brake light LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 38 of 3229

Flammabl e - OBSERVE NO SMOKING POLICY .

Irrit at ion of t he mout h and t hroat may res ult from s wallowi ng. The main hazard from s wallowi ng ari ses if li qui d as pirat ionint o t he lungs occurs.

Liquid contact dri es the ski n and can caus e i rrit at ion or dermati ti s. Splas hes in the eye may be s light ly i rrit ati ng.

In normal circums t ances t he low vol ati lit y does not give ris e t o harmful vapors . Expos ure to mis t s and vapors fromkeros ene at el evat ed t emperature s houl d be avoi ded (mis ts may ari s e in dewaxing). Avoi d s ki n and eye cont act and makes ure t here i s adequat e vent il ati on.

If sw allow ed, DO NOT induce vomiting - SEEK IMMEDIAT E MEDICAL AT T ENT ION.

Gas Cylinders

Gas es such as oxygen, acet ylene, argon and propane are normall y s tored in cyli nders at pres s ures of up t o 138 bar (13800kPa) (2000 lbf/i n²) and great care should be taken i n handl ing t hese cyli nders t o avoi d mechani cal damage t o t hem or t ot he val ve gear at tached. The contents of each cylinder s houl d be clearl y ident ifi ed by appropri ate markings .

Cylinders should be s tored in wel l vent il at ed encl osures, and protected from ice and s now or direct sunli ght . Fuel gas es,for example acetyl ene and propane should not be st ored i n clos e proximit y t o oxygen cylinders .

Care should be exerci sed to prevent l eaks from gas cyl inders and l ines and als o t o avoid s ources of ignit ion.

Only trai ned pers onnel s houl d undertake work involving gas cyli nders .

General Workshop Tools and Equipment

It is es s ent ial t hat al l tools and equipment are maint ained in good condit ion and t he correct s afet y equi pment is us edwhere required.

Never us e t ools or equipment for any purpos e other t han that for whi ch they were desi gned. Never overl oad equi pments uch as hoi st s , jacks, axle and chas si s s tands or li ft ing sl ings . Damage caus ed by overloading i s not always immediatel yapparent and may res ult i n a fatal fai lure the next t ime that t he equi pment is us ed.

Do not us e damaged or defect ive t ools or equipment, part icularly hi gh s peed equipment s uch as gri ndi ng wheel s . Adamaged grindi ng wheel can dis int egrate wit hout warning and cause serious i njury.

W ear s uit abl e eye prot ect ion when us ing grinding, chis elli ng or s and bl ast ing equi pment .

W ear a s uit able breat hing mas k when us i ng abrasi ve blas ti ng equi pment or us i ng sprayi ng equi pment.

Make s ure t here i s adequat e vent il ati on to cont rol dust s , mis t s and fumes .

High Pressure Air, Lubrication and Oil Test Equipment

Always keep high press ure equi pment i n good condi ti on, and regul arly maint ai ned, parti cularly at joint s and uni ons.

Never di rect a high press ure nozzle, for example dies el i njector, at t he s kin as the fluid may penet rat e t o t he underlyingt is sue and caus e s eri ous i njury.

Jacking

Always refer to the Jacki ng and Lifti ng s ect ion of t hi s manual prior t o rai s ing t he vehi cl e off the ground.

W hen vehicle is t o be rais ed by means of a jack, ensure t hat i t is st andi ng on l evel ground, that parking brake is appli edand wheels are chocked. ALW AY S us e t he recommended jacking poi nt s and ens ure t hat vehi cl e jack has s ufficient loadcapacit y for t he weight of t he vehi cl e.

W ARNING: Do not work on or under a vehi cle s upported onl y by a jack. Always s upport t he vehi cl e on s afet y s tands .

Ensure t hat hois t s have s uffi ci ent load capacit y for t he wei ght of t he vehi cl e.

Legal Aspects

There are many l aws and regulat ions rel at ing to healt h and s afet y i n the us e and di spos al of materials and equipment i n aworks hop.

For a s afe worki ng envi ronment and t o avoi d environment al poll uti on, workshops s hould be famil iar, i n detai l, wi th t hemany healt h and s afety laws and regul ati ons wit hi n t hei r count ry, publ is hed by both nat ional and local aut horit ies .

Lubricants and Greases

Avoi d all prolonged and repeat ed contact wit h mi neral oils . All l ubricants and greases may be irri tat ing t o t he eyes ands ki n.

Used Engine Oil

Prol onged and repeat ed cont act wi th engi ne oil wil l res ult i n t he removal of nat ural fat s from the s kin, leading to drynes s ,irri tat ion and dermati ti s. In addit ion, used engi ne oil cont ains potent iall y harmful cont aminants whi ch may caus e s kincancer. Adequat e means of s kin protecti on and washi ng facil it ies mus t be provi ded.

Do not employ us ed engine oi ls as l ubricants or for any appli cat ion where appreciable s kin cont act i s li kel y t o occur.

Page 44 of 3229

Publi s hed: 11-May-2011

General Information - Road/Roller Testing

Des cript ion and Operat ion

Road or roll ing road t es t ing may be carri ed out for various reasons and a procedure det ail ing pre-t es t checks , throughengi ne s tarti ng and s topping, pre-driving checks , on-t es t checks to final checks on complet ion of t he tes t are given.

Unles s complete vehi cl e performance is bei ng checked, t he ful l road t est procedure need not be carried out . Ins tead, t hos eit ems part icularly relevant t o t he s yst em(s) bei ng checked can be ext racted.

Pre-Test Checks

W ARNING: If t he brake s yst em hydraul ic fluid level i s l ow, pedal travel i s exces si ve or a hydraulic leak is found, donot att empt to road t est t he vehicle unt il t he reas on for t he low fl ui d l evel, excess ive pedal travel or hydraulic leak isfound and rect ified.

It is s ugges t ed that pre-t es t and funct ional t es ts of t hose sys tems/circuit s whi ch affect t he safe and l egal operati ons oft he vehi cl e, s uch as brakes , light s and s teeri ng, should al ways be carri ed out before the road or roll ing road tes t .

Engi ne oil l evelEngi ne cool ant levelTires, for correct pres sure, compat ible types and tread patt erns , and wear wi thi n limi ts .There i s s ufficient fuel in the t ank to compl ete the t est .Check al l around the engine, t rans mis s ion and under the vehicle for oil , coolant , hydraul ic and fuel l eaks . Make anote of any apparent leaks and wipe off t he surrounding areas t o make it easi er to identi fy t he extent of the leakon complet ion of t he tes t.

Starting the Engine

• NOTE: On i nit ial dri ve away from cold and wit hi n t he fi rs t 1.5 km (1 mile), do not depress accelerat or pedal beyond halft ravel unt il t he vehi cl e has att ained a minimum s peed of 25 km/h (15 mil es /h). Never operat e at high engi ne speed or wi tht he accelerat or pedal at ful l travel whil st the engine i s cold.

With the ignition off, check:

The parking brake is appli ed.Automatic transmission: The s el ect or lever is i n 'P' - PARK.Manual transmission: The gear l ever i s in NEUTRAL.All i ns t rument gauges read zero.

With the ignition on, check:

Igni ti on cont roll ed warni ng li ght s come on.Engi ne t emperature gauge regis t ers a readi ng compat ibl e wi th t he engine t emperat ure.Fuel gauge regi st ers a reading appropriate to the fuel l evel i n t he tank.The operati on of the parki ng brake warning l ight and fl ui d l evel warni ng indicator light.

On Road Test Check:

CAUTION: At commencement of road tes ti ng, check the brake operati on while s ti ll travel li ng at low speed beforecont inuing wit h t he tes t. If t he brakes pul l to one si de, or appear to be ot herwi se fault y, do not cont inue wit h t he roadt es t unti l the fault has been found and rect ified.

The parking brake releas es completel y.Gear changing i s s mooth, and t here are no abnormal noi s es or vi brati ons from t he t rans mis s ion.The engi ne power out put is s ati s factory, accel erati on is smoot h and accel erator pedal operat ion is not s ti ff orheavy, and engi ne s peed ret urns t o idl e correctl y.There i s no exces s ive or abnormall y colored s moke from t he engi ne under normal driving, heavy l oad or overruncondi ti ons .Steering operat ion i s s moot h, accurat e, not exces s ively heavy or wit h exces s ive free pl ay or vibrat ion. Does not pul lt o one s ide and s elf centres smoot hly after corneri ng.All i ns t rument s regis t er the correct readi ngs and operate correctl y.Swit ches and controls operat e s moothl y and posi ti vel y, warning or i ndi cat or light s operate correctl y and thedirect ion i ndi cat or cont rol s elf cancels when the s t eering i s ret urned t o t he s traight ahead pos it ion.Heati ng and vent il at ion sys tems work correct ly and effect ively.Brakes operate efficientl y.

