oil level LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 7 of 1007

CONTENTS

4CONTENTS

MAINTENANCE ........................................................................................ 10-1

MAINTENANCE

Td4 - Diesel Engine - Under Bonnet View ...................................................................................... 10-1

K1.8 – Petrol Engine – Under Bonnet View .................................................................................... 10-2

KV6 – Petrol Engine – Under Bonnet View .................................................................................... 10-3

Seats and Seat Belts ...................................................................................................................... 10-4

Lamps, Horns and Warning Indicators ........................................................................................... 10-4

Wipers and Washers ...................................................................................................................... 10-5

Handbrake ...................................................................................................................................... 10-5

Alarm Handset Battery.................................................................................................................... 10-6

Road Wheels .................................................................................................................................. 10-6

Tyres ............................................................................................................................................... 10-7

Brake Pads and Calipers ................................................................................................................ 10-7

Brake Fluid...................................................................................................................................... 10-9

Road Wheel Speed Sensors .......................................................................................................... 10-9

Fuel Filter - Petrol ........................................................................................................................... 10-10

Fuel Filter - Diesel........................................................................................................................... 10-10

Fuel Pump and Filter assembly - Diesel - 03 Model Year onwards ................................................ 10-10

Fuel Sedimenter - Diesel - 03 Model Year onwards ....................................................................... 10-10

Door Locks, Hinges, Check Straps and Bonnet Catch ................................................................... 10-11

Anti-freeze ...................................................................................................................................... 10-12

Cooling System and Intercooler...................................................................................................... 10-12

Vent filter - turbocharger boost control solenoid valve - Td4 .......................................................... 10-13

Spark Plugs – K1.8 ......................................................................................................................... 10-13

Spark Plugs – KV6.......................................................................................................................... 10-13

Air Cleaner – Petrol Models ............................................................................................................ 10-13

Ancillary Drive Belt – Td4 ............................................................................................................... 10-14

Ancillary Drive Belt – K1.8 .............................................................................................................. 10-14

Ancillary Drive Belt – KV6 ............................................................................................................... 10-15

Camshaft Timing Belt – K1.8 .......................................................................................................... 10-15

Camshaft Timing Belt – KV6........................................................................................................... 10-16

Brake/Clutch Reservoir ................................................................................................................... 10-16

PAS Fluid Level .............................................................................................................................. 10-17

Intermediate Reduction Drive - Non NAS models .......................................................................... 10-17

Intermediate Reduction Drive - NAS models .................................................................................. 10-18

Manual Gearbox – PG1 .................................................................................................................. 10-18

Manual Gearbox – GETRAG .......................................................................................................... 10-19

Automatic Gearbox – JATCO ......................................................................................................... 10-19

Rear Axle ........................................................................................................................................ 10-20

Clutch Pipes and Unions ................................................................................................................ 10-21

Windscreen and Rear Washer Reservoir ....................................................................................... 10-21

Battery ............................................................................................................................................ 10-21

Engine Oil and Filter – Td4 ............................................................................................................. 10-22

Engine Oil and Filter – K1.8 ............................................................................................................ 10-23

Engine Oil and Filter – KV6 ............................................................................................................ 10-24

Fuel Hoses and Pipes..................................................................................................................... 10-25

Brake Hoses and Pipes ................................................................................................................. 10-26

Check Exhaust System................................................................................................................... 10-26

Suspension ..................................................................................................................................... 10-27

Steering ......................................................................................................................................... 10-28

Road Test ....................................................................................................................................... 10-28

Endorse Service Record ................................................................................................................. 10-30

Report any Unusual Features ......................................................................................................... 10-30

Page 23 of 1007

CONTENTS

20 CONTENTS

LIGHTING.................................................................................................. 86-2-1

ADJUSTMENTS

Headlamps - pair - align beam - up to 04MY .................................................................................. 86-2-1

Headlamps - pair - align beam - from 04MY ................................................................................... 86-2-1

REPAIRS

Headlamp assembly - up to 04MY.................................................................................................. 86-2-3

Headlamp assembly - from 04MY .................................................................................................. 86-2-4

Lamp assembly - flasher side repeater - front ................................................................................ 86-2-5

Lamp assembly - tail ....................................................................................................................... 86-2-5

Lamp assembly - number plate ...................................................................................................... 86-2-6

Lamp assembly - fog/driving - from 04MY ...................................................................................... 86-2-6

