oil pressure LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 8 of 1007

CONTENTS

CONTENTS 5

ENGINE - K SERIES KV6 ......................................................................... 12-3-1

ADJUSTMENTS

Engine oil pressure check ............................................................................................................... 12-3-1

REPAIRS

Camshafts - LH cylinder head......................................................................................................... 12-3-3

Camshafts - RH cylinder head ........................................................................................................ 12-3-5

Inlet camshaft front oil seal ............................................................................................................. 12-3-8

Camshaft rear oil seal ..................................................................................................................... 12-3-9

Pulley - crankshaft ......................................................................................................................... 12-3-10

Crankshaft front oil seal .................................................................................................................. 12-3-11

Crankshaft rear oil seal ................................................................................................................... 12-3-12

Cylinder head gasket - LH .............................................................................................................. 12-3-13

Cylinder head gasket - RH .............................................................................................................. 12-3-16

Camshaft cover gasket - LH - Up to 03MY ..................................................................................... 12-3-20

Camshaft cover gasket - LH - from 03MY ....................................................................................... 12-3-21

Camshaft cover gasket - RH ........................................................................................................... 12-3-23

Cover - engine acoustic ................................................................................................................. 12-3-25

Engine and automatic gearbox - up to 03MY .................................................................................. 12-3-25

Engine and automatic gearbox - from 03MY .................................................................................. 12-3-35

Arm assembly - engine mounting RH ........................................................................................... 12-3-45

Engine mounting - LH ..................................................................................................................... 12-3-46

Hydramount - engine - RH ............................................................................................................. 12-3-47

Engine steady - upper RH ............................................................................................................... 12-3-47

Engine steady - lower ..................................................................................................................... 12-3-48

Torque converter drive plate ........................................................................................................... 12-3-49

Filter - engine oil ............................................................................................................................ 12-3-50

Oil pick-up strainer .......................................................................................................................... 12-3-50

Gasket - oil pump ........................................................................................................................... 12-3-51

Sump - reseal.................................................................................................................................. 12-3-53

Switch - oil pressure ....................................................................................................................... 12-3-54

Oil pressure relief valve .................................................................................................................. 12-3-55

Oil cooler - engine ........................................................................................................................... 12-3-57

Camshaft timing belt ....................................................................................................................... 12-3-58

Camshaft timing belt cover - RH front ............................................................................................. 12-3-66

Camshaft timing belt cover - LH front ............................................................................................. 12-3-67

Camshaft timing belt cover - LH rear .............................................................................................. 12-3-68

Camshaft timing belt cover - RH rear .............................................................................................. 12-3-68

Camshaft rear timing belt - LH cylinder head .................................................................................. 12-3-69

Camshaft rear timing belt - RH cylinder head ................................................................................. 12-3-73

OVERHAUL

Piston assemblies - engine set ....................................................................................................... 12-3-77

Crankshaft front oil seal ................................................................................................................ 12-3-80

Crankshaft rear oil seal ................................................................................................................... 12-3-81

Crankshaft....................................................................................................................................... 12-3-82

Cylinder head gasket - LH .............................................................................................................. 12-3-87

Cylinder head gasket - RH .............................................................................................................. 12-3-91

Cylinder head - decarbonise ........................................................................................................... 12-3-94

Oil pump - Overhaul ........................................................................................................................ 12-3-104

Sump - engine oil ........................................................................................................................... 12-3-106

Camshaft timing belt ....................................................................................................................... 12-3-107

Page 9 of 1007

CONTENTS

6CONTENTS

EMISSION CONTROL ............................................................................. 17-1-1

ADJUSTMENTS

Evaporative loss control system (EVAPS) - leak test - NAS........................................................... 17-1-1

REPAIRS

Valve - depression limiter - Td4 ..................................................................................................... 17-1-3

Solenoid - canister purge - KV6 ...................................................................................................... 17-1-4

Charcoal canister - petrol - Non NAS ............................................................................................. 17-1-4

Charcoal canister - NAS ................................................................................................................. 17-1-5

Valve - canister purge - K1.8 .......................................................................................................... 17-1-6

Valve - EGR - Td4 .......................................................................................................................... 17-1-7

Solenoid/modulator valve - EGR - Td4 ........................................................................................... 17-1-8

Thermal valve - exhaust gas recirculation (EGR) -

Td4 Automatic transmission (hot climates) - from 03 MY ............................................................... 17-1-9

Cooler - EGR - Td4 ......................................................................................................................... 17-1-9

Module - tank leakage diagnostic (DMTL) ...................................................................................... 17-1-11

Filter - fuel leak detection pump - KV6 - NAS ................................................................................ 17-1-12

Catalytic converter - RH - KV6 - NAS ............................................................................................ 17-1-12

ENGINE MANAGEMENT SYSTEM - SIEMENS....................................... 18-3-1

REPAIRS

Spark plugs - up to 03MY ............................................................................................................... 18-3-1

Spark plugs - from 03MY ................................................................................................................ 18-3-2

Coil - each - LH bank - up to 03MY ................................................................................................ 18-3-3

Coil - each - LH bank - from 03MY ................................................................................................. 18-3-3

Coil - each - RH bank - up to 03MY ................................................................................................ 18-3-4

Coil - each - RH bank - from 03MY................................................................................................. 18-3-4

Engine control module (ECM) - Non NAS ..................................................................................... 18-3-5

Engine control module (ECM) - fuel - NAS .................................................................................... 18-3-6

Idle Air Control Valve (IACV) ......................................................................................................... 18-3-7

Sensor - intake air temperature (IAT) - NAS .................................................................................. 18-3-8

Sensor - engine coolant temperature (ECT) .................................................................................. 18-3-8

Sensor - crankshaft position (CKP) ............................................................................................... 18-3-9

Sensor - throttle position (TP) ......................................................................................................... 18-3-10

Sensor - thermostat monitoring (TM) - KV6 - NAS ........................................................................ 18-3-11

Sensor - camshaft position (CMP) ................................................................................................. 18-3-12

Sensor - knock (KS) ....................................................................................................................... 18-3-13

Switch - throttle pedal - Non NAS ................................................................................................... 18-3-13

