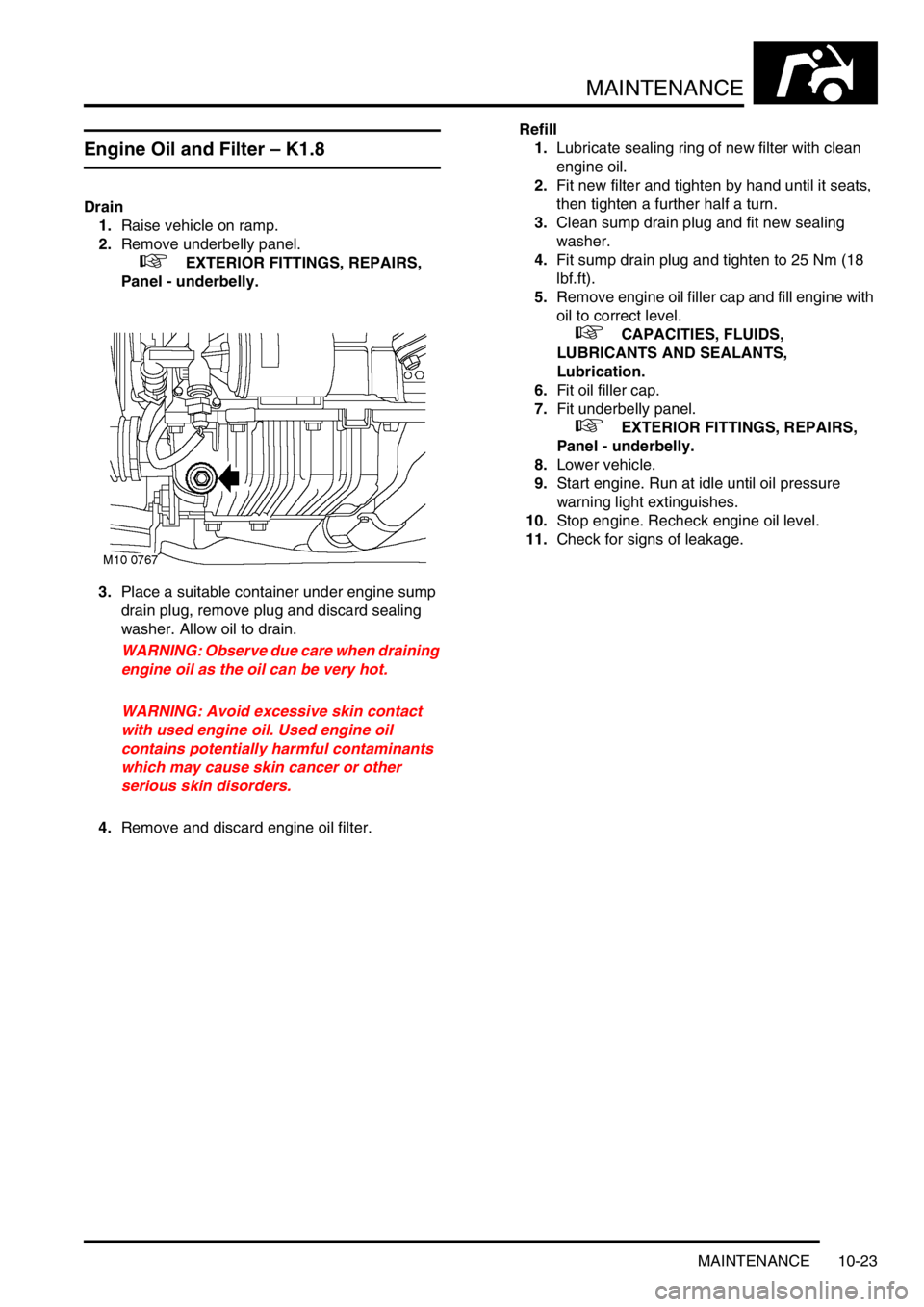

Engine Oil and Filter – K1.8

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.Refill

1.Lubricate sealing ring of new filter with clean

engine oil.

2.Fit new filter and tighten by hand until it seats,

then tighten a further half a turn.

3.Clean sump drain plug and fit new sealing

washer.

4.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

5.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Start engine. Run at idle until oil pressure

warning light extinguishes.

10.Stop engine. Recheck engine oil level.

11.Check for signs of leakage.