Brake Testing

Avoi d brake t es ti ng on busy roads where i t can caus e i nconveni ence or danger t o ot her road users.

CAUTION: Brake t es ti ng which i ncludes heavy brake appl icati ons should not be carri ed out wit h new brake pads /dis csunti l the component s have bedded-i n. New brake fri ct ion component s wi ll not reach ful l efficiency unt il t he beddi ng-inprocess is complet e. Not e t hat when new parking brake shoes or rear brake di scs have been ins t al led, it i s es sent ial thatt he 'beddi ng-in' procedure i s carri ed out.For addit ional informat ion, refer t o: Parking Brake Shoes Bedding-In (206-05 Parking Brake and Actuati on, GeneralProcedures).

Test t he brakes at s everal speeds wit hin the normal operat ing range usi ng both light and heavy pedal pres s ure. Note anyt endency to snat ch, pull or drag, and any undue del ay in appli cat ion or release.

Page 78 of 3229

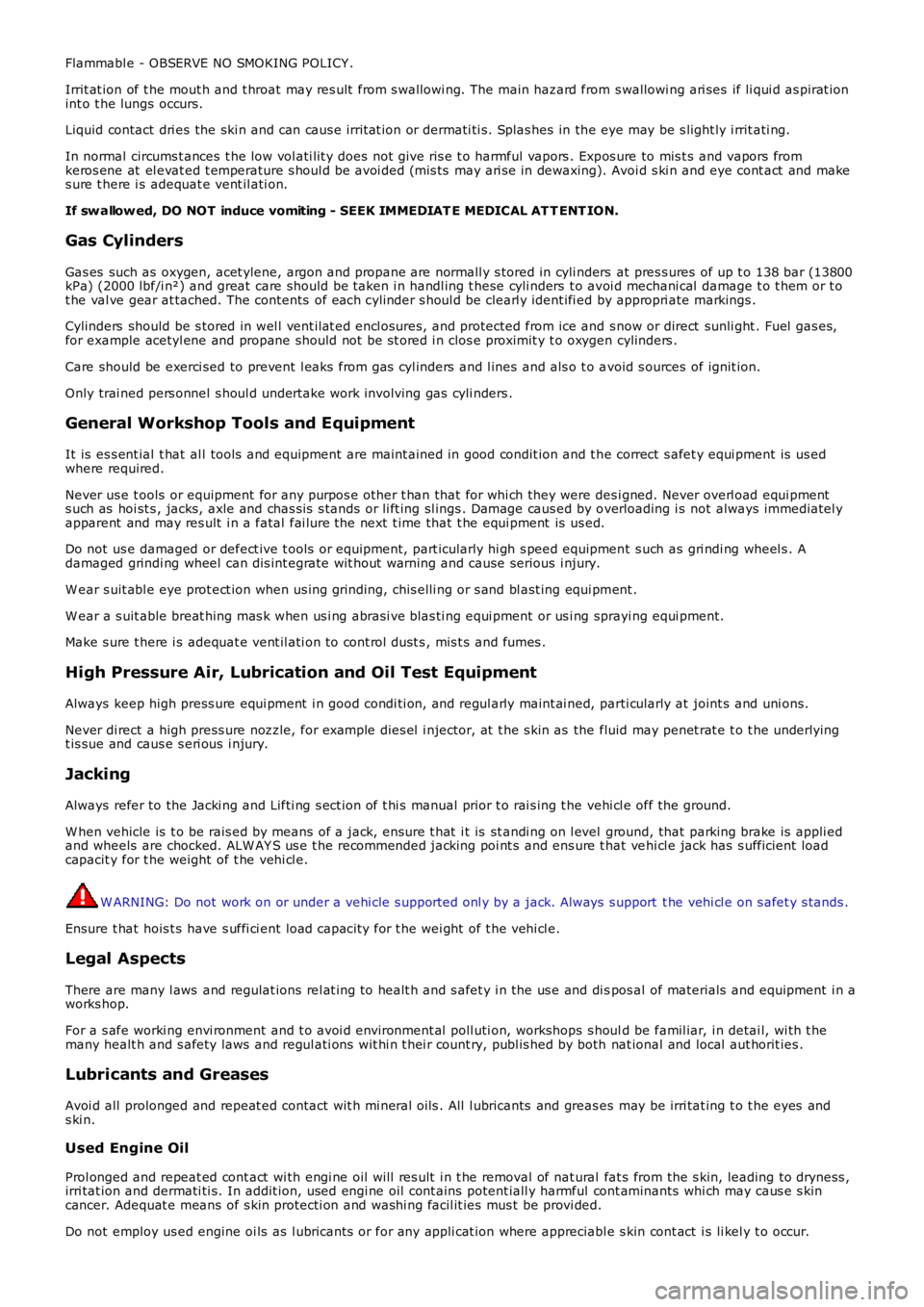

DT CDescriptionPossible CauseAction

tank unit ci rcuit (Fuel eject s ens or) for s hort to ground.Us ing t he manufacturer approved diagnost ic sys temcheck and ins t al l lat es t relevant l evel of s oft ware t othe central juncti on box and the i nst rument panelcl ust er. If t he level of s oft ware is correct carry out abat t ery resetP1674-00Control ModuleSoft ware Corrupt edA s oft ware as s ert ion fai ledwit hi n t he moduleLoad the l ates t rel evant level of s oftware usi ng t hemanufacturer approved diagnost ic sys tem

U0001-00High Speed CANCommunicati on BusBus O ffCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0010-00Medium Speed CANCommunicati on BusBus O ffCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0100-00Lost Communi cat ionW i th ECM/PCM 'A'Los t communicat ion wit hECMCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0101-00Lost Communi cat ionwi th TCMLos t communicat ion wit hTCMCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0104-00Lost Communi cat ionW i th Speed Cont rolModule

Los t communicat ion wit hs peed cont rol moduleCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0126-00Lost Communi cat ionW i th Steeri ng AngleSensor Module

Los t communicat ion wit hs t eering angle s ens orCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0129-00Lost Communi cat ionW i th Brake Syst emControl Module

Los t communicat ion wit hABS modul eCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0135-00Lost Communi cat ionW i th Different ialControl Module -Front

Los t communicat ion wit hdi fferenti al control modul eCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0155-00Lost Communi cat ionW i th Ins t rumentPanel Cl us t er (IPC)Control Module

Los t communicat ion wit hi nst rument clus t erCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0156-00Lost Communi cat ionW i th Informat ionCenter "A"

Los t communicat ion wit hi nformati on cent erCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0159-00Lost Communi cat ionW i th Parking As s is tControl Module "A"

Los t communicat ion wit hparki ng aid modul eCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0164-00Lost Communi cat ionW i th HVAC ControlModule

Los t communicat ion wit hcl imat e cont rol moduleCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0166-00Lost Communi cat ionW i th Auxi li ary HeaterControl Module

Los t communicat ion wit hauxil iary heat er cont rolmodul e

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0181-00Lost Communi cat ionW i th Headl ampLevel ling Cont rolModule

Los t communicat ion wit hheadlamp Levell ing controlmodul e

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0199-00Lost Communi cat ionW i th "Door ControlModule A"

Los t communicat ion wit hDriver Door Modul e (DDM)Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0200-00Lost Communi cat ionW i th "Door ControlModule B"

Los t communicat ion wit hPas s enger Door Modul e(PDM)

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0208-00Lost Communi cat ionW i th "Seat ControlModule A"

Los t communicat ion wit hPas s enger Seat Modul e(PSM)

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0214-00Lost Communi cat ionW i th Remote Functi onActuati on

Los t communicat ion wit hRemot e Keyles s Entrymodul e

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0231-00Lost Communi cat ionW i th Rain Sens ingModule

Los t communicat ion wit hrain sens ing moduleCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0236-00Lost Communi cat ionW i th Column LockModule

Los t communicat ion wit hs t eering column lockmodul e

Carry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0252-00Lost Communi cat ionW i th Lighti ng Cont rolModule - Rear 'B'

Los t communicat ion wit ht rai ler moduleCarry out the as s oci at ed network t es t for this DTCusi ng t he manufact urer approved diagnost ic s ys tem

