radiator LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 11 of 1007

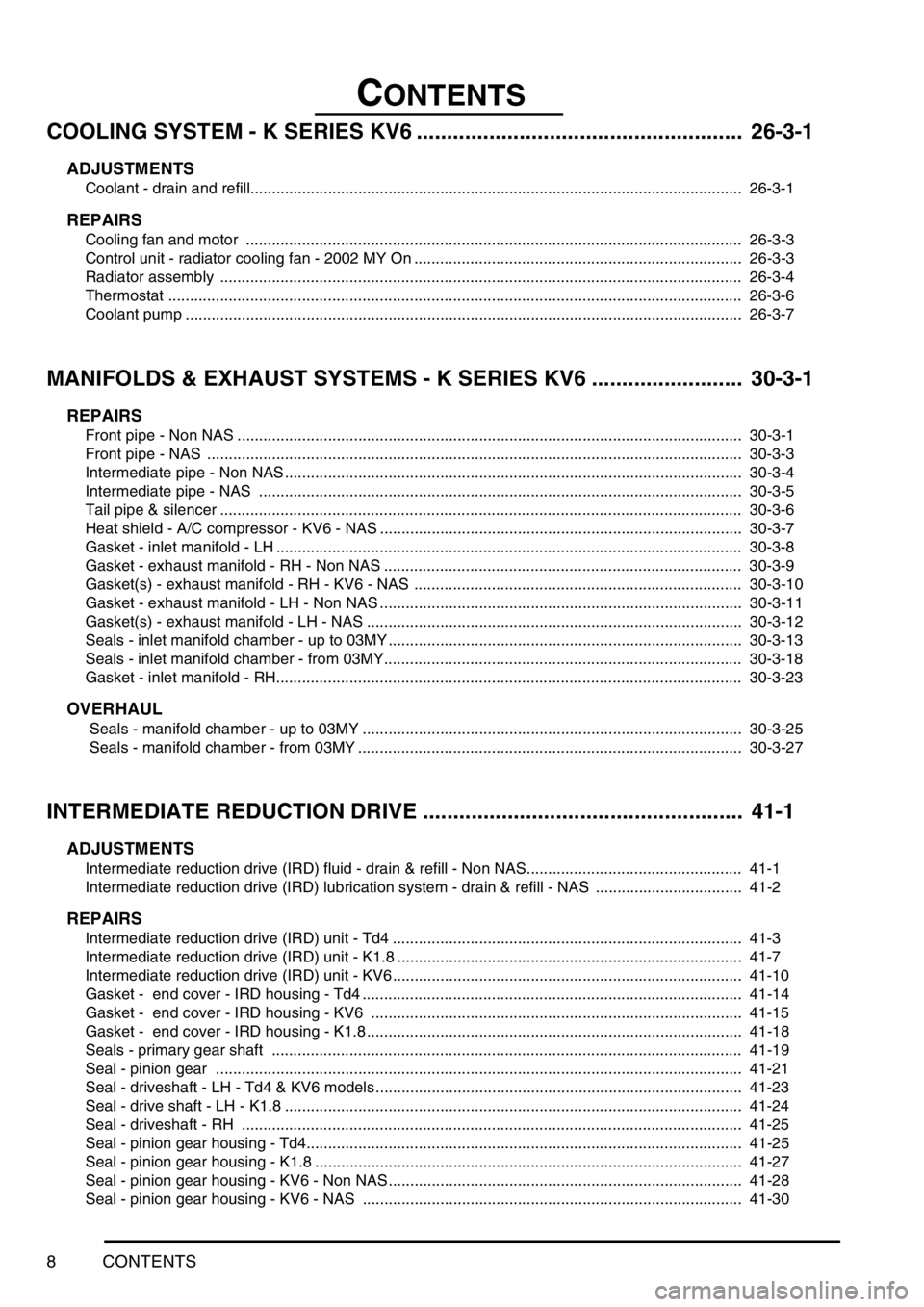

CONTENTS

8CONTENTS

COOLING SYSTEM - K SERIES KV6 ...................................................... 26-3-1

ADJUSTMENTS

Coolant - drain and refill.................................................................................................................. 26-3-1

REPAIRS

Cooling fan and motor ................................................................................................................... 26-3-3

Control unit - radiator cooling fan - 2002 MY On ............................................................................ 26-3-3

Radiator assembly ......................................................................................................................... 26-3-4

Thermostat ..................................................................................................................................... 26-3-6

Coolant pump ................................................................................................................................. 26-3-7

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6 ......................... 30-3-1

REPAIRS

Front pipe - Non NAS ..................................................................................................................... 30-3-1

Front pipe - NAS ............................................................................................................................ 30-3-3

Intermediate pipe - Non NAS .......................................................................................................... 30-3-4

Intermediate pipe - NAS ................................................................................................................ 30-3-5