Page 171 of 1007

MAINTENANCE

10-24 MAINTENANCE

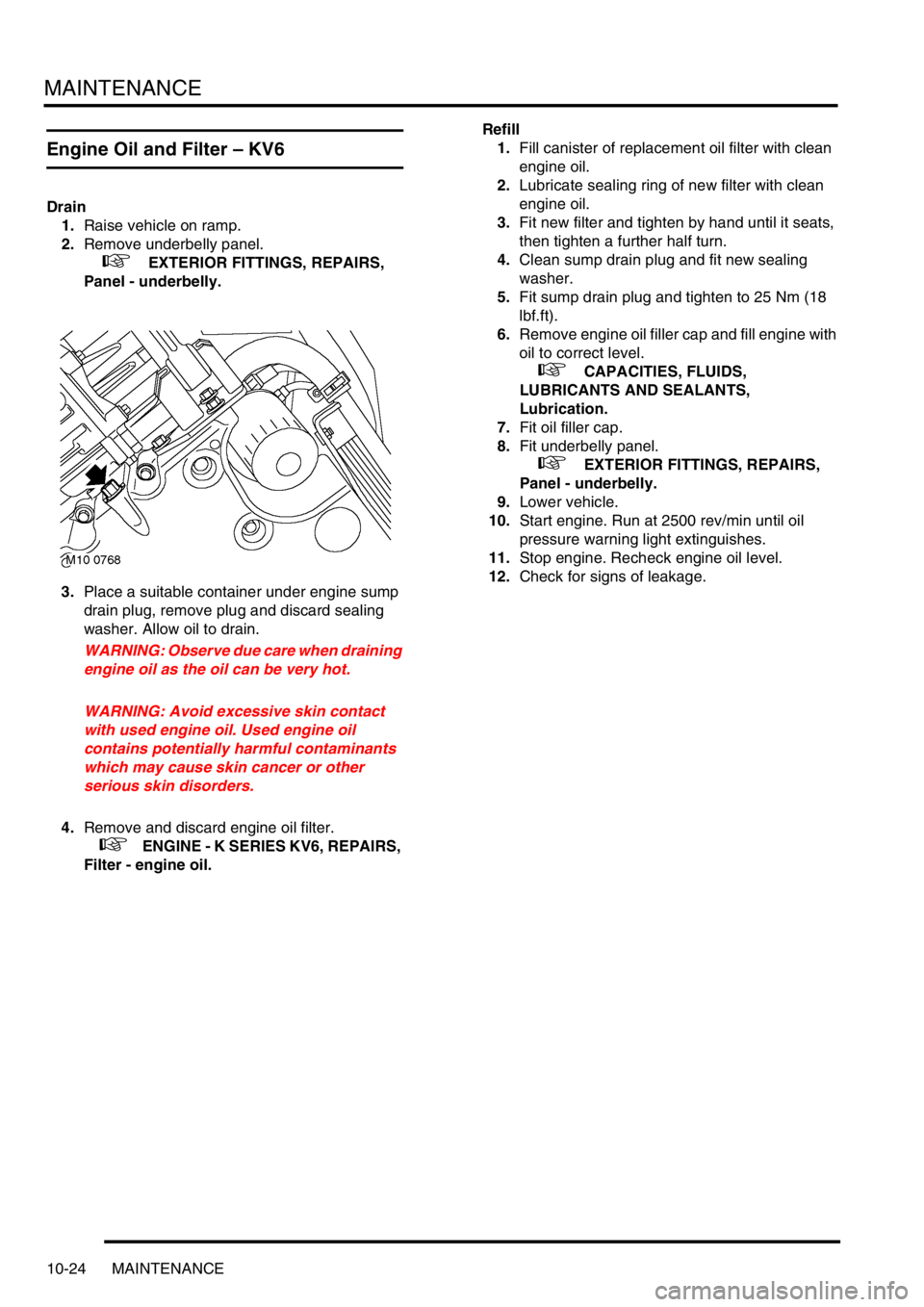

Engine Oil and Filter – KV6

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.

+ ENGINE - K SERIES KV6, REPAIRS,

Filter - engine oil.Refill

1.Fill canister of replacement oil filter with clean

engine oil.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit new filter and tighten by hand until it seats,

then tighten a further half turn.

4.Clean sump drain plug and fit new sealing

washer.

5.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

6.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

7.Fit oil filler cap.

8.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

9.Lower vehicle.