U0301-00Soft wareIncompati bil it y wit hECM/PCM

ECM dis connect edIncorrect ECM i nst all edCheck el ect ri cal connecti ons to ECM. Check correct ECMis i nst all ed

Page 102 of 3229

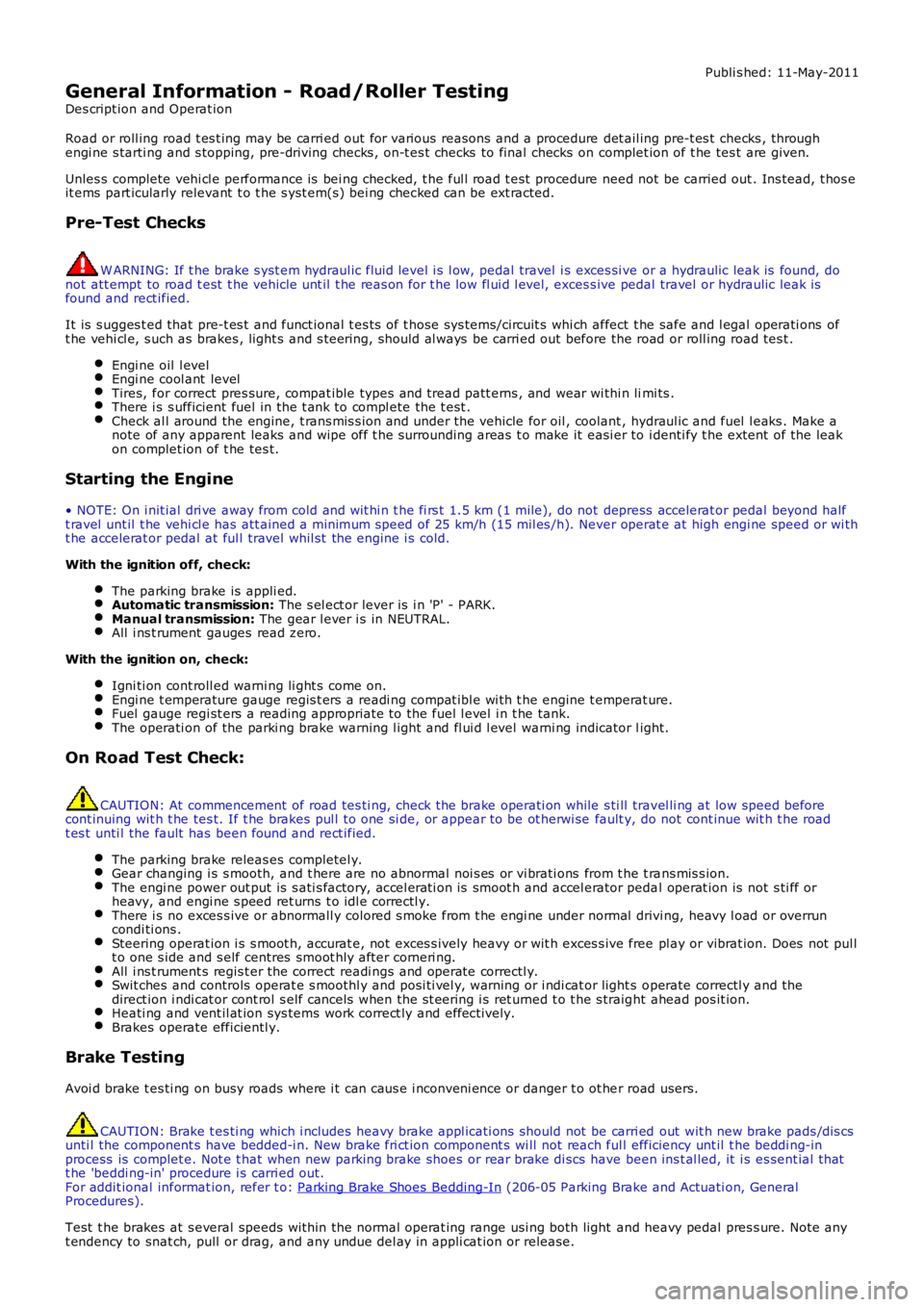

DT CDescriptionPossible CauseAction

U0101-00Lost communicat ionwit h TCM - No s ubt ype i nformati on

Los t communi cat ion wi tht he Trans mis s ionControl Modul eCAN net work fault

Check t he Trans mis s ion Cont rol Module for st ored DTCs .Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Trans mis s ion Cont rol Modul eU0121-00Lost communicat ionwit h Ant i-lock BrakeSyst em (ABS)Control Module - Nos ub type i nformati on

Los t communi cat ion wi tht he Anti -l ock BrakeSys tem Modul eCAN net work fault

Check t he Anti -l ock Brake Sys t em Module for s tored DTCs.Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Anti -l ock Brake Sys t em ModuleU0126-00Lost communicat ionwit h St eering Angl eSens or Module - Nos ub type i nformati on

Los t communi cat ion wi tht he Steering AngleSensor ModuleCAN net work fault

Check t he Steering Angle Sens or Modul e for s t ored DTCs .Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Steeri ng Angle Sens or Module

U0140-00Lost communicat ionwit h Body ControlModule - No subt ype i nformati on

Los t communi cat ion wi tht he Central Junct ion BoxCAN net work fault

Check t he Central Junct ion Box for s tored DTCs . Us ing themanufacturer approved diagnost ic sys tem, complet e t heCAN Net work Integri ty tes t. Refer t o t he electrical ci rcuitdiagrams and check the CAN network bet ween t he Adapt iveFront Lighti ng Sys t em (AFS) Cont rol Modul e and t he CentralJuncti on Box

U0300-00Int ernal Cont rolModule Soft wareIncompati bili ty - Nos ub type i nformati on

Car Configurat ion Fi le(CCF) i nformati oni ncompati ble t o t heAdapti ve Front Li ghti ngSys tem (AFS) Cont rolModule

• NOTE: The Car Configurat ion Fil e (CCF) parametersrequired are (Vehicle type)(Headl amp t ype)(Gearbox t ype)and (Dayrunning light )

Re-configure the Car Confi gurati on Fil e (CCF) as requi redusi ng t he manufact urer approved diagnost ic s ys tem. Cl earDTC and re-t es t . If t he DTC remains s us pect t he Adapt iveFront Lighti ng Sys t em (AFS) Cont rol Modul e, refer t o t henew module ins tall ati on not e at t he t op of the DTC IndexU0402-00Invali d Dat aRecei ved FromTrans mis s ion Cont rolModule - No subt ype i nformati on

Inval id Dat a Recei vedfrom the Transmis si onControl Modul eTrans mi ss i on componentfaul t

Check t he Trans mis s ion Cont rol Module for st ored DTCs .Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Trans mis s ion Cont rol Modul eU0415-00Invali d Dat aRecei ved FromAnti -Lock BrakeSyst em (ABS)Control Module - Nos ub type i nformati on

Inval id dat a receivedfrom Anti -l ock BrakeSys tem Modul eAnt i-lock Brake Syst emModule component fault

Check t he Anti -l ock Brake Sys t em Module for s tored DTCs.Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Anti -l ock Brake Sys t em Module

U0422-00Invali d data fromBody Cont rol Module- No s ub t ypeinformat ion

Inval id s i gnal from theCentral Juncti on BoxCentral Juncti on Boxfaul t

Check t he Central Junct ion Box for s tored DTCs . Us ing themanufacturer approved diagnost ic sys tem, complet e t heCAN Net work Integri ty tes t. Refer t o t he electrical ci rcuitdiagrams and check the CAN network bet ween t he Adapt iveFront Lighti ng Sys t em (AFS) Cont rol Modul e and t he CentralJuncti on Box

U0428-00Invali d Dat aRecei ved FromSteering AngleSens or Module - Nos ub type i nformati on

Inval id Dat a Recei vedfrom the St eeri ng Angl eSensor ModuleSt eering Angle Sens orModule fault

Check t he Steering Angle Sens or Modul e for s t ored DTCs .Us ing t he manufacturer approved diagnost ic sys tem,compl ete the CAN Net work Int egrit y t est . Refer t o theelectrical ci rcuit diagrams and check t he CAN networkbet ween t he Adapt ive Front Li ght ing Sys tem (AFS) ControlModul e and t he Steeri ng Angle Sens or

U2100-00Ini ti al Configurat ionNot Complet e - Nos ub type i nformati on

Car Configurat ion Fi le(CCF) i nformati on notreceived complet ely

• NOTE: The Car Configurat ion Fil e (CCF) parametersrequired are (Vehicle type)(Headl amp t ype)(Gearbox t ype)and (Dayrunning light )

