transmission fluid LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 404 of 1007

INTERMEDIATE REDUCTION DRIVE

ADJUSTMENTS 41-1

INTERMEDIATE RE DUCTION DRIVE ADJUST ME NTS

Intermediate reduction drive (IRD) fluid -

drain & refill - Non NAS

$% 41.25.06

Drain

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

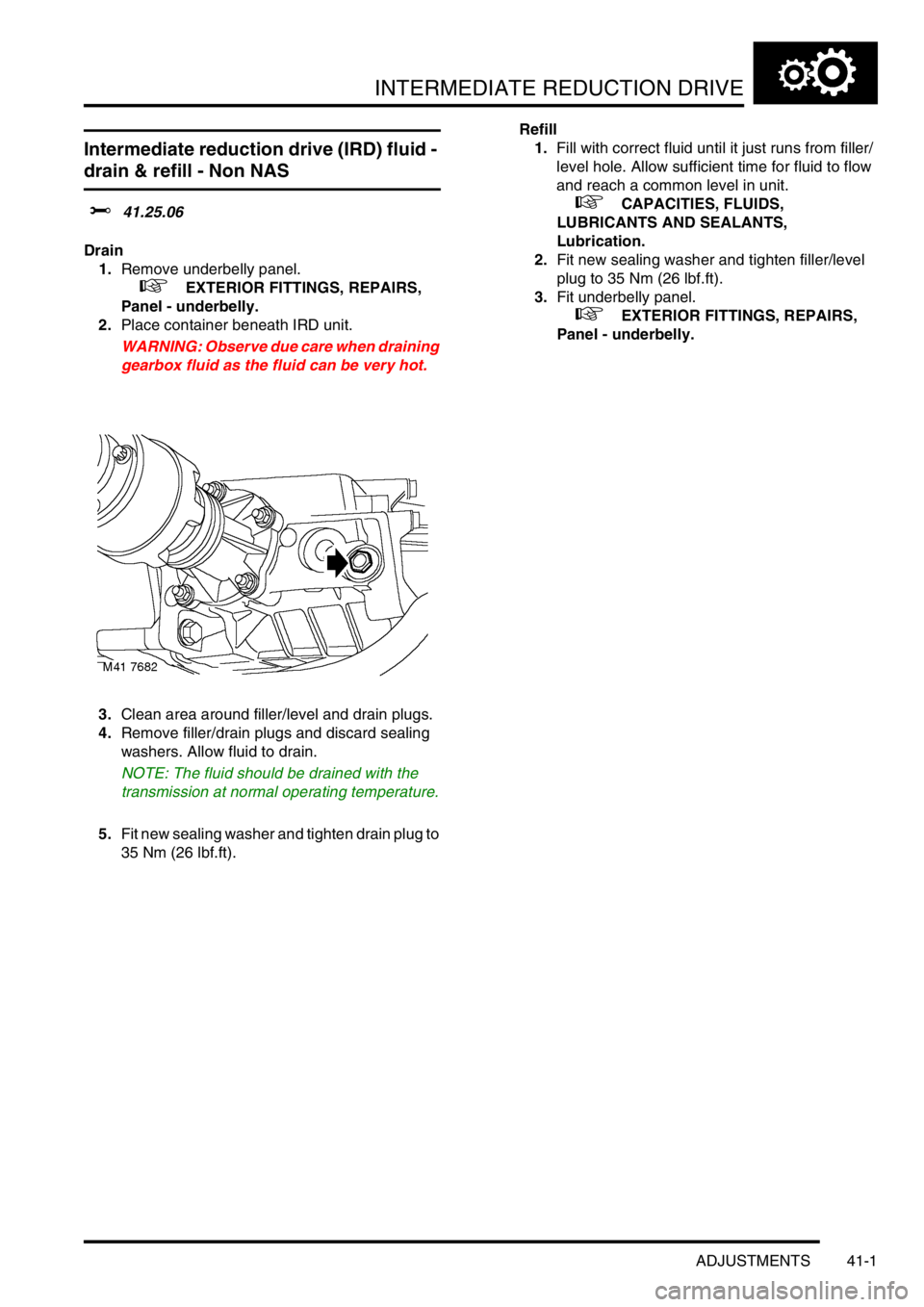

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Clean area around filler/level and drain plugs.

4.Remove filler/drain plugs and discard sealing

washers. Allow fluid to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

5.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).Refill

1.Fill with correct fluid until it just runs from filler/

level hole. Allow sufficient time for fluid to flow

and reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 405 of 1007

INTERMEDIATE REDUCTION DRIVE

41-2 ADJUSTMENTS

Intermediate reduction drive (IRD)