10.Start engine. Run at 2500 rev/min until oil

pressure warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 551 of 1007

BRAKES

70-2 ADJUSTMENTS

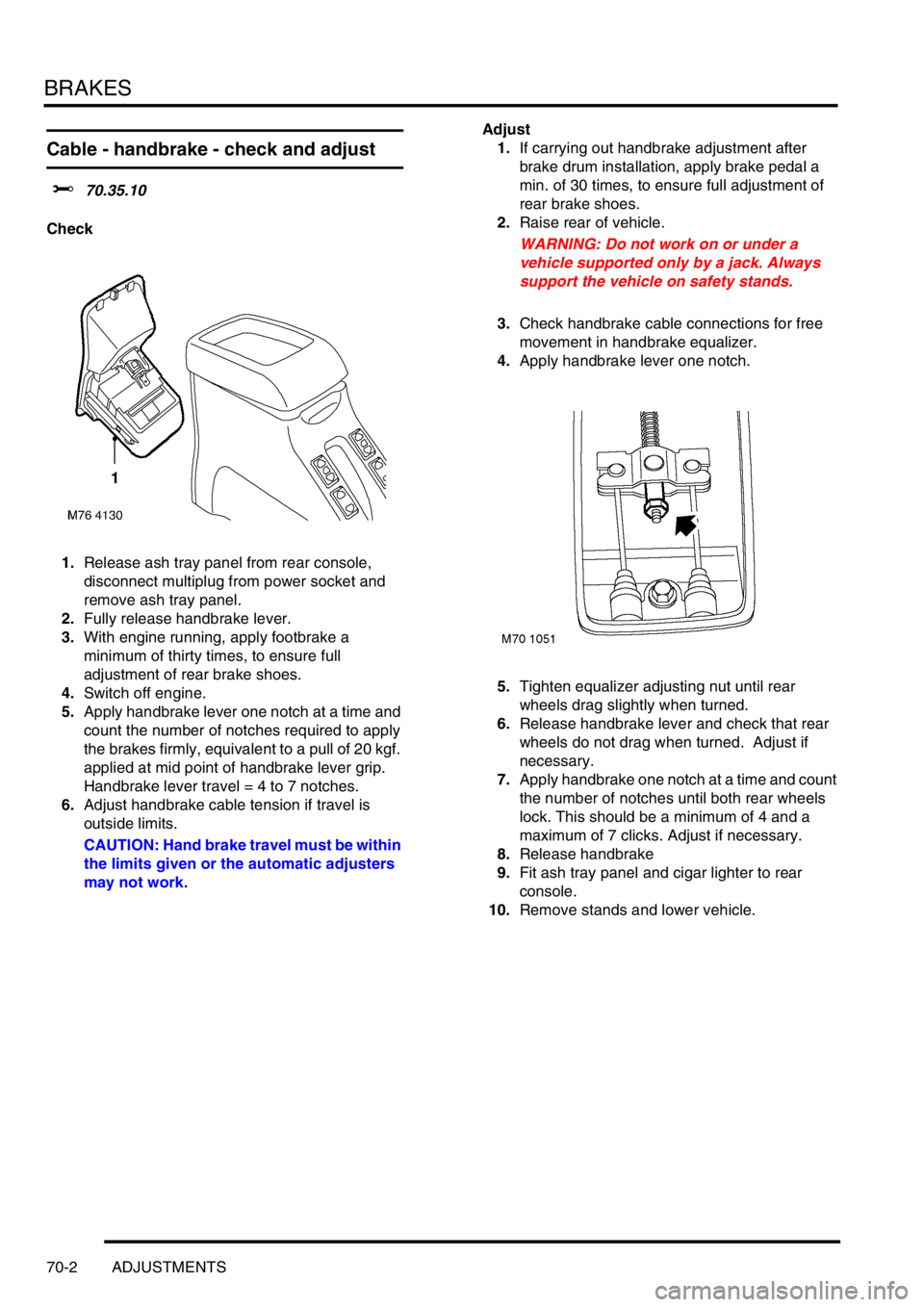

Cable - handbrake - check and adjust

$% 70.35.10

Check

1.Release ash tray panel from rear console,

disconnect multiplug from power socket and

remove ash tray panel.

2.Fully release handbrake lever.

3.With engine running, apply footbrake a

minimum of thirty times, to ensure full

adjustment of rear brake shoes.

4.Switch off engine.

5.Apply handbrake lever one notch at a time and

count the number of notches required to apply

the brakes firmly, equivalent to a pull of 20 kgf.

applied at mid point of handbrake lever grip.

Handbrake lever travel = 4 to 7 notches.

6.Adjust handbrake cable tension if travel is

outside limits.

CAUTION: Hand brake travel must be within

the limits given or the automatic adjusters

may not work.Adjust

1.If carrying out handbrake adjustment after

brake drum installation, apply brake pedal a

min. of 30 times, to ensure full adjustment of

rear brake shoes.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Check handbrake cable connections for free

movement in handbrake equalizer.

4.Apply handbrake lever one notch.

5.Tighten equalizer adjusting nut until rear

wheels drag slightly when turned.

6.Release handbrake lever and check that rear

wheels do not drag when turned. Adjust if

necessary.

7.Apply handbrake one notch at a time and count

the number of notches until both rear wheels

lock. This should be a minimum of 4 and a

maximum of 7 clicks. Adjust if necessary.

8.Release handbrake

9.Fit ash tray panel and cigar lighter to rear

console.

10.Remove stands and lower vehicle.