Re-configure the Car Confi gurati on Fil e (CCF) as requi redusi ng t he manufact urer approved diagnost ic s ys tem. Cl earDTC and re-t es t . If t he DTC remains s us pect t he Adapt iveFront Lighti ng Sys t em (AFS) Cont rol Modul e, refer t o t henew module ins tall ati on not e at t he t op of the DTC IndexU2101-00Control ModuleConfigurat ionIncompati ble - Nos ub type i nformati on

Car Configurat ion Fi le(CCF) i nformati oni ncompati ble t oAdapti ve Front Li ghti ngSys tem (AFS) Cont rolModule

Check t he correct Adapti ve Front Li ght ing Sys t em (AFS)Cont rol Module is i ns t alled to vehicle s pecificati on. Refitori gi nal or repl ace the modul e as required. Refer to thenew module/component ins tall ati on note at t he t op of theDTC Index

U3003-16Batt ery Vol tage -Circui t vol tage belowt hreshol d

The power s upply to theModule has been below9 Vol ts for more than1000 mi ll is econds

Sus pect Bat t ery or Charging fault . Check t he batt erycondit ion and st ate of charge. Check t he vehicle chargi ngs ys t em. Refer to the relevant workshop manual s ect ion.Clear the DTC, cycl e i gni ti on s tat e to off t hen on, i f DTCret urns refer to the el ect ri cal circui t diagrams and checkpower and ground ci rcuit t o t he Adapt ive Front Light ingSys t em (AFS) Cont rol Modul e

Page 409 of 3229

Publi s hed: 11-May-2011

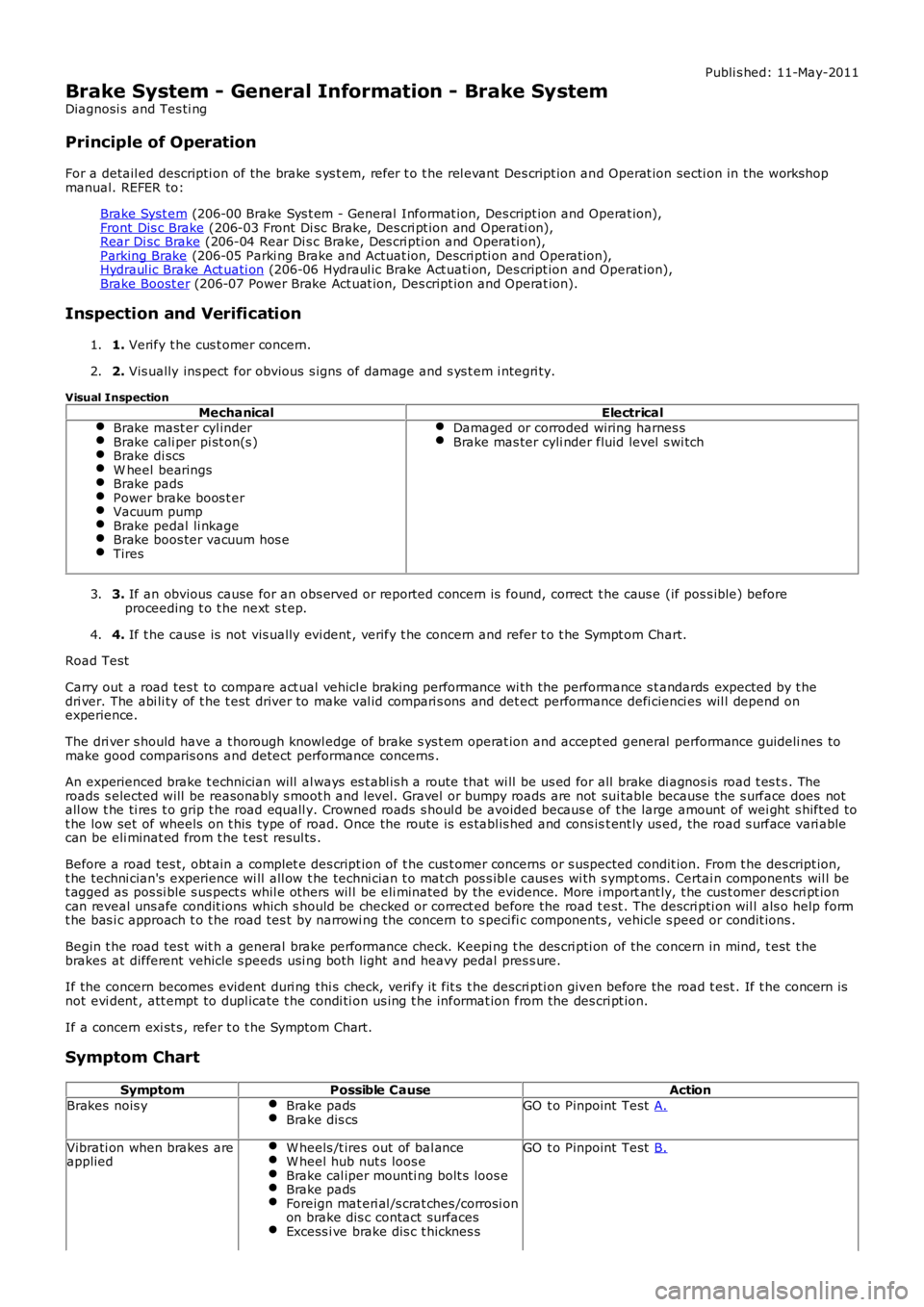

Brake System - General Information - Brake System

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the brake s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshopmanual. REFER to:

Brake Syst em (206-00 Brake Sys t em - General Informat ion, Des cript ion and Operat ion),Front Dis c Brake (206-03 Front Di sc Brake, Des cri pt ion and Operati on),Rear Di sc Brake (206-04 Rear Di s c Brake, Des cri pti on and Operati on),Parking Brake (206-05 Parki ng Brake and Actuat ion, Descri pti on and Operat ion),Hydraul ic Brake Act uati on (206-06 Hydraul ic Brake Act uati on, Des cript ion and Operat ion),Brake Boost er (206-07 Power Brake Act uat ion, Des cript ion and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.2.

Visual Inspection

MechanicalElectricalBrake mast er cyl inderBrake cali per pi st on(s )Brake di scsW heel bearingsBrake padsPower brake boos t erVacuum pumpBrake pedal li nkageBrake boos ter vacuum hos eTires

Damaged or corroded wiring harnes sBrake mas ter cyli nder fluid level s wi tch

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he concern and refer t o t he Sympt om Chart.4.

Road Test

Carry out a road tes t to compare act ual vehicl e braking performance wi th the performance s t andards expected by t hedri ver. The abi li ty of t he t est driver to make val id compari s ons and det ect performance defi cienci es wil l depend onexperience.

The dri ver s hould have a t horough knowl edge of brake s ys t em operat ion and accept ed general performance guideli nes tomake good comparis ons and detect performance concerns .

An experienced brake t echnician will al ways es t abl is h a route that wi ll be us ed for all brake di agnos is road t es t s . Theroads s elected will be reasonably s moot h and level. Gravel or bumpy roads are not sui table because the s urface does notall ow t he ti res t o grip t he road equall y. Crowned roads s houl d be avoided becaus e of t he large amount of wei ght s hifted tot he low set of wheels on t his type of road. Once the route is es tabl is hed and cons ist ent ly us ed, the road s urface vari ablecan be eli minat ed from t he t es t resul ts .

Before a road tes t, obt ain a compl et e des cript ion of t he cus t omer concerns or s uspected condit ion. From t he des cript ion,t he techni cian's experience wi ll all ow t he techni cian t o mat ch pos s ibl e caus es wi th s ympt oms. Certai n components wil l bet agged as pos si ble s us pect s whil e others wil l be eli minated by the evidence. More i mport ant ly, t he cus t omer des cri pt ioncan reveal uns afe condit ions which s hould be checked or correct ed before the road t est . The descri pti on wil l als o help formt he bas i c approach t o t he road tes t by narrowi ng t he concern t o s peci fi c components , vehicle s peed or condit ions .

Begin t he road tes t wit h a general brake performance check. Keepi ng t he des cri pti on of the concern in mind, t est t hebrakes at different vehicle s peeds usi ng both light and heavy pedal pres s ure.

If the concern becomes evident duri ng thi s check, verify it fit s t he descri pti on given before the road t est . If t he concern isnot evi dent , att empt to dupl icate t he condi ti on us ing t he informat ion from the des cri pt ion.