lubrication system - drain & refill - NAS

$% 41.25.06

Drain

1.Remove underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

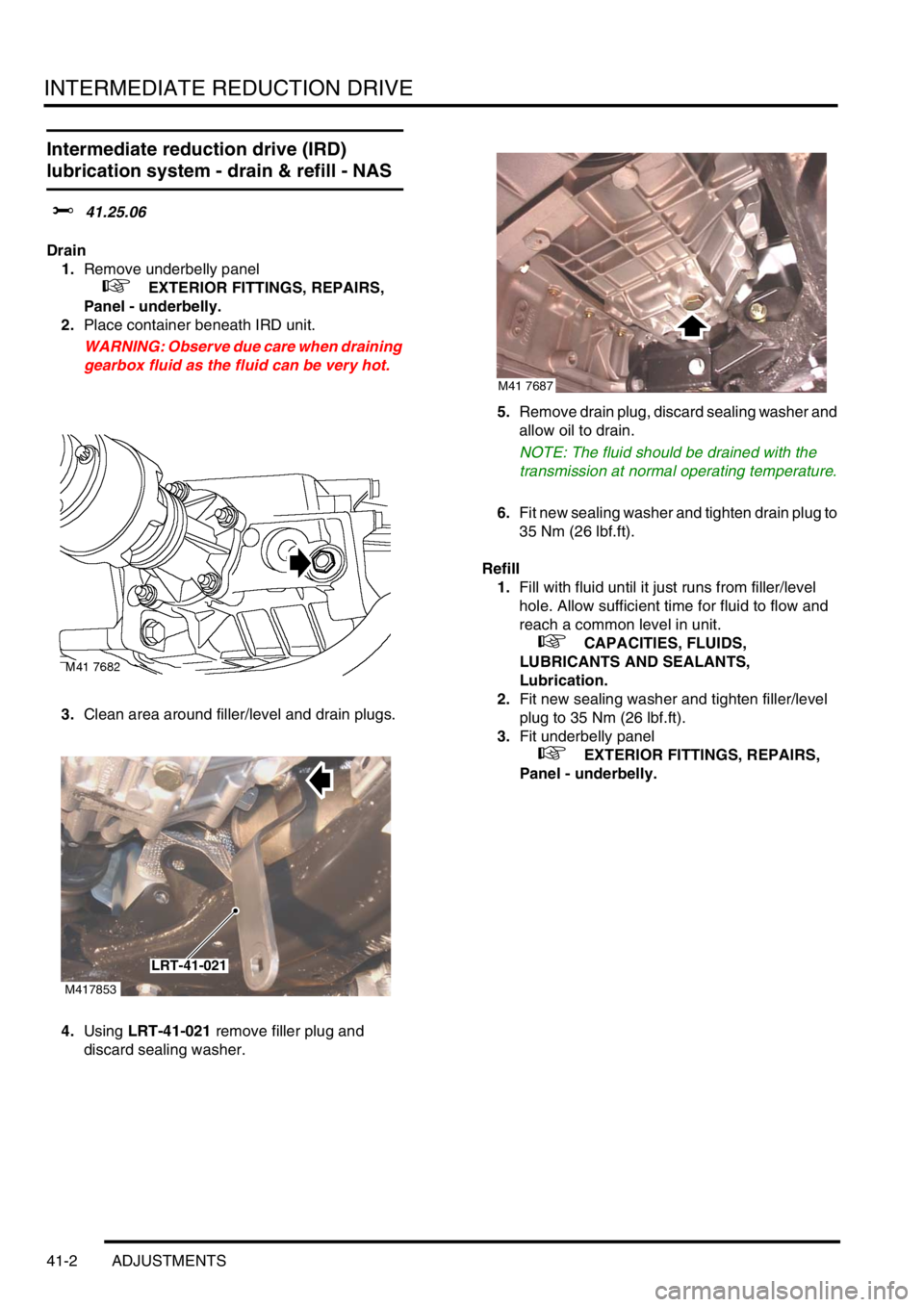

3.Clean area around filler/level and drain plugs.

4.Using LRT-41-021 remove filler plug and

discard sealing washer.5.Remove drain plug, discard sealing washer and

allow oil to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

6.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).

Refill

1.Fill with fluid until it just runs from filler/level

hole. Allow sufficient time for fluid to flow and

reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M417853

LRT-41-021

M41 7687

Page 437 of 1007

AUTOMATIC GEARBOX - JATCO

44-2 ADJUSTMENTS

Gearbox fluid - drain & refill

$% 44.24.02

Drain

1.Position vehicle on ramp.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Position container under gearbox.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