Lamp assembly - rear ..................................................................................................................... 86-2-7

Lamp assembly - centre high mounted stop (CHMSL) ................................................................... 86-2-7

Lamp assembly - glove compartment ............................................................................................. 86-2-8

Lamp assembly - load space .......................................................................................................... 86-2-8

Switch - headlamp levelling ............................................................................................................ 86-2-9

Switch - glove compartment ........................................................................................................... 86-2-9

Switch - hazard warning ................................................................................................................. 86-2-10

Switch - combined direction indicator/headlight/horn ..................................................................... 86-2-10

Switch - rear fog lamp ..................................................................................................................... 86-2-11

CONTROL UNITS ..................................................................................... 86-3-1

REPAIRS

Control unit - window lift ................................................................................................................. 86-3-1

Relay - power folding mirrors - from 02MY ..................................................................................... 86-3-1

Central Control Unit (CCU) ............................................................................................................. 86-3-2

Control Unit - power fold mirrors - up to 02MY ............................................................................... 86-3-3

SECURITY................................................................................................. 86-4-1

REPAIRS

Solenoid/motor - taildoor................................................................................................................. 86-4-1

Switch/push - horn .......................................................................................................................... 86-4-2

Horn ................................................................................................................................................ 86-4-2

Immobilisation - electronic control unit (ECU) - ............................................................................. 86-4-3

Sensor - volumetric - alarm system - 3 door ................................................................................... 86-4-3

Module (ECU) - volumetric - alarm system - 5 door - without sunroof ........................................... 86-4-5

Module (ECU) - volumetric - alarm system - 5 door - with sunroof ................................................ 86-4-7

Receiver - alarm system ................................................................................................................. 86-4-10

Coil - passive immobilisation - alarm system .................................................................................. 86-4-10

Page 33 of 1007

GENERAL INFORMATION

03-2

Environmental Protection Precautions

It is illegal to pour used oil on to the ground, down

sewers or drains, or into water courses.

Burning of used engine oil in small space heaters or

boilers should only be considered for units of

approved design and in compliance with the

equipment manufacturer's recommendations. The

heating system must meet the regulatory standards

of HMIP for small burners of less than 0.4 MW. If in

doubt check with the appropriate local authority and/

or manufacturer of the approved appliance.

Dispose of used oil and filters through authorised

waste disposal contractors and licensed waste

disposal sites, or through the waste oil reclamation

trade. If in doubt, contact the Local Authority for

advice on disposal facilities.

Safety instructions

Whenever possible, use a lift or pit when working

beneath vehicle, in preference to jacking. Chock

wheels as well as applying parking brake.

Jacking

Always use the recommended jacking points. The

recommended jacking points are shown in

theLIFTING AND TOWING sub-section of the

INFORMATION section.

Always ensure that any lifting apparatus has

sufficient load capacity for the weight to be lifted.

Ensure the vehicle is standing on level ground prior

to lifting or jacking.

Apply the handbrake and chock the wheels.

WARNING: Do not work on or under a vehicle

supported only by a jack. Always support the

vehicle on safety stands.

Do not leave tools, lifting equipment, spilt oil, etc.,

around or on the work bench area. Always keep a

clean and tidy work area.

Brake shoes and pads

Always fit the correct grade and specification of

brake linings. When renewing brake pads and brake

shoes always replace as complete axle sets only.

Page 34 of 1007

GENERAL INFORMATION

03-3

Brake hydraulics

Observe the following recommendations when

working on the brake system:

lAlways use two spanners when loosening or

tightening brake pipe or hose connections.

lEnsure that hoses run in a natural curve and are

not kinked or twisted.

lFit brake pipes securely in their retaining clips

and ensure that the pipe run cannot contact a

potential chafing point.

lContainers used for hydraulic brake fluid must

be kept absolutely clean.

lDo not store hydraulic brake fluid in an unsealed

container, it will absorb water and in this

condition would be dangerous to use due to a

lowering of its boiling point.

lDo not allow hydraulic brake fluid to be

contaminated with mineral oil, or put new

hydraulic brake fluid in a container which has

previously contained mineral oil.

lDo not re-use hydraulic brake fluid previously

removed from the system.

lAlways use clean brake fluid or a recommended

alternative to clean hydraulic components.

lFit a blanking cap to a hydraulic union and a

plug to its socket, immediately after

disconnection of pipes and hoses to prevent the

ingress of dirt.

lAbsolute cleanliness must be observed when

working with hydraulic components.

lIt is imperative that the correct brake fittings are

used and that threads of components are

compatible.