Tail pipe & silencer ......................................................................................................................... 30-3-6

Heat shield - A/C compressor - KV6 - NAS .................................................................................... 30-3-7

Gasket - inlet manifold - LH ............................................................................................................ 30-3-8

Gasket - exhaust manifold - RH - Non NAS ................................................................................... 30-3-9

Gasket(s) - exhaust manifold - RH - KV6 - NAS ............................................................................ 30-3-10

Gasket - exhaust manifold - LH - Non NAS .................................................................................... 30-3-11

Gasket(s) - exhaust manifold - LH - NAS ....................................................................................... 30-3-12

Seals - inlet manifold chamber - up to 03MY .................................................................................. 30-3-13

Seals - inlet manifold chamber - from 03MY................................................................................... 30-3-18

Gasket - inlet manifold - RH............................................................................................................ 30-3-23

OVERHAUL

Seals - manifold chamber - up to 03MY ........................................................................................ 30-3-25

Seals - manifold chamber - from 03MY ......................................................................................... 30-3-27

INTERMEDIATE REDUCTION DRIVE ..................................................... 41-1

ADJUSTMENTS

Intermediate reduction drive (IRD) fluid - drain & refill - Non NAS.................................................. 41-1

Intermediate reduction drive (IRD) lubrication system - drain & refill - NAS .................................. 41-2

REPAIRS

Intermediate reduction drive (IRD) unit - Td4 ................................................................................. 41-3

Intermediate reduction drive (IRD) unit - K1.8 ................................................................................ 41-7

Intermediate reduction drive (IRD) unit - KV6 ................................................................................. 41-10

Gasket - end cover - IRD housing - Td4 ........................................................................................ 41-14

Gasket - end cover - IRD housing - KV6 ...................................................................................... 41-15

Gasket - end cover - IRD housing - K1.8 ....................................................................................... 41-18

Seals - primary gear shaft ............................................................................................................. 41-19

Seal - pinion gear .......................................................................................................................... 41-21

Seal - driveshaft - LH - Td4 & KV6 models ..................................................................................... 41-23

Seal - drive shaft - LH - K1.8 .......................................................................................................... 41-24

Seal - driveshaft - RH .................................................................................................................... 41-25

Seal - pinion gear housing - Td4..................................................................................................... 41-25

Seal - pinion gear housing - K1.8 ................................................................................................... 41-27

Seal - pinion gear housing - KV6 - Non NAS .................................................................................. 41-28

Seal - pinion gear housing - KV6 - NAS ........................................................................................ 41-30

Page 115 of 1007

TORQUE WRENCH SETTINGS

06-12

Fuel Delivery System – Diesel

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner cover Allen screws 8 Nm 6 lbf.ft

Condenser to radiator bolts 3 Nm 2.2 lbf.ft

Filler neck to body nuts and bolt 9 Nm 6.5 lbf.ft

Fuel cooler to mounting bracket bolts 10 Nm 7 lbf.ft

Fuel cooler matrix to bonnet locking platform nuts 10 Nm 7 lbf.ft

Fuel cut-off (inertia) switch to bracket nuts 2 Nm 1.5 lbf.ft

Fuel injector clamp nuts 10 Nm 7 lbf.ft

Fuel injector pipe union nuts 20 Nm 15 lbf.ft

Fuel injection pump nuts 24 Nm 18 lbf.ft

Fuel injection pump sprocket nut 65 Nm 48 lbf.ft

Fuel injector studs 10 Nm 7 lbf.ft

Fuel pressure regulator Torx screws 9 Nm 6.5 lbf.ft

Fuel pressure sensor 38 Nm 28 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rails to support bracket bolt 10 Nm 7.5 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel tank to body bolts 45 Nm 33 lbf.ft

Glow plugs20 Nm 15 lbf.ft

High pressure fuel pipe union nuts 20 Nm 15 lbf.ft

Intercooler to radiator bolts 3 Nm 2.2 lbf.ft

Low pressure fuel rail bolts 10 Nm 7 lbf.ft

Timing case access plug 30 Nm 22 lbf.ft

Turbocharger boost control solenoid valve mounting bracket to turbocharger bolts 10 Nm 7 lbf.ft

Turbocharger boost control solenoid valve to mounting rubber nuts 5 Nm 3.7 lbf.ft

Turbocharger boost pressure sensor to inlet manifold bolt 8 Nm 6 lbf.ft

Turbocharger oil drain pipe bracket bolts 20 Nm 15 lbf.ft

Turbocharger oil drain pipe flange bolts 8 Nm 6 lbf.ft

Turbocharger oil feed pipe banjo bolts 22 Nm 16 lbf.ft

Turbocharger outlet pipe to bracket bolts:

⇒ 6 mm10 Nm 7 lbf.ft

⇒ 8 mm20 Nm 15 lbf.ft

Turbocharger to exhaust manifold bolts 50 Nm 37 lbf.ft

Page 117 of 1007

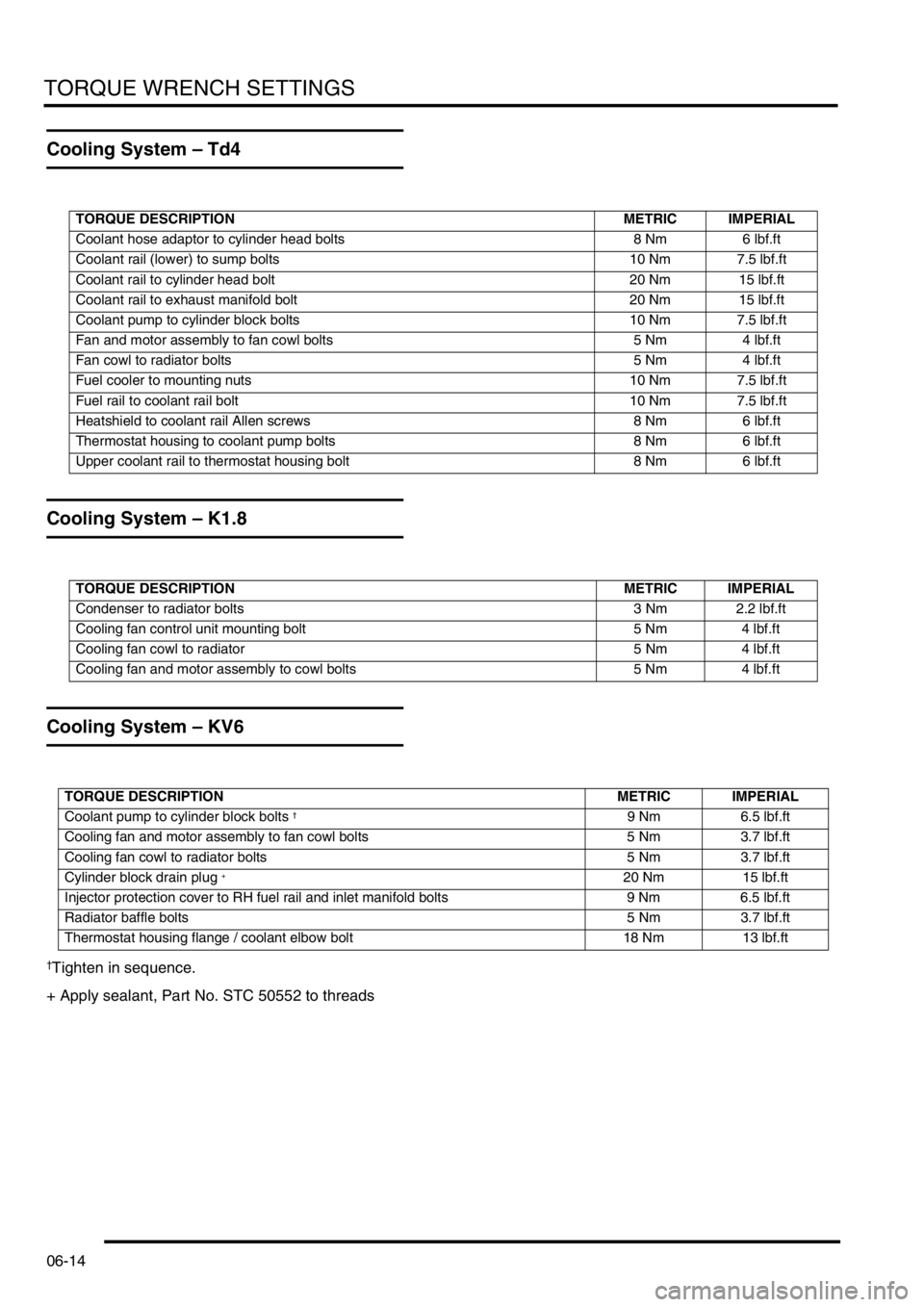

TORQUE WRENCH SETTINGS

06-14

Cooling System – Td4

Cooling System – K1.8

Cooling System – KV6

†Tighten in sequence.