If a concern exi st s , refer t o t he Symptom Chart.

Symptom Chart

SymptomPossible CauseAction

Brakes nois yBrake padsBrake dis csGO t o Pinpoint Test A.

Vibrati on when brakes areappliedW heels /t ires out of bal anceW heel hub nut s loos eBrake cal iper mounti ng bolt s loos eBrake padsForeign mat eri al /s crat ches /corrosi onon brake dis c contact surfacesExcess i ve brake dis c t hicknes s

GO t o Pinpoint Test B.

Page 416 of 3229

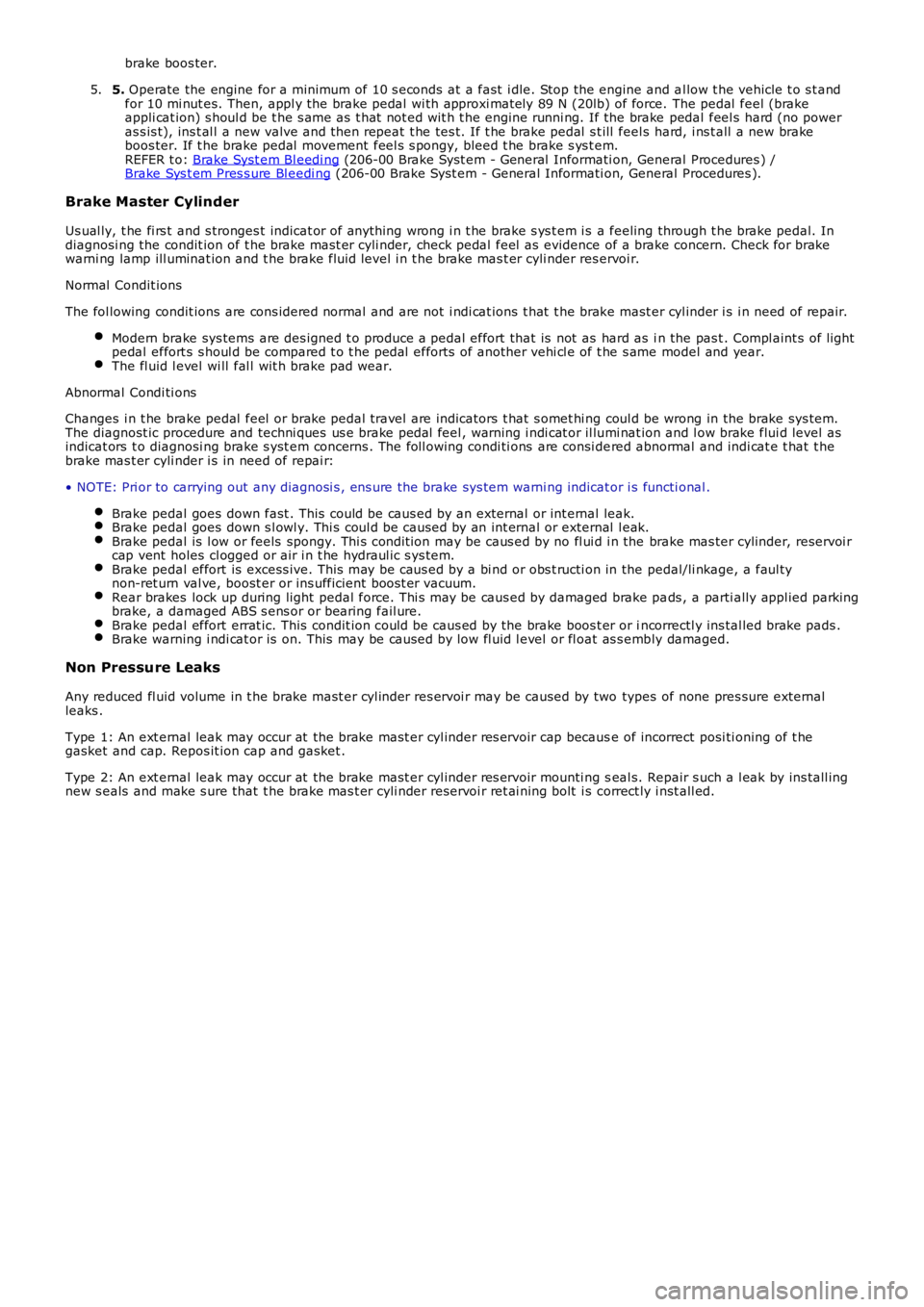

brake boos ter.

5. Operate the engine for a minimum of 10 s econds at a fast i dle. Stop the engine and al low t he vehicle t o s t andfor 10 mi nut es. Then, appl y the brake pedal wi th approxi mately 89 N (20lb) of force. The pedal feel (brakeappli cat ion) s houl d be t he s ame as t hat not ed wit h t he engine runni ng. If the brake pedal feel s hard (no poweras s is t), ins t al l a new valve and t hen repeat t he tes t. If t he brake pedal s t ill feels hard, i ns t all a new brakeboos ter. If t he brake pedal movement feel s s pongy, bleed t he brake s ys t em.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ) /Brake Sys t em Pres s ure Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ).

5.

Brake Master Cylinder

Us ual ly, t he fi rs t and s tronges t indicat or of anything wrong i n t he brake s ys t em i s a feeling through t he brake pedal. Indiagnosi ng the condit ion of t he brake mas t er cyli nder, check pedal feel as evidence of a brake concern. Check for brakewarni ng lamp ill uminat ion and t he brake fluid level i n t he brake mas t er cyli nder reservoi r.

Normal Condit ions

The fol lowing condit ions are cons idered normal and are not i ndi cat ions t hat t he brake mast er cyl inder i s i n need of repair.

Modern brake sys tems are des igned t o produce a pedal effort that is not as hard as in the pas t . Compl aint s of lightpedal effort s s houl d be compared t o t he pedal efforts of another vehi cl e of t he s ame model and year.The fl uid l evel wi ll fal l wit h brake pad wear.

Abnormal Condi ti ons

Changes i n t he brake pedal feel or brake pedal travel are indicators t hat s omet hi ng coul d be wrong in the brake sys tem.The diagnost ic procedure and techni ques us e brake pedal feel , warning i ndi cat or il lumi nat ion and l ow brake flui d level asindicat ors t o diagnosi ng brake s yst em concerns . The foll owing condi ti ons are consi dered abnormal and indi cat e t hat t hebrake mas t er cyli nder i s in need of repai r:

• NOTE: Pri or to carrying out any diagnosi s , ens ure the brake sys tem warni ng indicator i s functi onal .

Brake pedal goes down fast . This could be caus ed by an external or int ernal leak.Brake pedal goes down s l owl y. Thi s coul d be caused by an int ernal or external l eak.Brake pedal is l ow or feels spongy. Thi s condit ion may be caus ed by no fl ui d i n the brake mas ter cylinder, reservoi rcap vent holes cl ogged or air i n t he hydraul ic s ys tem.Brake pedal effort is excess ive. This may be caus ed by a bi nd or obs t ructi on in the pedal/li nkage, a faul tynon-ret urn val ve, boost er or ins ufficient boos t er vacuum.Rear brakes lock up during light pedal force. Thi s may be caus ed by damaged brake pads , a parti ally appl ied parkingbrake, a damaged ABS s ens or or bearing fail ure.Brake pedal effort errat ic. This condit ion could be caus ed by the brake boos t er or incorrectl y ins tal led brake pads .Brake warning i ndi cat or is on. This may be caus ed by low fl uid l evel or fl oat as s embly damaged.

Non Pressure Leaks

Any reduced fl uid volume in t he brake mast er cyl inder res ervoi r may be caused by two types of none pres sure externalleaks .

Type 1: An ext ernal leak may occur at the brake mast er cyl inder res ervoir cap because of incorrect posi ti oning of t hegasket and cap. Repos it ion cap and gasket .

Type 2: An ext ernal leak may occur at the brake mast er cyl inder res ervoir mounti ng seal s. Repair s uch a l eak by ins tall ingnew s eals and make s ure that t he brake mas t er cyli nder reservoi r ret ai ning bolt i s correct ly i nst all ed.