Cooling system caps and plugs

Extreme care is necessary when removing engine

cooling system expansion tank caps and coolant

drain or bleed screws when the engine is hot, and

especially if it is overheated.

To avoid the possibility of scalding allow the engine

to cool before attempting coolant cap or plug

removal.

Environmental Precautions

General

This section provides general information which can

help to reduce adverse environmental impacts

incurred through the activities carried out in

workshops.

Emissions to air

Many of the activities that are carried out in

workshops emit gases and fumes which contribute to

global warming, depletion of the ozone layer and/or

the formation of photo-chemical smog at ground

level. By considering and controlling how the

workshop activities are carried out, these gases and

fumes can be minimised, thus reducing the damage

to the environment.

Exhaust fumes

Running car engines is an essential part of workshop

activities and exhaust fumes need to be ventilated to

atmosphere. However, the amount of time engines

are running and the position of the vehicle should be

carefully considered at all times, to reduce the

release of poisonous gases and minimise the

inconvenience to people living nearby.

Solvents

Some of the cleaning agents used are solvent based

and will evaporate to atmosphere if used carelessly,

or if cans are left unsealed. All solvent containers

should be firmly closed when not needed and solvent

should be used sparingly. Suitable alternative

materials may be available to replace some of the

commonly used solvents. Similarly, many paints are

solvent based and the spray should be minimised to

reduce solvent emissions.

Refrigerant

It is illegal to release any refrigerants into the

atmosphere. Discharge and replacement of these

materials from air conditioning units should only be

carried out using the correct equipment.

Checklist

Always adhere to the following:

Engines –

ldon't leave engines running unnecessarily;

lminimise testing times and check where the

exhaust fumes are being blown.