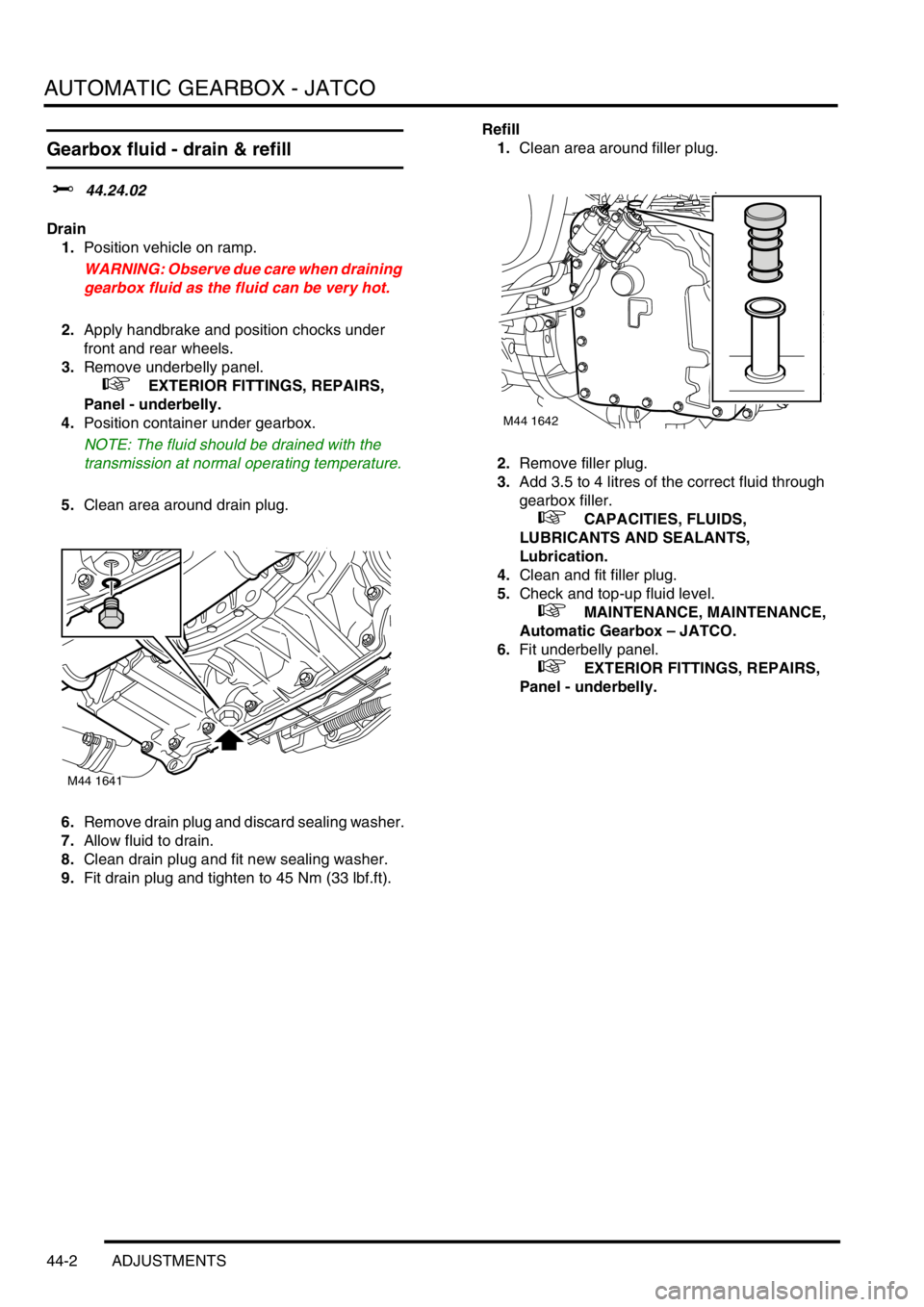

5.Clean area around drain plug.

6.Remove drain plug and discard sealing washer.

7.Allow fluid to drain.

8.Clean drain plug and fit new sealing washer.

9.Fit drain plug and tighten to 45 Nm (33 lbf.ft).Refill

1.Clean area around filler plug.

2.Remove filler plug.

3.Add 3.5 to 4 litres of the correct fluid through

gearbox filler.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

4.Clean and fit filler plug.

5.Check and top-up fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M44 1641