Sensor - combined - manifold absolute pressure/Intake air temperature (MAP/IAT) ..................... 18-3-14

Sensor - throttle position (TP) - NAS - up to 03MY......................................................................... 18-3-15

Sensor - throttle position (TP) - NAS - from 03MY ......................................................................... 18-3-16

Page 13 of 1007

CONTENTS

10 CONTENTS

REAR AXLE & FINAL DRIVE ................................................................... 51-1

REPAIRS

Differential assembly ..................................................................................................................... 51-1

Cover - rear - differential ................................................................................................................. 51-2

Bush - differential mounting - front ................................................................................................. 51-3

Bush - differential mounting - rear ................................................................................................. 51-4

Oil seal - pinion .............................................................................................................................. 51-5

Oil seal - differential housing ......................................................................................................... 51-6

STEERING ................................................................................................ 57-1

ADJUSTMENTS

Power assisted steering (PAS) system - bleed............................................................................... 57-1

Cable - key interlock - adjust .......................................................................................................... 57-1

Front wheel alignment - check & adjust .......................................................................................... 57-2

Alignment - rear wheel - check & adjust ......................................................................................... 57-3

Power steering - pressure test ........................................................................................................ 57-4

REPAIRS

Power steering rack ........................................................................................................................ 57-5

Gaiter - PAS rack ............................................................................................................................ 57-8

Oil cooler - Td4 & K1.8 models ....................................................................................................... 57-9

Oil cooler - KV6 models .................................................................................................................. 57-10

Drive belt - K1.8 .............................................................................................................................. 57-11

Pump - steering - KV6 .................................................................................................................... 57-12

Pump - steering - K1.8 .................................................................................................................... 57-14

Pump - steering - Td4 ..................................................................................................................... 57-15

Nacelle - column ............................................................................................................................. 57-16

Column lock & ignition/starter switch assembly .............................................................................. 57-17

Cable - key interlock ....................................................................................................................... 57-18

Column assembly - inner & outer ................................................................................................... 57-19

Ball joint - track rod ......................................................................................................................... 57-23

Track rod......................................................................................................................................... 57-24

Steering wheel ................................................................................................................................ 57-25

FRONT SUSPENSION .............................................................................. 60-1

REPAIRS

Anti roll bar...................................................................................................................................... 60-1

Ball joint link - anti roll bar .............................................................................................................. 60-2

Mounting rubbers - anti roll bar - set .............................................................................................. 60-2

Bearing - hub ................................................................................................................................. 60-3

Damper .......................................................................................................................................... 60-7

Lower arm assembly ...................................................................................................................... 60-10

Rear beam ..................................................................................................................................... 60-13

Bush - lower arm - front .................................................................................................................. 60-15

Bush - lower arm - rear ................................................................................................................... 60-16

Page 62 of 1007

GENERAL INFORMATION

03-31

When a major repair has been completed, a leak test

should be conducted; refer to the air conditioning

section of this manual for the correct procedure.

Refrigerant oil

Use an approved refrigerant lubricating oil:

ND Oil 8

CAUTION: Do not use any other type of

refrigerant oil.

CAUTION: Refrigerant oil easily absorbs water

and must not be stored for long periods. Do not

pour unused oil back into the container.

When renewing system components, add the

quantities of refrigerant oil recommended in the Air

Conditioning section of this manual.

Compressor

A new compressor is sealed and pressurised with

Nitrogen gas. When fitting a new compressor, slowly

release the sealing cap; gas pressure should be

heard to vent as the seal is broken.

CAUTION: A new compressor should always be

sealed and could be pressurised with nitrogen

gas. To avoid possible oil loss, release the

sealing cap(s) slowly. Do not remove the cap(s)

until immediately prior to connecting the air

conditioning pipes to the compressor.

Rapid refrigerant discharge

If the air conditioning system is involved in accident

damage and the system is punctured, the refrigerant

will discharge rapidly. The rapid discharge of

refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled in accordance with the 'Air

Conditioning Compressor Replacement Procedure'.

Air conditioning compressor

replacement

A new compressor is supplied filled with a full charge

of (X cm3) of refrigerant oil.

A new compressor is supplied with an oil fill (X cm) of

120 cm

3.

A calculated quantity of oil must be drained from the

new compressor before fitting. To calculate the

quantity of oil to be drained:

1Remove the drain plug from the old

compressor.

2Invert the compressor and gravity drain the oil

into a calibrated measuring cylinder. Rotate the

compressor clutch to ensure the compressor is

completely drained.

3Note the quantity of oil drained (Y cm

3).

4Calculate the quantity of oil to be drained from

the new compressor using the following

formula:

X cm

3 – (Y cm3 + 20 cm3) = Q cm3

5Remove the drain plug from the new

compressor and drain Q cm3 of oil.

6Fit and tighten the compressor drain plug.

System components

When renewing system components, add the

following quantities of refrigerant oil:

lCondenser = 40 cm

3

lEvaporator = 30 cm 3

lReceiver drier = 15 cm 3

lPipe or hose = 5 cm 3

Page 65 of 1007

GENERAL DATA

04-2

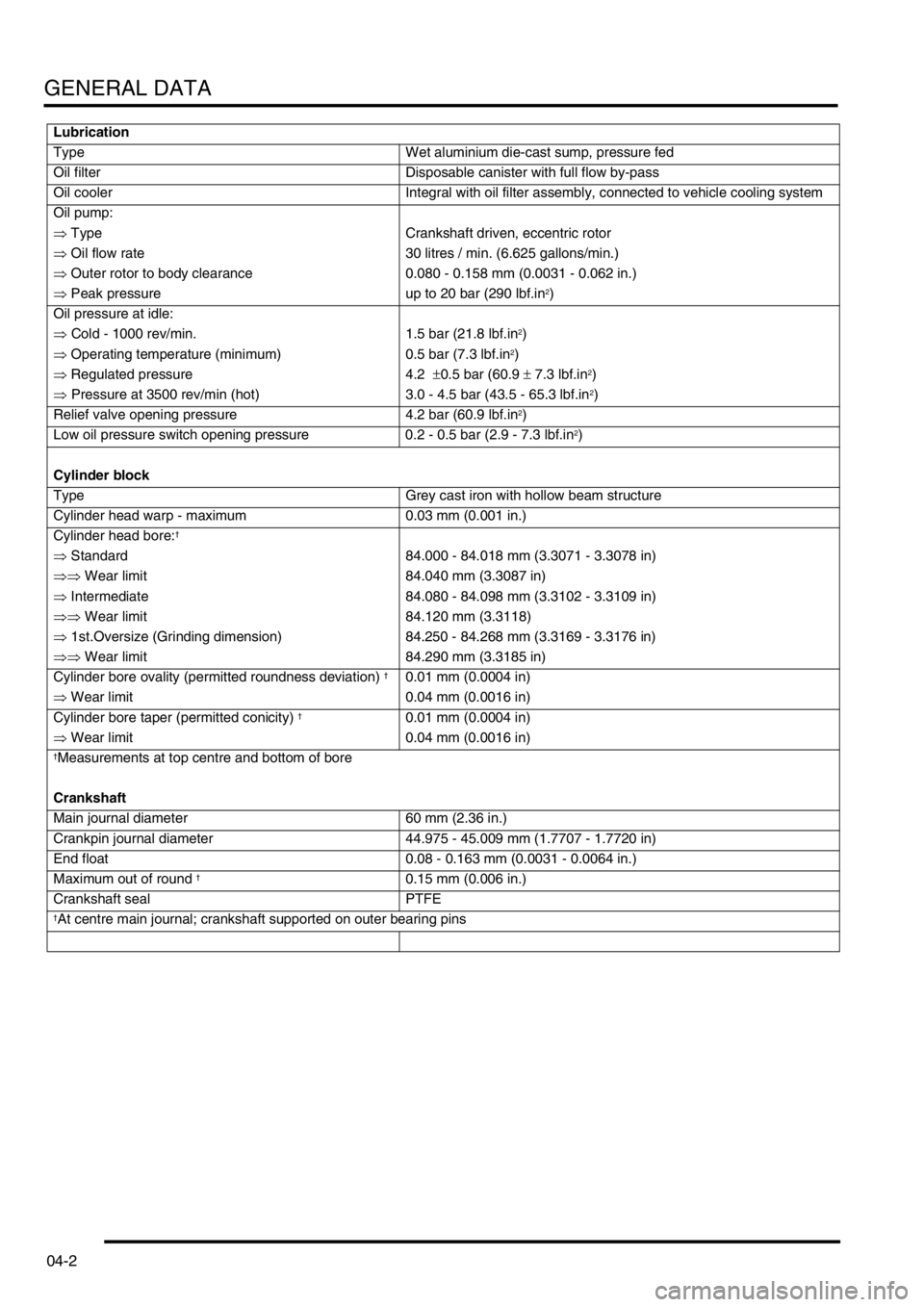

Lubrication

Type Wet aluminium die-cast sump, pressure fed

Oil filter Disposable canister with full flow by-pass

Oil cooler Integral with oil filter assembly, connected to vehicle cooling system

Oil pump:

⇒ Type Crankshaft driven, eccentric rotor

⇒ Oil flow rate 30 litres / min. (6.625 gallons/min.)

⇒ Outer rotor to body clearance 0.080 - 0.158 mm (0.0031 - 0.062 in.)

⇒ Peak pressure up to 20 bar (290 lbf.in

2)

Oil pressure at idle:

⇒ Cold - 1000 rev/min. 1.5 bar (21.8 lbf.in

2)

⇒ Operating temperature (minimum) 0.5 bar (7.3 lbf.in

2)

⇒ Regulated pressure 4.2 ±0.5 bar (60.9 ± 7.3 lbf.in

2)

⇒ Pressure at 3500 rev/min (hot) 3.0 - 4.5 bar (43.5 - 65.3 lbf.in

2)

Relief valve opening pressure 4.2 bar (60.9 lbf.in

2)

Low oil pressure switch opening pressure 0.2 - 0.5 bar (2.9 - 7.3 lbf.in

2)

Cylinder block

Type Grey cast iron with hollow beam structure

Cylinder head warp - maximum 0.03 mm (0.001 in.)

Cylinder head bore:

†

⇒ Standard 84.000 - 84.018 mm (3.3071 - 3.3078 in)

⇒⇒ Wear limit 84.040 mm (3.3087 in)

⇒ Intermediate 84.080 - 84.098 mm (3.3102 - 3.3109 in)

⇒⇒ Wear limit 84.120 mm (3.3118)

⇒ 1st.Oversize (Grinding dimension) 84.250 - 84.268 mm (3.3169 - 3.3176 in)

⇒⇒ Wear limit 84.290 mm (3.3185 in)

Cylinder bore ovality (permitted roundness deviation)

†0.01 mm (0.0004 in)

⇒ Wear limit 0.04 mm (0.0016 in)

Cylinder bore taper (permitted conicity)

†0.01 mm (0.0004 in)

⇒ Wear limit 0.04 mm (0.0016 in)

†Measurements at top centre and bottom of bore

Crankshaft

Main journal diameter 60 mm (2.36 in.)

Crankpin journal diameter 44.975 - 45.009 mm (1.7707 - 1.7720 in)

End float 0.08 - 0.163 mm (0.0031 - 0.0064 in.)

Maximum out of round

†0.15 mm (0.006 in.)