Page 104 of 1007

TORQUE WRENCH SETTINGS

06-1

TORQUE WRE NCH SETTINGS

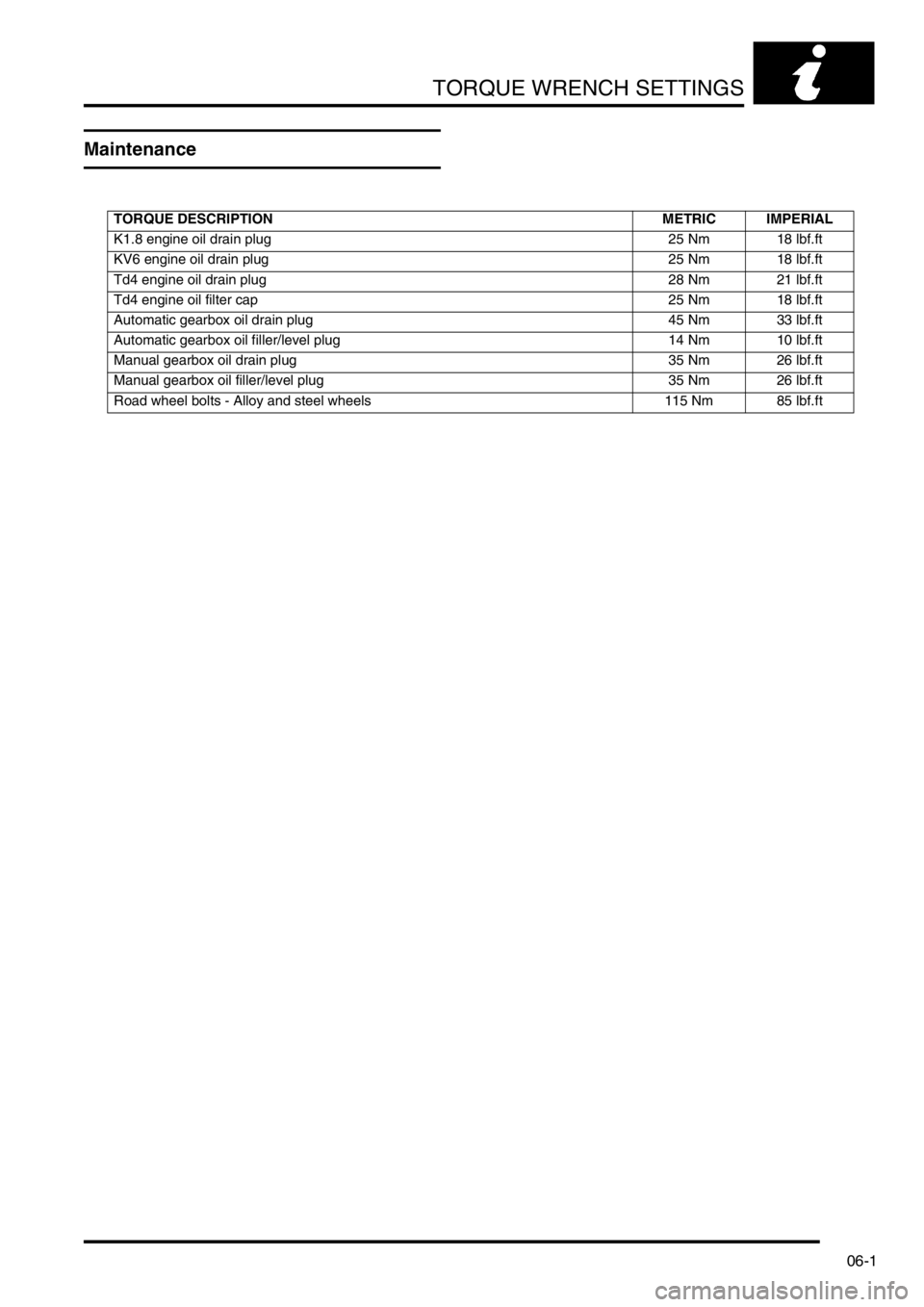

Maintenance

TORQUE DESCRIPTION METRIC IMPERIAL

K1.8 engine oil drain plug 25 Nm 18 lbf.ft

KV6 engine oil drain plug 25 Nm 18 lbf.ft

Td4 engine oil drain plug 28 Nm 21 lbf.ft

Td4 engine oil filter cap 25 Nm 18 lbf.ft

Automatic gearbox oil drain plug 45 Nm 33 lbf.ft

Automatic gearbox oil filler/level plug 14 Nm 10 lbf.ft

Manual gearbox oil drain plug 35 Nm 26 lbf.ft

Manual gearbox oil filler/level plug 35 Nm 26 lbf.ft

Road wheel bolts - Alloy and steel wheels 115 Nm 85 lbf.ft

Page 151 of 1007

MAINTENANCE

10-4 MAINTENANCE

Seats and Seat Belts

Check

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return

under its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check for correct operation of seat belt height

adjusters.

8.Check security of seat belt buckle mountings.

9.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure.

Release seat belt buckle and check for correct

operation.

10.Check tightness of accessible seat belt

mountings.

Lamps, Horns and Warning Indicators

Check

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of

brake lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

10.Switch on headlamps (with ignition switch at 'O'

position) and check light reminder warning

operates when door is opened.