M44 1642

Page 446 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-11

Oil seal - torque converter

$% 44.17.11

Remove

1.Remove gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

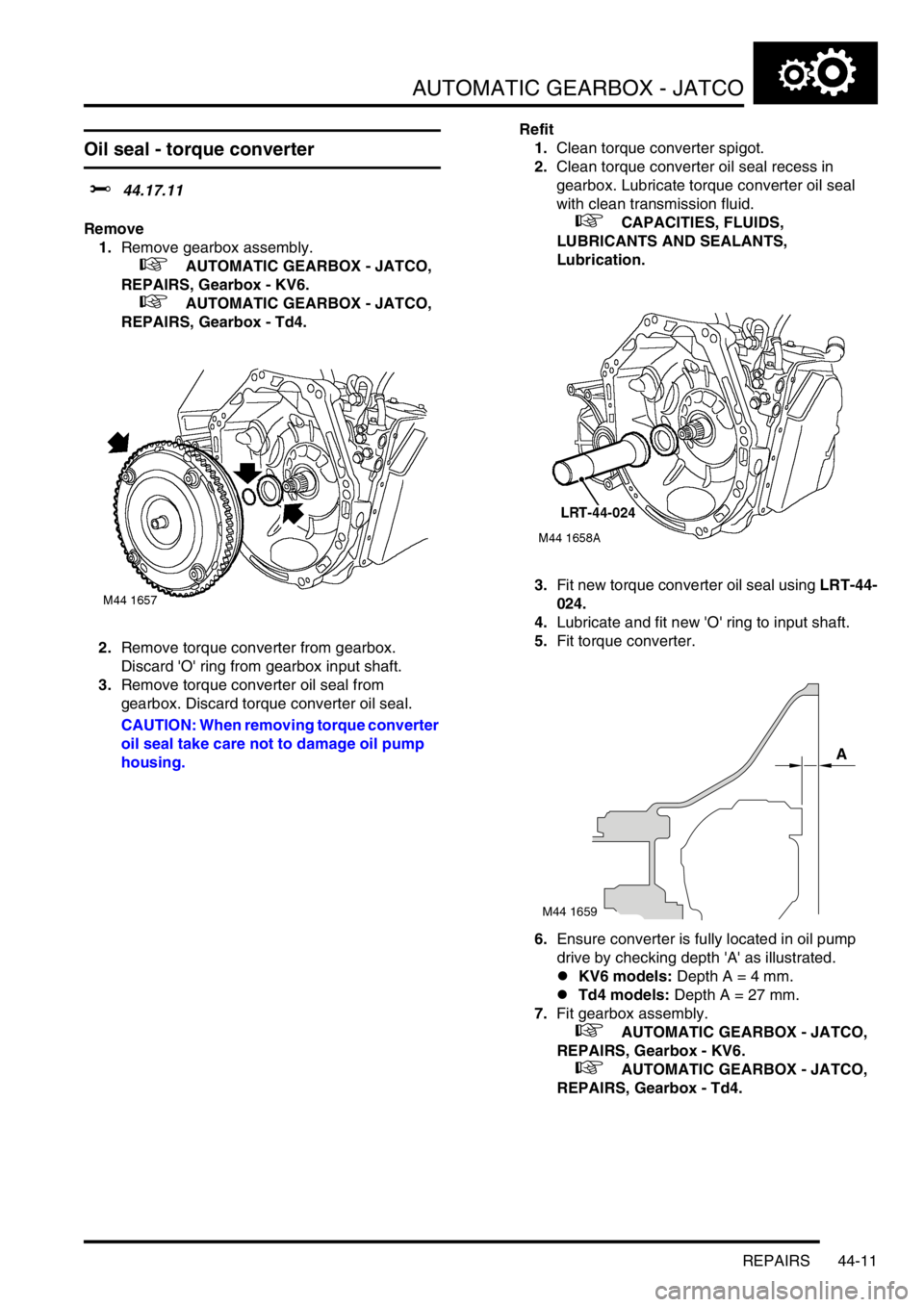

2.Remove torque converter from gearbox.

Discard 'O' ring from gearbox input shaft.

3.Remove torque converter oil seal from

gearbox. Discard torque converter oil seal.

CAUTION: When removing torque converter

oil seal take care not to damage oil pump

housing.Refit

1.Clean torque converter spigot.

2.Clean torque converter oil seal recess in

gearbox. Lubricate torque converter oil seal

with clean transmission fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Fit new torque converter oil seal using LRT-44-

024.

4.Lubricate and fit new 'O' ring to input shaft.

5.Fit torque converter.

6.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated.

lKV6 models: Depth A = 4 mm.

lTd4 models: Depth A = 27 mm.

7.Fit gearbox assembly.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - Td4.

M44 1659

A

Page 451 of 1007

AUTOMATIC GEARBOX - JATCO

44-16 REPAIRS

35.Remove 2 top bolts securing gearbox to

engine.

36.Release gearbox from 2 dowels.

37.Remove gearbox assembly.

38.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Disconnect lifting equipment.

7.Clean CKP sensor and mating face.

8.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

9.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

10.Connect hoses to fluid cooler.

11.Clean fluid cooler unions.

12.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

13.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

14.Clean starter motor mating faces.

15.Position starter motor to gearbox, align CKP

sensor multiplug bracket, fit and tighten bolts to

45 Nm (33 lbf.ft).

16.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

17.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

18.Align marks on drive plate to torque converter.

19.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

20.Clean torque converter access plate.

M44 1689

A

M44 1668

Page 458 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-23

23.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

24.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

25.Clean fluid cooler unions.

26.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

27.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

28.Clean exhaust manifold and mating face on

cylinder head.

29.Fit exhaust manifold gasket.

30.Position exhaust manifold, fit nuts and

progressively tighten, from centre outwards to

45 Nm (33 lbf.ft).

31.Connect HO2S multiplug and secure to support

bracket.

32.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

33.Align marks on drive plate to torque converter.

34.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

35.Clean torque converter access plate.

36.Position access plate, fit bolts and tighten to 9

Nm (7 lbf.ft).

37.Clean end of drive shaft and mating splines in

gearbox.

38.Fit new circlip to LH drive shaft.

39.With assistance pull hub outwards, align drive

shaft and fit to gearbox, taking care not to

damage drive shaft oil seal.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

40.Fit splash shield and secure with bolts.

41.Position trunnion to selector lever, locate inner

cable through trunnion, do not tighten nut at this

stage.

42.Position selector cable to gearbox bracket and

secure with clip.

43.Adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

44.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

45.Connect battery earth lead.

46.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

47.Untie and close bonnet.