Crankshaft seal PTFE

†At centre main journal; crankshaft supported on outer bearing pins

Page 69 of 1007

GENERAL DATA

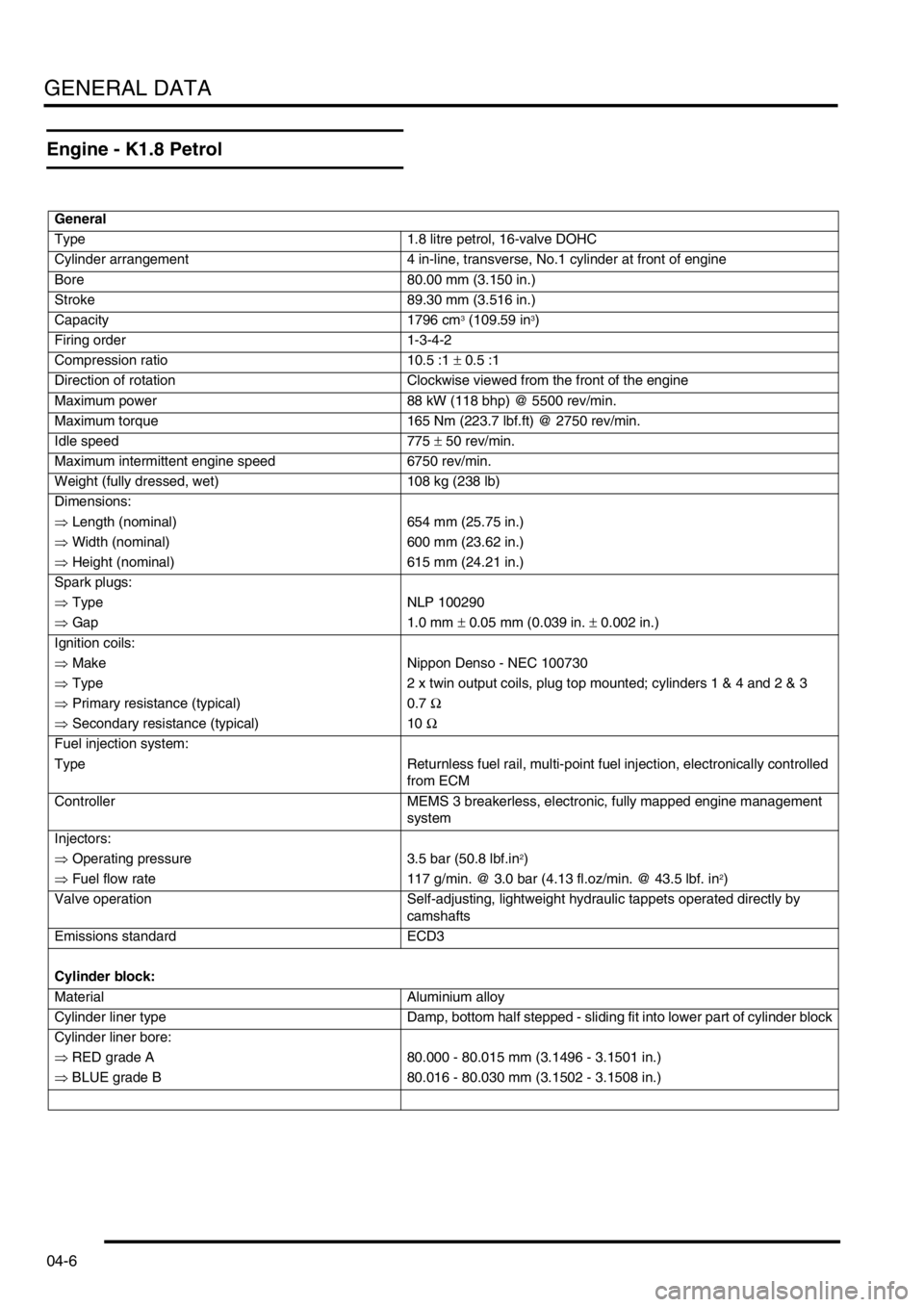

04-6

Engine - K1.8 Petrol

General

Type 1.8 litre petrol, 16-valve DOHC

Cylinder arrangement 4 in-line, transverse, No.1 cylinder at front of engine

Bore 80.00 mm (3.150 in.)

Stroke 89.30 mm (3.516 in.)

Capacity 1796 cm

3 (109.59 in3)

Firing order 1-3-4-2

Compression ratio 10.5 :1 ± 0.5 :1

Direction of rotation Clockwise viewed from the front of the engine

Maximum power 88 kW (118 bhp) @ 5500 rev/min.

Maximum torque 165 Nm (223.7 lbf.ft) @ 2750 rev/min.

Idle speed 775 ± 50 rev/min.

Maximum intermittent engine speed 6750 rev/min.

Weight (fully dressed, wet) 108 kg (238 lb)

Dimensions:

⇒ Length (nominal) 654 mm (25.75 in.)

⇒ Width (nominal) 600 mm (23.62 in.)

⇒ Height (nominal) 615 mm (24.21 in.)

Spark plugs:

⇒ Type NLP 100290

⇒ Gap 1.0 mm ± 0.05 mm (0.039 in. ± 0.002 in.)

Ignition coils:

⇒ Make Nippon Denso - NEC 100730

⇒ Type 2 x twin output coils, plug top mounted; cylinders 1 & 4 and 2 & 3

⇒ Primary resistance (typical) 0.7 Ω

⇒ Secondary resistance (typical) 10 Ω

Fuel injection system:

Type Returnless fuel rail, multi-point fuel injection, electronically controlled

from ECM

Controller MEMS 3 breakerless, electronic, fully mapped engine management

system

Injectors:

⇒ Operating pressure 3.5 bar (50.8 lbf.in

2)

⇒ Fuel flow rate 117 g/min. @ 3.0 bar (4.13 fl.oz/min. @ 43.5 lbf. in

2)

Valve operation Self-adjusting, lightweight hydraulic tappets operated directly by

camshafts

Emissions standard ECD3

Cylinder block:

Material Aluminium alloy

Cylinder liner type Damp, bottom half stepped - sliding fit into lower part of cylinder block

Cylinder liner bore:

⇒ RED grade A 80.000 - 80.015 mm (3.1496 - 3.1501 in.)

⇒ BLUE grade B 80.016 - 80.030 mm (3.1502 - 3.1508 in.)

