seat adjustment LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 15 of 1007

CONTENTS

12 CONTENTS

RESTRAINT SYSTEMS ............................................................................ 75-1

REPAIRS

Automatic belt assembly - front - 3 door ......................................................................................... 75-1

Automatic belt assembly - front - 5 door ......................................................................................... 75-2

Seat belt - centre - rear ................................................................................................................... 75-3

Seat belt - rear - LH ........................................................................................................................ 75-4

Adjustable mounting - seat belt - 'B' pillar ....................................................................................... 75-5

Stalk - rear seat belt - LH - 3 door .................................................................................................. 75-6

Stalk - rear seat belt - LH - 5 door .................................................................................................. 75-7

Pre-tensioner - seat belt - front ....................................................................................................... 75-8

Pre-tensioner - seat belt - front - deployment - off vehicle ............................................................. 75-9

Stalk - rear seat belt - centre .......................................................................................................... 75-11

Air bag - steering wheel .................................................................................................................. 75-13

Air bag - fascia - passenger - up to 04MY ...................................................................................... 75-14

Air bag - fascia - passenger - from 04MY ....................................................................................... 75-15

Diagnostic control unit (DCU) ........................................................................................................ 75-16

Airbag - passenger - deployment - off vehicle ............................................................................... 75-17

Rotary coupler - (SRS) air bag system ........................................................................................... 75-19

Airbag module - steering wheel - deployment - off vehicle ............................................................ 75-20

Airbag module - steering wheel - deployment - in-vehicle .............................................................. 75-21

Pre-tensioner - front seatbelt - deployment - in-vehicle .................................................................. 75-23

DOORS...................................................................................................... 76-1-1

ADJUSTMENTS

Door - front or rear - adjust on striker ............................................................................................ 76-1-1

Door - front - align on hinges .......................................................................................................... 76-1-2

REPAIRS

Door assembly - front - remove for access & refit .......................................................................... 76-1-3

Door assembly - rear - remove for access & refit ........................................................................... 76-1-4

Door - tail assembly - remove for access & refit ............................................................................. 76-1-5

Glass - front door .......................................................................................................................... 76-1-6

Glass - rear door ............................................................................................................................ 76-1-7

Rubber/felt - glass channel - front door ........................................................................................ 76-1-8

Rubber/felt - glass channel - rear door .......................................................................................... 76-1-9

Glass - tail door .............................................................................................................................. 76-1-10

Quarter light - rear door .................................................................................................................. 76-1-11

Glass regulator - tail door .............................................................................................................. 76-1-12

Seal - waist inner - tail door ............................................................................................................ 76-1-13

Trim casing - front door - 3 door .................................................................................................... 76-1-14

Trim casing - front door - 5 door - up to 04MY................................................................................ 76-1-15

Trim casing - front door - 5 door - from 04MY ................................................................................ 76-1-16

Trim casing - rear door - up to 04MY .............................................................................................. 76-1-18

Trim casing - rear door - from 04MY............................................................................................... 76-1-20

Trim casing - tail door ..................................................................................................................... 76-1-22

Plastic sheet - front door - lower - 3 door........................................................................................ 76-1-23

Pocket - front door - 3 door ............................................................................................................. 76-1-23

Plastic sheet - front door - upper - 3 door ....................................................................................... 76-1-24

Plastic sheet - tail door ................................................................................................................... 76-1-24

Plastic sheet - front door - 5 door .................................................................................................. 76-1-25

Plastic sheet - rear door.................................................................................................................. 76-1-25

Latch - front door - 3 door ............................................................................................................... 76-1-26

Latch - front door - 5 door .............................................................................................................. 76-1-27

Latch - rear door ............................................................................................................................. 76-1-28

Latch - tail door ............................................................................................................................... 76-1-29

Page 59 of 1007

GENERAL INFORMATION

03-28

SRS component replacement policy

The following information details the policy for

replacement of SRS components; either as a result

of a vehicle accident or as a result of vehicle age.

Impacts which do not deploy the airbags or seat

belt pre-tensioners

Check for structural damage in the area of the

impact, paying particular attention to bumper

armatures, longitudinals, crash cans and bracketry.

Impacts which deploy the airbags and/or seat

belt pre-tensioners

The inspection and replacement policy is dependent

on the type and severity of the crash condition. The

following guidelines are the minimum that should be

exercised as a result of the deployment of specific

SRS components.