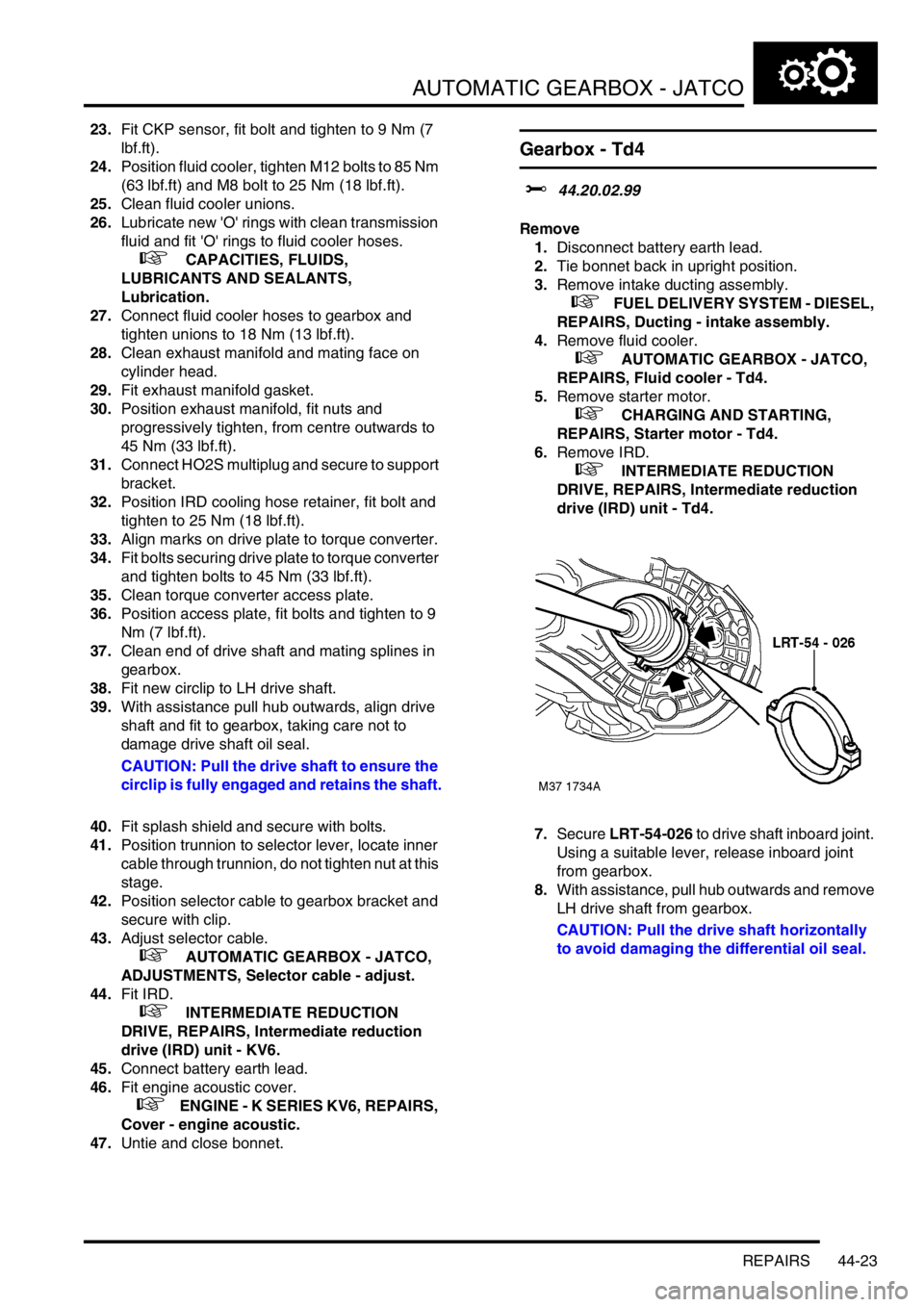

Gearbox - Td4

$% 44.20.02.99

Remove

1.Disconnect battery earth lead.

2.Tie bonnet back in upright position.

3.Remove intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

4.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

5.Remove starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

6.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

7.Secure LRT-54-026 to drive shaft inboard joint.

Using a suitable lever, release inboard joint

from gearbox.

8.With assistance, pull hub outwards and remove

LH drive shaft from gearbox.

CAUTION: Pull the drive shaft horizontally

to avoid damaging the differential oil seal.