Page 164 of 1007

MAINTENANCE

MAINTENANCE 10-17

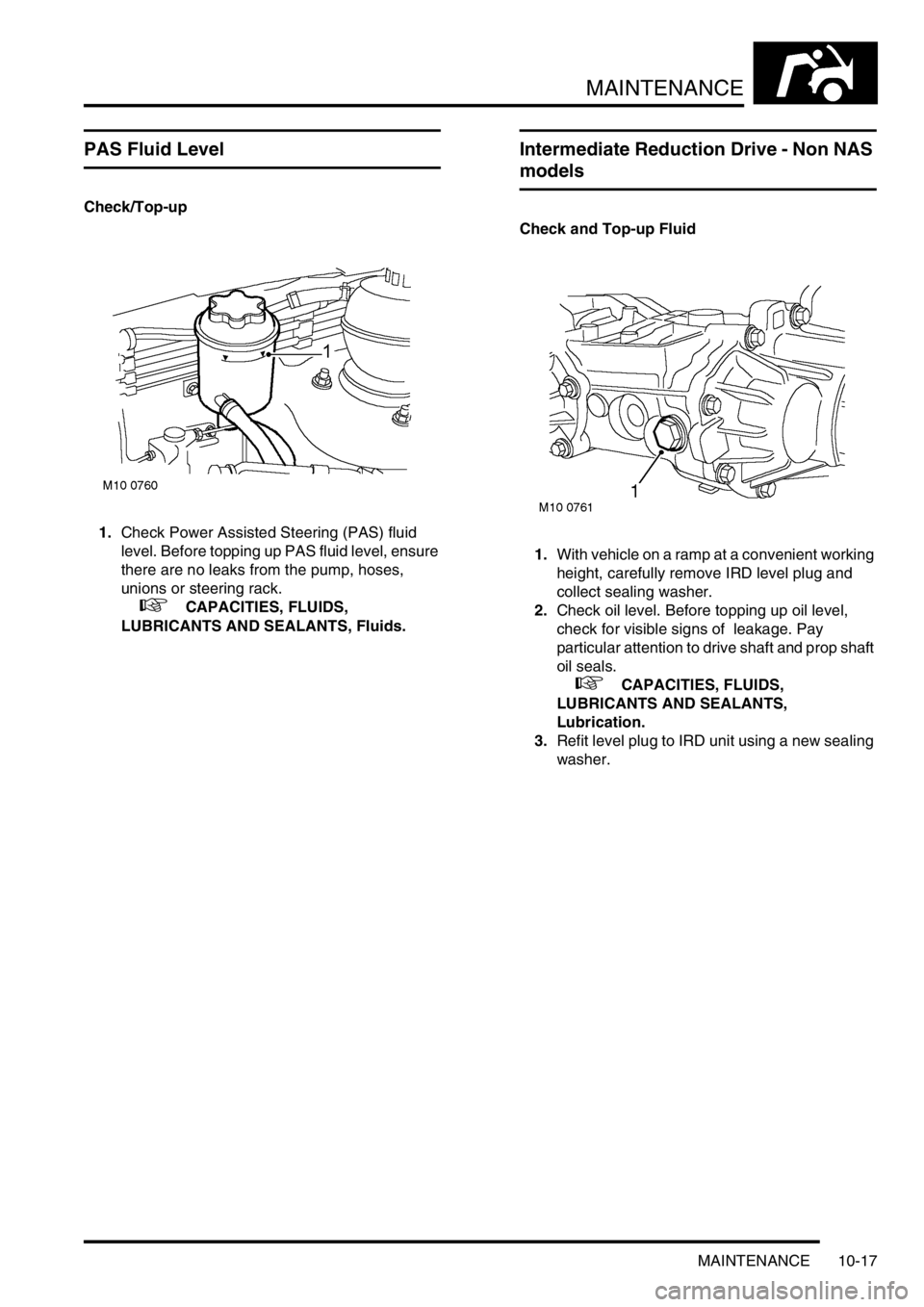

PAS Fluid Level

Check/Top-up

1.Check Power Assisted Steering (PAS) fluid

level. Before topping up PAS fluid level, ensure

there are no leaks from the pump, hoses,

unions or steering rack.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

Intermediate Reduction Drive - Non NAS

models

Check and Top-up Fluid

1.With vehicle on a ramp at a convenient working

height, carefully remove IRD level plug and

collect sealing washer.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft and prop shaft

oil seals.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Refit level plug to IRD unit using a new sealing

washer.