Front airbag/ seat belt pre-tensioner deployment

(driver and passenger)

If the front airbags and/or seat belt pre-tensioners are

deployed as a result of a front, front angled or side

impact, the following parts must be replaced:

lDriver airbag module

lPassenger airbag module (where fitted)

lSRS flyleads

lSRS DCU

lRotary coupler

lFront seat belt pre-tensioners

In addition, the following should be inspected for

damage and replaced as necessary:

lFront seat belt and buckle tongue (anchorage

points, webbing etc.)

lFascia moulding adjacent to passenger airbag

module (where fitted)

lSteering wheel (if damage is evident)

lFront seat frames and head restraints (if there is

evidence of damage to the seat frame or

cushion pan)

lSteering column (if adjustment is lost or there

are signs of collapse)

lFront seat belt height adjusters on 'BC' posts (5

door models only)

lRear seat belts and seat belt buckles (webbing,

buckle covers, body anchorage and tongue

latching function)Rear Impact

If the seat belt pre-tensioners are deployed during a

rear impact, the following components must be

replaced:

lSeat belt pre-tensioners

lFront and rear automatic seat belt assemblies

used during an impact.

lSRS DCU

In addition, the following components should be

inspected for damage and replaced as necessary:

lFront seat frames

lFront seat belts and buckle (retractors,

webbing, tongue latching, buckle covers, body

anchorages and 'D' loops)

lSeat belt height adjusters (5 door models only)

lRear seat belts and seat belt buckles (webbing,

buckle covers, body anchorage and tongue

latching function)

Periodic replacement of SRS components

The performance of the propellants within airbags

and seat belt pre-tensioners will deteriorate over a

period of time. As a result, it is essential that the

airbags and seat belt pre-tensioners are periodically

replaced to maintain occupant safety. Airbags, seat

belt pre-tensioners and the rotary coupler should be

replaced at the recommended intervals.