Page 465 of 1007

AUTOMATIC GEARBOX - JATCO

44-30 REPAIRS

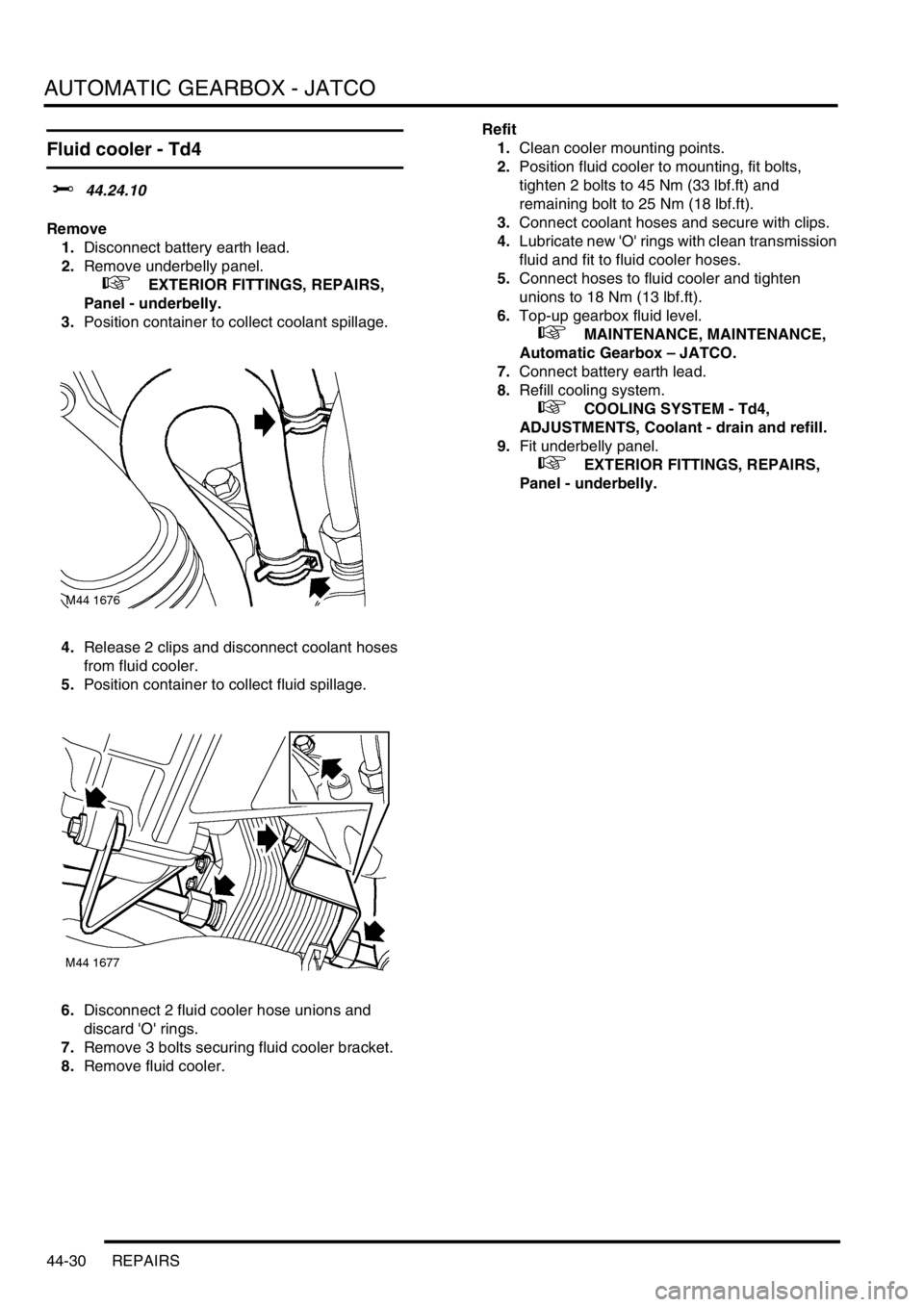

Fluid cooler - Td4

$% 44.24.10

Remove

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Position container to collect coolant spillage.

4.Release 2 clips and disconnect coolant hoses

from fluid cooler.

5.Position container to collect fluid spillage.

6.Disconnect 2 fluid cooler hose unions and

discard 'O' rings.

7.Remove 3 bolts securing fluid cooler bracket.

8.Remove fluid cooler.Refit

1.Clean cooler mounting points.

2.Position fluid cooler to mounting, fit bolts,

tighten 2 bolts to 45 Nm (33 lbf.ft) and

remaining bolt to 25 Nm (18 lbf.ft).

3.Connect coolant hoses and secure with clips.

4.Lubricate new 'O' rings with clean transmission

fluid and fit to fluid cooler hoses.

5.Connect hoses to fluid cooler and tighten

unions to 18 Nm (13 lbf.ft).

6.Top-up gearbox fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

7.Connect battery earth lead.

8.Refill cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

9.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 466 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-31