Page 165 of 1007

MAINTENANCE

10-18 MAINTENANCE

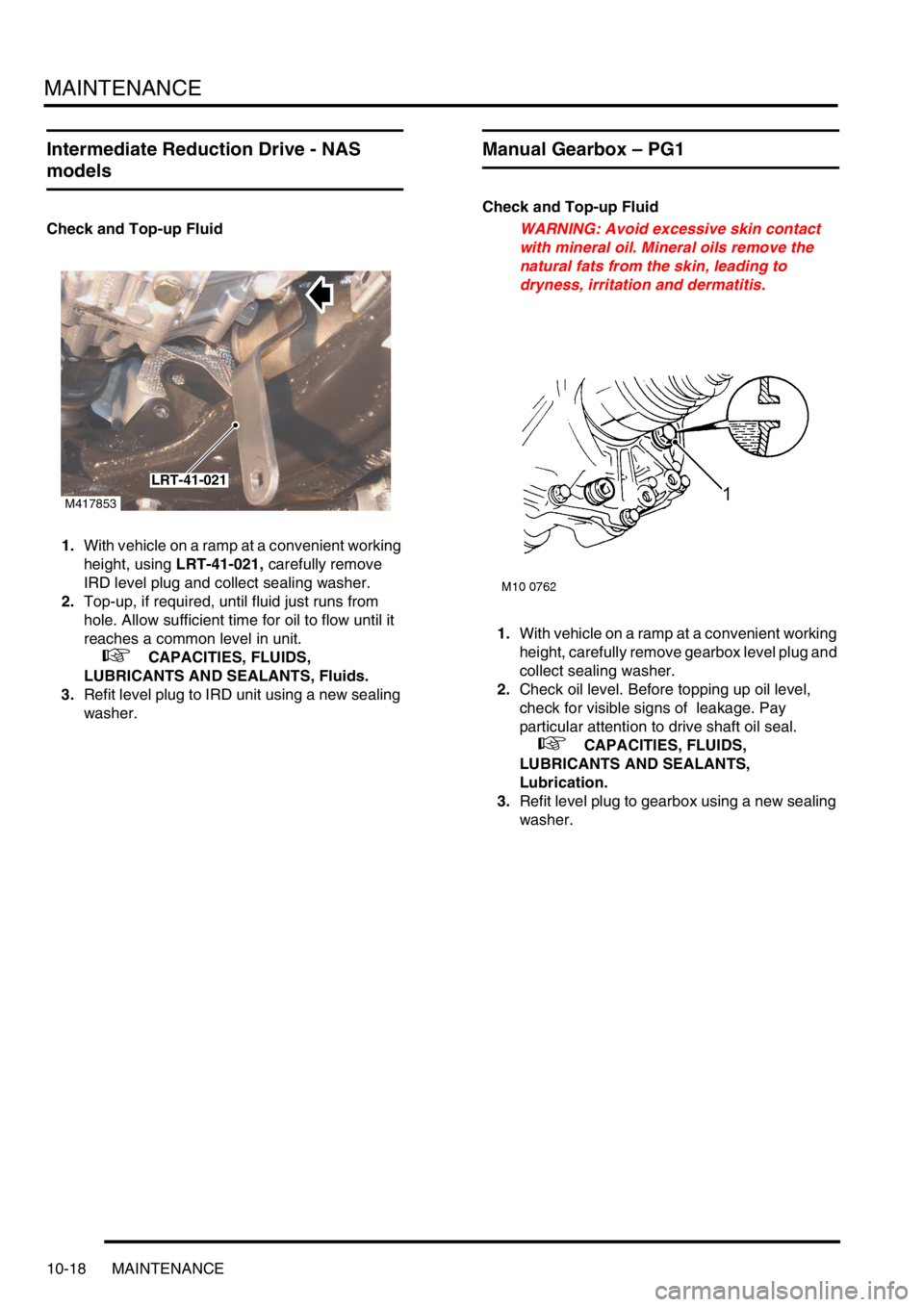

Intermediate Reduction Drive - NAS

models

Check and Top-up Fluid

1.With vehicle on a ramp at a convenient working

height, using LRT-41-021, carefully remove

IRD level plug and collect sealing washer.

2.Top-up, if required, until fluid just runs from

hole. Allow sufficient time for oil to flow until it

reaches a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

3.Refit level plug to IRD unit using a new sealing

washer.

Manual Gearbox – PG1

Check and Top-up Fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.With vehicle on a ramp at a convenient working

height, carefully remove gearbox level plug and

collect sealing washer.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft oil seal.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Refit level plug to gearbox using a new sealing

washer.

M417853

LRT-41-021

Page 166 of 1007

MAINTENANCE

MAINTENANCE 10-19

Manual Gearbox – GETRAG

Replace Fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Replace gearbox fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

Automatic Gearbox – JATCO

Check and top-up fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Position vehicle on ramp.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Connect TestBook/T4 to monitor gearbox fluid

temperature.

CAUTION: The gearbox fluid level must only

be checked when the temperature of the

fluid is between 35° and 45°. The reading

obtained will be incorrect if the fluid is

outside this temperature range.

5.Start engine, move selector lever from 'P'

through all gear positions, pausing in each gear

position for 2-3 seconds and return to 'P'

position.

6.Clean area around level plug.