Page 72 of 1007

GENERAL DATA

04-9

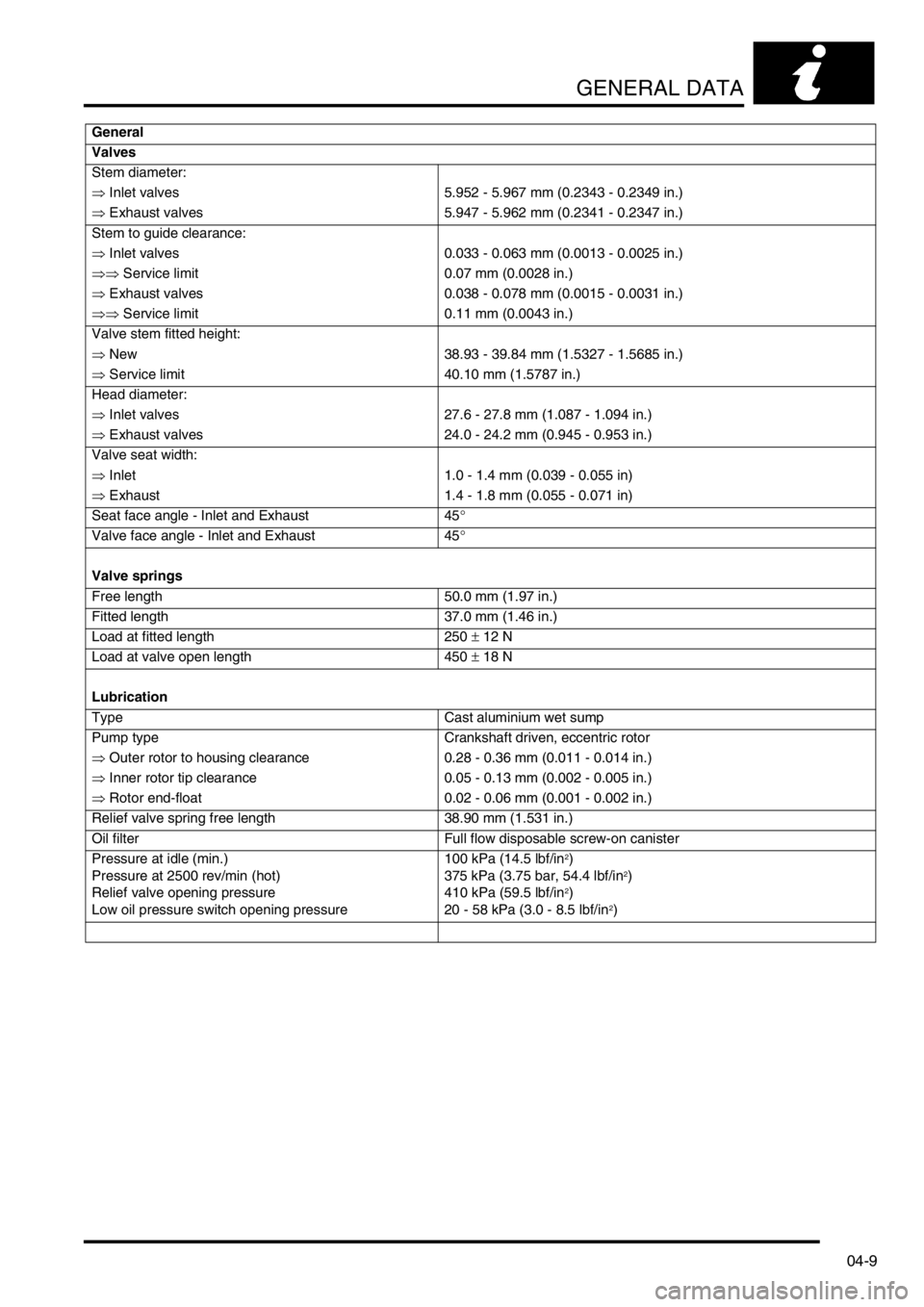

Valves

Stem diameter:

⇒ Inlet valves 5.952 - 5.967 mm (0.2343 - 0.2349 in.)

⇒ Exhaust valves 5.947 - 5.962 mm (0.2341 - 0.2347 in.)

Stem to guide clearance:

⇒ Inlet valves 0.033 - 0.063 mm (0.0013 - 0.0025 in.)

⇒⇒ Service limit 0.07 mm (0.0028 in.)

⇒ Exhaust valves 0.038 - 0.078 mm (0.0015 - 0.0031 in.)

⇒⇒ Service limit 0.11 mm (0.0043 in.)

Valve stem fitted height:

⇒ New 38.93 - 39.84 mm (1.5327 - 1.5685 in.)

⇒ Service limit 40.10 mm (1.5787 in.)

Head diameter:

⇒ Inlet valves 27.6 - 27.8 mm (1.087 - 1.094 in.)

⇒ Exhaust valves 24.0 - 24.2 mm (0.945 - 0.953 in.)

Valve seat width:

⇒ Inlet 1.0 - 1.4 mm (0.039 - 0.055 in)

⇒ Exhaust 1.4 - 1.8 mm (0.055 - 0.071 in)

Seat face angle - Inlet and Exhaust 45°

Valve face angle - Inlet and Exhaust 45°

Valve springs

Free length 50.0 mm (1.97 in.)

Fitted length 37.0 mm (1.46 in.)

Load at fitted length 250 ± 12 N

Load at valve open length 450 ± 18 N

Lubrication

Type Cast aluminium wet sump

Pump type Crankshaft driven, eccentric rotor

⇒ Outer rotor to housing clearance 0.28 - 0.36 mm (0.011 - 0.014 in.)

⇒ Inner rotor tip clearance 0.05 - 0.13 mm (0.002 - 0.005 in.)

⇒ Rotor end-float 0.02 - 0.06 mm (0.001 - 0.002 in.)

Relief valve spring free length 38.90 mm (1.531 in.)

Oil filter Full flow disposable screw-on canister

Pressure at idle (min.)