Page 210 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-33

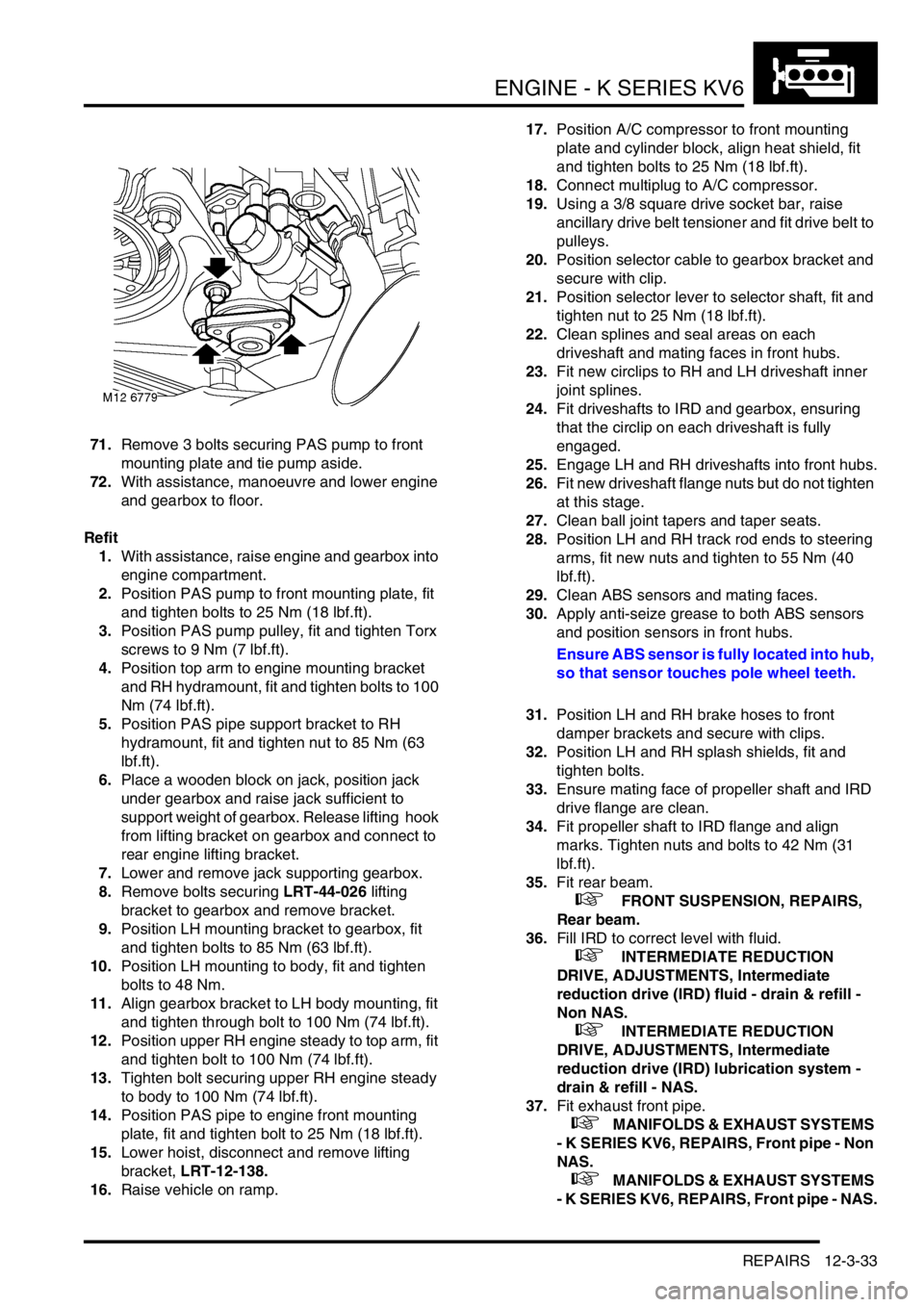

71.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

72.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm (18 lbf.ft).

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm (74 lbf.ft).

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm (63

lbf.ft).

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.

8.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm (18 lbf.ft).

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on ramp.17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

18.Connect multiplug to A/C compressor.

19.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm (18 lbf.ft).

22.Clean splines and seal areas on each

driveshaft and mating faces in front hubs.

23.Fit new circlips to RH and LH driveshaft inner

joint splines.

24.Fit driveshafts to IRD and gearbox, ensuring

that the circlip on each driveshaft is fully

engaged.

25.Engage LH and RH driveshafts into front hubs.

26.Fit new driveshaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm (40

lbf.ft).