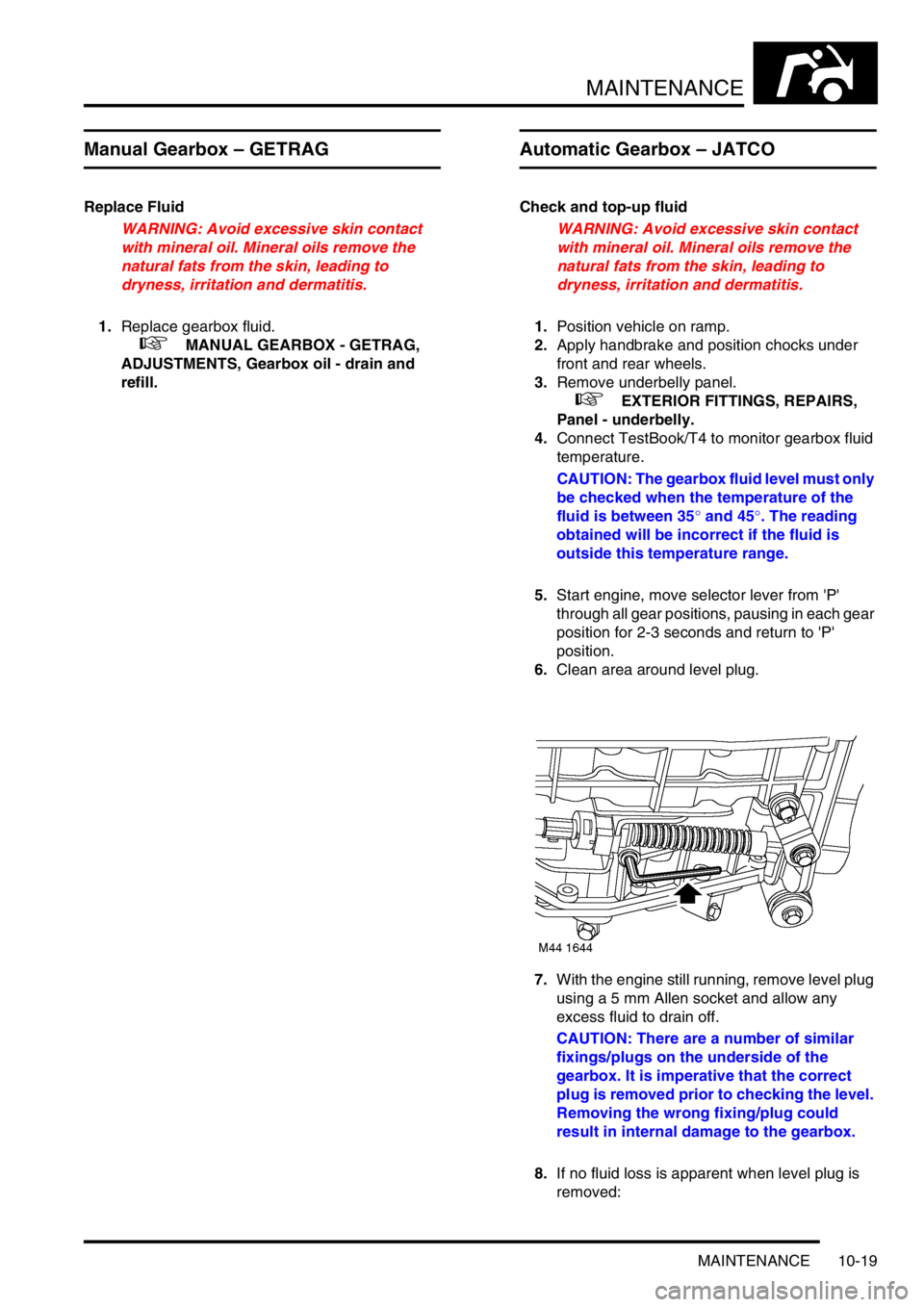

7.With the engine still running, remove level plug

using a 5 mm Allen socket and allow any

excess fluid to drain off.

CAUTION: There are a number of similar

fixings/plugs on the underside of the

gearbox. It is imperative that the correct

plug is removed prior to checking the level.

Removing the wrong fixing/plug could

result in internal damage to the gearbox.