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Coolant hose adaptor to cylinder head bolts 8 Nm 6 lbf.ft

Coolant rail (lower) to sump bolts 10 Nm 7.5 lbf.ft

Coolant rail to cylinder head bolt 20 Nm 15 lbf.ft

Coolant rail to exhaust manifold bolt 20 Nm 15 lbf.ft

Coolant pump to cylinder block bolts 10 Nm 7.5 lbf.ft

Fan and motor assembly to fan cowl bolts 5 Nm 4 lbf.ft

Fan cowl to radiator bolts 5 Nm 4 lbf.ft

Fuel cooler to mounting nuts 10 Nm 7.5 lbf.ft

Fuel rail to coolant rail bolt 10 Nm 7.5 lbf.ft

Heatshield to coolant rail Allen screws 8 Nm 6 lbf.ft

Thermostat housing to coolant pump bolts 8 Nm 6 lbf.ft

Upper coolant rail to thermostat housing bolt 8 Nm 6 lbf.ft

TORQUE DESCRIPTION METRIC IMPERIAL

Condenser to radiator bolts 3 Nm 2.2 lbf.ft

Cooling fan control unit mounting bolt 5 Nm 4 lbf.ft

Cooling fan cowl to radiator 5 Nm 4 lbf.ft

Cooling fan and motor assembly to cowl bolts 5 Nm 4 lbf.ft

TORQUE DESCRIPTION METRIC IMPERIAL

Coolant pump to cylinder block bolts

†9 Nm 6.5 lbf.ft

Cooling fan and motor assembly to fan cowl bolts 5 Nm 3.7 lbf.ft

Cooling fan cowl to radiator bolts 5 Nm 3.7 lbf.ft

Cylinder block drain plug

+20 Nm 15 lbf.ft

Injector protection cover to RH fuel rail and inlet manifold bolts 9 Nm 6.5 lbf.ft

Radiator baffle bolts 5 Nm 3.7 lbf.ft

Thermostat housing flange / coolant elbow bolt 18 Nm 13 lbf.ft

Page 136 of 1007

TORQUE WRENCH SETTINGS

06-33

Air Conditioning

TORQUE DESCRIPTION METRIC IMPERIAL

A/C compressor to mounting bracket bolts (Td4 & K1.8) 25 Nm 18 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (Td4 & K1.8) 45 Nm 33 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (KV6) 45 Nm 33 lbf.ft

A/C compressor support bracket to sump bolt (Td4) 10 Nm 7.5 lbf.ft

A/C compressor drive belt tensioner clamp bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor drive belt tensioner pivot bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor upper and lower securing bolts (KV6) 25 Nm 18 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