Page 500 of 3229

1

2

Publi s hed: 11-May-2011

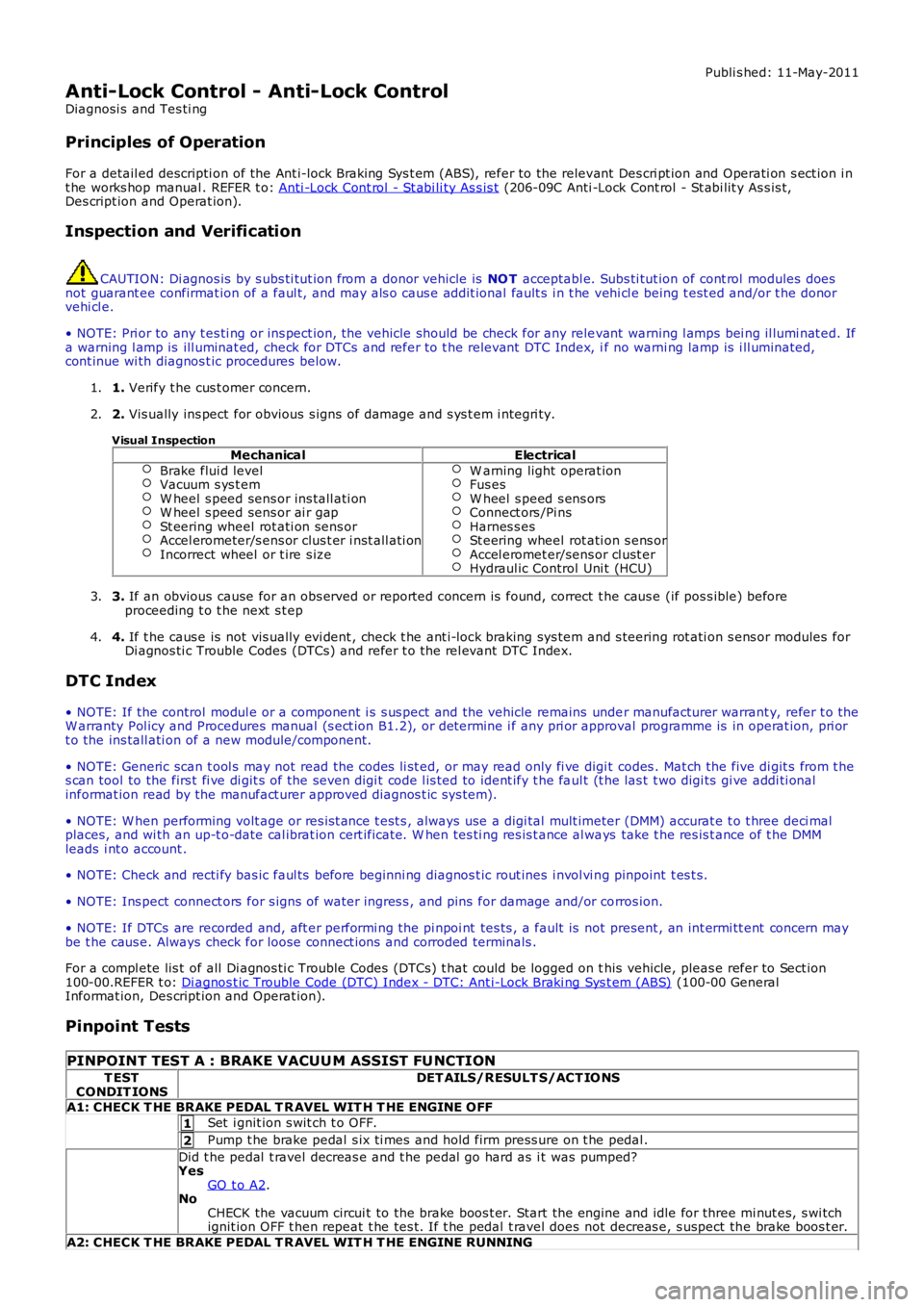

Anti-Lock Control - Anti-Lock Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Ant i-lock Braking Sys t em (ABS), refer to the relevant Des cri pt ion and Operati on s ect ion i nt he works hop manual . REFER t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Pri or to any t es ti ng or ins pect ion, the vehicle should be check for any relevant warning l amps bei ng il lumi nat ed. Ifa warning l amp is ill uminat ed, check for DTCs and refer to t he relevant DTC Index, if no warni ng lamp is i ll uminated,cont inue wi th diagnos t ic procedures below.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.

Visual InspectionMechanicalElectrical

Brake flui d levelVacuum s ys t emW heel s peed sens or ins tall ati onW heel s peed sens or ai r gapSt eering wheel rot ati on sens orAccel erometer/s ens or clus t er i nst all ati onIncorrect wheel or t ire s ize

W arning light operat ionFus esW heel s peed s ens orsConnect ors /Pi nsHarnes s esSt eering wheel rot ati on s ens orAccel eromet er/sens or cl ust erHydraul ic Control Uni t (HCU)

2.

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check t he ant i-lock braking sys tem and s teering rot ati on s ens or modules forDi agnos ti c Trouble Codes (DTCs) and refer t o t he rel evant DTC Index.4.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Ant i-Lock Braki ng Sys t em (ABS) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : BRAKE VACUU M ASSIST FU NCTION

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

A1: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE OFF

Set i gnit ion s wit ch t o OFF.

Pump t he brake pedal s ix ti mes and hold firm press ure on t he pedal .

Did t he pedal t ravel decreas e and t he pedal go hard as i t was pumped?YesGO t o A2.NoCHECK the vacuum circui t to the brake boos t er. Start the engine and idle for three mi nut es, s wi tchignit ion OFF t hen repeat t he tes t. If t he pedal t ravel does not decreas e, s uspect the brake boos t er.

A2: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE RUNNING

Page 1109 of 3229

Fuel fired heat er

The FFBH (fuel fired boost er heat er) and St op/Start s ys t em wi ll not operate si mult aneous ly, due to low ambientt emperatures bei ng a fact or in t he funct ion of both sys tems .

Hood Latch Ajar-Switch

W ARNING: To avoi d injury when performing repai r work on t he vehicle al ways di s abl e the Stop/St art s ys tem bypres s ing t he ‘ECO’ butt on, ens ure that ‘ECO STOP/START OFF’ is di s pl ayed in t he mes sage Cent er and the ECO tel l-taleli ght in t he s wit ch is ext inguis hed.

The hood lat ch ajar-s wit ch hardwired to the CJB, has two functi ons :

Acts as a s top i nhi bit or, all owing t he engi ne t o remai n running if t he hood latch i s rel eased.Deact ivates the St op/Start s ys t em i f an engi ne s top i s t aki ng place, t his res ul ts in an engine st all ed condit ion. Theengi ne can be res t art ed usi ng t he ignit ion but ton. Stal l recovery wil l not funct ion i n t hi s condi ti on; refer t o t he StallRecovery secti on.

Aft er the hood i s clos ed reacti vat ion of t he Stop/Start sys tem is achieved by manuall y s tarti ng the engine.

System Fault

The Stop/St art s ys tem is aut omati cal ly acti vat ed each ti me an ignit ion cycl e occurs; t he dri ver will be i nformed t he sys t emis operat ing by the t ell -t ale l ight in the Eco s wi tch i lluminati ng. If the tell -t ale light does not il luminat e t hi s wi ll indicat et hat t here i s eit her a s ys t em faul t or the sys tem is not avail abl e. Onl y when t he dri ver at tempt s t o act ivat e t he sys t em bypres s ing t he ‘Eco’ but ton will t hey be informed of a fault by ‘ECO STOP/START FAULT’ being di spl ayed i n t he mes sageCenter.

Owi ng to the St op/Start s ys t em’s complexit y due t o many ot her vehicle modul es and communicat ion net works i nvol ved i nit s funct ion. It i s recommended t hat al l ot her sys tem faul ts be init ial ly diagnos ed and eliminated when inves t igati ngStop/St art fault s as t hes e could affect the operat ion of t he St op/Start sys tem.

Syst em DTC (di agnos ti c troubl e code)can be diagnos ed us ing Land Rover approved di agnos ti c equi pment.

STOP INHIBITORS, START INITIATORS AND START INHIBITORS

A number of s el ect able feat ures or vehicle si tuat ions can infl uence t he operat ion of t he Stop/St art s yst em’s operati on.Thes e can, depending on the parti cular circumst ances :

prevent the engine s hutt ing down (s t op inhibi tor),ini ti at e an aut onomous res tart (s tart ini ti at or),prevent an engi ne res t art (st art i nhi bit or).

Stop Inhibitors

Under normal ci rcums tances the St op/St art s ys t em wi ll automat icall y s hut down t he engi ne if:

t he vehi cl e is st ati onary,t he trans mi s si on is in neutral,t he cl utch pedal i s ful ly releas ed.