8.If no fluid loss is apparent when level plug is

removed:

Page 167 of 1007

MAINTENANCE

10-20 MAINTENANCE

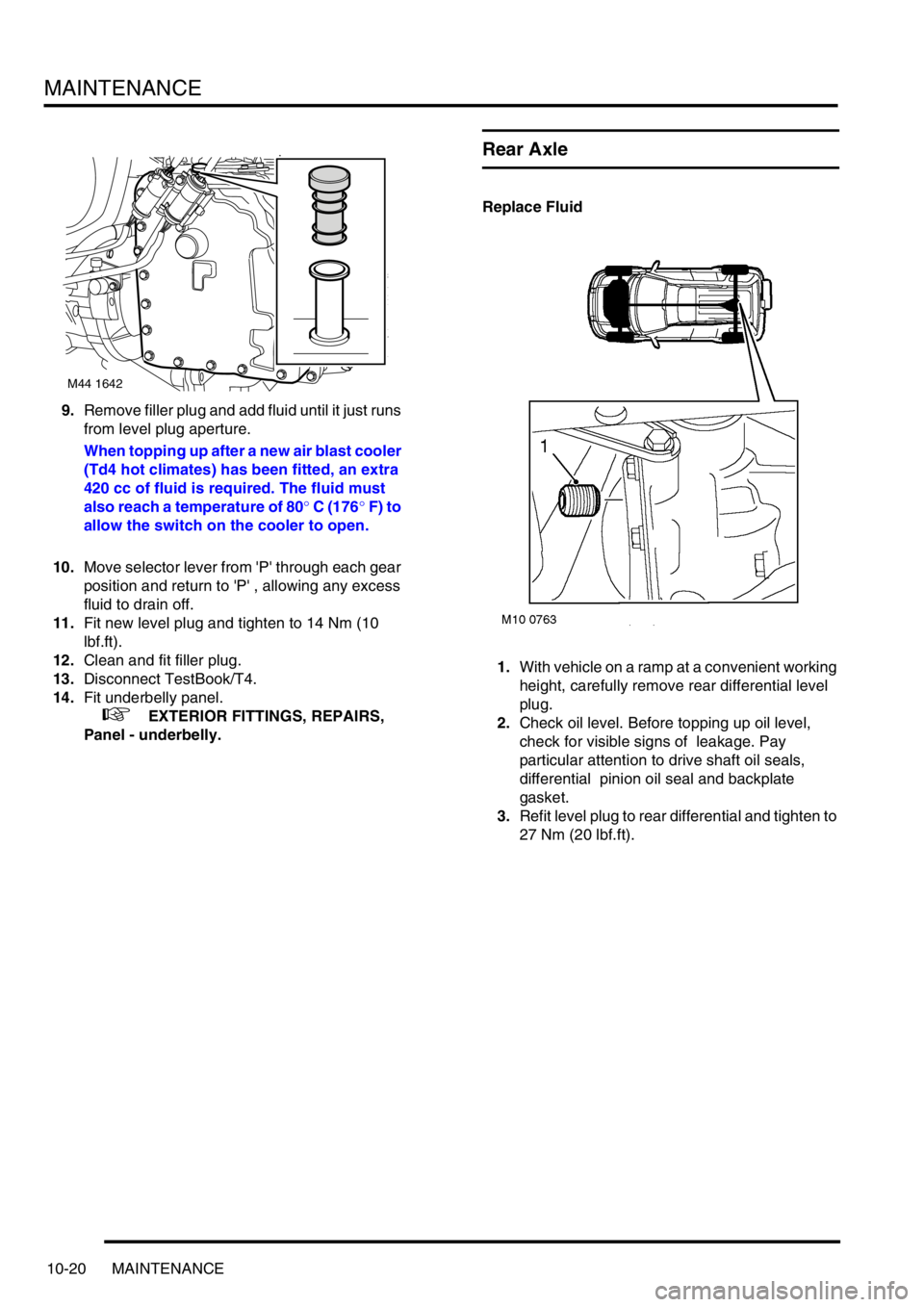

9.Remove filler plug and add fluid until it just runs

from level plug aperture.

When topping up after a new air blast cooler

(Td4 hot climates) has been fitted, an extra

420 cc of fluid is required. The fluid must

also reach a temperature of 80° C (176° F) to

allow the switch on the cooler to open.

10.Move selector lever from 'P' through each gear

position and return to 'P' , allowing any excess

fluid to drain off.

11.Fit new level plug and tighten to 14 Nm (10

lbf.ft).

12.Clean and fit filler plug.

13.Disconnect TestBook/T4.

14.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Rear Axle

Replace Fluid

1.With vehicle on a ramp at a convenient working

height, carefully remove rear differential level

plug.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft oil seals,

differential pinion oil seal and backplate

gasket.

3.Refit level plug to rear differential and tighten to

27 Nm (20 lbf.ft).

M44 1642