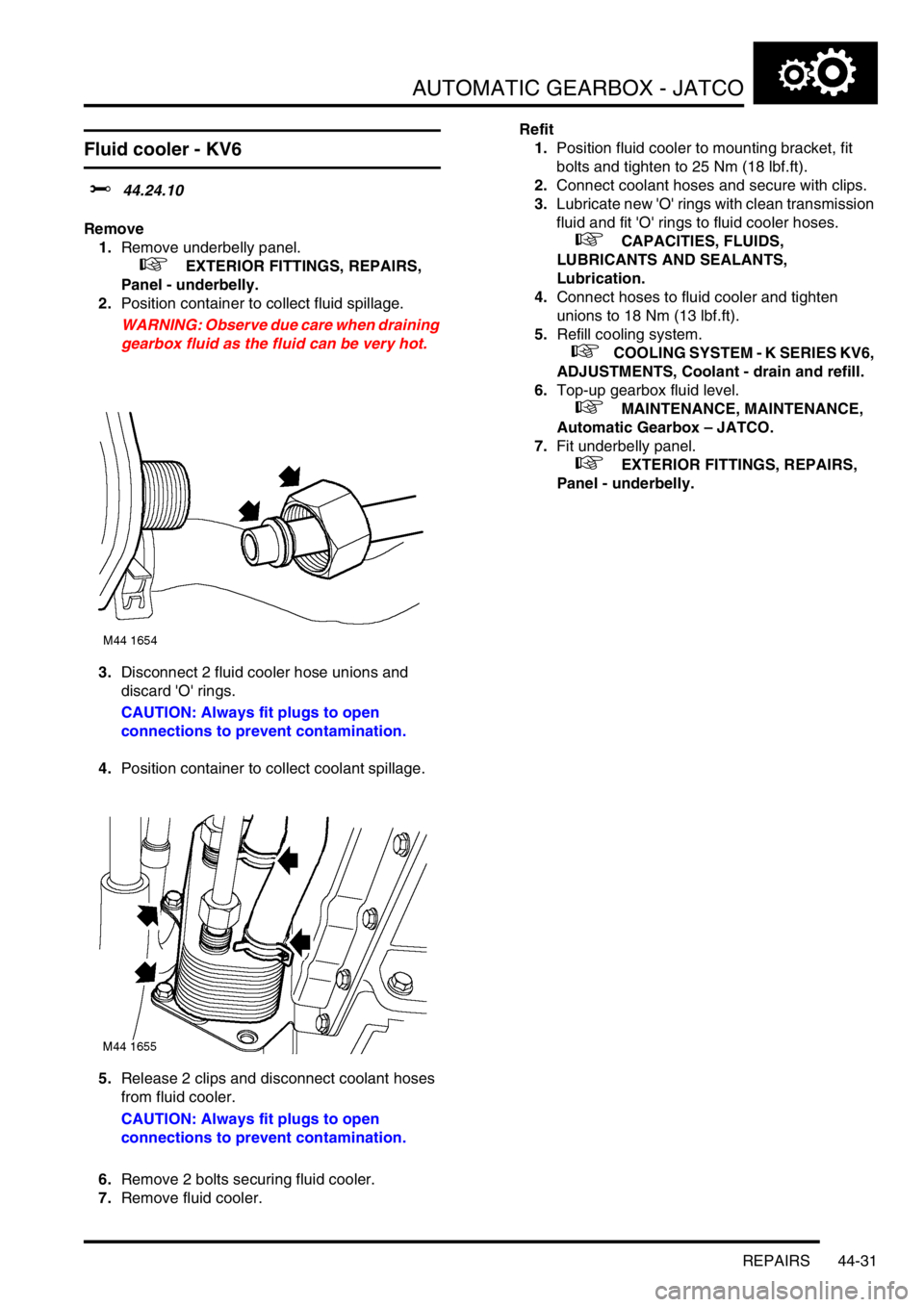

Fluid cooler - KV6

$% 44.24.10

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Position container to collect fluid spillage.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Disconnect 2 fluid cooler hose unions and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Position container to collect coolant spillage.

5.Release 2 clips and disconnect coolant hoses

from fluid cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 bolts securing fluid cooler.

7.Remove fluid cooler.Refit

1.Position fluid cooler to mounting bracket, fit

bolts and tighten to 25 Nm (18 lbf.ft).

2.Connect coolant hoses and secure with clips.

3.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

4.Connect hoses to fluid cooler and tighten

unions to 18 Nm (13 lbf.ft).

5.Refill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

6.Top-up gearbox fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 467 of 1007