The fol lowing condit ions wi ll inhibi t the engine from s hutt ing down:

Dri ver effected st op inhi bi tor

The fol lowing driver effect ed condi ti ons will i nhi bit t he engi ne from shut ti ng down:

Dri ver s wi tches off t he Stop/St art s ys temTrans mis s ion not i n neut ral((no te that the d rive r re sting their ha nd o n the g ea r le ve r ca n move the tra ns mis sion o ut o f the ne utra l w ind o w w itho ut e nga g ing a ge a r))

Clut ch pedal not full y rel easedAccelerator pedal depres s edHood is openDri ver’s door is openDri ver’s safet y belt i s dis engagedHDC (hil l decent cont rol) i s acti veTR (terrain res pons e) mode i s act iveCli mate cont rol s ys t em us ed above cal ibrat ed thresholdW i nds hiel d demis t i s operati ngTrai ler electrical connect ion det ect ed

Vehicle s ys tem effect ed s top i nhi bit or

The fol lowing vehicl e s ys t em condi ti ons wil l inhibit t he engine from s hut ti ng down:

Dri ver s wi tches off t he Stop/St art s ys temBrake s ervo vacuum below thres holdBatt ery cold cranki ng capabil it y below t hres holdBatt ery s t ate of charge i s lowCatal yt ic converter out si de eit her pre or post cali brati on rangeDPF (di esel part iculat e filt er) i s regenerat ingEngi ne cool ant temperat ure bel ow t hreshol dEngi ne oil t emperature below thres hold

Page 1772 of 3229

il lumi nat ed for t he remaining 2 s econds of the bulb check, this indicates t hat faults are st ored in t he ABS module memory.

If the warning i ndi cat or was il luminat ed due to a wheel speed s ensor faul t, t he i ndicat or will remain ill uminat ed at thenext i gnit ion cycl e, even i f the fault is recti fi ed. W hen the vehicle is driven above a s peed of 20 km/h (12.5 mph) theindicat or wi ll be ext ingui s hed. This al lows t he ABS module to perform a thorough check of t he s yst em and to es t abl is h t hatt he out put from t he repl aced s ensor i s correct .

Low Fuel Level Indicator

The low fuel level indicator is cont roll ed by t he fuel level gage s oftware (s ee above). W hen t he vehicle ent ers power mode6, the low fuel i ndicat or is ill uminat ed in an amber color for a 3 s econd bulb check. If t he fuel level gage softwaredetermines t he low fuel indicator s houl d be i ll uminated, it flas hes t he indicator at a rate of 2 Hz for 5 seconds . The firstfl ash is accompani ed by a chime from t he ins t rument clus ter s ounder. After t he 5 s econd fl as hing period t he indi cat or willremai n i llumi nated unt il fuel is added t o t he t ank or t he vehi cle i gni ti on is swi tched off.

Parking Brake Indicator

The red parking brake i ndi cat or is i ll uminated on receipt of a medium s peed CAN bus s ignal from t he CJB. The s ignalori ginates i n t he parking brake micros wit ch, whi ch is hardwired to the CJB. The parking brake indicator wil l onl y i llumi nateif t he parking brake is appli ed and t he vehi cl e is in power mode 6.

Rear Fog Lamp Indicator

The rear fog lamp indicator is il luminat ed on receipt of a medi um s peed CAN bus s ignal from t he CJB. The i ndicat or isil lumi nat ed i n an amber col or if t he vehi cl e is in power mode 6 and rear fog l amp operat ion has been reques ted.

Front Fog Lamp Indicator

The front fog l amp i ndi cat or is i ll uminated on recei pt of a medium s peed CAN bus si gnal from the CJB. The indi cat or i sil lumi nat ed i n a green color i f the vehicle is i n power mode 6 and front fog lamp operat ion has been reques ted.

Adaptive Front Lighting System Indicator

The Adapt ive Front l ight ing Syst em (AFS) indicator i s cont rol led by t he AFS module. The AFS module i s hardwi red t o t heCJB, whi ch relays s ignals to the i nst rument clus ter over the medi um s peed CAN bus . When t he vehi cl e enters power mode6, the AFS indicator is ill uminat ed in an amber color for a 3 s econd bul b check. If duri ng AFS operati on a faul t is det ect ed,t he AFS indicator wi ll fl ash at a frequency of 2 Hz.

Speed Control Indicator

The s peed control indicator i s cont roll ed by t he ECM, which t rans mit s a s peed cont rol acti ve si gnal t o t he ins t rumentclus ter via the CJB. The indicator wi ll il lumi nat e i n an amber col or when the vehicle is i n power mode 6 and s peed cont rolis act ive.

Trailer Indicator

The t rail er indicator is cont roll ed by t he ins trument cl ust er on receipt of medium speed CAN bus si gnal s from the CJB.W hen a trailer i s connected t o t he vehi cle el ect ri cal s ys t em and t he t urn s i gnal indicat or s wi tch i s operated, t he CJBt ransmit s a s ignal to the ins trument cl us t er to operat e t he t rail er indicator. The inst rument clus t er s oftware cont rol s thefl ash rat e of the indicator which flas hes in a green color. The t rai ler indi cat or flas hes s lowly, at t he s ame rat e as t he t urns ignal indicators .

Low Washer Fluid Indicator

The low washer fluid indicator is il luminat ed on receipt of a medi um s peed CAN bus signal from t he CJB. The s i gnalori ginates i n t he low washer fl uid l evel s wit ch, whi ch is hardwired to the CJB.

The amber low was her fl uid i ndi cat or is s ubject t o a 3 second bul b check when the vehicle ent ers power mode 6. If a lowwas her fluid level is detect ed for more t han 15 seconds when the vehicle is i n power mode 6, the ins trument cl us t er wil lil lumi nat e t he indi cat or.

Low Engine Coolant Level Warning Ind icator

The low engi ne cool ant l evel warni ng indicat or i s il lumi nat ed on recei pt of a medium speed CAN bus s i gnal from the CJBwhen t he vehi cl e is in power mode 6. The s ignal origi nat es in the ECM, whi ch trans mits the s i gnal t o t he CJB over t he highs peed CAN bus.

W hen t he vehicle ent ers power mode 6, the amber l ow engine coolant level warning i ndi cat or is i ll uminated for a 3 secondbulb check. If the warning i ndi cat or remai ns ill uminat ed aft er this period, the engine cooli ng s yst em s hould be checked forleaks and t opped up as necess ary.