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

Ensure ABS sensor is fully located into hub,

so that sensor touches pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

Page 428 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-25

Seal - driveshaft - RH

$% 41.29.09

Remove

1.Remove RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

Refit

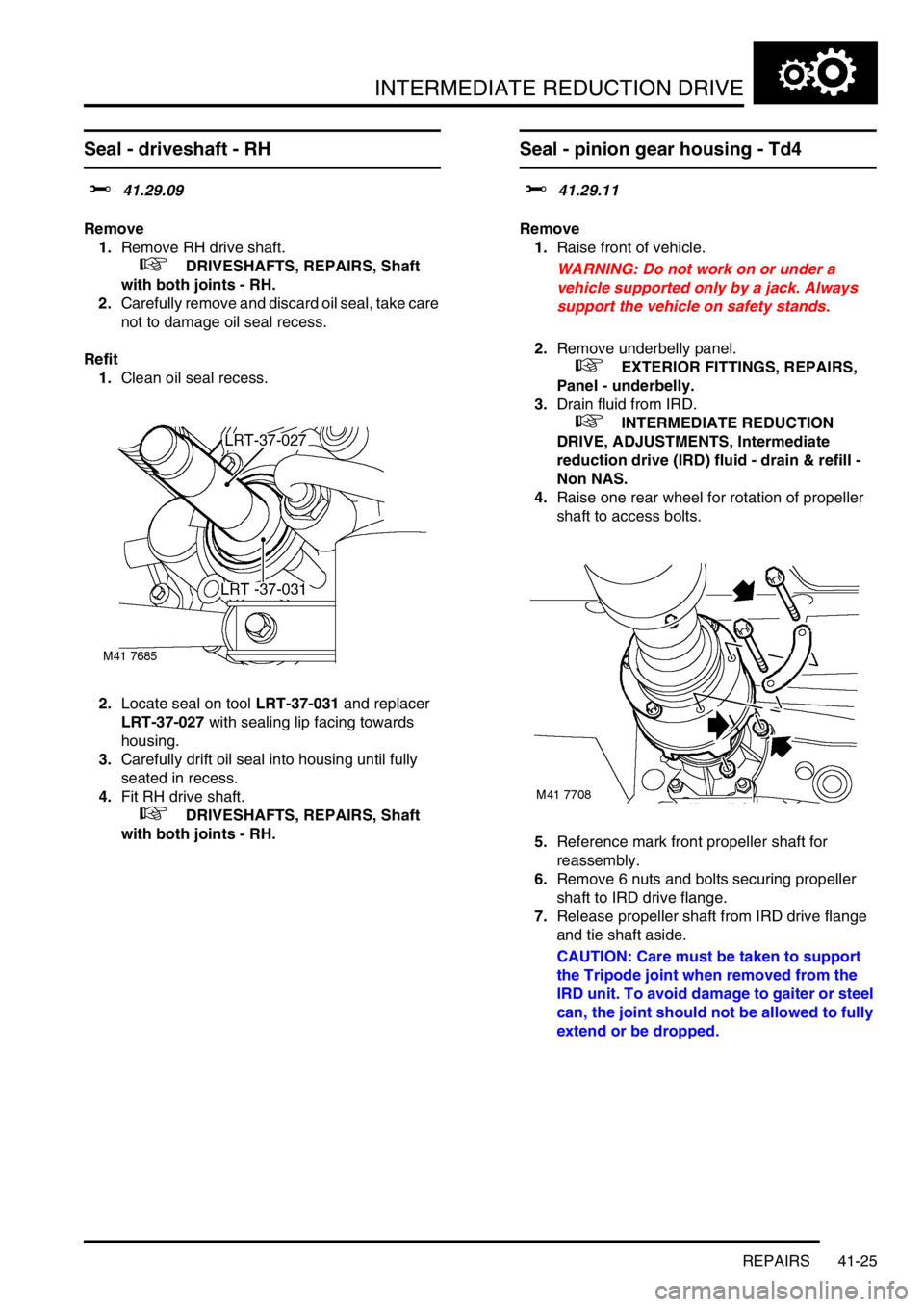

1.Clean oil seal recess.

2.Locate seal on tool LRT-37-031 and replacer

LRT-37-027 with sealing lip facing towards

housing.

3.Carefully drift oil seal into housing until fully

seated in recess.

4.Fit RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

Seal - pinion gear housing - Td4

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

Page 516 of 1007

STEERING

REPAIRS 57-23

Ball joint - track rod

$% 57.55.07

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheel.