Condenser bracket to radiator bolts 8 Nm 6 lbf.ft

Receiver drier to condenser bolts 12 Nm 9 lbf.ft

Refrigerant pressure sensor 10 Nm 7.5 lbf.ft

TXV to bulkhead Allen screws 25 Nm 18 lbf.ft

Page 159 of 1007

MAINTENANCE

10-12 MAINTENANCE

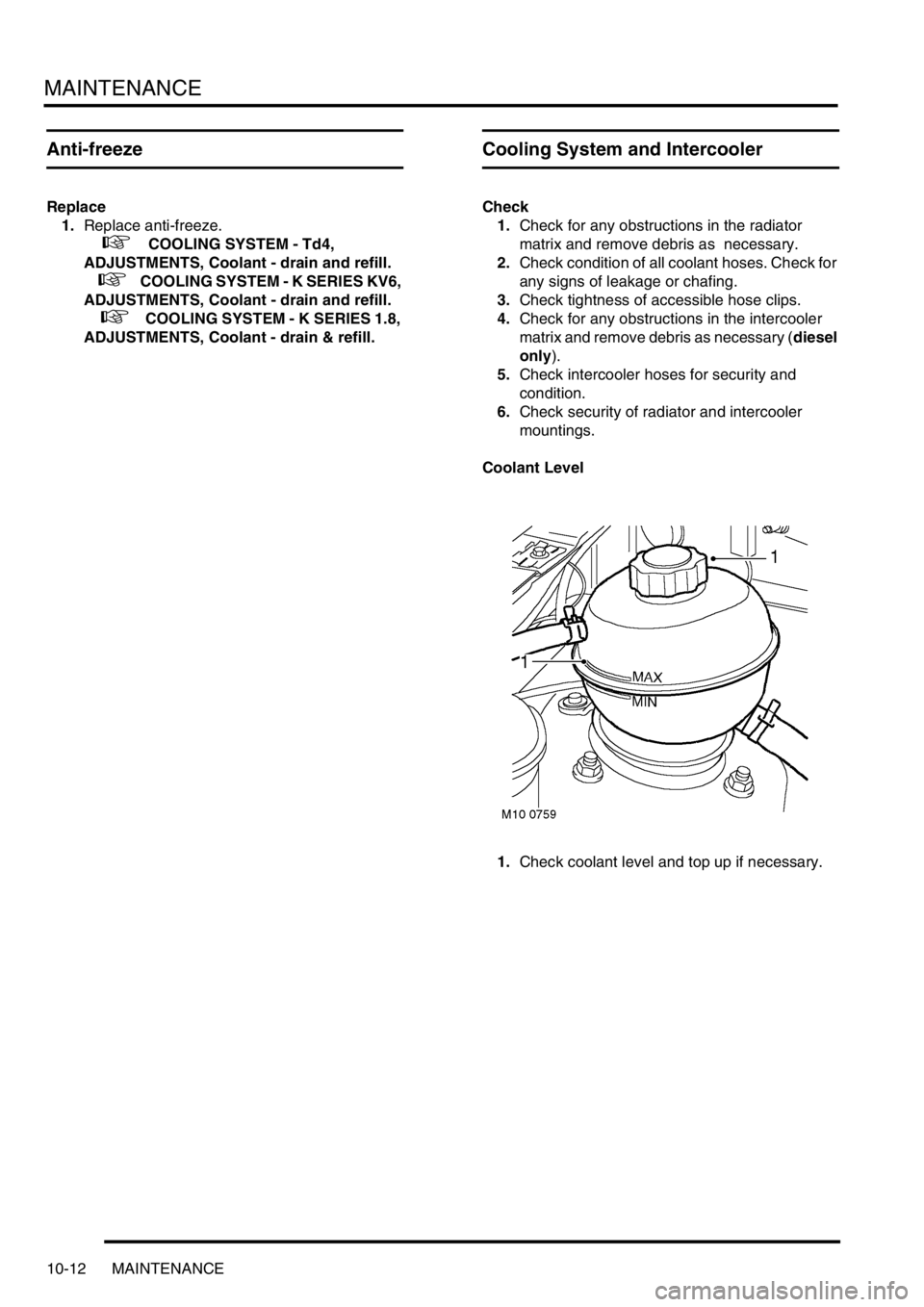

Anti-freeze

Replace

1.Replace anti-freeze.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

+ COOLING SYSTEM - K SERIES 1.8,

ADJUSTMENTS, Coolant - drain & refill.

Cooling System and Intercooler

Check

1.Check for any obstructions in the radiator

matrix and remove debris as necessary.

2.Check condition of all coolant hoses. Check for

any signs of leakage or chafing.

3.Check tightness of accessible hose clips.

4.Check for any obstructions in the intercooler

matrix and remove debris as necessary (diesel

only).

5.Check intercooler hoses for security and

condition.

6.Check security of radiator and intercooler

mountings.

Coolant Level

1.Check coolant level and top up if necessary.