Pressure at 2500 rev/min (hot)

Relief valve opening pressure

Low oil pressure switch opening pressure100 kPa (14.5 lbf/in

2)

375 kPa (3.75 bar, 54.4 lbf/in2)

410 kPa (59.5 lbf/in2)

20 - 58 kPa (3.0 - 8.5 lbf/in2) General

Page 78 of 1007

GENERAL DATA

04-15

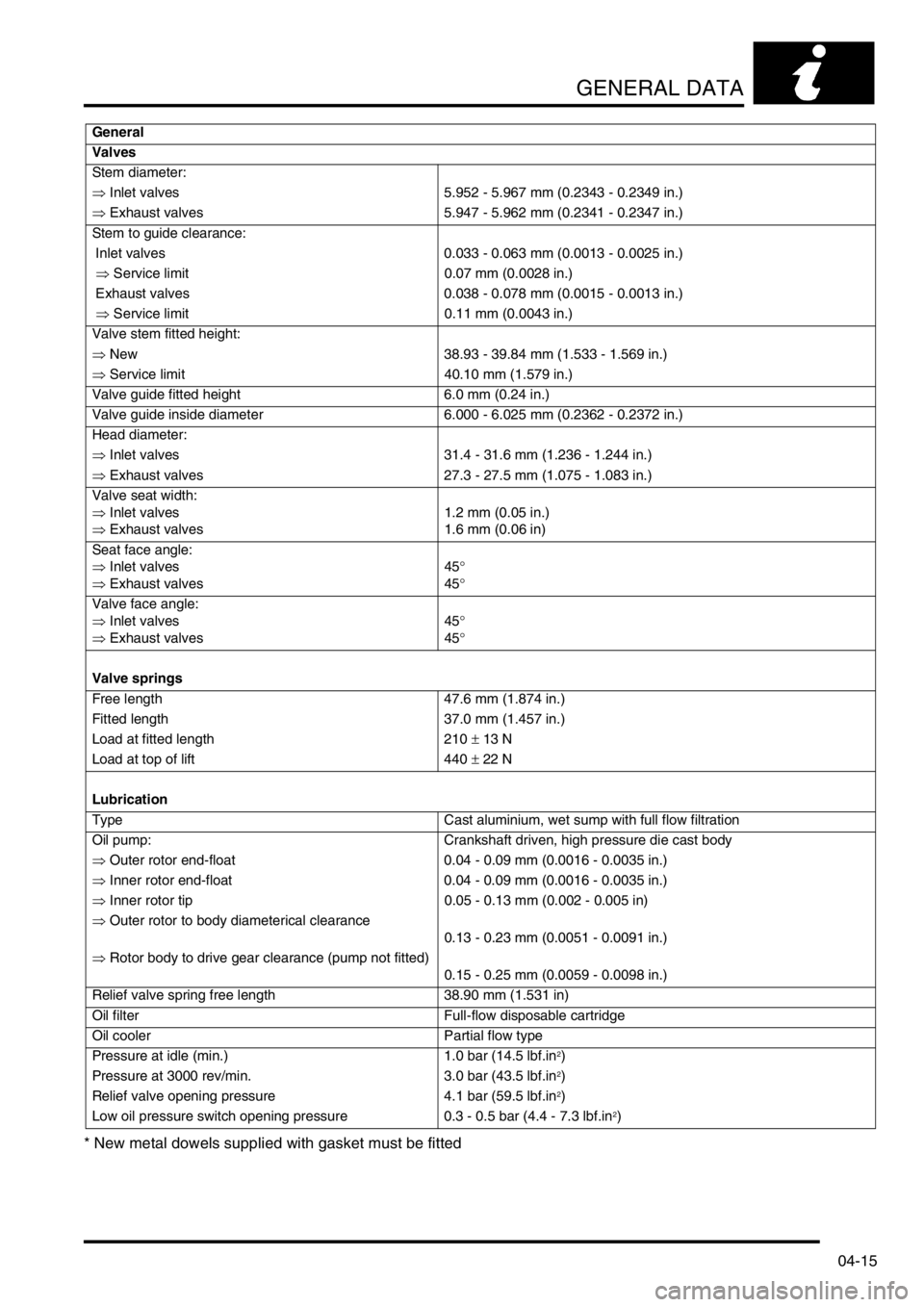

* New metal dowels supplied with gasket must be fitted

Valves

Stem diameter:

⇒ Inlet valves 5.952 - 5.967 mm (0.2343 - 0.2349 in.)

⇒ Exhaust valves 5.947 - 5.962 mm (0.2341 - 0.2347 in.)

Stem to guide clearance:

Inlet valves 0.033 - 0.063 mm (0.0013 - 0.0025 in.)

⇒ Service limit 0.07 mm (0.0028 in.)

Exhaust valves 0.038 - 0.078 mm (0.0015 - 0.0013 in.)

⇒ Service limit 0.11 mm (0.0043 in.)

Valve stem fitted height:

⇒ New 38.93 - 39.84 mm (1.533 - 1.569 in.)

⇒ Service limit 40.10 mm (1.579 in.)

Valve guide fitted height 6.0 mm (0.24 in.)

Valve guide inside diameter 6.000 - 6.025 mm (0.2362 - 0.2372 in.)

Head diameter:

⇒ Inlet valves 31.4 - 31.6 mm (1.236 - 1.244 in.)

⇒ Exhaust valves 27.3 - 27.5 mm (1.075 - 1.083 in.)

Valve seat width:

⇒ Inlet valves

⇒ Exhaust valves1.2 mm (0.05 in.)

1.6 mm (0.06 in)

Seat face angle:

⇒ Inlet valves

⇒ Exhaust valves45°

45°

Valve face angle:

⇒ Inlet valves

⇒ Exhaust valves45°

45°

Valve springs

Free length 47.6 mm (1.874 in.)

Fitted length 37.0 mm (1.457 in.)

Load at fitted length 210 ± 13 N

Load at top of lift 440 ± 22 N

Lubrication

Type Cast aluminium, wet sump with full flow filtration

Oil pump: Crankshaft driven, high pressure die cast body

⇒ Outer rotor end-float 0.04 - 0.09 mm (0.0016 - 0.0035 in.)

⇒ Inner rotor end-float 0.04 - 0.09 mm (0.0016 - 0.0035 in.)

⇒ Inner rotor tip 0.05 - 0.13 mm (0.002 - 0.005 in)

⇒ Outer rotor to body diameterical clearance

0.13 - 0.23 mm (0.0051 - 0.0091 in.)

⇒ Rotor body to drive gear clearance (pump not fitted)

0.15 - 0.25 mm (0.0059 - 0.0098 in.)