AUTOMATIC GEARBOX - JATCO

44-32 REPAIRS

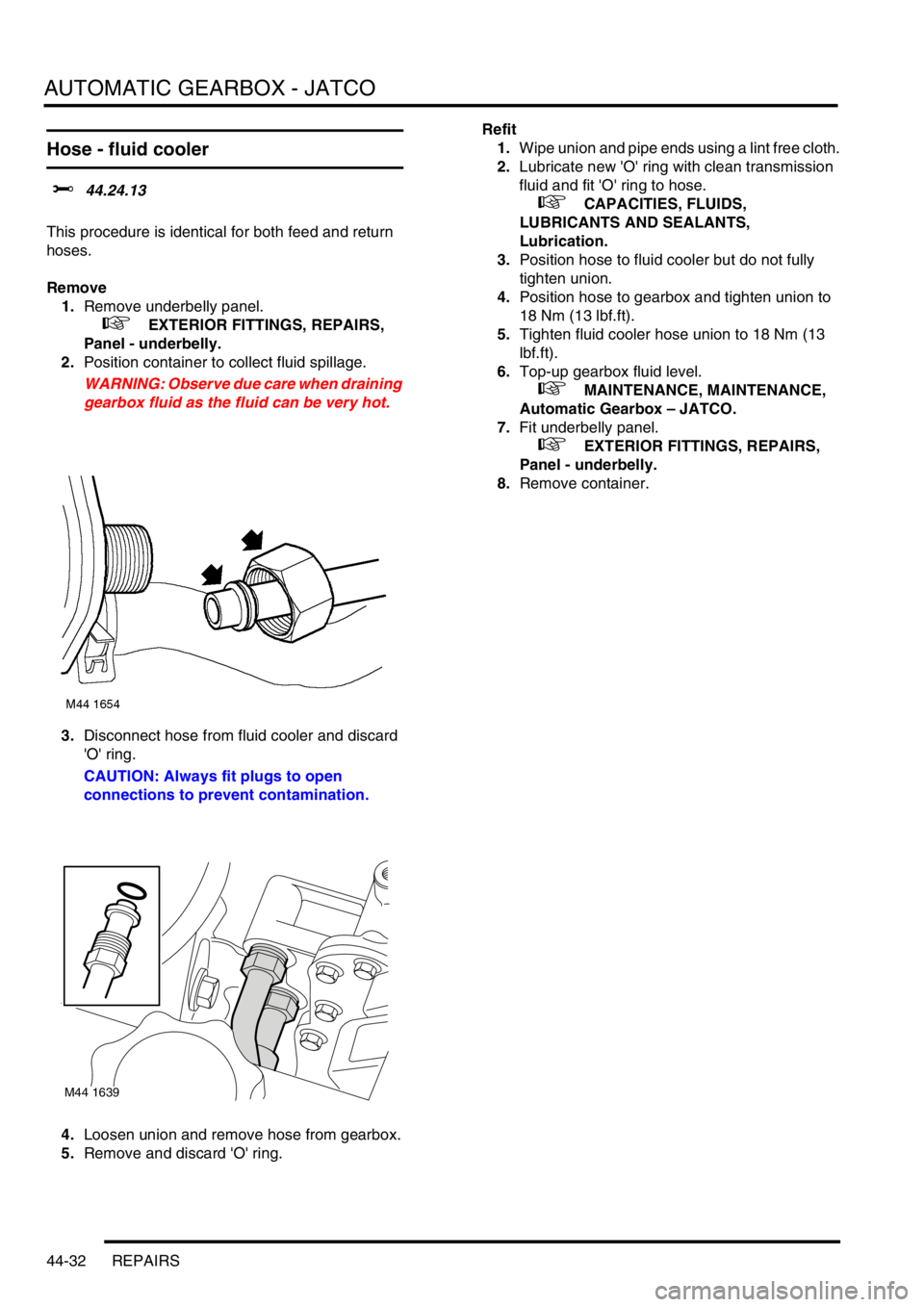

Hose - fluid cooler

$% 44.24.13

This procedure is identical for both feed and return

hoses.

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Position container to collect fluid spillage.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Disconnect hose from fluid cooler and discard

'O' ring.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Loosen union and remove hose from gearbox.

5.Remove and discard 'O' ring.Refit

1.Wipe union and pipe ends using a lint free cloth.

2.Lubricate new 'O' ring with clean transmission

fluid and fit 'O' ring to hose.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Position hose to fluid cooler but do not fully

tighten union.

4.Position hose to gearbox and tighten union to

18 Nm (13 lbf.ft).

5.Tighten fluid cooler hose union to 18 Nm (13

lbf.ft).

6.Top-up gearbox fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Remove container.

M44 1639

Page 756 of 1007

PANEL REPAIRS

BODY REPAIRS 77-2-1

PANEL REPAIRS

General

Body shells are of monocoque construction. Front and rear sections of the shell are designed as 'energy absorbing'

zones. This means they are designed to deform progressively when subjected to impact in order to minimise the

likelihood of injury to vehicle occupants.

It is essential that design dimensions and strength are restored in accident rectification. It is important that neither

structural weakness nor excessive local stiffness are introduced into the vehicle during body repair.

Repairs usually involve a combination of operations ranging from straightening procedures to renewal of individual

panels or panel assemblies. The repairer will determine the repair method and this decision will take into account a

balance of economics between labour and material costs and the availability of repair facilities in both equipment and

skills. It may also involve considerations of the vehicles' downtime, replacement vehicle availability and repair turn-

around time.

It is expected that a repairer will select the best and most economic repair method possible, making use of the facilities

available. The instructions given are intended to assist a skilled body repairer by expanding approved procedures for

panel replacement. The objective is to restore the vehicle to a safe running condition by carrying out a repair which is

as close as is feasible to original standard. The results should not advertise to the experienced eye that the vehicle

has been damaged, although the repair might not be identical in all respects to the original factory build. Commercial

bodyshop repair facilities cannot always duplicate methods of construction used during production.

Operations covered in this Manual do not include reference to testing the vehicle after repair. It is essential that work

is inspected and suspension geometry checked after completion. Where necessary a road test of the vehicle should

be carried out, particularly where safety-related items are concerned.

Where major units have been disconnected or removed it is necessary to ensure that fluid levels are checked and

topped up where necessary. It is also necessary to ensure that the repaired vehicle is in a roadworthy condition in

respect of tyre pressures, lights, washer fluid etc.

Body repairs often involve the removal of mechanical and electrical units and associated wiring. Where necessary,

refer to the relevant section of the Workshop Manual for removal and refitting instructions.

Body components

Taking into consideration the differences in body styles, suspension systems and engine and transmission layouts,

the location of the following components as applicable to a particular vehicle is critical:

lFront suspension upper damper mountings.

lFront suspension or sub frame mountings.

lRear suspension upper damper mountings.

lRear suspension mountings or lower pivots.

Additional points which can be used to check alignment and assembly are:

lInner holes in crossmember - side - main floor.

lHoles in front longitudinals.

lHoles in side members.

lHoles in rear longitudinals.

lHoles in rear lower panels or extension rear floor.

Apertures for windscreen, backlight, bonnet and doors can be measured and checked using the dimensional

information provided and also by offering up an undamaged component as a gauge.

Straightening

Whenever possible, structural members should be cold straightened under tension. Do not attempt to straighten with

a single pull but rework the damaged area using a series of pulls, releasing tension between each stage and using

the opportunity to check alignment.