Page 205 of 1007

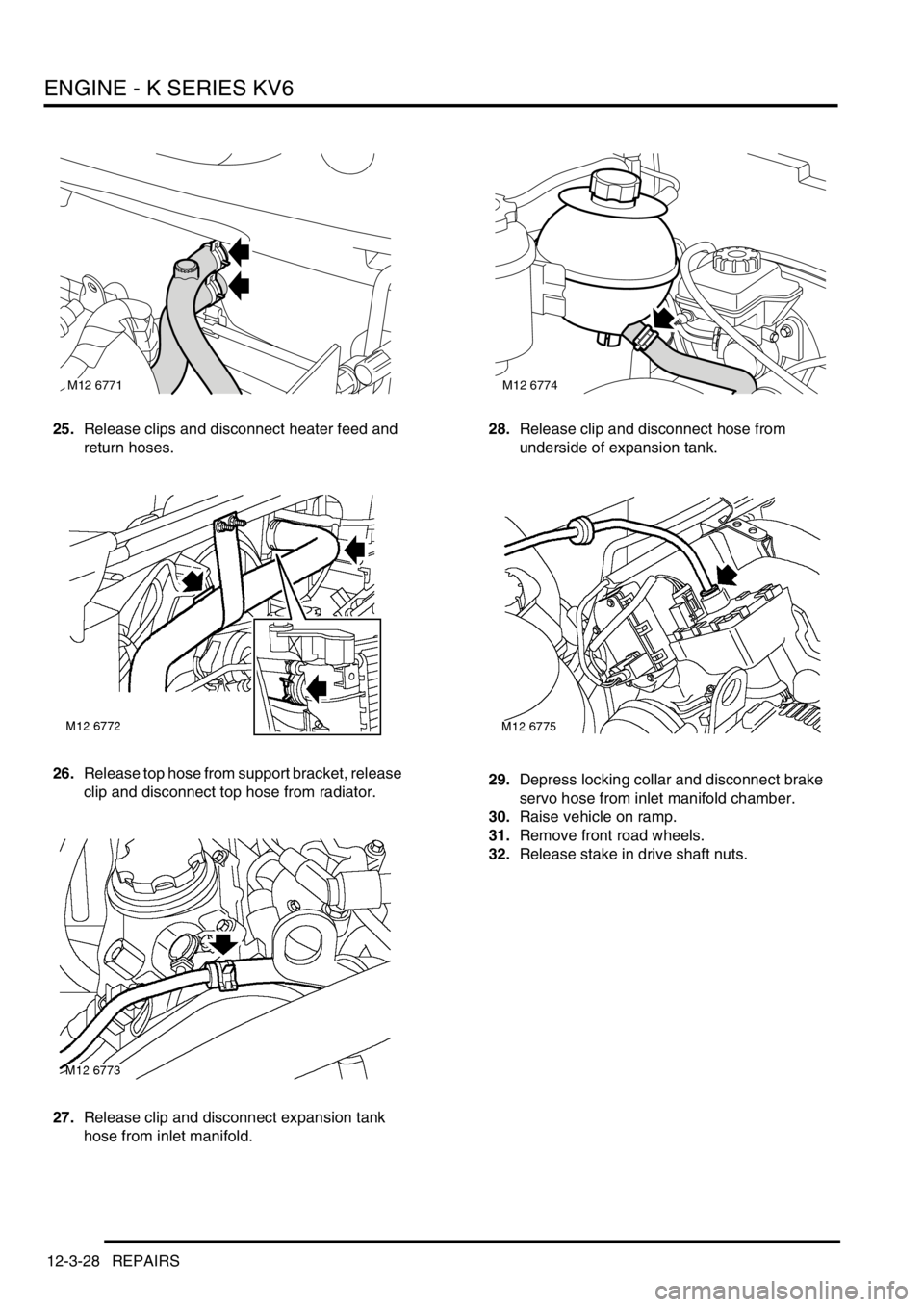

ENGINE - K SERIES KV6

12-3-28 REPAIRS

25.Release clips and disconnect heater feed and

return hoses.

26.Release top hose from support bracket, release

clip and disconnect top hose from radiator.

27.Release clip and disconnect expansion tank

hose from inlet manifold.28.Release clip and disconnect hose from

underside of expansion tank.

29.Depress locking collar and disconnect brake

servo hose from inlet manifold chamber.

30.Raise vehicle on ramp.

31.Remove front road wheels.

32.Release stake in drive shaft nuts.

M12 6771M12 6774

Page 211 of 1007

ENGINE - K SERIES KV6

12-3-34 REPAIRS

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm (295 lbf.ft).

39.Stake nut to shaft.

40.Fit front road wheels, fit and tighten nuts to 115

Nm (85 lbf.ft).

41.Lower vehicle on ramp.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

48.Secure throttle cable in clips on harness

brackets, if fitted.

49.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

50.Connect hose to purge control valve.

51.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

52.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

53.Connect Lucar connector to starter solenoid.

54.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm (18 lbf.ft).

55.Position engine harness to 'E' box mounting

bracket and secure with clips.

56.Connect earth header multiplug.

57.Connect multiplug to underbonnet fuse box.

58.Position battery and starter motor lead to

underbonnet fuse box, fit and tighten bolts to 8

Nm (6 lbf.ft).

59.Fit underbonnet fuse box cover.

60.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm (7 lbf.ft).

61.Position carrier in 'E' box and secure with clips.

62.Position and secure air duct and harness

rubber sleeve in 'E' box.

63.Connect multiplugs securing main harness to

engine harness.

64.Position ECM harness and multiplug to 'E' box,

align harness clamp and secure screws to 'E'

box.

65.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - Non NAS.

66.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.67.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

68.Connect battery earth lead.