Relief valve spring free length 38.90 mm (1.531 in)

Oil filter Full-flow disposable cartridge

Oil cooler Partial flow type

Pressure at idle (min.) 1.0 bar (14.5 lbf.in

2)

Pressure at 3000 rev/min. 3.0 bar (43.5 lbf.in

2)

Relief valve opening pressure 4.1 bar (59.5 lbf.in

2)

Low oil pressure switch opening pressure 0.3 - 0.5 bar (4.4 - 7.3 lbf.in

2) General

Page 96 of 1007

GENERAL DATA

04-33

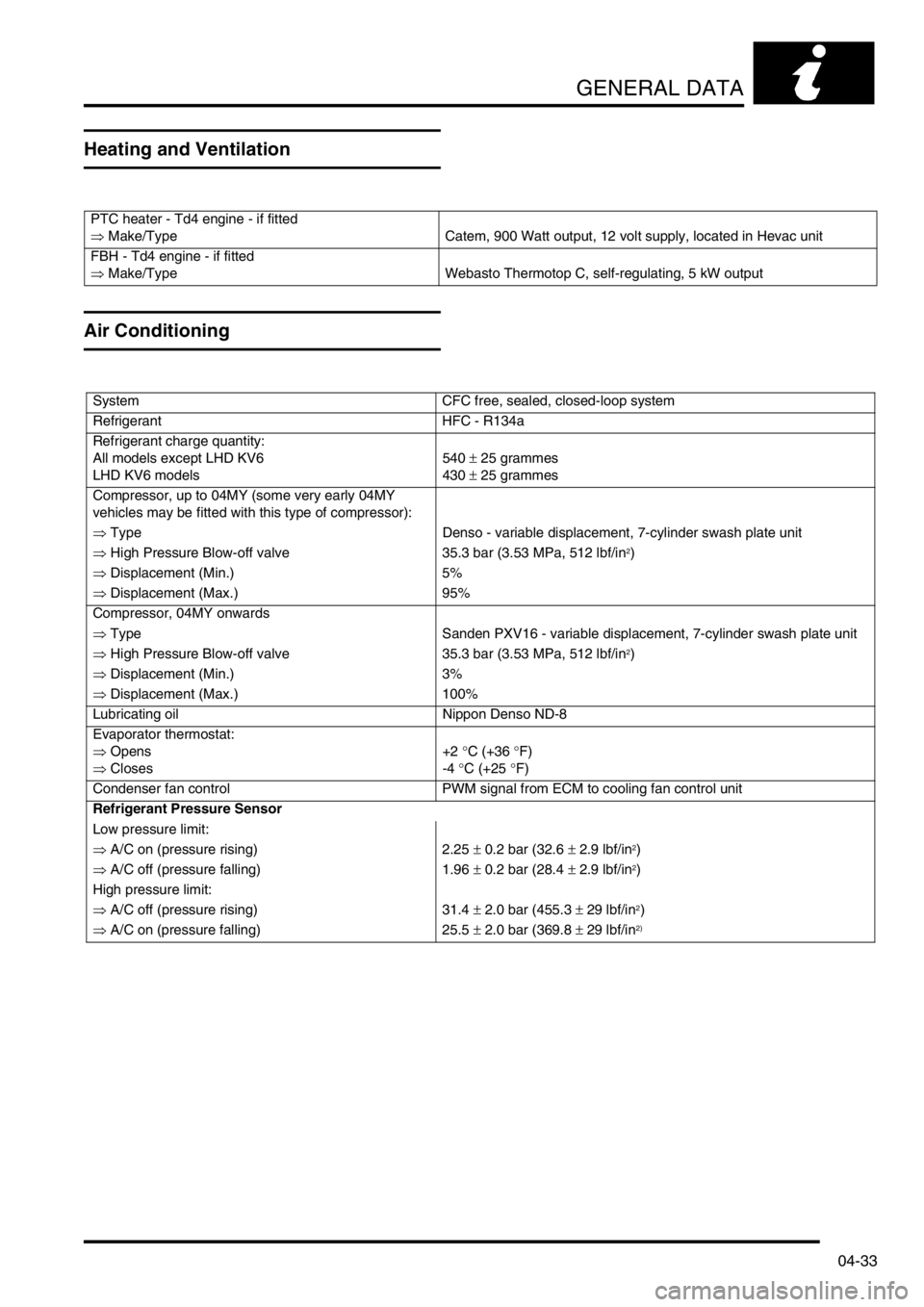

Heating and Ventilation

Air Conditioning

PTC heater - Td4 engine - if fitted

⇒ Make/Type Catem, 900 Watt output, 12 volt supply, located in Hevac unit

FBH - Td4 engine - if fitted

⇒ Make/Type Webasto Thermotop C, self-regulating, 5 kW output

System CFC free, sealed, closed-loop system

Refrigerant HFC - R134a

Refrigerant charge quantity:

All models except LHD KV6

LHD KV6 models540 ± 25 grammes

430 ± 25 grammes

Compressor, up to 04MY (some very early 04MY

vehicles may be fitted with this type of compressor):

⇒ Type Denso - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 5%

⇒ Displacement (Max.) 95%

Compressor, 04MY onwards

⇒ Type Sanden PXV16 - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 3%

⇒ Displacement (Max.) 100%

Lubricating oil Nippon Denso ND-8

Evaporator thermostat:

⇒ Opens

⇒ Closes+2 °C (+36 °F)

-4 °C (+25 °F)

Condenser fan control PWM signal from ECM to cooling fan control unit

Refrigerant Pressure Sensor

Low pressure limit:

⇒ A/C on (pressure rising) 2.25 ± 0.2 bar (32.6 ± 2.9 lbf/in

2)

⇒ A/C off (pressure falling) 1.96 ± 0.2 bar (28.4 ± 2.9 lbf/in

2)

High pressure limit:

⇒ A/C off (pressure rising) 31.4 ± 2.0 bar (455.3 ± 29 lbf/in

2)

⇒ A/C on (pressure falling) 25.5 ± 2.0 bar (369.8 ± 29 lbf/in

2)