Transmission Warning Indicator

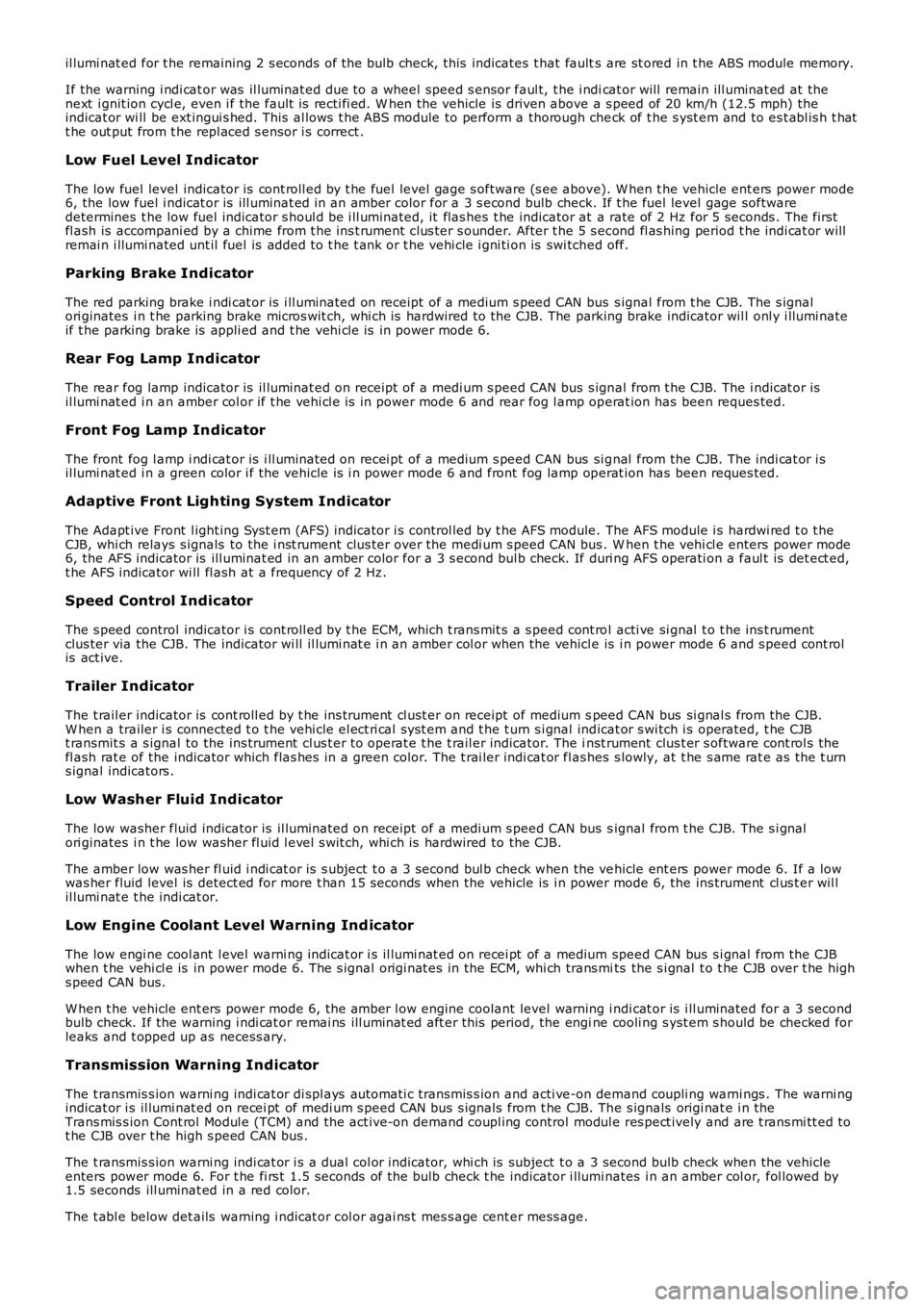

The t ransmis s ion warni ng indi cat or di spl ays aut omati c transmis s ion and acti ve-on demand coupli ng warni ngs . The warni ngindicat or i s il lumi nat ed on recei pt of medi um s peed CAN bus s ignals from t he CJB. The s ignals origi nat e i n theTrans mis s ion Cont rol Modul e (TCM) and the act ive-on demand coupl ing control modul e res pect ively and are t rans mi tt ed tot he CJB over t he high s peed CAN bus .

The t ransmis s ion warni ng indi cat or i s a dual col or indicator, whi ch is subject t o a 3 second bulb check when the vehicleenters power mode 6. For t he fi rs t 1.5 seconds of the bulb check t he indicator i llumi nates i n an amber col or, fol lowed by1.5 seconds ill uminat ed in a red color.

The t abl e below det ails warning i ndicat or col or agai ns t mes s age cent er mess age.

Page 1773 of 3229

Message Center Message

Warning Indicator Color

Automatic T ransmission RelatedWarningActive On-demand Coupling RelatedWarningTRANSMISSION FAULTAmberRed

TRANSMISSION FAULT AND OVERHEATRedn/a

TRANSMISSION FAULT LIMITED GEARSAVAILABLERedn/a

TRANSMISSION FAULT TRACTION REDUCEDn/aRedTRANSMISSION OVERHEAT SLOW DOW NAmberRed

Hill Descent Control Fault Warning Ind icator

The amber Hil l Des cent Cont rol (HDC) warning i ndi cat or is i ll uminated on receipt of medium speed CAN bus s i gnal s fromt he CJB . The si gnal s ori ginate in t he ABS module and are t rans mi tt ed to the CJB over the hi gh s peed CAN bus.

W hen t he vehicle ent ers power mode 6, the HDC warni ng indicator i s s ubject t o a 3 s econd bulb check. If duri ng HDCoperati on t he HDC warni ng indicat or i ll uminates i t s ignifies t hat the 'fade out' s t rategy has been i nvoked due tocomponent fai lure.

If the HDC warning indicator fl ashes i t s ignifies t hat t he 'fade out' s trategy has been invoked due to brake s ys t emoverheat . In thi s ins t ance, the firs t fl as h is accompanied by a chi me from t he ins trument cl ust er and the green HDC acti veindicat or wi ll be ext ingui s hed.For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Door Open Indicator

The door open i ndi cat or is i ll uminated on receipt of medium speed CAN bus s i gnal s from t he CJB. The si gnal s ori gi nate i nt he door modules , which are hardwired t o t he CJB. The door open indicator wil l il lumi nat e i n a red col or if a door opens ignal is received by t he CJB from any door module while the vehicle is i n power mode 6.

Engine Management System Warning Indicator

The engi ne management s ys tem warni ng indicator i s il lumi nat ed on receipt of medium speed CAN bus s ignals from theCJB. The s i gnals origi nat e i n t he ECM and are transmit ted t o t he CJB over t he high speed CAN bus .

The amber engi ne management s yst em warning i ndicat or is ill uminat ed for a 3 second bulb check when the vehicle ent erspower mode 6. If t he indicat or s ubs equentl y il lumi nat es a DTC wil l be logged in t he ECM whi ch s houl d be int errogat edus ing t he Land Rover approved diagnos t ic s yst em.

Side Lamp Indicator

The green s ide light i ndi cat or is i ll uminated on recei pt of a medium s peed CAN bus si gnal from the CJB. The s ignalori ginates i n t he li ght s wi tch module and is t rans mi tt ed to the CJB over the Local Int erconnect Network (LIN) bus . Theins t rument clus ter wil l onl y i llumi nate t he s ide lamp i ndi cat or when the vehicl e is in power mode 6.

Dynamic Stability Control Indicator

The Dynamic St abi li ty Cont rol (DSC) i ndi cat or is i ll uminated by the i nst rument clus ter on recei pt of medi um s peed CAN buss ignals from the CJB. The s ignal origi nat es in the ABS modul e. The indicator is il luminat ed in an amber color for 3 s econdsfor a bul b check when t he vehicle ent ers power mode 6. If no fault s exis t, t he i ndi cat or is exti ngui shed after t he bulb checkperi od.

W hen DSC is acti ve, t he i ndi cat or flas hes t o inform the driver that t he s ys t em i s regulat ing engine out put and braki ngforces . If the i ndi cat or remai ns il luminat ed aft er the bulb check peri od or ill uminat es when dri vi ng, t he DSC s ys tem has afaul t or DSC has been des elected by t he driver us i ng the DSC swit ch on the floor cons ole.

Hill Descent Control Active Indicator

The HDC acti ve indicat or i s il lumi nat ed by t he ins t rument clus ter on receipt of medium s peed CAN bus s ignals from theCJB. The s i gnal ori ginates i n t he ABS module. The indicat or i s il lumi nat ed i n a green col or when HDC is act ive and t hevehi cl e s peed is bel ow a predet ermi ned thres hold. If the vehicle speed i s fas t er t han t he threshold li mit , the HDC indicat orwil l fl ash unt il t he vehi cl e s peed is reduced. On high line ins trument cl us t ers a support ing mess age wi ll als o be di spl ayedin the mess age cent er. For addi ti onal i nformat ion, refer to:

Ant i-Lock Cont rol - Stabi lit y As s is t (206-09C Ant i-Lock Cont rol - Stabil it y As s is t, Des cript ion and O perati on),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

If the us e of HDC caus es the brake di s cs to exceed their pre-determined t emperat ure, the HDC s ys t em i nit iates a 'fadeout'. The HDC indicat or flas hes during 'fade out ' and on hi gh li ne ins t rument clus ters a s upporti ng mes sage i s dis played i nt he mes sage center. W hen t he brake dis cs have cooled suffi ci ent ly, HDC i s react ivated and t he HDC i ndicat or ispermanentl y il lumi nat ed.

Anti-theft Alarm Indicator

The anti -t heft alarm i ndi cat or is controll ed direct ly from the CJB vi a a hardwi red connect ion. There i s no s oft warefuncti onal it y wit hin the i nst rument clus t er t o control operat ion of t he anti -t heft alarm i ndicat or.For addit ional informat ion, refer t o: Anti -Theft - Act ive (419-01A Anti -Theft - Acti ve, Des cri pt ion and Operati on).

Glow Plug Indicator

The glow pl ug indi cat or i s i llumi nated on recei pt of a medium speed CAN bus si gnal from the CJB. The s ignal originat es int he dies el ECM and indicates t he glow plugs are operat ional. The i ndi cat or wil l ill uminat e in an amber color when t hevehi cl e enters power mode 6 and a gl ow plugs acti ve s ignal is received from t he ECM. W hen t he combus ti on pre-heatprocedure has been carri ed out, t he ECM i nforms the ins trument cl us t er to ext inguis h t he glow pl ug indicat or.