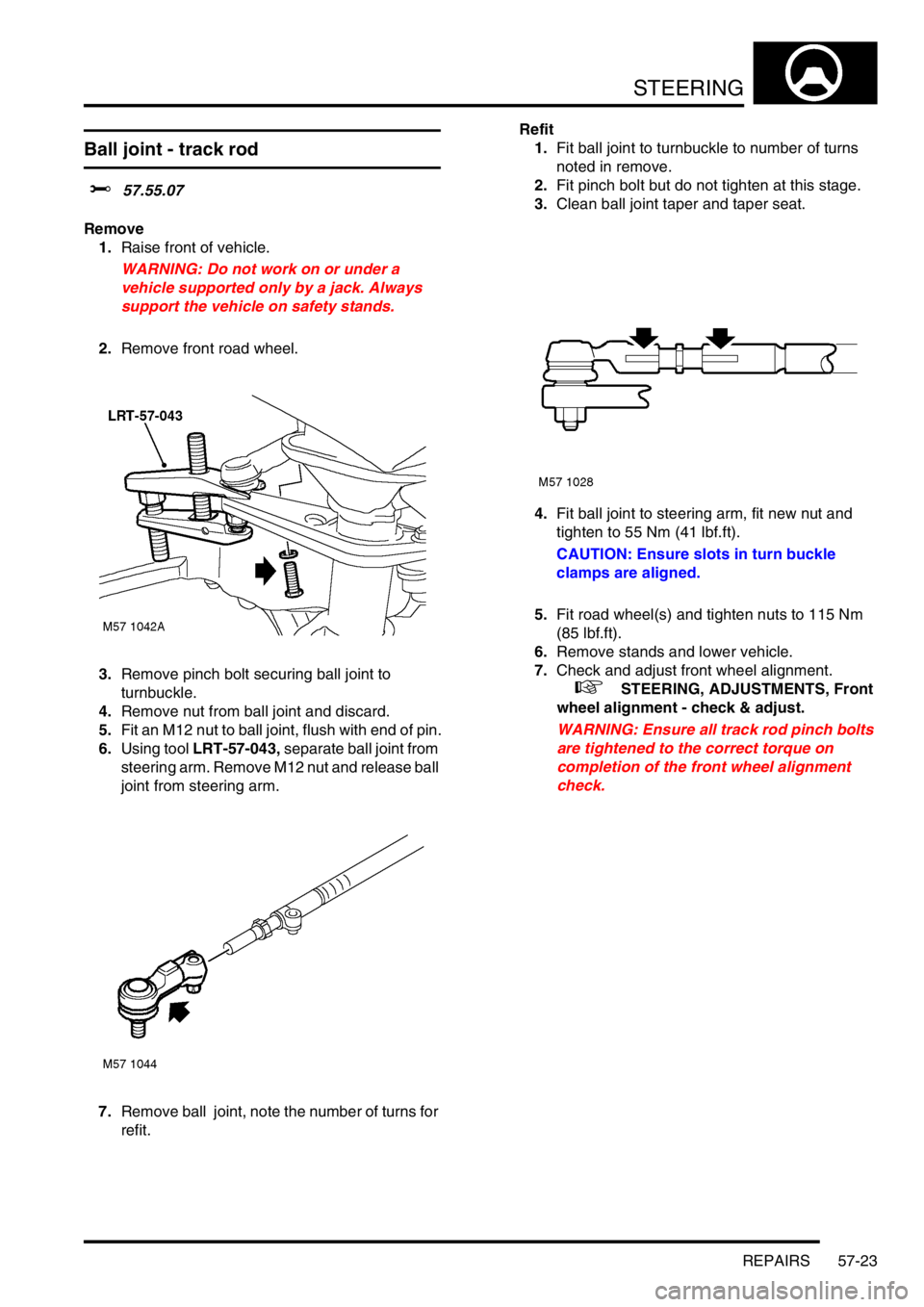

3.Remove pinch bolt securing ball joint to

turnbuckle.

4.Remove nut from ball joint and discard.

5.Fit an M12 nut to ball joint, flush with end of pin.

6.Using tool LRT-57-043, separate ball joint from

steering arm. Remove M12 nut and release ball

joint from steering arm.

7.Remove ball joint, note the number of turns for

refit.Refit

1.Fit ball joint to turnbuckle to number of turns

noted in remove.

2.Fit pinch bolt but do not tighten at this stage.

3.Clean ball joint taper and taper seat.

4.Fit ball joint to steering arm, fit new nut and

tighten to 55 Nm (41 lbf.ft).

CAUTION: Ensure slots in turn buckle

clamps are aligned.

5.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

6.Remove stands and lower vehicle.

7.Check and adjust front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

WARNING: Ensure all track rod pinch bolts

are tightened to the correct torque on

completion of the front wheel alignment

check.

Page 542 of 1007

REAR SUSPENSION

REPAIRS 64-7

17.Remove cover from top mounting.

18.Compress spring by 2 to 3 cm until loose, hold

damper shaft with Allen key, remove and

discard mounting plate nut.

19.Remove top mounting plate.

20.Remove rebound washer and mounting plate.

21.Remove spring aid and bump plate.

22.Remove spring seat, dust cover and bump stop

cup.

23.Remove damper from spring.

24.Release and remove spring from compressor.Refit

1.Inspect damper, spring mounting rubbers and

bearing for deterioration and damage.

2.Clean mating faces of spring, mounting and

mounting plate.

3.Clean damper shaft and bump stop plate.

4.Position spring and damper assembly to spring

compressor. Compress spring.

5.Fit damper to spring, ensure spring locates in

cut recess in damper plate.

6.Fit bump stop, bump stop cup and dust cover to

damper.

7.Fit spring aid and bump plate.

8.Fit mounting plate and rebound washer.

9.Using new nut, hold damper shaft with Allen

key and tighten nut to 57 Nm (42 lbf.ft).

CAUTION: Note alignment of top mounting,

spring and damper dust cover.

10.Fit top mounting cover.

11.Release and remove spring from compressor.

12.Clean mating face of top mounting plate.

13.Fit rubber seal to top mounting.

14.Position damper assembly and align top

mounting to body, fit nuts and tighten to 45 Nm

(33 lbf.ft).

15.Fit rear quarter lower trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 5 door.

16.Fit hub to damper and tighten bolts to 205 Nm

(151 lbf.ft).

17.Clean ABS sensor, smear sensor with an anti-

seize grease and fit sensor to hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

18.Secure brake hose and ABS sensor harness to

damper.

19.Secure brake hose with 'C' clip.

20.Remove plugs and clean brake pipe male end.

21.Align hose to brake pipe and tighten union to 14

Nm (10 lbf.ft).

22.Remove clamp from brake hose.

23.Bleed brake system.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

24.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

25.Remove stands and lower vehicle.