Page 106 of 1007

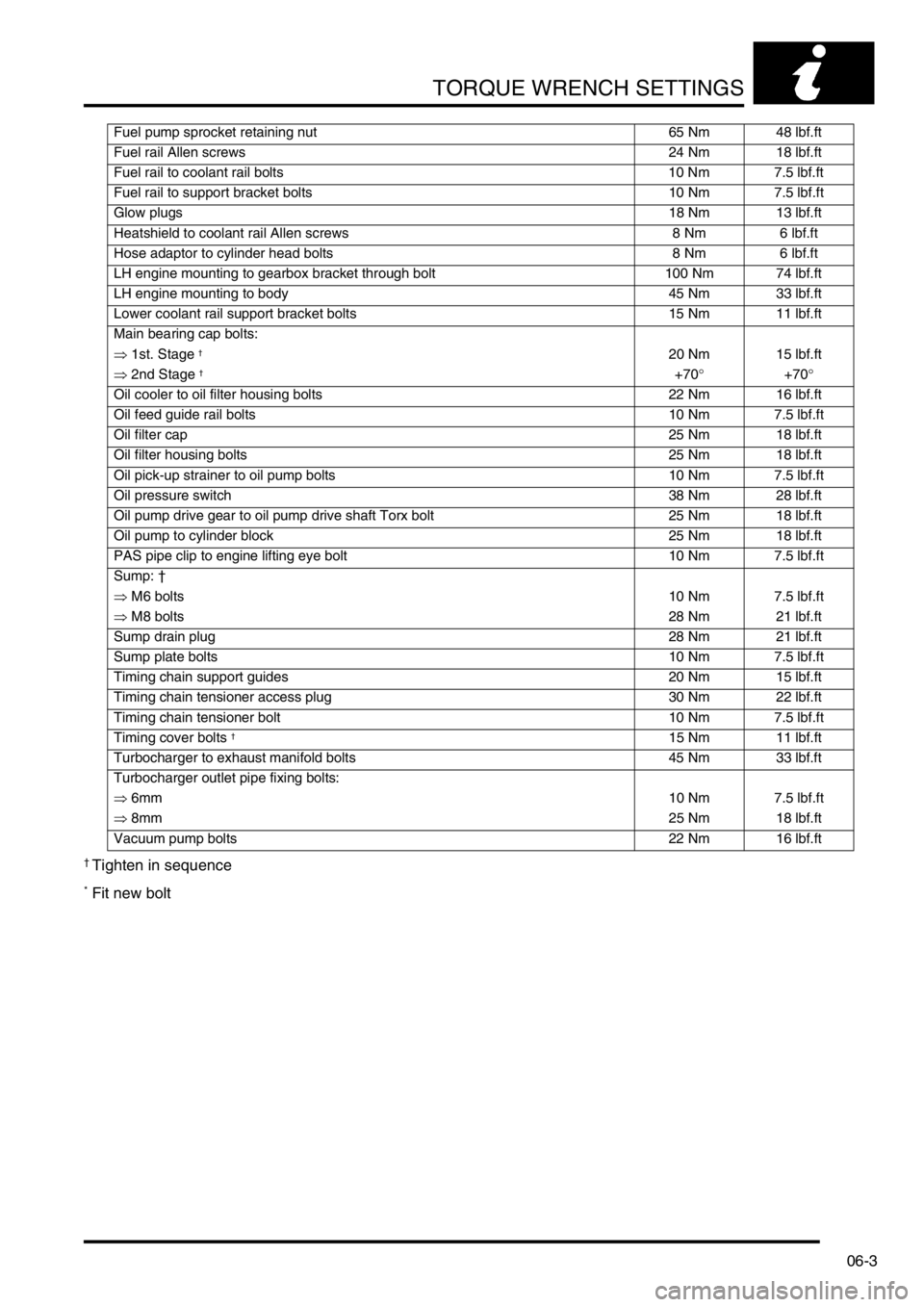

TORQUE WRENCH SETTINGS

06-3

† Tighten in sequence

* Fit new bolt

Fuel pump sprocket retaining nut 65 Nm 48 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel rail to coolant rail bolts 10 Nm 7.5 lbf.ft

Fuel rail to support bracket bolts 10 Nm 7.5 lbf.ft

Glow plugs18 Nm 13 lbf.ft

Heatshield to coolant rail Allen screws 8 Nm 6 lbf.ft

Hose adaptor to cylinder head bolts 8 Nm 6 lbf.ft

LH engine mounting to gearbox bracket through bolt 100 Nm 74 lbf.ft

LH engine mounting to body 45 Nm 33 lbf.ft

Lower coolant rail support bracket bolts 15 Nm 11 lbf.ft

Main bearing cap bolts:

⇒ 1st. Stage

† 20 Nm 15 lbf.ft

⇒ 2nd Stage

† +70°+70°

Oil cooler to oil filter housing bolts 22 Nm 16 lbf.ft

Oil feed guide rail bolts 10 Nm 7.5 lbf.ft

Oil filter cap25 Nm 18 lbf.ft

Oil filter housing bolts 25 Nm 18 lbf.ft

Oil pick-up strainer to oil pump bolts 10 Nm 7.5 lbf.ft

Oil pressure switch 38 Nm 28 lbf.ft

Oil pump drive gear to oil pump drive shaft Torx bolt 25 Nm 18 lbf.ft

Oil pump to cylinder block 25 Nm 18 lbf.ft

PAS pipe clip to engine lifting eye bolt 10 Nm 7.5 lbf.ft

Sump: †

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts28 Nm 21 lbf.ft

Sump drain plug28 Nm 21 lbf.ft

Sump plate bolts10 Nm 7.5 lbf.ft

Timing chain support guides 20 Nm 15 lbf.ft

Timing chain tensioner access plug 30 Nm 22 lbf.ft

Timing chain tensioner bolt 10 Nm 7.5 lbf.ft

Timing cover bolts

† 15 Nm 11 lbf.ft

Turbocharger to exhaust manifold bolts 45 Nm 33 lbf.ft

Turbocharger outlet pipe fixing bolts:

⇒ 6mm10 Nm 7.5 lbf.ft

⇒ 8mm25 Nm 18 lbf.ft

Vacuum pump bolts 22 Nm 16 lbf.ft