69.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

70.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 215 of 1007

ENGINE - K SERIES KV6

12-3-38 REPAIRS

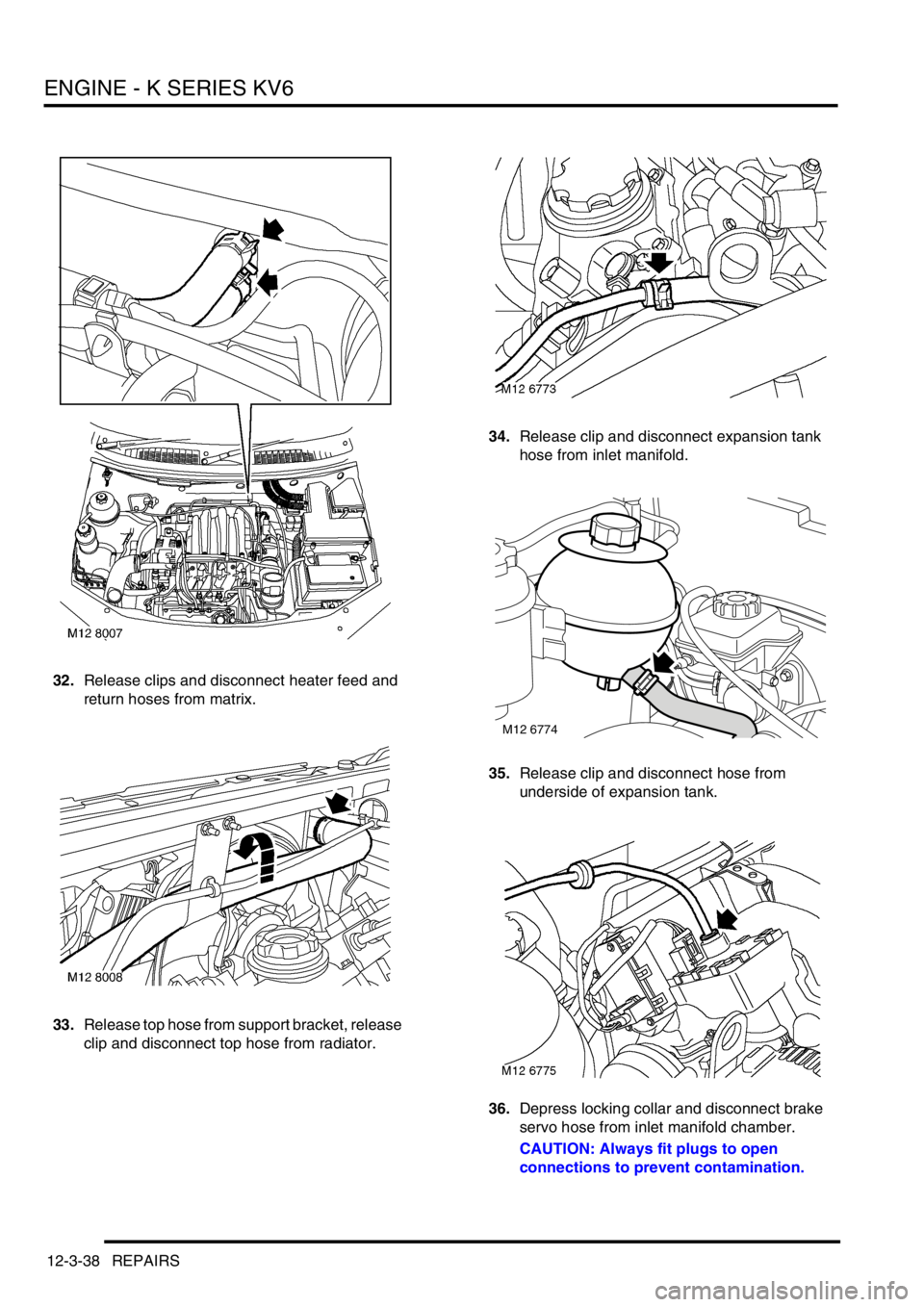

32.Release clips and disconnect heater feed and

return hoses from matrix.

33.Release top hose from support bracket, release

clip and disconnect top hose from radiator.34.Release clip and disconnect expansion tank

hose from inlet manifold.

35.Release clip and disconnect hose from

underside of expansion tank.

36.Depress locking collar and disconnect brake

servo hose from inlet manifold chamber.

CAUTION: Always fit plugs to open

connections to prevent contamination.

M12 6774

Page 221 of 1007

ENGINE - K SERIES KV6

12-3-44 REPAIRS

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm.

39.Stake nuts to drive shafts

40.Fit front road wheels, fit and tighten nuts to 115

Nm.

41.Lower vehicle on lift.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket.

48.Connect hose to purge valve.

49.Fit purge hose into clip.

50.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

51.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

52.Connect Lucar connector to starter solenoid.

53.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm.

54.Position engine harness to 'E' box mounting

bracket and secure with clips.

55.Connect earth header multiplug.

56.Connect multiplug to under bonnet fuse box.

57.Position battery and starter motor lead to under

bonnet fuse box, fit and tighten bolts to 8 Nm.

58.Fit under bonnet fuse box cover.

59.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm.

60.Fit carrier to 'E' box.

61.Fit air ducting to 'E' box.

62.Fit body harness to 'E' box, secure grommet

and harness clip.

63.Connect 'E' box cooling fan multiplug.

64.Connect multiplug to 'E' box temperature

sensor.

65.Connect multiplug to gearbox ECU.

66.Position engine harness to 'E' box and secure

grommet.67.Fit engine harness clamp and secure with

screws.

68.Connect engine harness multiplug to body

harness multiplug and fit multiplug to 'E' box.

69.Fit heated front screen harness to battery

positive cable and tighten bolt to 15 Nm (11

lbf.ft).

70.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - fuel - NAS.

71.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

72.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

73.Connect the battery earth lead.

74.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

75.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

76.Untie and close bonnet.

Page 366 of 1007

COOLING SYSTEM - K SERIES KV6

ADJUSTMENTS 26-3-1

COOLING SYS TEM - K SER IES KV6 ADJUST ME NTS

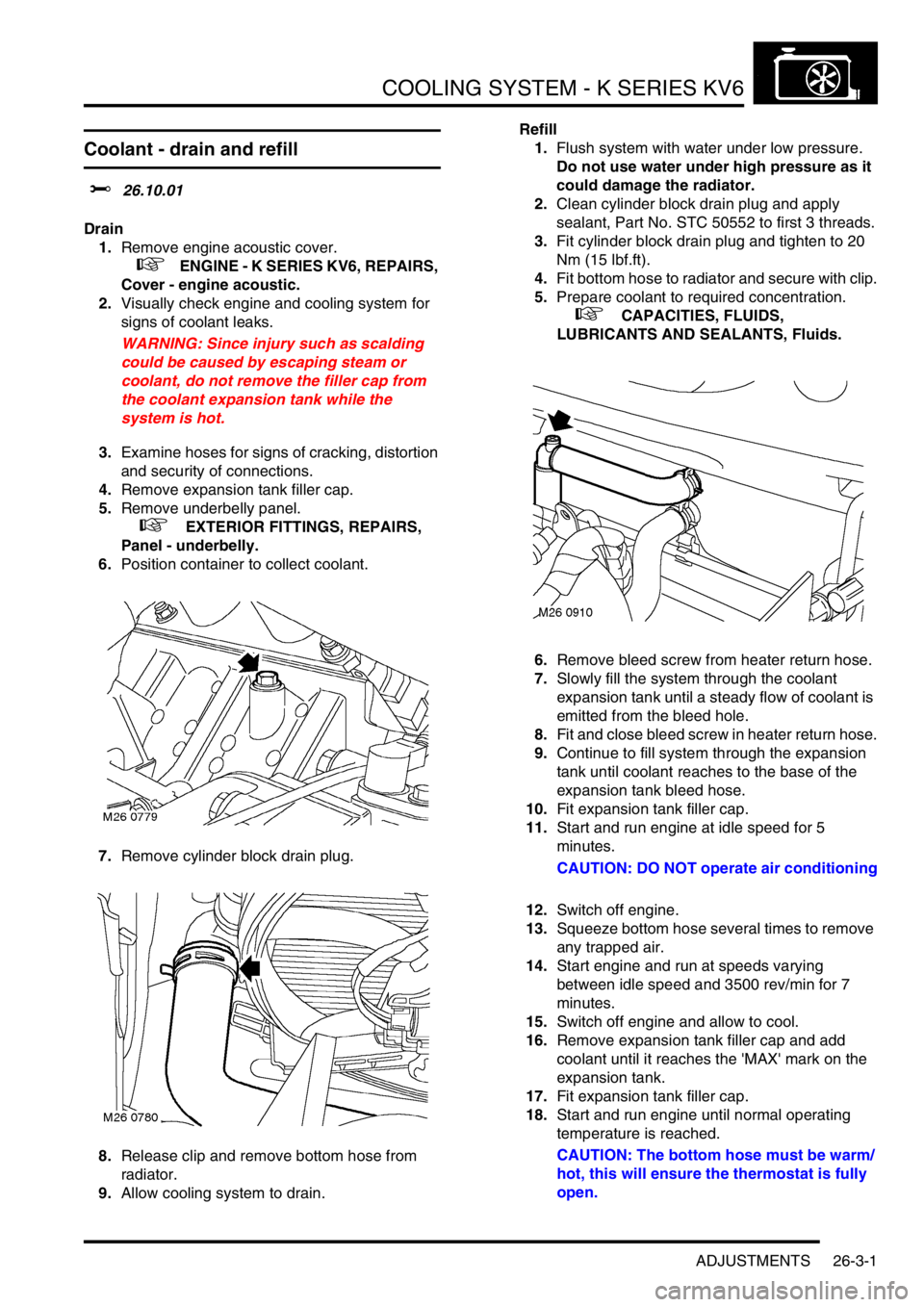

Coolant - drain and refill

$% 26.10.01

Drain

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Visually check engine and cooling system for

signs of coolant leaks.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Remove expansion tank filler cap.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Position container to collect coolant.

7.Remove cylinder block drain plug.

8.Release clip and remove bottom hose from

radiator.

9.Allow cooling system to drain.Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Clean cylinder block drain plug and apply

sealant, Part No. STC 50552 to first 3 threads.

3.Fit cylinder block drain plug and tighten to 20

Nm (15 lbf.ft).

4.Fit bottom hose to radiator and secure with clip.

5.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

6.Remove bleed screw from heater return hose.

7.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

8.Fit and close bleed screw in heater return hose.

9.Continue to fill system through the expansion

tank until coolant reaches to the base of the

expansion tank bleed hose.

10.Fit expansion tank filler cap.

11.Start and run engine at idle speed for 5

minutes.

CAUTION: DO NOT operate air conditioning

12.Switch off engine.

13.Squeeze bottom hose several times to remove

any trapped air.

14.Start engine and run at speeds varying

between idle speed and 3500 rev/min for 7

minutes.

15.Switch off engine and allow to cool.

16.Remove expansion tank filler cap and add

coolant until it reaches the 'MAX' mark on the

expansion tank.

17.Fit expansion tank filler cap.

18.Start and run engine until normal operating

temperature is reached.

CAUTION: The bottom hose must be warm/

hot, this will ensure the thermostat is fully

open.